Status Instruments SEM1700 User manual

D2475-01-09 CN5787 SEM1700 User Guide

SEM1700

USER INSTRUCTIONS

Important - Please read this document before installing.

Every effort has been taken to ensure the accuracy of this document; however, we do

not accept responsibility for damage, injury, loss or expense resulting from errors and

omissions, and we reserve the right of amendment without notice.

IMPORTANT - CE & SAFETY REQUIREMENTS

Product must be DIN rail mounted, inside a suitable enclosure providing environmental

protection to IP65 or greater.

To maintain CE EMC requirements, input and supply wires must be less than 30

metres.

The product contains no serviceable parts, or internal adjustments. No attempt must be

made to repair this product. Faulty units must be returned to supplier for repair.

Before attempting any electrical connection work, please ensure all supplies are

switched off.

ABSOLUTE MAXIMUM CONDITIONS (To exceed may cause damage to the unit).

Working voltage terminals 1 to 10

± 30 V dc, ± 50 mA dc

Working voltage terminals 11 to 18

240 V ac, ± 240 V dc

Isolation (11 to 12) to (1 to 10)

3750 V

Isolation (11 to 12) to (13 to 18)

3750 V

Isolation (13 to 18) to (1 to 10)

3750 V

Supply voltage

±240 V dc, ±240 V ac (protected for over voltage)

Input voltage

±24 V between any input terminals

Input current

±50 mA between any input terminals

Output

30 V dc

Relays

(240 V ac @ 1 A, 30 V dc @ 1 A) non inductive

Ambient

Temperature (-20 to 70) °C, Humidity (0 to 95) % RH (Non-condensing)

External supply

1 A anti-surge fuse recommended

---------------------------------------------------------------------------------------------------------------

1~DESCRIPTION.

The SEM1700 is a DIN rail-mounted universal signal conditioner from Status Instruments.

It has been designed to accept most common process and temperature sensor inputs and

provide the user with a programmable current or voltage output signal, plus dual relays

with a programmable delay function. Isolation is provided between input, output and

supply. All temperature ranges are linear to temperature. Both input and output loop

excitation are provided, as well as a universal power supply.

2~RECEIVING AND UNPACKING.

Please inspect the packaging and instrument thoroughly for any signs of transit

damage. If the instrument has been damaged, please notify your supplier immediately.

3~SPECIFICATION.

Refer to data sheet for full specification. Download at www.status.co.uk

Factory defaults

Input Pt100, output (4 to 20) mA = (0 to 100) °C

relays high alarm @ 50°C, damping off, buttons off,

Sample rate 1000 ms

4~INSTALLATION AND WIRING.

Important safety requirements

This equipment is suitable for environment installation category II pollution degree 1

and is classed as "PERMANENTLY CONNECTED EQUIPMENT".

In NORMAL USE, the equipment will only be accessed for maintenance by qualified

personnel. Please ensure the equipment is mounted vertically with terminals (1-10) at

the bottom. This will provide maximum ventilation and ensure correct operation of the

cold junction sensor. This equipment may generate heat; ensure the enclosure size is

adequate to dissipate heat. Be sure to consider any other equipment inside the

enclosure.

The equipment surfaces may be cleaned with a damp cloth. Use a mild detergent on a

damp cloth. Ensure the supply is off before cleaning and on completion of cleaning the

equipment is completely dry before the supply is turned back ON.

To keep the safety distances, the relay on the device must not be connected to both

hazardous and non-hazardous voltages.

This equipment must be installed by a qualified person. All electrical wiring must be

carried out in accordance with the appropriate regulations for the place of installation.

Dc supply must be derived from a local supply and not a distribution system.

Supply (22 to 240) V ac 50/60 Hz, (20 to 240) V dc. If the supply is a HAZARDOUS

VOLTAGE, a supply isolation switch must be installed close to the equipment with the

“OFF” position clearly marked. Also, the supply must be fused with a suitable 1A (T)

fuse (circuit breaker) installed close to the equipment. Maximum cable run 50 m.

Relay 1,2 outputs are isolated from each other. Max switching current (1 A @ 240 V ac,

1 A @ 30 V dc) Non-Inductive. Fuse relay circuits with a suitable 2A (T) fuse installed

close the equipment. If a HAZARDOUS VOLTAGE is being switched, then an isolation

switch must also be installed close to the equipment with the off position clearly

marked.

USB configuration can be performed without the supply being connected. For safety

reasons, use a 24 VDC for functional test of unit prior to fixed installation. The following

operations should only be carried out on a disconnected device and under ESD safe

conditions.

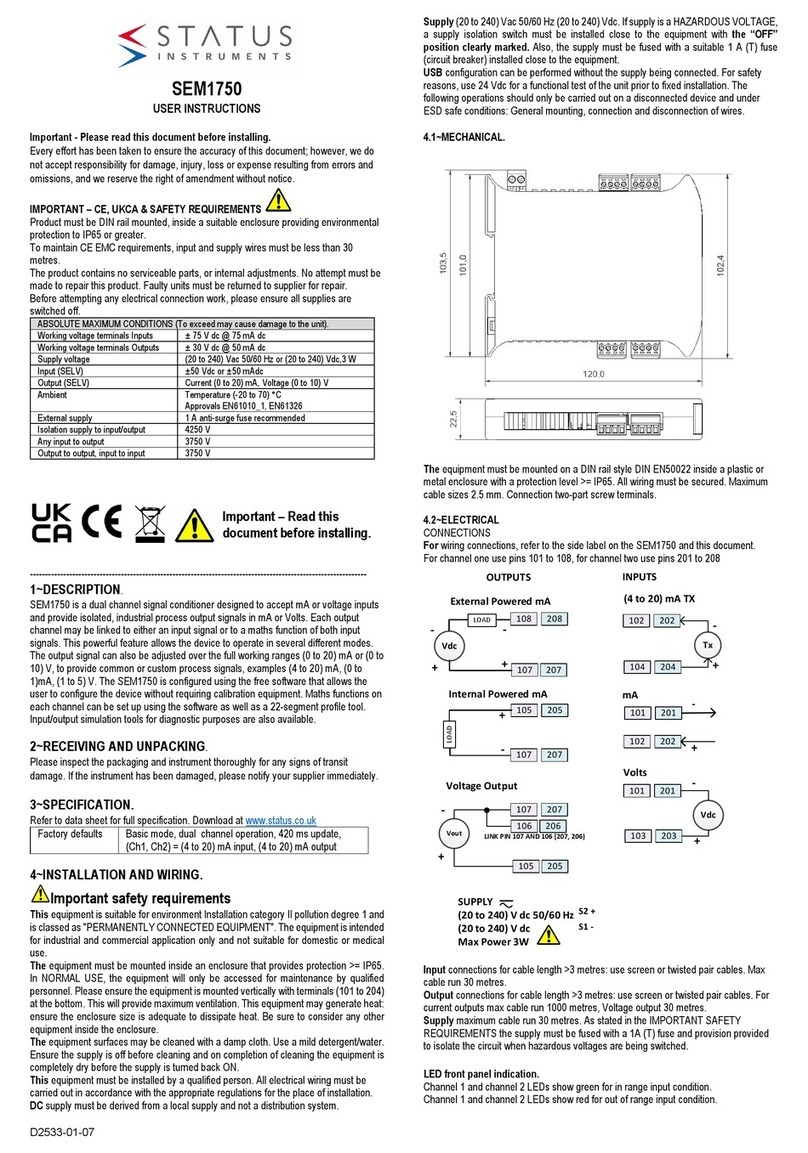

4.1~MECHANICAL.

The equipment must be mounted on a DIN rail style DIN EN 50022 inside a plastic or

metal enclosure with a protection level >= IP65. All wiring must be secured. Maximum

cable sizes 2.5 mm. Connection two-part screw terminals.

4.2~ELECTRICAL

CONNECTIONS

For wiring connections refer to the side label on the SEM1700 and this document.

Input connections for cable length >3 metres use screen or twisted pair cables.

Thermocouple connections: use the correct compensating cable. Pt100 connection; all

wires must be equal length (resistance). Max cable run 30 metres.

Output connections for cable length >3 metres use screen or twisted pair cables. For

current outputs max cable run 1000 metres, Voltage output 30 Metres.

Relay connections –relays 1 and 2 are isolated from each other. As stated in the

IMPORTANT SAFETY REQUIREMENTS relay circuit must be fused with a 2A (T) fuse

and provision provided to isolate the circuit when hazardous voltages are being

switched.

Supply maximum cable run 30 metres. As stated in the IMPORTANT SAFETY

REQUIREMENTS the supply must be fused with a 1A (T) fuse and provision provided

to isolate the circuit when hazardous voltages are being switched.

D2475-01-09 CN5787 SEM1700 User Guide

5~USER CONFIGURATION.

Read the Important safety requirements

5.1~MANUAL CONFIGURATION

User trim function allows manual adjustment of the analogue output. This is useful for

minor calibration adjustment or trimming out any sensor error; ± 5 % of range

adjustment is available at both offset and span. Raise and lower buttons are provided

on the front panel of the transmitter, accessed using a 3 mm flat blade screwdriver.

Insert the screwdriver into the appropriate slot to operate the button. The button has a

click action.

The transmitter will automatically detect the correct trim point (offset or span) based on

the output signal. Offset will be trimmed when the current is in the offset band, span

when the current is in the span band. No trim action occurs at any input value.

User trim method (option selected in software)

Connect the device to a suitable input simulator/sensor. Connect a digital meter to

monitor the output. Turn on device, set input to offset/span trim point.

Enter trim menu by pressing ˄for > 2 s.

When the trim menu is open the STATE LED will flash as shown below.

If performing two-point trim always trim, offset point first.

User trim method (continued)

Adjust output current by pressing either the ˄or ˅

button, single click to step advance, or press

continuously to auto advance.

Once adjust is complete, allow 30 s with no button

press. The transmitter will time out and return to

normal operation.

User range function allows two-point manual configuration of the re-transmission

current (voltage) at low and high range against a live input signal. This is useful for on-

site configuration. Example, with a slide wire input, the user manually positions the slide

at both low and high positions and configures the unit to operate over the range.

Configuration is achieved using either the raise (span) or lower (offset) buttons.

User range method (option selected in software)

Connect the device to a suitable input simulator/sensor. Connect a digital meter to

monitor the output. Turn on device, set input to offset/span range point.

Enter range menu by pressing ˄or ˅for > 2 s.

When the trim menu is open the STATE LED will flash as shown below.

User trim method (continued)

Once the menu has been entered, quickly

(within 1 s) ˄or ˅button to enter and

store setting.

To abort configuration, allow config to time

out by not pressing buttons for 5 s.

5.2~PC CONFIGURATION

During configuration the equipment takes its power from the USB port, therefore no

power connection is required. The equipment can be configured whilst powered but the

computer used must be isolated from the supply earth to avoid grounded earth loop

effects.

Device

USBSPEEDLINK software

USB CABLE

COMPUTER

Configuration steps using USBSpeedLink

Download install and run USBSpeedLink

Connect device to PC using an A to mini B USB lead

Upload device set-up into the configuration software

Adjust settings as required

Send new configuration to the device

USBSpeedLink software configuration screen for SEM1700

Note: When the device is correctly connected, the “Send” and “Receive” menu buttons

will turn black and the “data” section of the screen will open on the right.

INPUT TYPE

Select input sensor, or process type required. Also used for adjustable sample time and

gives a user-field to save text to the device

TEMPERATURE RANGE/SCALE PROCESS

Set the unit and range in temperature mode, and engineering units and scaling range in

process mode.

ANALOGUE OUTPUTS

Select mA or voltage output, either pre-set ranges or a user-defined range can be

entered.

User-adjustable damping of the analogue output is provided for both rising and falling

signals. The adjustable range is (0 to 250) second for a (0 to 20) mA or (0 to 10) V swing.

To calculate the maximum rate of change of the output signal, divide 20 mA (10 V) by

the damping setting. Example, if the damping is set to 100 s, the mA output will change

at a maximum rate of (20/100) = 0.2 mA /s.

Error signal direction for temperature mode.

Front of panel button function control for user trim, user range and off is selectable.

RELAY 1 and RELAY 2

The contacts are rated at 240 V ac 1 A (Non inductive) 30 V DC 1 A. An external

snubber network is recommended when switching inductive circuits. Please ensure the

snubber network is rated for the application. Four actions are provided, as detailed

below.

Alarm actions may also be used for inverted control applications. Adjustable setpoint

and dead-band are provided together with adjustable on and off delays for each relay.

The delay range is (0 to 250) s.

SP DB

Relay

Led

SP

Relay

Led

DB

Relay

Led

SP DB

SP

Relay

Led

DB

Hi_Alrm

or

Inverted

Hi_Ctrl

Lo_Alrm

or

Inverted

Lo_Ctrl

Hi_Ctrl

or

Inverted

Hi_Alrm

Lo_Ctrl

or

Inverted

Lo_Alrm

USBSpeedLink configuration software is available online at www.status.co.uk

This guide is also available online at www.status.co.uk

Status Instruments Ltd, Status Business Park, Gannaway Lane, Tewkesbury, Gloucestershire, UK, GL20 8FD,

Web Page: www.status.co.uk,

Tel: +44 (0) 1684 296818, Fax: +44 (0) 1684 293746

Other Status Instruments Test Equipment manuals

Popular Test Equipment manuals by other brands

Gamry Instruments

Gamry Instruments Universal Dummy Cell 3 Operator's manual

AFL

AFL FR1 Series manual

JDS Uniphase

JDS Uniphase IP Video Test Option HST-3000 instruction manual

EXFO

EXFO EX10 user guide

Tektronix

Tektronix TDS200 Series Operator training kit manual

CT Systems

CT Systems Wavetek 2500 Operation manual