Neumo BioControl User manual

Page 1 of 8

Release 02.12.2019 / Dep. QMB/ Rev 11 FB_084_Installaon and Maintenance Instrucons_BioControl Components-V3.doc

Installaon and Maintenance

Instrucons

BioControl® - Housing

including Components

PN16

-10°C to +200°C

Content:

1. Intended Usage Agreement

2. Field of Applicaon

3. Installaon

4. Maintenance

5. Notes and Recommendaons

6. Construcon

7. Spare Parts

8. Possible Hazards

9. Exclusion of liability

Page 2 of 8

Release 02.12.2019 / Dep. QMB/ Rev 11 FB_084_Installaon and Maintenance Instrucons_BioControl Components-V3.doc

1. Intended Use:

NEUMO BioControl® Components are suitable for being orbitally welded into pipe work

of industrial plants (pharmaceucal industry, chemical industry as well as food indust-

ry).

According to the PED (Pressure Equipment Direcve), Arcle 9, para. 2, no. 2.1 and 2.2,

uids of group 1 and 2 are allowed as ow media.

The intended use includes compliance with the maintenance and servicing specica-

ons provided by the manufacturer.

The work described herein is described in sucient detail for only a qualied person to

understand and complete it.

The denion follows the contents of DIN EN-60204-1:

Die BioControl® Components comprise the following single parts

– Housing

– Blind cover, set of sight glasses or measuring equipment

– BioControl®-O-ring

– hex-head screw

BioControl® housings may only be installed as original components with BioControl®

sealing contour!

In case of disregard, conformity with the Pressure Equipment Direcve lapses!

Qualied person:

A person who, based on his/her technical training, knowledge and experience as well as

his/her knowledge of the applicable standards, is capable of judging the tasks he/she is

entrusted with and can recognize possible risks.

2. Field of Applicaon:

These instrucons apply for the installaon and maintenance of the construcon de-

scribed below.

3. Installaon:

Preparaon for welding in the „BioControl®“ housing

Any built-in inspecon glasses, blind covers or measuring devices have to be removed

prior to the following installaon procedure as described under para. 4 „Maintenance“.

The weld-on ends of the housing and the pipe connecons have to be prepared for the

I-seam according to DIN EN ISO 9692-1

Please ensure that the sealing edges of the „BioControl®“ housing are not damaged and

cannot be damaged during the operaons with the parts.

Page 3 of 8

Release 02.12.2019 / Dep. QMB/ Rev 11 FB_084_Installaon and Maintenance Instrucons_BioControl Components-V3.doc

Never use a screwdriver, hammer or any other tool or object that could damage the

sealing faces within the sealing areal.

DANGER

The pipe work may contain corrosive cleansing media residues. Therefore, the pipe sec-

on for the BioControl® housing has to be rinsed thoroughly prior to assembly.

Welding the housing:

WIG oder WIG-Orbital. Please adhere to the corresponding process regulaons and cer-

cates of the appropriate welding procedures!

Assembly of the single components:

Prior to assembly the various elements have to be checked for damage and replaced if

necessary.

Aach the O-ring clean and free of grease to the designated slot of the blind cover, the

glass or the measuring device.

The O-ring may not be rolled onto the component!

Please draw parcular aenon to the O-ring, which has to be clean, t ghtly into the

slot and may not be twisted, turned or bent.

CAUTION

Pay aenon to proper t of the single components during installaon. Jammed locks

damage the seat and sealing surface and cause leakage.

Aenon!

Only original, NEUMO-„BioControl®“-O-rings may be installed

Place the cover, the glass or the measuring device carefully and with gentle pressure

into the groove provided in the housing.

(The „BioControl®“ O-ring can be moistened slightly for installaon.)

The at seal and the retaining ring are placed on the glass. The parts are secured with

the appropriate hex head screws by fastening the screws to cross.

For the permied ghtening torque of the single screws, please take the technical infor-

maon into account and refer to table 1.

Page 4 of 8

Release 02.12.2019 / Dep. QMB/ Rev 11 FB_084_Installaon and Maintenance Instrucons_BioControl Components-V3.doc

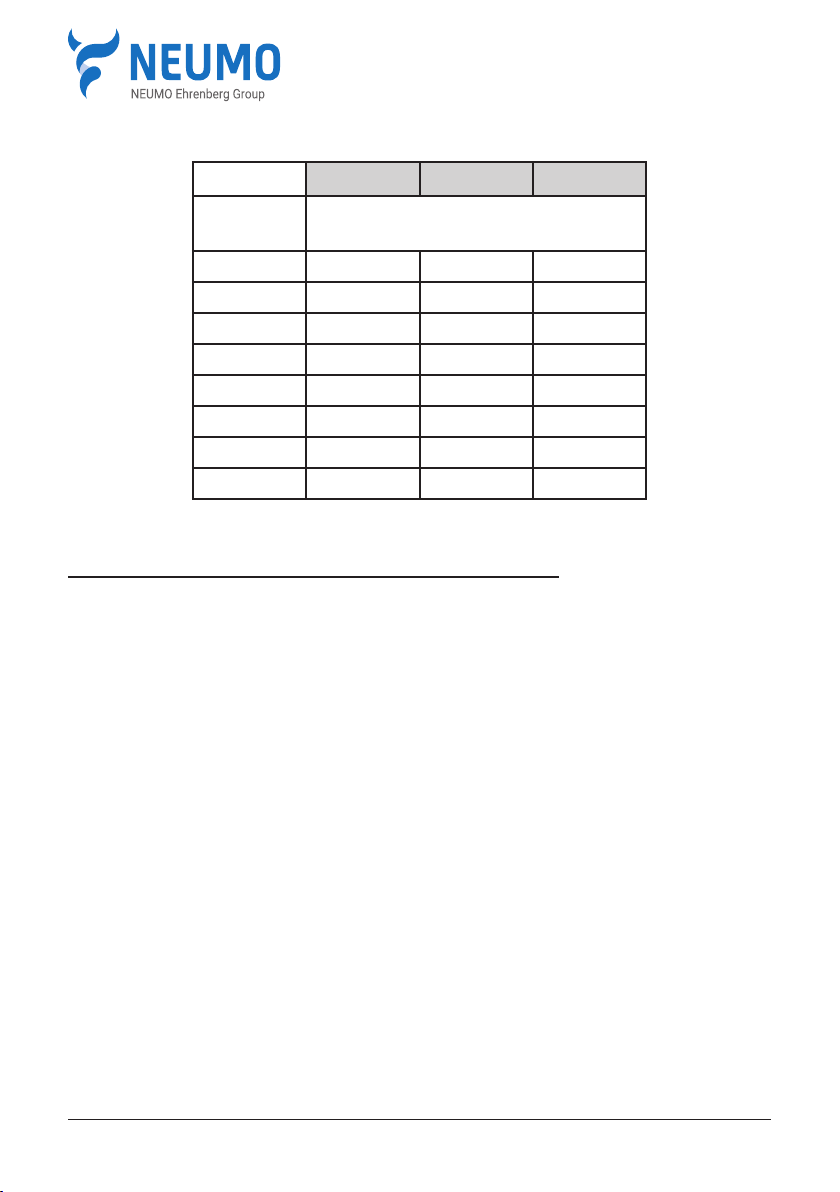

Table 1:

M6 M8 M10

Fricon

Coecient recommended ghtening torque (t)

0,10 5,9 14,5 30,0

0,12 6,7 16,3 33,0

0,14 7,4 17,8 36,0

0,16 7,9 19,3 39,0

0,18 8,4 20,4 41,0

0,20 8,8 21,5 44,0

0,30 10,4 25,5 51,0

0,40 11,3 27,6 56,0

Technical informaon for the ghtening torques for screws:

Since dierent fricon coecients can appear in pracce the torques quoted in table 1

can only be adopted as reference values!

The torqueses apply for screws EN 24014 / 24017, strength category 70 at room tem-

perature.

It is recommended to conduct an appropriate test under operaonal condions prior to

nal determinaon of the torque!

Page 5 of 8

Release 02.12.2019 / Dep. QMB/ Rev 11 FB_084_Installaon and Maintenance Instrucons_BioControl Components-V3.doc

4. Maintenance:

Loosen and remove screws.

CAUTION

Please ensure that the pipe connecon is in a pressure-free state before loosening the

screws.

DANGER

The pipe work may contain corrosive cleansing media residues. Therefore, the pipe sec-

on for the BioControl® housing has to be rinsed thoroughly prior to assembly.

Close, rinse and secure the pipe secon of the BioControl® housing

Remove the blind cover or measuring device carefully from the housing seat.

Please adhere to the following procedure during removal of the inspecon glass:

Remove the sealing ange and the at seal.

Raise the inspecon glass with the sucon cup (available with the supplier of the set

of inspecon glasses) or any other suitable sucon device with a careful pull unl the

O-ring can be removed from the seat. Pull out the glass completely, slowly and smoo-

thly.

Remove the seal ring and ensure that the sealing edges are not damaged.

Clean the sealing surfaces and check the sealing contours for possible damages.

In case of damage the components concerned have to be replaced.

Page 6 of 8

Release 02.12.2019 / Dep. QMB/ Rev 11 FB_084_Installaon and Maintenance Instrucons_BioControl Components-V3.doc

5. Advice and Recommendaons:

By default, the NEUMO „BioControl®“ components are undetachably marked for a no-

minal pressure of 16 bar. Should they be applied for higher pressures, please include the

following data in your inquiry to the company NEUMO

The required pressure = .......... bar

The overall size.

The pipe connecon dimensions = outer diameter x wall thicknes

By default, seal rings with appropriate tolerances are applied, which are made of mate-

rial grade: EPDM peroxidically crosslinked, FDA conform.

If a dierent sealing material should be applied, this has to be indicated in the inquiry,

too.

6. Execuon

Materials:

Housing: 1.4435 / 1.4404 (316L)

Blind Cover: 1.4435 / 1.4404 (316L)

Measuring Device: see device

Glass: Borosillicate glass

Flat Seal: Klinger Top Chem 2000

Sealing: EPDM peroxidically cross-linked, FDA-conform (max. 150 °C)

Screws: A4-70

7. Spare Parts:

On request.

Page 7 of 8

Release 02.12.2019 / Dep. QMB/ Rev 11 FB_084_Installaon and Maintenance Instrucons_BioControl Components-V3.doc

8. Possible dangers

BioControl® housings are designed and manufactured according to AD 2000-data sheet

for 16 bar posive operang pressure at steady operaon and 200°C operang tempe-

rature. If necessary, any deviang, or lower maximum permissible temperatures of the

applied sealings or instruments have to be taken into account.

The BioControl® housing are components designated for installaon in the pipe works.

The dangers in combinaon with components from other manufacturers, such as mea-

suring or control devices, need to be specied separately or prevented. Possible dan-

gers that can arise are mainly dened by the planers or operators.

Drainability

BioControl® housings type G cannot be completely emped in horizontal installaon.

We recommend vercal installaon with an inclinaon which must be provided by the

plant manufacturer depending on the operang condions (medium, temperature,

pressure, ...).

The responsibility for draining is generally the responsibility of the plant manufacturer

and the end customer.

Warranty:

In accordance with the general terms and condions of NEUMO GmbH + Co. KG

at www.neumo.de

9. Exclusion of liability:

In accordance with the general terms and condions of NEUMO GmbH + Co. KG

at www.neumo.de

Page 8 of 8

Release 02.12.2019 / Dep. QMB/ Rev 11 FB_084_Installaon and Maintenance Instrucons_BioControl Components-V3.doc

Table of contents