MAKE A GRAND ENTRANCE

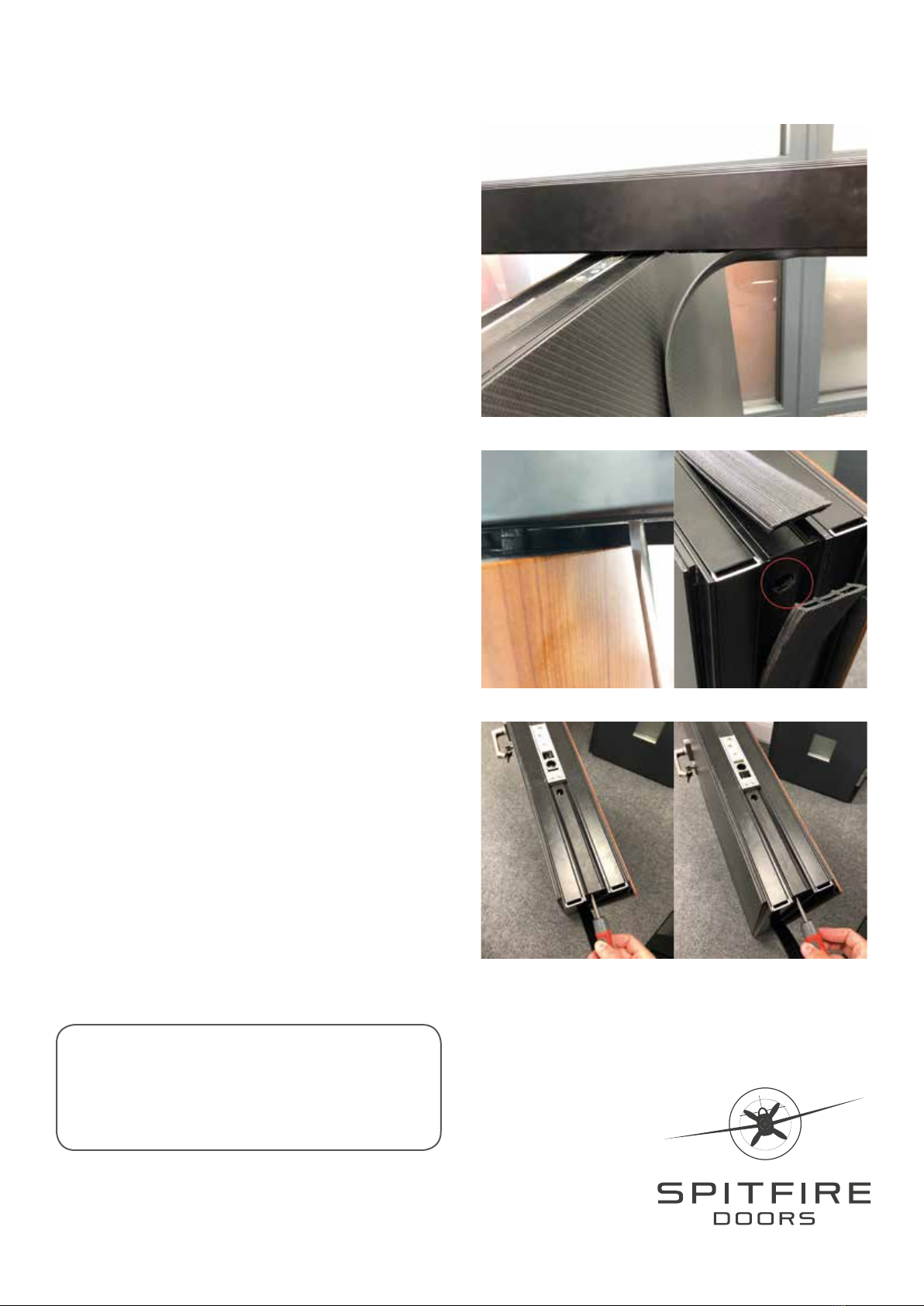

When the door is slotted into the baseplate, you will need to

sink the top pin back into the door sash to secure it in place.

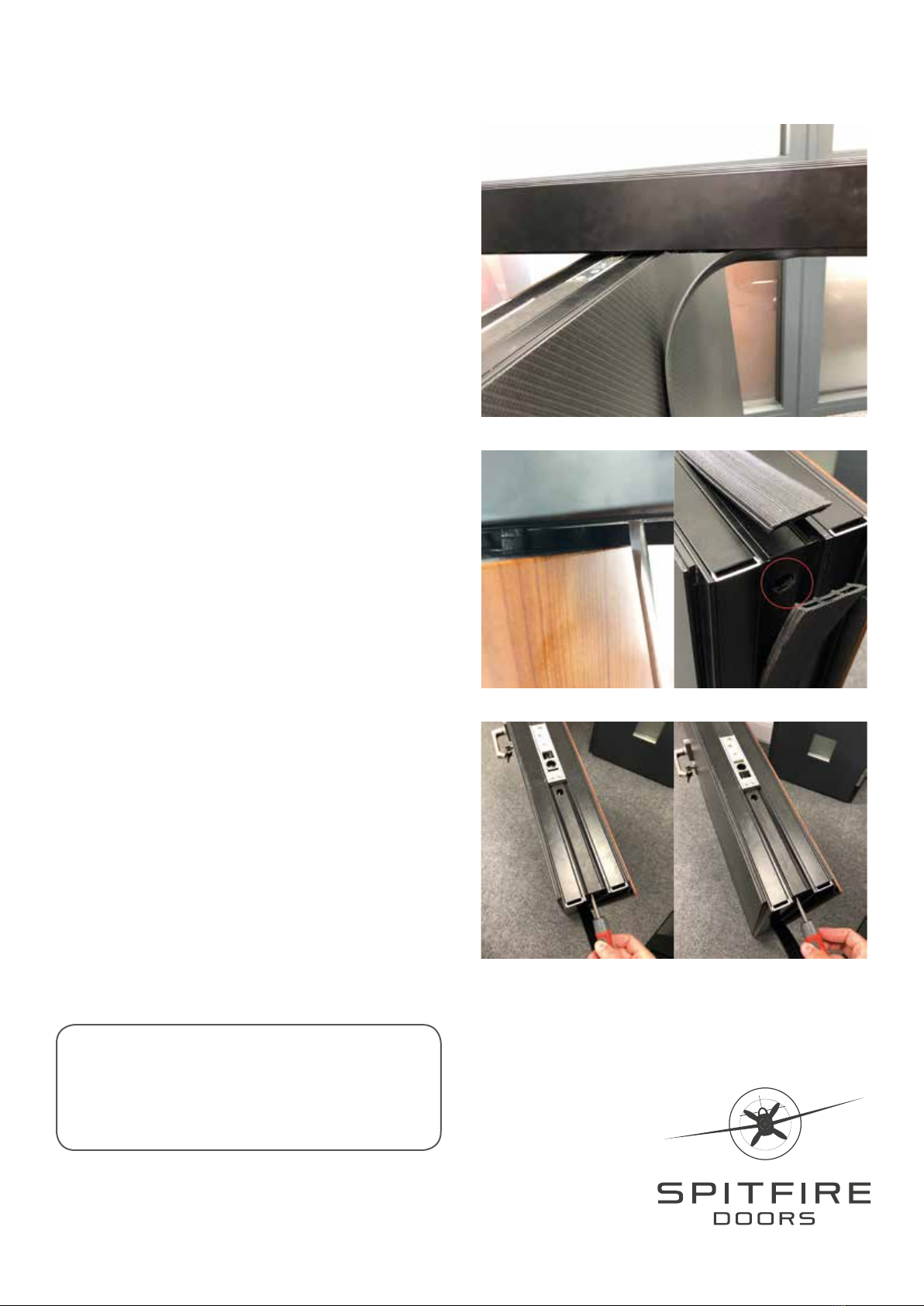

- Removing the top outside gasket will give you better

visibility of the top pin. (Image 5)

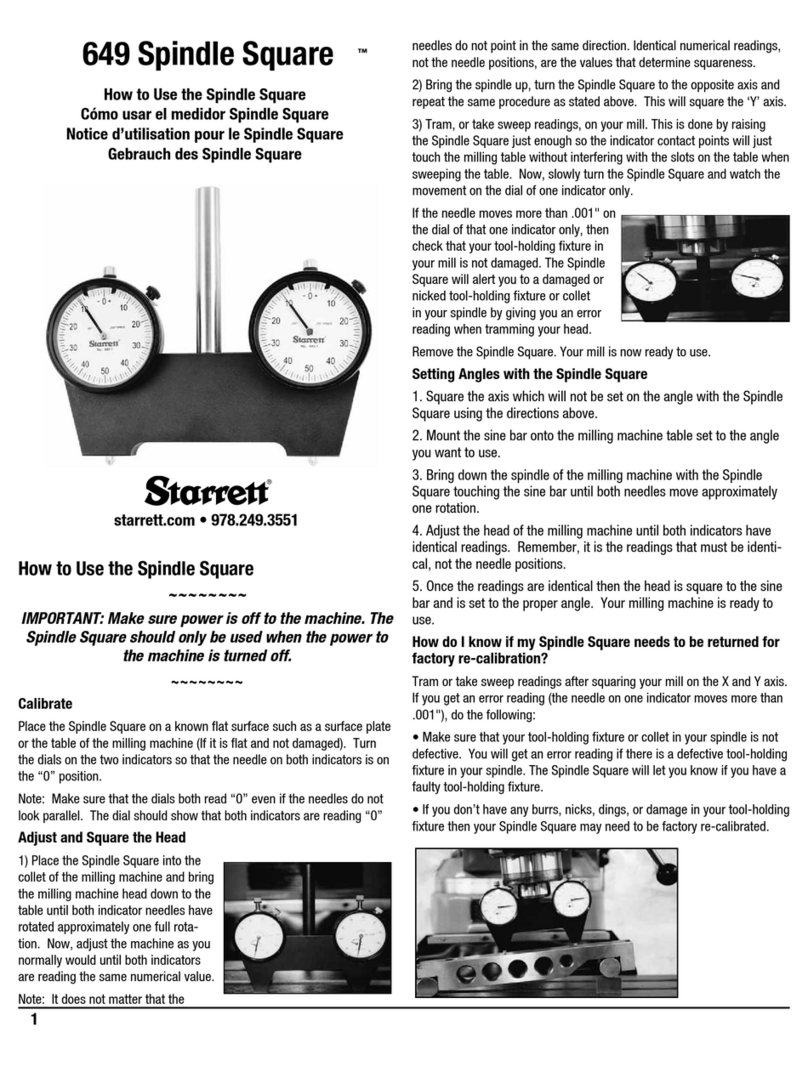

- Bring the top pin in line with the opening on the sash and

screw the top pin into place until the top pin retracting

screw is fully wound back into place (Image 6)

- Carefully close the door against the frame and align the door

sash with the frame and check the shadow joint around the

door/frame junctions as this should be equal all the way

around with a 6mm gap (+/– 1mm). The door should close

and lock should engage without undue force. If the door is

mis-aligned or proud at any point, the frame may be twisted

and should be realigned before proceeding further.

- Check that the bottom of the door seals meet the threshold

to give a weatherproof seal.

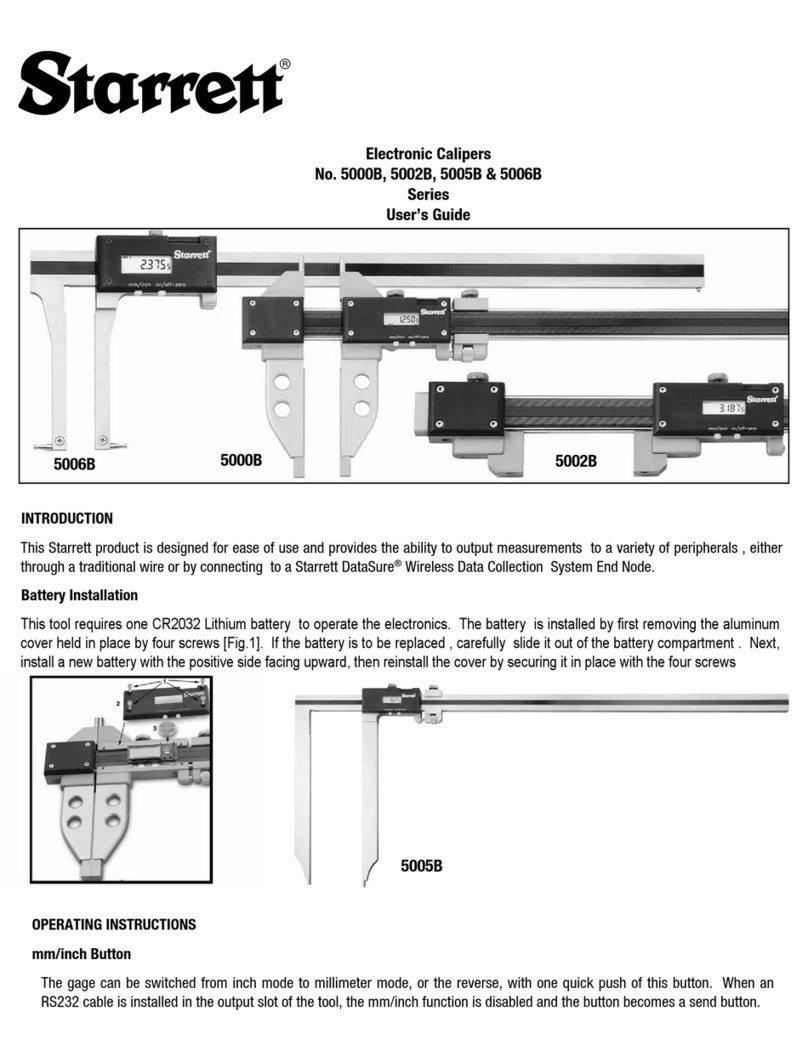

- If necessary, adjust the position of the door with the

levelling screw that is located on the pivot side of the sash,

underneath the gasket. You will need to insert an extra long

flat head screw driver into the side of the door sash to reach

this screw. (Image 7)

PLEASE BE AWARE: You MUST remove/unwind the top

pin and tilt the sash onto its side when making the levelling

adjustment. Otherwise the full weight of the sash will have to

be moved by the levelling screw. Failing to do this will result

in permanent damage to the mechanism and a costly remake

sash could be required. Adjusting the screw clockwise will

lift the corner of the lock side, spinning the screw counter

clockwise will lower the sash corner. (Image 8 & 9)

Once the door is operating satisfactorily, seal the gap between

perimeter of the frame and the wall. Depending on the gap size

use either pre-formed sealant material (Compriband or similar),

silicone sealant or low expansion foam sealant. Always keep

the door in the closed position until the sealant has fully cured

to avoid any movement in the frame.

Installation

Image 5

Image 6 Image 7

Image 8 Image 9

If in doubt contact us on

01625 412 570