Starret MMD Series User manual

The Better Solution

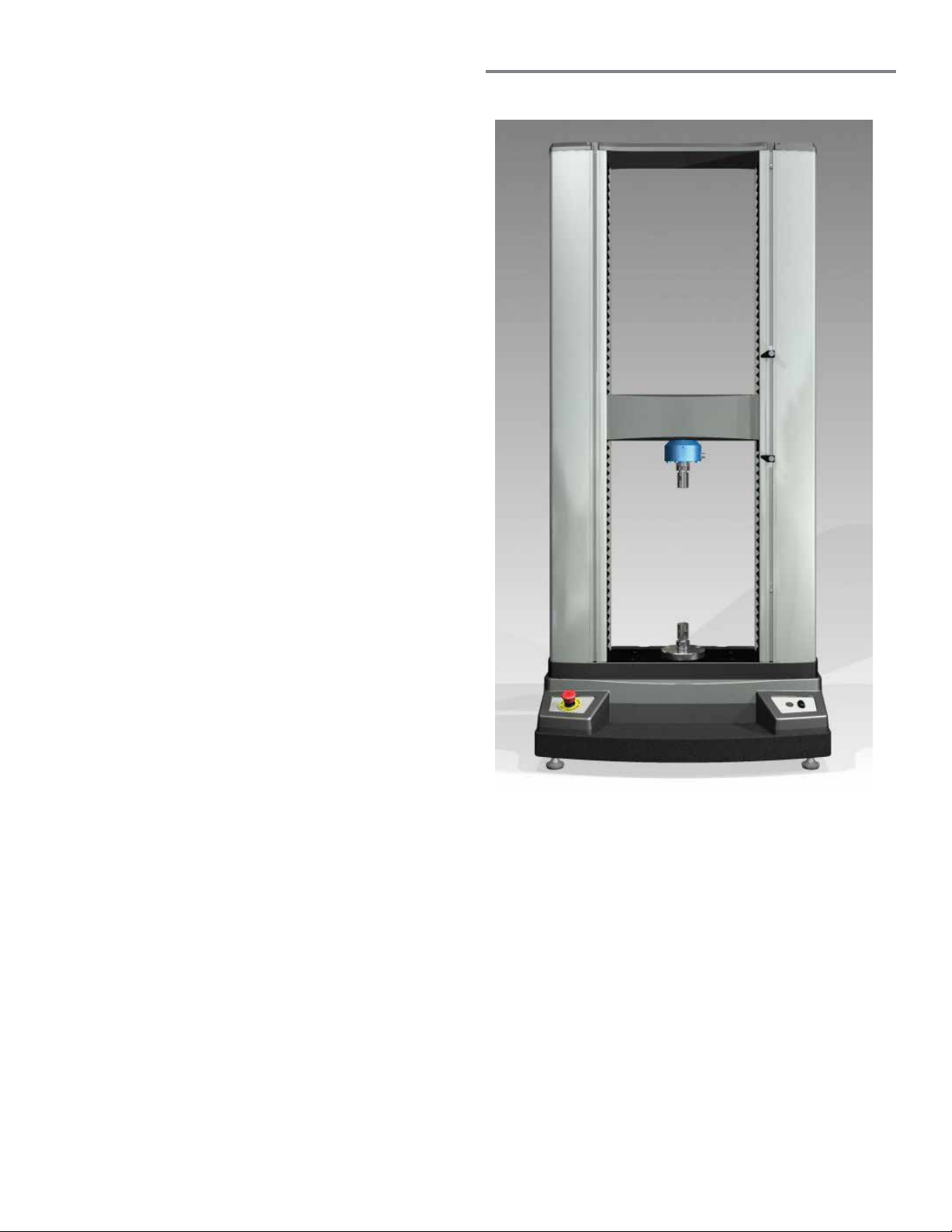

Twin Column Testing Frames

User Guide for

MMD Series Material Testers

FMD Series Force Testers

starrett.com 3

Table of Contents

Page

General Safety Precautions 4

Warnings 4

1.0 INTRODUCTION 6

1.1 System Description 6

1.2 System Safety and Labeling 7

1.3 Product Support 8

1.4 Calibration and Verification 8

1.5 Software Options 8

1.5.1 Using L3 Material Test Software 9

1.5.2 Using L2 Plus Advanced Force Analysis Software 9

1.5.3 Using L2 Force Measurement Software 9

2.0 SYSTEM DESCRIPTION 10

2.1 MMD Series Product Specifications 10

2.2 FMD Series Product Specifications 11

2.3 Common Specifications 14

2.3.1 Power Requirements 14

2.3.2 Fuse Ratings 14

2.3.3 Noise Level Rating 14

2.3.4 Environmental Specifications 15

2.3.5 Cyclic Testing 15

2.3.6 Load Hold Testing 15

2.3.7 Test Frame Weights 15

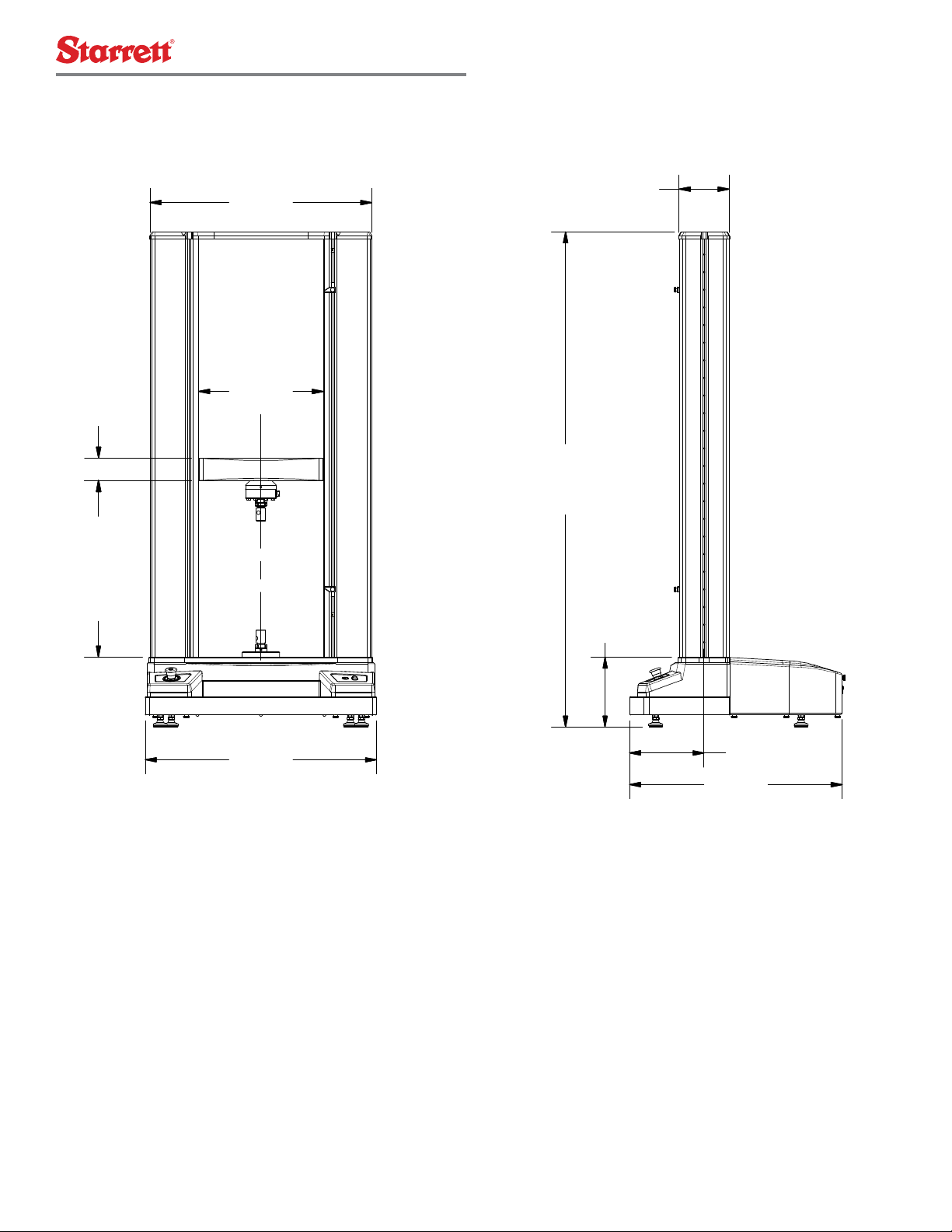

2.4 MMD/FMD Dimension Drawings 16

3.0 LIFTING AND HANDLING 19

3.1 General Precautions 19

3.2 Unpacking Your System 20

3.3 Moving Your System 22

3.3 Positioning Your System for Use 23

4.0 INSTALLATION 24

4.1 Customer Responsibilities 24

4.2 Starrett Responsibilities 24

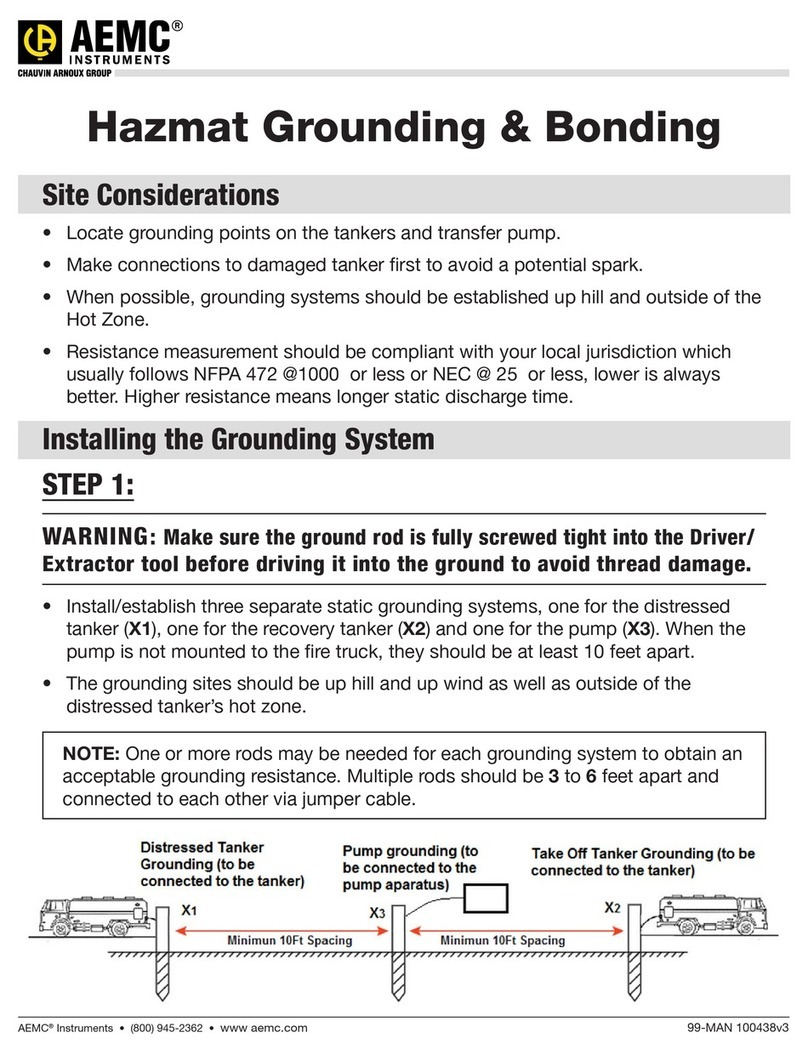

4.3 Site Considerations 25

4.4 Setting Input Voltage 26

4.4.1 Verifying Your Input Power Source 27

4.4.2 Setting Input Voltages 28

4.5 Connecting System Components 29

4.5.1 Installing L3/L2 Plus Workstations 29

4.5.2 Installing the L2 Tablet 30

4.5.3 Installing Base Clevis Assembly 31

4.5.4 Installing Load Cell Sensor 31

4.5.5 Installing Load Cell Sensor Clevis Assembly 34

4.5.6 Installing Test Fixture 34

4.5.7 Installing Extensometers (MMD Series only) 35

4.5.8 Installing a Printer 35

4.5.9 Installing Bench Mounting Clips 36

4.5.10 Using the Optional Splinter Shield 37

Page

5.0 SYSTEM OPERATION 38

5.1 Operating Principles 38

5.2 Operator Controls 38

5.2.1 Emergency Stop Switch 38

5.2.2 Mains Power Switch 39

5.2.3 Crosshead Jog Switch 39

5.2.4 Test Start/Stop Switch 40

5.2.5 Over Travel Limit Switches 41

6.0 USING YOUR MMD SERIES TEST FRAME 42

6.1 System Settings Options 42

6.1.1 Setting Crosshead Travel Limits 42

6.1.2 Setting Crosshead Maximum Travel Velocity 43

6.1.3 Setting Grip Protection 44

6.1.4 Setting Load Cell Limit 45

6.1.5 Using Deflection Compensation Correction 46

6.2 Using L3 Series Material Test Software 47

6.2.1 Starting an L3 Test 47

6.2.2 Pausing an L3 Test 47

6.2.3 Stopping an L3 Test 48

7.0 USING YOUR FMD SERIES TEST FRAME 49

7.1 Using L2 Plus Series Force Analysis Software 49

7.1.1 Starting an L2 Plus Test 49

7.1.2 Stopping an L2 Plus Test 49

7.2 Using L2 Series Force Measurement Software 50

7.2.1 Starting an L2 Test 50

7.2.2 Stopping an L2 Test 50

8.0 SYSTEM MAINTENANCE 51

8.1 Preventive Maintenance 51

8.1.1 Daily Maintenance Checks 51

8.1.2 Authorized Field Maintenance 51

8.1.3 Cleaning 51

8.1.4 Lubrication 51

8.2 Maintenance Procedures 51

8.2.1 Travel Limits 51

8.2.2 Emergency Stop 52

8.2.3 Fuse Replacement 52

9.0 CALIBRATION AND VERIFICATION 52

4

Product Warranty

Starrett force measurement products carry a one-year (from date of

purchase) warranty against defects in material and

workmanship (parts and labor), subject to factory inspection.

The L.S. Starrett Company will repair or replace, at its option, any part

or parts found to be defective in workmanship or material. Starrett

warrants repaired or replaced parts for the balance of the original

warranty period or 90 days, whichever is longer. Parts returned to the

factory under warranty will be repaired at no charge. Freight charges to

the factory will be paid by the customer. Return freight charges to the

customer will be paid by Starrett.

This warranty does not cover damages from such causes as abuse,

accident, neglect, fire or freight damage. It does not apply to defects

resulting from modifications made by the customer or improper use of

the system or its components.

Disclaimer of Liabilities

The L.S. Starrett Company shall have no liability or responsibility to the

customer or any other person or entity with respect to any liability, loss

or damage caused or alleged to be caused directly or indirectly by this

documentation, or the hardware described in it. This includes but is not

limited to any interruption of service, loss of business or anticipatory

profits, or consequential damages resulting from the use or operation

of hardware or equipment.

starrett.com 5

General Safety Precautions

Force measurement systems are potentially hazardous. Prior to

operating your testing system, Starrett recommends that you read and

understand the instruction manuals for your system and components

and that you receive training on the proper use of this equipment from

your authorized Starrett representative.

Observe all warnings and cautions identified in this manual for your

equipment. A warning identifies a function that may lead to injury

or death. A caution identifies a hazard that may lead to damage to

equipment or loss of data.

Starrett products, to the best of our knowledge, comply with various

national and international safety standards as they apply to material

and force measurement testing. This Starrett product has been tested

and found to comply with the following recognized standards:

• EN61010-1 Safety Requirements for Electrical Equipment

• EN61000-6-3 EMC Generic Emissions Standard

• EN61000-6-1 EMC Generic Immunity Standard

Starrett also certifies that this product complies with all relevant EU

directives and carries the CE mark.

Electromagnetic Compatibility

Your MMD Series material test system is designed to comply with

International Electromagnetic Compliance (IEC) standards.

To ensure reproduction of this EMC performance, connect this

equipment to a low impedance ground connection. Typical suitable

connections are a ground spike or the steel frame of a building.

Warnings

Emergency Stop

Press the emergency stop button whenever you feel there is an unsafe

condition during a test. The emergency stop button removes power to

the motor drive system causing the crosshead to stop.

Flying Debris

Eye protection, protective clothing and splinter/safety shields should

be used whenever any possibility exists of a hazard from the failure of

a sample, assembly or structure under test. Due to the wide range of

materials that may be tested and that may result in a failure which may

cause bodily injury, the precautions and preventative methods taken

prior to testing is entirely the responsibility of the owner and the user

of the equipment.

Crush Hazard

Always use caution when installing or removing apparatus and your

sample material between the frame’s crosshead and the base. A

potential pinch/crush hazard exists. Keep clear of the testing fixture,

and particularly the jaw faces at all times. Keep clear of the crosshead

during movement. If available, always make sure the Pinch Load

feature is enabled. This will stop inadvertent crosshead operation if in

manual mode. Always ensure that other personnel cannot operate the

system while you are working within the test fixture area.

Electrical Hazard

Disconnect equipment from the electrical power supply before

removing any electrical safety covers. Disconnect power when

replacing fuses. Never reconnect power while the covers are removed.

Never operate the system with protective covers removed.

Rotating Machinery Hazard

Always disconnect power before removing covers that protect the user

from the internal rotating mechanisms. If maintenance to the drive

mechanism is required, and power is needed to perform maintenance

to the drive system, maintenance should be performed by an

authorized Starrett representative who has received factory training on

performing such procedures.

Warning Labels

Listed below are the warning labels used in this manual including their

definitions. Please pay particular attention to these labels and sections

within this manual denoted with a warning label.

HAZARD: This label identifies a potentially dangerous hazard

that may lead to serious injury to personnel.

WARNING: This label alerts the user of a potentially serious

hazard that may result in injury to personnel and damage to

equipment.

CAUTION: This labels advises the user to proceed using

caution while performing this action. Failure to do so may

harm equipment.

NOTE: This label is used to call-out important information

including helpful operating instructions.

6

1.0 Introduction

Thank you and congratulations for selecting the Starrett FMD or MMD

Series twin column testing frame.

Your MMD and FMD Series testing frame may be used for tension and

compression testing including specific test methods such as peak,

break, constant hold, flexural, shear, peel, coefficient of friction and

more.

Your MMD and FMD testing frame should be used with Starrett

equipment and accessories only.

For optimum performance, your MMD and FMD testing frame should

be maintained and serviced annually by an authorized Starrett

representative.

HAZARD

MMD and FMD test frames are used in applications with

inherent hazards from high forces, rapid motions and stored

energy.

Users should be aware at all times of moving components

that are potentially hazardous, particularly moving

crossheads.

Failure to read and follow all operating instructions can result

in serious injury to personnel and damage to equipment and

facilities.

Operation and service of MMD and FMD test frames should

be by authorized personnel trained in their safe operation.

Starrett Twin Column Test Frames

1.1 System Description

Your Starrett MMD and FMD Series test frames are twin column testing

frame that make up any of the following testing systems:

• L3 Series System used for material testing

• L2 Plus Series System used for advanced force measurement and

analysis

• L2 Series System use for force measurement

L3 Series System

An L3 Series System uses our L3 Series software operating on an

all-in-one touchscreen workstation (L3 Workstation), combined with

an MMD Series testing frame. L3 Series Systems are used to measure

stress, strain, load, distance, height and time. L3 Series Systems are

optimized for research & development, engineering and advanced

quality control applications involving material characterization.

L2 Plus Series System

The L2 Plus Series System uses our L2 Plus Series software operating

on an all-in-one touchscreen workstation (L2 Plus Workstation),

combined with an FMD Series testing frame. The L2 Plus Series

Systems are used to measure load, distance, height and time. They

cannot be used with extensometers and cannot be used to measure

and analyze stress or strain. L2 Plus Series Systems are used for

advanced force measurement and analysis.

L2 and S2 Series System

L2 Series Systems are designed for high-volume testing in a production

environment. The L2 Series System uses our L2 Series software

operating on a table personal computer, combined with an FMD Series

testing frame. L2 Series Systems are used to measure load, distance,

height and time. The cannot be used with extensometers and cannot

be used to measure stress or strain. L2 Series Systems are optimized

for the production floor- they are easy-to-use, and provide basic force

measurement results.

The S2 Series System is an application-specific system used

exclusively for testing compression and extension springs.

MMD Series Test Frames

MMD Series test frames are designed for more complex material

testing and therefore, these testing frames have higher performance

specifications compared to the FMD Series. MMD Series further

distinguish themselves from an FMD Series by having two (2)

extensometer inputs, plus optional analog inputs, analog outputs and

digital I/O that may be used with ancillary equipment.

FMD Series Test Frames

FMD Series are for high load capacity force testing. FMD Series have

lower performance specifications compared to the MMD Series. FMD

Series cannot be used with extensometers. FMD Series cannot use

analog input or analog outputs. FMD Series can be supplied with

optional digital I/O.

starrett.com 7

1.2 System Safety and Labeling

ISO and ANSI safety labels are affixed to Starrett equipment to alert

users and operators of the equipment to warnings and cautions.

System users should obey all warnings and cautions and should be

trained on the safe operation of this equipment by an authorized

Starrett representative.

Starrett Twin Column Safety Labels

Front view Rear view

Pinch Hazards

Crush Hazards

Mechanical

Hazards

Electrical

Hazards

HAZARD

Never operate the MMD or FMD test frame without the

protective cover over the mechanical and electronic

components.

HAZARD

Servicing the MMD or FMD test frame should be performed

by authorized Starrett personnel only.

8

1.3 Product Support

If you ever require product support for your Starrett system,

contact your authorized Starrett representative. Authorized Starrett

representatives are listed on our website at www.starrett.com. In the

event that your Starrett representative may not be able to assist you,

contact Starrett at one of our many international sales offices. Our

sales offices are listed on our website at www.starrett.com.

1.4 Calibration and Verification

Your Starrett MMD and FMD Series test frames are calibrated and

tested at our factory prior to shipment to you. Our factory calibrations

are traceable to national standards. Prior to shipment, Starrett

performs the following at our manufacturing facility:

• Force Calibration per ASTM E4

• Displacement Calibration per ASTM E2309/E2309M

• Speed Verification ASTM E2658

If you require an on-site calibration, Starrett or a Starrett authorized

representative can perform a calibration at your location to comply with

these international calibration standards.

NOTE

MMD Series used for material testing require calibration at

the time of installation.

Starrett recommends that you calibrate your system at least annually.

More frequently calibrations may be required depending on the

frequency of which the system is used. If your system is calibrated to

ASTM E4, ASTM E2309/E2309M or equivalent international standards,

the system must be calibrated whenever the system is relocated, e.g.

moved from its location where the previous calibration occurred.

1.5 Software Options

Your Starrett MMD and FMD Series test frame is designed to be used

for material testing and force measurement applications. Starrett

offers three different software products, each one optimized for its

intended application. The user interface differs depending on the

software selected. Force measurement applications utilize a tablet

computer operating our L2 Series software or an all-in-one desktop

touchscreen computer with our L2 Plus Series advanced force

measurement and analysis software. Material testing applications

utilize an all-in-one desktop touchscreen computer with our L3

Series material test software. Contact your Starrett representative for

assistance in selecting the correct software application for your needs.

FMD Series with L2 Plus Workstation

starrett.com 9

1.5.1 Using L3 Material Test Software

Starrett L3 Series material test software is designed for general

purpose material testing application and for use on a variety of

materials including metals, composites, rubber, plastic, elastomers,

films, foils, adhesives, etc. The software is optimized for use for

material characterization, material research & development and

material quality and specification verification. L3 Series software

supports a variety of testing methods for load, distance, stress, and

strain based on industry standards from ASTM, DIN, ISO, TAPPI and

others.

1.5.2 Using L2 Plus Force Measurement Software

Starrett L2 Plus Series force measurement software is designed for

detailed force analysis in the laboratory. The software is optimized

for research & design, engineering and quality control testing where

load and distance are measured and where detailed analysis, including

force characterization is necessary.

1.5.3 Using L2 Force Measurement Software

Starrett L2 Series force measurement software is designed for high

volume production environments. The software is optimized for

in-situ production or quality control testing where load and distance

are measured on a variety of products including adhesives, medical

devices, foam/film, springs, etc.

FMD Series with L2 Tablet Controller

10

2.0 System Descriptions

2.1 MMD Series Test Frames

The Starrett MMD Series are twin column, electromechanical test

frames designed for material testing applications. The MMD Series

are bench top systems ideal for tensile, compression, shear, flexural,

cyclic and other forms of testing applications.

Three model test frames are available:

• MMD-10K Series

• MMD-30K Series

• MMD-50K Series

The MMD Series has been designed to be used with Starrett L3

software for material testing operating on an all-in-one, touchscreen

computer.

The MMD Series features include:

• Precision motion controls including powerful motors with excellent

acceleration and position resolution

• High Axial Stiffness with granite base and adjustable deflection

compensation and linear error correction

• Pre-loaded ball screws and bearings and low-stretch belts for

outstanding responsiveness and repeatability

• Extra heavy-duty crosshead for testing loads up to 50kN

• Data sampling from 1 to 2000Hz

• USB communications

• Interfaces for up to two (2) extensometers capable of exceeding

strain measurement accuracies per ASTM E83, ISO 9513 and EN

10002-4.

• Load measurement using IEEE 1451.4 TEDs-compliant load cell

sensors with accuracies up to 0.5% of reading down to 1/1000 of

load cell capacity.

• Digital and analog I/O channels for interfacing with ancillary

testing equipment or for incorporating programmable logic control

• Easy to use fixture mounting for the many hundreds of different

test fixtures and grips that may be used

• Worldwide sales and service support

Test Frame

Your MMD Series test frame consists of a granite base, cast-aluminum

base plate, two (2) extruded aluminum columns and a cast-aluminum

top plate. The precision aluminum crosshead is engineered for

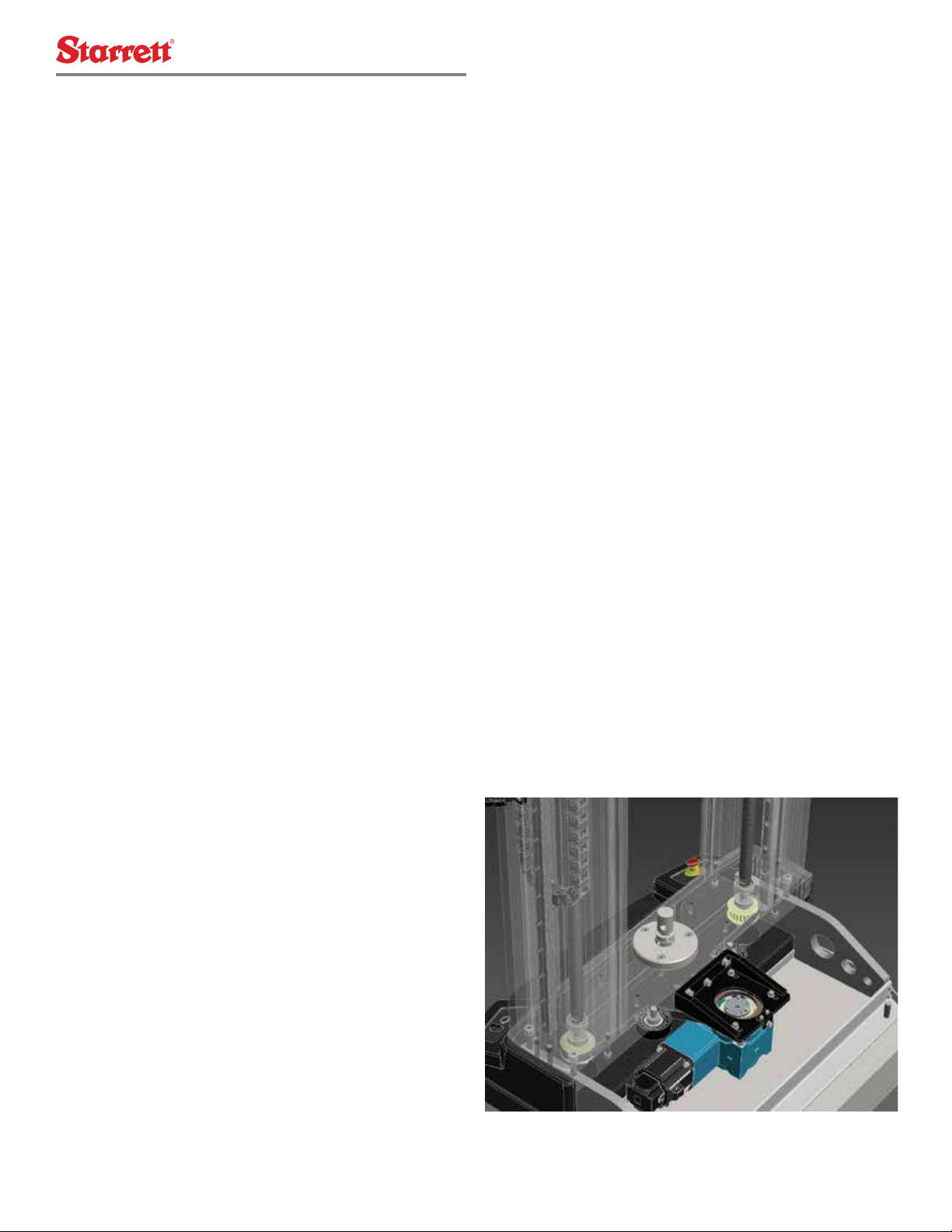

MMD /FMD Series System Drive System

minimal deflection under full loads at full velocity. Within each

column are precision ballscrews. The ballscrews are preloaded. The

ballscrews rotated synchronously driven by a precision motion control

system. Overall, the system components provide an industry-leading

system with extraordinary axial stiffness.

Drive System

The drive system for your MMD Series test frame resides within the

back housing protected by a lightweight fiberglass housing. The drive

system connects to the lower end of the ballscrews using a belt and

pulley system. Motor rotation rotates the ballscrews synchronously

which moves the crosshead up or down with excellent position control

resolution.

Load String

The load string consists of the load cell sensor, clevis adapter and test

fixture. The load cell is mounted to the crosshead using a set screw

that secures the load cell to the crosshead surface.

Starrett recommends using low-profile load cell sensors for material

testing because of their excellent axial stiffness.

Starrett recommends that your load cell sensor is attached to a base

adapter. The base adapter is standard with ULC Series load cells and

optional for MLC Series load cells. The base adapter helps ensure a

proper surface mounting.

The test fixture is mounted using the clevis adapter. The clevis

adapter has an M16 thread and comes in either a 15.9mm or 31.8mm

diameter. The clevis adapter threads into the load cell sensors. The

test fixture slides onto the clevis adapter and is secured using locking

rings and a grip pin.

Communications

Communications between the L3 Series workstation and your MMD

Series test frame is via USB 2.0.

starrett.com 11

MMD/FMD Series System Design

2.2 FMD Series Test Frames

The Starrett FMD Series are twin column, electromechanical test

frames designed for force testing applications. The FMD Series are

bench top systems ideal for tensile, compression, shear, flexural, cyclic

and other forms of testing applications.

Three model test frames are available:

• FMD-10K Series

• FMD-30K Series

• FMD-50K Series

The FMD Series has been designed to be used with Starrett L2 Plus

software for advanced force measurement testing operating on an all-

in-one, touchscreen computer. Or, the FMS Series may be used with

Starrett L2 software for basic force measurement testing operating on

a tablet personal computer.

The FMD Series features include:

• Precision motion controls including powerful motors with excellent

acceleration and position resolution

• High Axial Stiffness with granite base and adjustable deflection

compensation and linear error correction

• Pre-loaded ball screws and bearings and low-stretch belts for

outstanding responsiveness and repeatability

• Extra heavy-duty crosshead for testing loads up to 50kN

• Data sampling from 1 to 2000Hz

• USB communications

• Load measurement using IEEE 1451.4 TEDs-compliant load cell

sensors with accuracies up to 0.5% of reading down to 1/1000 of

load cell capacity.

• Digital I/O channels for interfacing with ancillary testing equipment

or for incorporating programmable logic control

• Easy to use fixture mounting for the many hundreds of different

test fixtures and grips that may be used

• Worldwide sales and service support

12

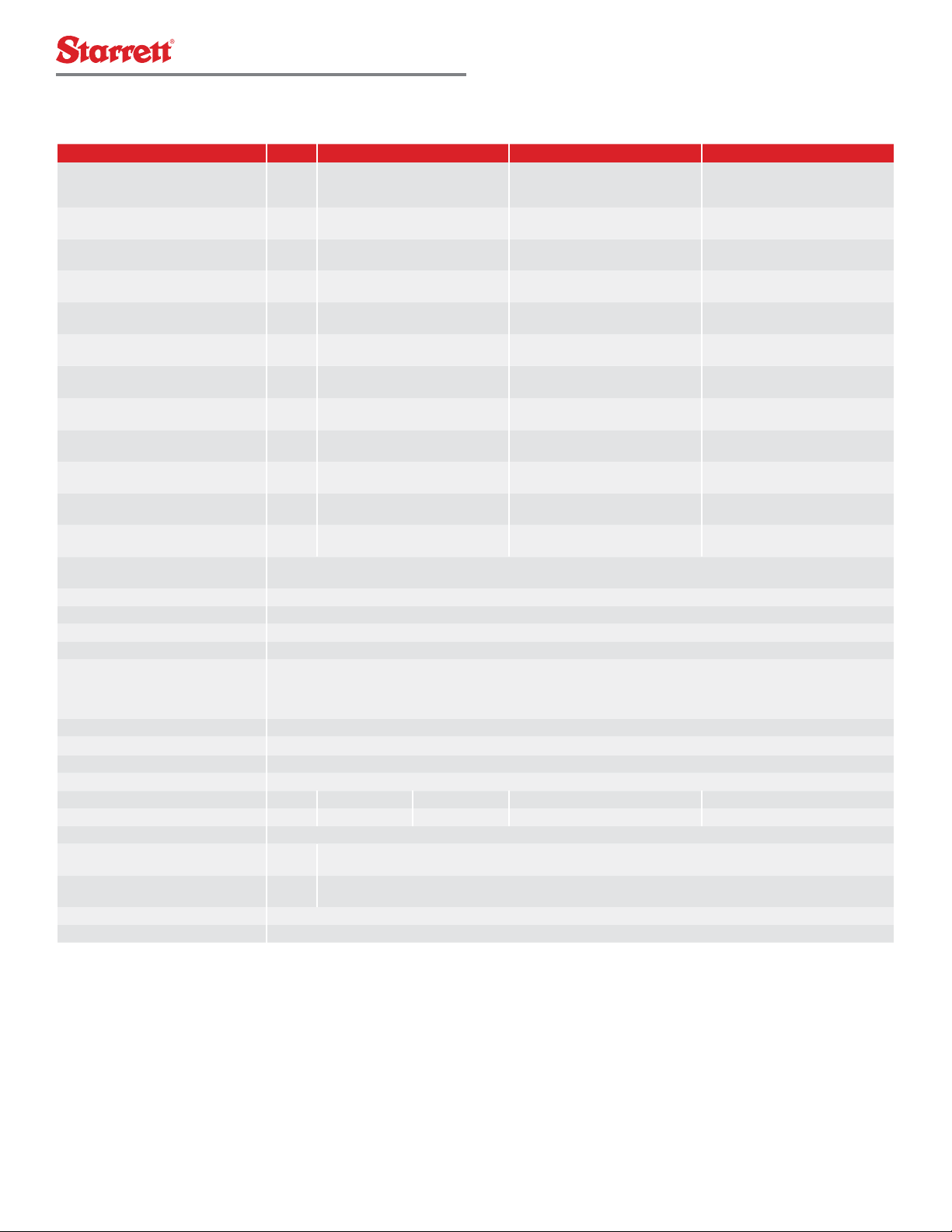

MMD Series Product Specifications

Specification MMD-10K Series MMD-30K Series MMD-50K Series

Load Capacity

kN

kgf

lbf

10

1000

2250

30

3000

6750

50

5000

11,250

Crosshead Speed - MINIMUM mm/min

in/min

0.001

0.00004

0.001

0.00004

0.001

0.00004

Crosshead Speed - MAXIMUM mm/min

in/min

1500

60

1500

60

750

30

Position Control Resolution µm

µin

0.05

1.9

0.025

0.9

0.025

0.9

Frame Axial Stiffness kN/mm

lbf/in

72

412,844

150

855,513

161

918,367

Vertical Test Space1mm

in

1270

50

1245

49

1220

48

Total Crosshead Travel mm

in

1162

45.75

1137

44.75

1111

43.75

Column Spacing mm

in

424

16.7

424

16.7

424

16.7

Total Height mm

in

1626

64

1626

64

1626

64

Total Width mm

in

787

31

787

31

787

31

Total Depth mm

in

736

29

736

29

736

29

Test Frame Weight kg

lb

136

300

192

425

225

500

Load Measurement Accuracy ±0.5% of reading down to 1/1000 of load cell capacity. Starrett load cell sensors are supplied with a Certificate of Calibration

traceable to NIST. Starrett recommends verification of load cell accuracy during installation per ASTM E4, ISO 7500-1 or EN 10002.

Position Measurement Accuracy2

±0.0002 inch (±5 µm)

Strain Measurement Accuracy ±0.5% of reading down to 1/50 of full scale with ASTM E83 class B or ISO 9513 class 0.5 extensometer

Crosshead Velocity Accuracy ±0.1% of set speed at zero or constant load hold

Data Sampling 1 to 2000Hz

Digital I/O

12 total channels

Channel 1 & 2 for Power (5-24V)

Channels 3 thru 10 for either digital inputs or outputs

Channels 11 & 12 for Ground

Analog Inputs 1 channel @ ±10V

Analog Outputs 2 channels @ 0-10V

Extensometer Ports 2 channels for independent connection to an extensometer(s)

USB Interface 1 USB 2.0 connector

Single Phase Voltage (Vac) ±10% 100-120Vac 220-240Vac 220-240Vac 220-240Vac

Maximum Power (A) Amps 4.0 1.5 3.7 3.7

Frequency 50/60Hz

Operating Temperature °C

°F

+10 to +38 °C

+50 to +100 °F

Storage Temperature °C

°F

-40 to +66 °C

-40 to +150 °F

Humidity 10% to 90%, non-condensing

CE Compliance MMD Series Systems meet all relevant CE standards

Notes:

1 Total vertical space is the distance from the top surface of the base plate to the bottom surface of the crosshead, excluding load cell sensor,

test fixtures, and clevis adapter.

2 Assumes Linear Error Correction and Deflection Compensation have been performed on test frame.

starrett.com 13

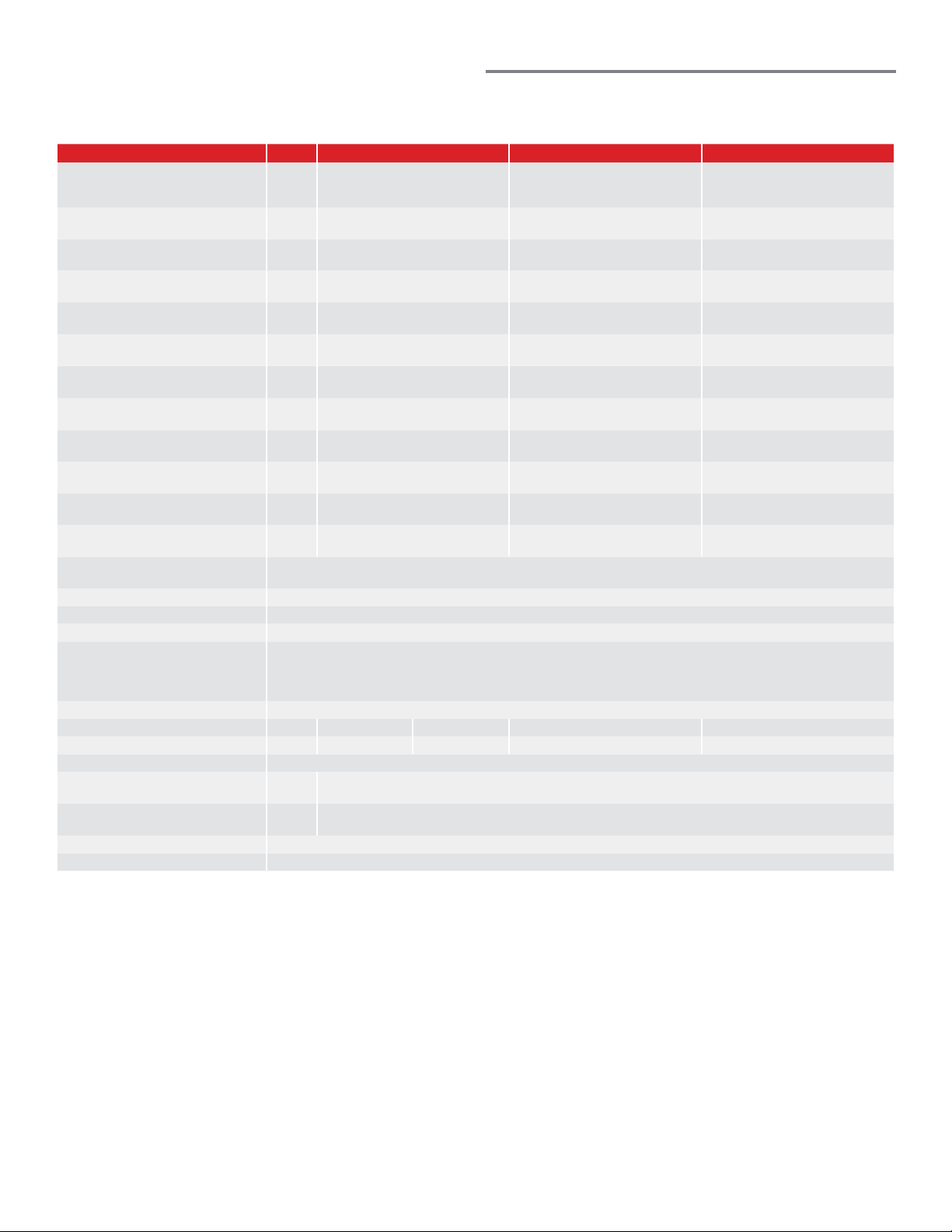

FMD Series Product Specifications

Specification FMD-10K Series FMD-30K Series FMD-50K Series

Load Capacity

kN

kgf

lbf

10

1000

2250

30

3000

6750

50

5000

11,250

Crosshead Speed - MINIMUM mm/min

in/min

0.001

0.00004

0.001

0.00004

0.001

0.00004

Crosshead Speed - MAXIMUM mm/min

in/min

1500

60

1500

60

750

30

Position Control Resolution µm

µin

0.05

1.9

0.025

0.9

0.025

0.9

Frame Axial Stiffness kN/mm

lbf/in

72

412,844

150

855,513

161

918,367

Vertical Test Space1mm

in

1270

50

1245

49

1220

48

Total Crosshead Travel mm

in

1162

45.75

1137

44.75

1111

43.75

Column Spacing mm

in

424

16.7

424

16.7

424

16.7

Total Height mm

in

1626

64

1626

64

1626

64

Total Width mm

in

787

31

787

31

787

31

Total Depth mm

in

736

29

736

29

736

29

Test Frame Weight kg

lb

136

300

192

425

225

500

Load Measurement Accuracy ±0.5% of reading down to 1/1000 of load cell capacity. Starrett load cell sensors are supplied with a Certificate of Calibration

traceable to NIST. Starrett recommends verification of load cell accuracy during installation per ASTM E4, ISO 7500-1 or EN 10002.

Position Measurement Accuracy2

±0.001inch (±20 µm)

Crosshead Velocity Accuracy ±0.1% of set speed at zero or constant load hold

Data Sampling 1 to 2000Hz

Digital I/O

12 total channels

Channel 1 & 2 for Power (5-24V)

Channels 3 thru 10 for either digital inputs or outputs

Channels 11 & 12 for Ground

USB Interface 1 USB 2.0 connector

Single Phase Voltage (Vac) ±10% 100-120Vac 220-240Vac 220-240Vac 220-240Vac

Maximum Power (A) Amps 4.0 1.5 3.7 3.7

Frequency 50/60Hz

Operating Temperature °C

°F

+10 to +38 °C

+50 to +100 °F

Storage Temperature °C

°F

-40 to +66 °C

-40 to +150 °F

Humidity 10% to 90%, non-condensing

CE Compliance MMD Series Systems meet all relevant CE standards

Notes:

1 Total vertical space is the distance from the top surface of the base plate to the bottom surface of the crosshead, excluding load cell sensor,

test fixtures, and clevis adapter.

2 Assumes Linear Error Correction and Deflection Compensation have been performed on test frame.

14

2.3.3 Noise Level Rating

The noise output for your MMD and FMD Series does not exceed

70dBa. Noise levels do not include noise from specimen breaks.

WARNING

Noise caused by sample fracture may exceed 70 dBa,

therefore, personal ear protection is recommended for these

types of applications.

2.3.4 Environmental Specifications

Your MMD and FMD Series is designed for use under normal labora-

tory conditions. Protective measures may be required if excessive dust,

corrosive fumes, electromagnetic fields or hazardous conditions are

encountered.

MMD Series Specification

Operating Temperature +10°C to +38°C (+50°F to +100°F)

Storage Temperature -40°C to +66°C (-40°F to +150°F)

Humidity 10% to 90% non-condensing

Environmental Conditions

Designed for use under normal laboratory conditions.

Protective measures maybe required if excessive dust,

corrosive fumes, electromagnetic fields or Hazardous

conditions are encountered.

Environment Specifications

2.3 Common Specifications

2.3.1 Power Requirements

The power specifications for Starrett MMD and FMD Series testing

frames are shown below.

Models

Electrical Phase

Single Phase (Vac) ±10%

Maximum

Power (A)

Frequency

(Hz)

MMD-10K

FMD-10K 100-120Vac 4.0 50/60

MMD-10K

FMD-10K 220-240Vac 1.5 50/60

MMD-30K

FMD-30K 220-240Vac 3.7 50/60

MMD-50K

FMD-50K 220-240Vac 3.7 50/60

Power Specifications

CAUTION

Your MMD Series requires “clean” and stable electrical

power. Power fluctuations and surges may cause perfor-

mance problems that may lead to extensive damage to your

test frame.

NOTE

An in-line power surge protector is recommended for all

installations.

2.3.2 Fuse Ratings

See Fuse Table (below).

HAZARD

Make sure to shut all power to your MMD or FMD Series test

frame to OFF. Dangerous voltage may cause personal injury.

NOTE

The MMD-10K and FMD-10K Series used with 100V or 120V

input power use two (2) 6.3A slow-blow fuses.

NOTE

All MMD and FMD Series used with 220-240V input power

use two (2) 3.5A slow blow fuse.

WARNING

Always replace the fuse with the correct type and amp rating.

Model Input Power Frequency Fuse Type Fuse Size Number Required

Littlefuse Brand

Part Number

FMD-10K

MMD-10K 100-120Vac 4.0A 50-60Hz 6.3A Slow-Blo 5 x 20mm 2 each 021806.3MXP

FMD-10K

MMD-10K 220-240Vac 1.5A 50-60Hz 3.15A Slow-Blo 5 x 20mm 2 each 02183.15MXP

FMD-30K

MMD-30K

FMD-50K

MMD-50K

220-240Vac 3.7A 50-60Hz 6.3A Slow-Blo 5 x 20mm 2 each 021806.3MXP

Fuse Specifications

starrett.com 15

2.3.5 Cyclic Testing

Cyclic testing is defined as tests where the frame constantly reverses

direction. Cyclic testing on MMD and FMD test frames is limited to a

continuous 24 hour duration @ 1Hz sampling.

CAUTION

The MMD and FMD test frames are not suitable for fatigue

testing applications.

2.3.6 Load Hold Testing

Constant load testing is defined as tests where the frame maintains a

constant load for a specified period of time, e.g. creep and relaxation

applications. Cyclic testing on MMD and FMD test frames is limited to a

continuous 24 hour duration at 1Hz sampling rate.

2.3.7 Frame Weights

MMD and FMD Series weights are listed below, including dimensions.

Model

Machine

Weight

Shipping

Weight1

Height

mm/in

Width

mm/in

Depth

mm/in

MMD-10K

FMD-10K

136 kg

300 lbs

~320 kg

~700 lbs

1626mm

64 in

787mm

31 in

736mm

29 in

MMD-30K

FMD-30K

192 kg

425 lbs

~340 kg

~750 lbs

1626mm

64 in

787mm

31 in

736mm

29 in

MMD-50K

FMD-50K

225 kg

500 lbs

~360 kg

~800 lbs

1626mm

64 in

787mm

31 in

736mm

29 in

Physical Weights and Dimensions

1The shipping weight will vary depending on the accessories included

with your order. Accessories are packaged in a single shipping crate.

NOTE

All shipping containers used for the 10K, 30K and 50K frames

are 38.5” W x 36” D x 74” H (97.8 x 91.4 x 188.0 cm).

16

TITLE:

MATERIAL:

Assembly, Twin Column, 10KN, Overall Dimensions

FINISH:

REV:DRAWING NUMBER:

10510-02 00

DATE: SCALE:

1 : 15

7/30/2013

The information in this drawing is the CONFIDENTIAL property of MetLogix. Disclosure or duplication

without prior approval is strictly prohibited.

0.00 [0.0]: ±0.030 [±0.75]

0.000 [0.00]: ±0.004 [±0.10]

0.0000 [0.000]: ±0.0010 [±0.025]

UNITS = INCH [MM]

TOLERANCES: (UNLESS NOTED)

DESIGN BY: DRAWN BY:

Craig Smigel cjs

SHEET:

OF

1 2

REVISION HISTORY

REV. DESCRIPTION DATE BY

00 As Issued 07/30/13 cjs

29.7 [754]

16.7 [424]

3.0 [76]

50.00

4.25

1270.0

108.0

[]

MAX-MIN HEIGHT

31.0 [787]

28.5 [724]

10.0 [254]

9.4 [238]

66.4 [1685]

6.7 [170]

2.4 MMD and FMD Dimension Drawings

10kN Load Capacity Series Test Frames

starrett.com 17

30kN Load Capacity Series Test Frames

TITLE:

MATERIAL:

Assembly, Twin Column, 30KN, Overall Dimensions

FINISH:

REV:DRAWING NUMBER:

10530-02 00

DATE: SCALE:

1 : 15

7/30/2013

The information in this drawing is the CONFIDENTIAL property of MetLogix. Disclosure or duplication

without prior approval is strictly prohibited.

0.00 [0.0]: ±0.030 [±0.75]

0.000 [0.00]: ±0.004 [±0.10]

0.0000 [0.000]: ±0.0010 [±0.025]

UNITS = INCH [MM]

TOLERANCES: (UNLESS NOTED)

DESIGN BY: DRAWN BY:

Craig Smigel cjs

SHEET:

OF

1 2

REVISION HISTORY

REV. DESCRIPTION DATE BY

00 As Issued 07/30/13 cjs

29.7 [754]

16.7 [424]

4.0 [102]

49.00

4.25

1244.6

108.0

[]

MAX-MIN HEIGHT

31.0 [787]

28.5 [724]

10.0 [254]

10.4 [263]

67.4 [1711]

6.7 [170]

MMD and FMD Dimension Drawings

18

TITLE:

MATERIAL:

Assembly, Twin Column, 50KN, Overall Dimensions

FINISH:

REV:DRAWING NUMBER:

10550-02 01

DATE: SCALE:

1 : 13

7/30/2013

The information in this drawing is the CONFIDENTIAL property of MetLogix. Disclosure or duplication

without prior approval is strictly prohibited.

0.00 [0.0]: ±0.030 [±0.75]

0.000 [0.00]: ±0.004 [±0.10]

0.0000 [0.000]: ±0.0010 [±0.025]

UNITS = INCH [MM]

TOLERANCES: (UNLESS NOTED)

DESIGN BY: DRAWN BY:

Craig Smigel cjs

SHEET:

OF

1 2

REVISION HISTORY

REV. DESCRIPTION DATE BY

01 As Issued 07/30/13 cjs

16.7 [424]

48.00

4.25

1219.2

108.0

[]

MAX-MIN HEIGHT

31.0 [787]

28.5 [724]

67.4 [1711]

10.4 [263]

5.0 [127]

10.0 [254]

6.7 [170]29.7 [754]

50kN Load Capacity Series Test Frames

MMD and FMD Dimension Drawings

starrett.com 19

3.0 Lifting and Handling

The MMD and FMD Series twin column testing frames are heavy. Any

lifting and positioning should be done by authorized personnel in

accordance to local safety standards, e.g. training required by Occupa-

tional Safety and Health Act (OSHA) in the United States, or comparable

safety standards when installed internationally.

Proper rigging equipment is required for lifting and positioning all MMD

and FMD Series test frames. Personnel responsible for test frame

lifting and position must follow the instructions within this manual.

Personnel should contact Starrett if they have any questions about how

to safely lift and position the MMD or FMD Series test frames.

Starrett recommends leaving the MMD and FMD Series test frame

in its packaging while moving the instrument to its final site location

within your facility.

CAUTION

Make sure hallways and door openings are large enough to

safely move your MMD and FMD Series to its final site loca-

tion.

Make sure that floors leading to the final site location are

rated to support the weight of the MMD and FMD Series

while in its Starrett Packaging.

3.1 General Precautions

Starrett recommends that only individuals experienced with the

operation of lifting equipment and rigging techniques should attempt to

lift or move your MMD and FMD Series testing frames.

Equipment operators must have the appropriate licenses and have

complied with your local safety standards (e.g. the appropriate training

required by OSHA in the U.S. or appropriate safety institutions around

the world).

WARNING

NEVER lift the frame by the top plate. This plate does not

support the weight of the frame. The plate could break and

cause personal injury and equipment damage.

WARNING

Do not use a lifting device or straps rated for less than twice

the weight of the load frame. All lifting devices and straps

must be rated for a capacity at least twice the weight of the

load frame.

WARNING

Do not tilt an unsupported load frame more than 15-degrees

when it is in the upright position.

Lift by Crosshead

Do NOT lift by top plate

20

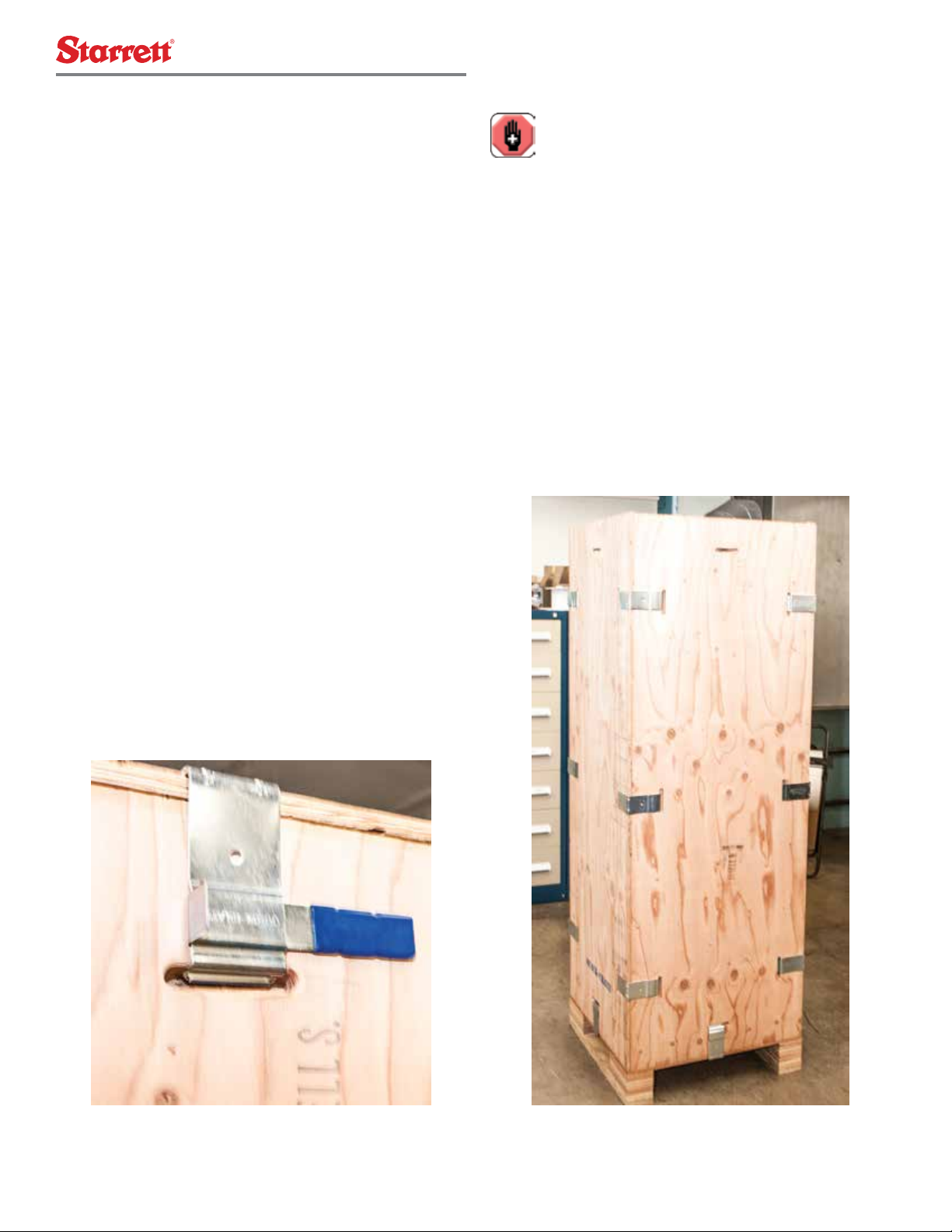

3.2 Unpacking Your System

Starrett recommends that you wait to unpack your MMD or FMD Series

once it has been located in its final site location.

Your MMD and FMD Series should be moved using a forklift or crane to

its final site location.

Starrett uses environmentally safe portable crating systems to trans-

port the MMD or FMD Series. These systems are reusable, so take

care to store them flat when you are finished removing your test frame.

Disassemble your packaging create as follows:

1. Remove the metal clips holding the top plate of the crate system.

2. Remove the wooden top plate.

3. Remove the metal side clips.

4. Remove one of the metal base clips.

5. Remove the wooden side where you removed the metal base clip.

6. Repeat steps 3-5 as your work around each side of the crate

system.

7. Remove the shrink wrap vapor barrier around the test frame. DO

NOT USE A KNIFE. Take care not to cut the shrink wrap as you

may accidentally damage the surface finish.

8. Review the Packing List to ensure all components have been

shipped. Contact Starrett if you find any accessories or compo-

nents missing.

9. Remove all accessories and components from the base and save

to a side location. Do NOT disassemble or remove any compo-

nents or parts from the Accessory packages. Retain all packaging

materials until the system is satisfactorily installed and all parts,

components and accessories are

accounted for and located.

10. Prepare to move the MMD or FMD test frame to its final site

location.

Starrett Crate Tool

WARNING

When removing the wooden sides from the crate system, you

should work with the help of an assistant to keep the oppos-

ing sides from falling off the bottom skid.

Once the top and sides of the crate system have been removed, leave

the MMD or FMD test frame in the base on the skid. The skid is

required if you choose to life the frame under the base.

Starrett Crate System

This manual suits for next models

1

Table of contents

Popular Test Equipment manuals by other brands

Zehntner

Zehntner ZOL 1150 instruction manual

MULTI MEASURING INSTRUMENTS CO.,LTD.

MULTI MEASURING INSTRUMENTS CO.,LTD. MCL-800IRV instruction manual

PeakTech

PeakTech P 3441 manual

Viavi

Viavi MTS 2000 Quick Card

Pintek

Pintek DP-16V instruction manual

Armada Technologies

Armada Technologies Pro48 instruction manual