Operating instructions for SAMBO Worm Gear Operator V1.00-2021.04.29

3 Storage

WARNING: Read this installation and maintenance manual carefully and completely before

attempting to store the operator. If an electric actuator is attached to the SBWG manual

operator, be aware of the electrical hazards. Consult the electric actuator installation and

maintenance manual for guidance.

NOTE: The following is the recommended storage procedure to retain maximum product integrity during stor-

age. Failure to comply with recommended procedure will void the warranty.

Storage (less than one year)

Store the gearboxes on wooden skids to protect the machined mounting flange. Place the wooden skids

containing the gearboxes in a clean, dry, protected warehouse. If the gearboxes must be stored outside, they

must be covered in polyethylene protection with silica gel crystals to absorb moisture.

If an electric actuator is attached to the V gearbox, refer to the storage procedures in its respective manual for

appropriate storage procedures. Rotate input shafts every three months tomix the lubricant.

Recommended storage temperature range: 0°C to 40°C (32°F – 104°F).

4 Unpacking

Gearboxes are packed in a variety of configurations depending on size, type and quantity of the consignment.

It is the responsibility of the individual unpacking and handling the combination to carry out a risk assessment

for the supplied arrangement to ensure safe working.

Packaging material used may include wood, cardboard, polyethylene and steel. Packaging should be recycled

according to local regulations.

5 Handling

Individual weights for gearboxes are recorded on their respective nameplates.

CAUTION: Only trained and experienced personnel should carry out handling. At all times, safe

handling must be ensured.

Each combination must be assessed to identify all risks associated with handling.

The gearboxes must be fully supported until full valve shaft/stem engagement is achieved and the gearbox

is secured to the valve flange.

Once connected to the valve, each assembly must be assessed on an individual basis for safe handling/lifting.

Never lift the complete combination-valve assembly via the gearbox.

If it is necessary to lift the gearbox using lifting equipment, certified soft slings are recommended. Damage to

protective coatings should be correctly rectified and may invalidate warranty.

6 General Mounting Instructions

CAUTION: To avoid the potential for disengaging the worm gear segment, ensure that the pointer

cap pointer is oriented to the mid-point of the 90º valve travel. Full stroke rotation of the quadrant

should not move the pointer past the corresponding Open or Close ID marks on the housing cover.

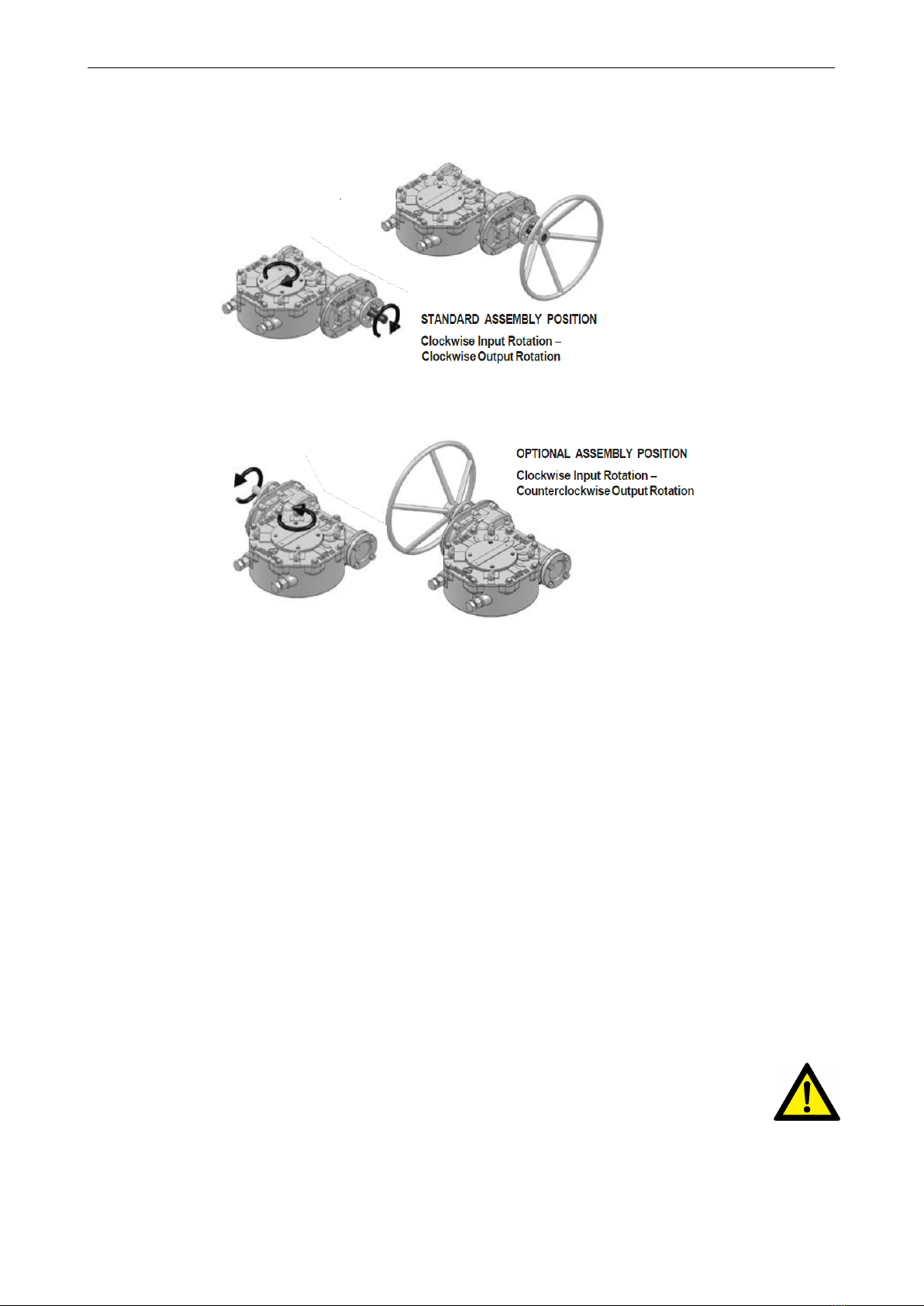

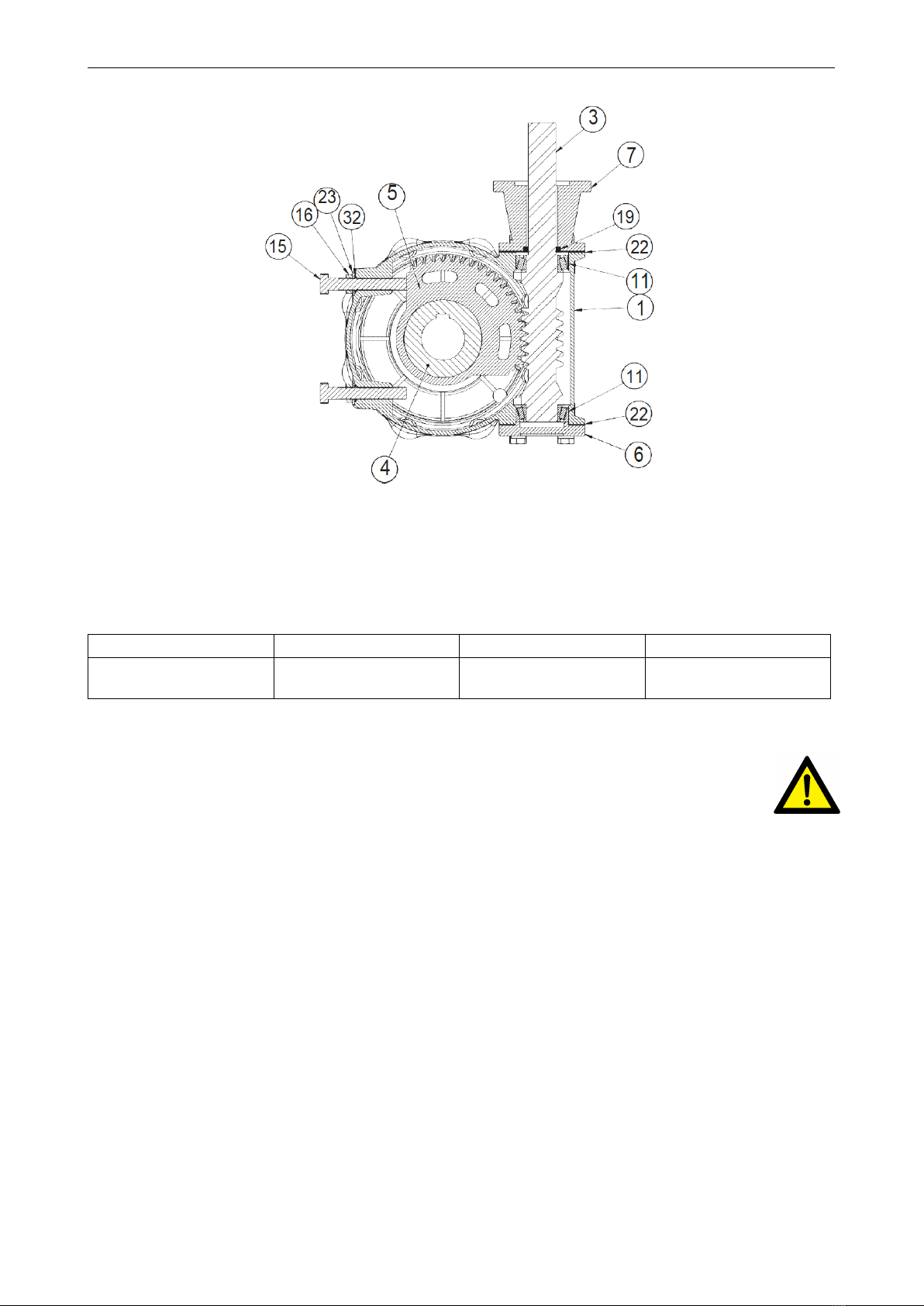

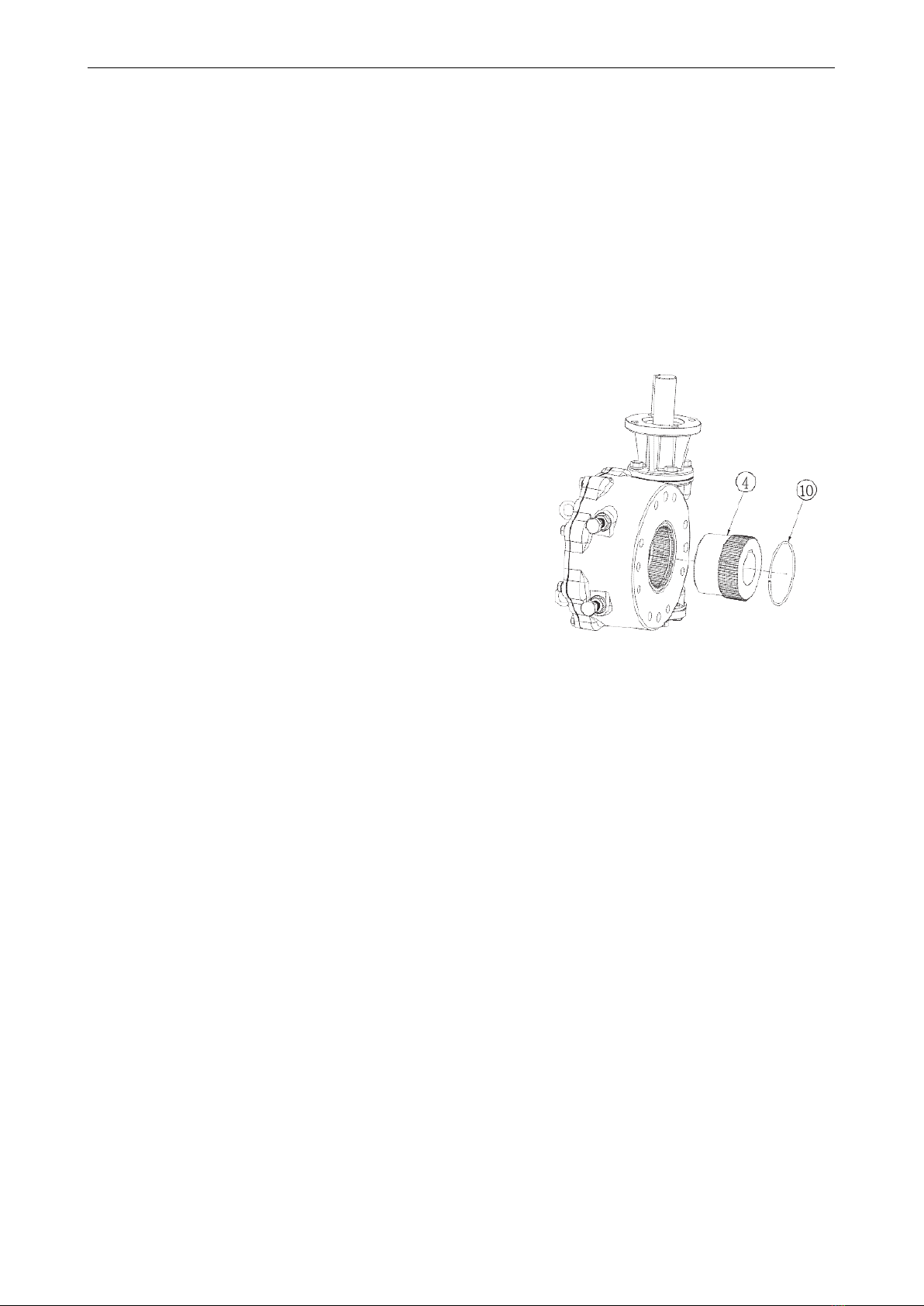

The mounting instructions for the SBWG series worm gearboxes are outlined below. The SBWG-00 through

SBWG-35 gearboxes are designed with a bottom entry splined adapter. The SBWG-04 through SBWG-12

3