STAUFF SMFS-U-CM-110 User manual

Instruction manual

Original instructions

Mobile Filter System

SMFS-U-CM-110

To prevent injury and damage, read this instruction manual carefully

and attentively and retain it for future reference.

6100243510 V 1.0 11/02/2022

Walter Stauffenberg GmbH & Co. KG

Im Ehrenfeld 4

58791 Werdohl, Germany

+49 2392 916-0

www.stauff.com

Additional instructions in other languages can be downloaded from:

www.stauff.com

Mobile Filter System

2 / 40 www.stauff.com

Table of Contents

SMFS-U-CM-110 3 / 40

www.stauff.com

Table of Contents

1 Information on this manual ...................................................................5

1.1 Structure of the warnings.............................................................. 5

1.2 Structure of the operating instructions .......................................... 6

1.3 For better orientation .................................................................... 6

2 For your safety........................................................................................7

2.1 Intended use ................................................................................. 7

2.2 General safety instructions ........................................................... 8

2.3 Specific safety instructions ........................................................... 8

2.4 Tasks and duties of the operating company ................................. 9

2.5 Personnel qualification................................................................ 10

2.6 Personal protective equipment ................................................... 11

3 Machine description.............................................................................12

3.1 Overview..................................................................................... 12

3.2 Function ...................................................................................... 13

3.3 Technical Data............................................................................ 13

3.4 Type plate ................................................................................... 14

3.5 Display and operating elements ................................................. 15

3.5.1 Electrical main switch.......................................................15

3.5.2 Clogging indicator ............................................................15

3.6 Spare and wear parts ................................................................. 16

4 Transport and storage .........................................................................17

4.1 For your safety............................................................................ 17

4.2 Transport .................................................................................... 17

4.3 Storage ....................................................................................... 17

5 Installation.............................................................................................19

5.1 For your safety............................................................................ 19

5.2 Initial commissioning................................................................... 20

5.3 Particle counter........................................................................... 21

5.3.1 Operation .........................................................................22

5.3.2 Entering the purity level ...................................................24

5.3.3 Evaluating the measurement data ...................................27

6 Operation...............................................................................................28

6.1 For your safety............................................................................ 28

6.2 Starting the pumping process ..................................................... 29

6.3 Stopping pumping....................................................................... 29

7 Maintenance..........................................................................................30

7.1 For your safety............................................................................ 30

Table of Contents

Mobile Filter System

4 / 40 www.stauff.com

7.2 Inspection and maintenance schedule ....................................... 31

7.3 Cleaning...................................................................................... 31

7.3.1 Cleaning the pre-filter.......................................................31

7.4 Replacing the filter element ........................................................ 32

8 Faults .....................................................................................................34

8.1 For your safety............................................................................ 34

8.2 Procedure for troubleshooting .................................................... 34

8.3 Fault table ................................................................................... 35

9 Decommissioning.................................................................................36

9.1 For your safety............................................................................ 36

9.2 Disposal ...................................................................................... 37

10 EC declaration of conformity ..............................................................38

Keyword index .....................................................................................39

1 Information on this manual

SMFS-U-CM-110 5 / 40

www.stauff.com

1 Information on this manual

This instruction manual contains important notes and information on proper

use. The instruction manual must be kept accessible for the operating staff.

1.1 Structure of the warnings

Warning notices are made particularly obvious via colour-shaded signal

word panels. Always read the complete text of the warning notice to ensure

you are fully protected against hazards.

The following signal word panels use different colours and signal words to

indicate different levels of danger:

DANGER

Failure to heed this warning notice will result in serious or fatal injury.

WARNING

Failure to heed this warning notice may result in serious or fatal injury.

CAUTION

Failure to heed this warning notice may result in slight or moderate

injury.

NOTICE

Failure to heed this warning notice may result in damage to property.

Warning notices always have the same structure. They contain the signal

word, nature and source of the danger, the consequence of failure to heed

the notice and measures designed to prevent/avoid the danger.

Example:

WARNING

Tasks on electrical equipment

Severe or fatal injury due to electrical voltage

► Work on electrical equipment may only be performed by trained

electricians.

► Switch the machine off and safeguard it from being restarted.

► Perform work on live parts only under the supervision of a second

person.

1 Information on this manual

6 / 40 Mobile Filter System

www.stauff.com

1.2 Structure of the operating instructions

Operating instructions request you to carry out an activity directly. They have

an action-oriented structure. Always carry out the individual action steps in

the specified order.

Operating instructions are structured as follows and are identified by

corresponding symbols:

uObjective of the operating instruction

1. Action step

üEffect of the action step to check whether it has been carried out

correctly.

2. Further action step

þResult of the complete operating instruction.

1.3 For better orientation

For better orientation, this instruction manual provides the following:

• Table of contents at the beginning

• Title of the main section in the header

• Links to other sections, for example to „Information on the manual“

(Section 1, P. 5)

• Additional information and tips marked with an i-symbol

Example for additional information

2 For your safety

SMFS-U-CM-110 7 / 40

www.stauff.com

2 For your safety

2.1 Intended use

The mobile filter system is designed for cleaning hydraulic and lubricating oil

systems in machines and plants or for filling in new oil.

The mobile filter system is only intended for use with commercial mineral

oils.

The intended use includes:

• observation of all safety instructions and warnings of this instruction

manual ( Section 2.2, P. 8)

• utilisation only within the specifications given in section "Technical

Data"( Section 3.3, P. 13)

• consideration for the maintenance intervals and requirements

(Section 7.2, P. 31)

Modifications, extensions or conversions are not permitted without prior

discussion with the manufacturer. Such modifications can jeopardise the

operational safety and are considered as non-intended use.

Misuse

Any use other than that stated in the „Intended Use“ section is not permitted.

The mobile filter system must not be used

• in explosive atmospheres

• in unventilated rooms

The mobile filter system must not be used with the following media:

• explosive substances

• aggressive substances

• toxic substances

• highly abrasive substances

• faeces

The basic contamination of the conveyed liquid must not exceed

category 22/20/16 as per ISO 4406.

2 For your safety

8 / 40 Mobile Filter System

www.stauff.com

2.2 General safety instructions

Safety instructions help you to prevent injuries and damage to property.

Ensure that you have read and understood all safety instructions in this

instruction manual.

For safe working, it is not sufficient to only read the general safety

instructions in this section. You must also read and follow the special safety

instructions in all sections concerning your work. Note and follow also the

information and instructions in the reference documents.

The following safety instructions apply generally:

• Comply with the respective relevant national and international safety

regulations regarding health and safety at work.

• Operate the machine only …

– if it is in perfect technical condition,

– safely and aware of the hazards,

– as intended ( Section 2.1, P. 7),

– paying attention to this instruction manual,

– with unchanged, fully installed, properly installed and fully functional

safety devices and

– with properly installed and functioning control.

• Wear personal protective equipment ( Section 2.6, P. 11).

• Correct immediately any faults that could have a negative effect on your

safety or on safe operation of the machine. Shut down the machine until

the fault is corrected and safeguard it against restarting.

• Adhere all inspection and maintenance dates, including information

concerning part replacement.

• For maintenance and repair work, switch off the machine and disconnect

the mains plug.

• Work on electrical installations may only be carried out by qualified

electricians. Work on live parts may only be carried out under the

supervision of a second person.

• Be aware of the presence of possible residual energies in mechanical

and electrical components.

• Use spare parts authorised by the manufacturer to replace components.

Unauthorised spare parts can endanger the operating safety.

• Check electrical equipment regularly. Remove loose connections and

braised cables immediately.

2.3 Specific safety instructions

The product is designed in line with the best technology available and the

recognized safety-relevant regulations. Even so. its use can entail risks to

the life and limb of the operator and third parties or damage to the product

and its operating field.

2 For your safety

SMFS-U-CM-110 9 / 40

www.stauff.com

Electric shock from live components

• All electrical installation and maintenance work is to be carried out

only by qualified electricians

• Disconnect unit from power supply prior to performing work

• Check components for electric charge prior to performing work

Burns from hot surfaces

• Let hot components cool down before starting any work

• Wear protective gloves

2.4 Tasks and duties of the operating company

To ensure safe operation of the machine the operating company has at least

the duty …

• to ensure that the machine is only operated according to its intended

use, in a proper condition, with completely assembled safety equipment

and without damage.

• to define the area of use and draw up corresponding operating

instructions (standard operating procedures).

• procure the respective latest version of the regulations concerning

operation and to familiarise the operating personnel with these

regulations.

• to provide the operating instructions always legibly and complete near to

the operating site.

• to ensure adequate stability.

• to avoid tripping hazards.

• to ensure adequate ventilation and illumination of the work areas.

• Instruct personnel in safe working practices and regularly check that

personnel work with an awareness for safety and hazards.

• to ensure that unauthorized persons have no access to the danger zone.

• to provide the necessary personal protective equipment.

• have electrical installations tested at least once a year by electrical

specialists.

2 For your safety

10 / 40 Mobile Filter System

www.stauff.com

2.5 Personnel qualification

Any work on the machine is only be carried out by qualified and authorised

personnel. Personnel trained in the work involved as backed up by

appropriate certificates are considered to be qualified.

Qualifications

The personnel approved for particular tasks belong to the following target

groups, based on the qualification:

•Operating personnel has been instructed in how to operate the

machine and how it works. They enter the data required for operation

and carry out the steps necessary for operation of the machine. They are

also responsible for simple maintenance work.

•Setup and maintenance personnel are responsible for commissioning

and decommissioning as well as for setting up and retooling the

machine. The responsibilities of the setup and maintenance personnel

also extend to performing extensive maintenance work and to instructing

the operating personnel on how the machine operates.

•Qualified electricians are responsible for all work on the electric

components.

•Qualified transport personnel are qualified for proper and secure

loading and transport of heavy goods.

Skilled jobs

Certain qualifications are needed for a number of jobs. Only those with the

specified qualifications are allowed to perform the listed jobs.

Job Qualification

Transporting the machine to the destina-

tion

Qualified transport personnel

Installation Setup and maintenance personnel

Fault rectification Set-up and maintenance personnel

Maintenance and troubleshooting of elec-

trical equipment

Electrician

General inspection and maintenance

work

Setup and maintenance personnel

2 For your safety

SMFS-U-CM-110 11 / 40

www.stauff.com

Safety briefing

All persons working on the machine must receive a safety briefing at least

once a year. Indispensable elements of this briefing are:

• Personnel qualifications and authorisations

• Functionality and operating

• Area of application and surrounding conditions

• Personal protective equipment

• Transport to the place of installation

• Regular maintenance work

2.6 Personal protective equipment

To limit hazards during work, use the required personal protective

equipment:

Symbol PPE Life phase Job

Close-fitting work clothing all all

Safety shoes all all

Protective gloves Operation When working on

the system before it

has cooled down

Startup

Troubleshooting

Maintenance

Eye protection Operation When working on

the system under

pressure

Startup

Troubleshooting

Maintenance

3 Machine description

12 / 40 Mobile Filter System

www.stauff.com

3 Machine description

3.1 Overview

1

2

3

4

5

6

7

8

9

10

11

Fig.1: Overall view

1 Hose on delivery side 7 Clogging indicator

2 Lance 8 Power cable and power plug

3 Gear pump with pressure limiting

valve

9 Hose on intake side

4 SMK 10 Electrical main switch (rear)

5 Filter housing with filter element 11 Particle counter

6 Handle

3 Machine description

SMFS-U-CM-110 13 / 40

www.stauff.com

3.2 Function

The mobile filter system is connected to the external power supply after

installation and connection of the hoses at the installation site. After

switching on, the medium is aspired by the pump, cleaned in the filter and

discharged again through the hose on the delivery side.

3.3 Technical Data

Measures and weights

Dimensions (width x depth x height) 947 x 620 x 984 mm

Weight 220 kg

Media compatibility

Suitable for: Mineral oils

Upon consultation with

Walter Stauffenberg GmbH&Co.KG:

• water, especially drinking water

• food

• flammable liquids

• liquids with degreasing action

• DOT brake fluids

• phosphate esters (e.g. Skydrol,

Hyjet)

• HFDR liquids as per ISO12922

based on phosphoric acid esters

• HEPG liquids as per ISO15380

based on polyglycol

• MIL-L-7080 E

• caustic liquids

Hoses and lances

Material PVC, reinforced with internal spiral

Length of hose, intake side 3 m [9.84ft] on the intake side

Length of hose, delivery side 3 m [9.84ft] on the delivery side

Dimensions, intake side DN 38

Dimensions, delivery side DN 28

Flow rate

Flow rate

110 l/min (depending on viscosity)

Temperature

Medium temperature -20° C ... +60° C

Ambient temperature -20° C ... +40° C

Viscosity

Permitted 12 ... 800 mm²/s

Recommended (with continuous use) 20 ... 100 mm²/s

Pressure

Operating pressure 4 bar

Intake pressure - 0,4 bar

Switch-off pressure for electric motor 7 bar overpressure

3 Machine description

14 / 40 Mobile Filter System

www.stauff.com

Pressure

Burst pressure on the intake side 11 bar

Burst pressure on the delivery side 15 bar

Test pressure 24 bar

Motor with CEE connector 3P+N+PE

Voltage/frequency 400 V AC/50 Hz

Phase 3

Power 4 kW

Pump

Gear pump with pressure limiting valve

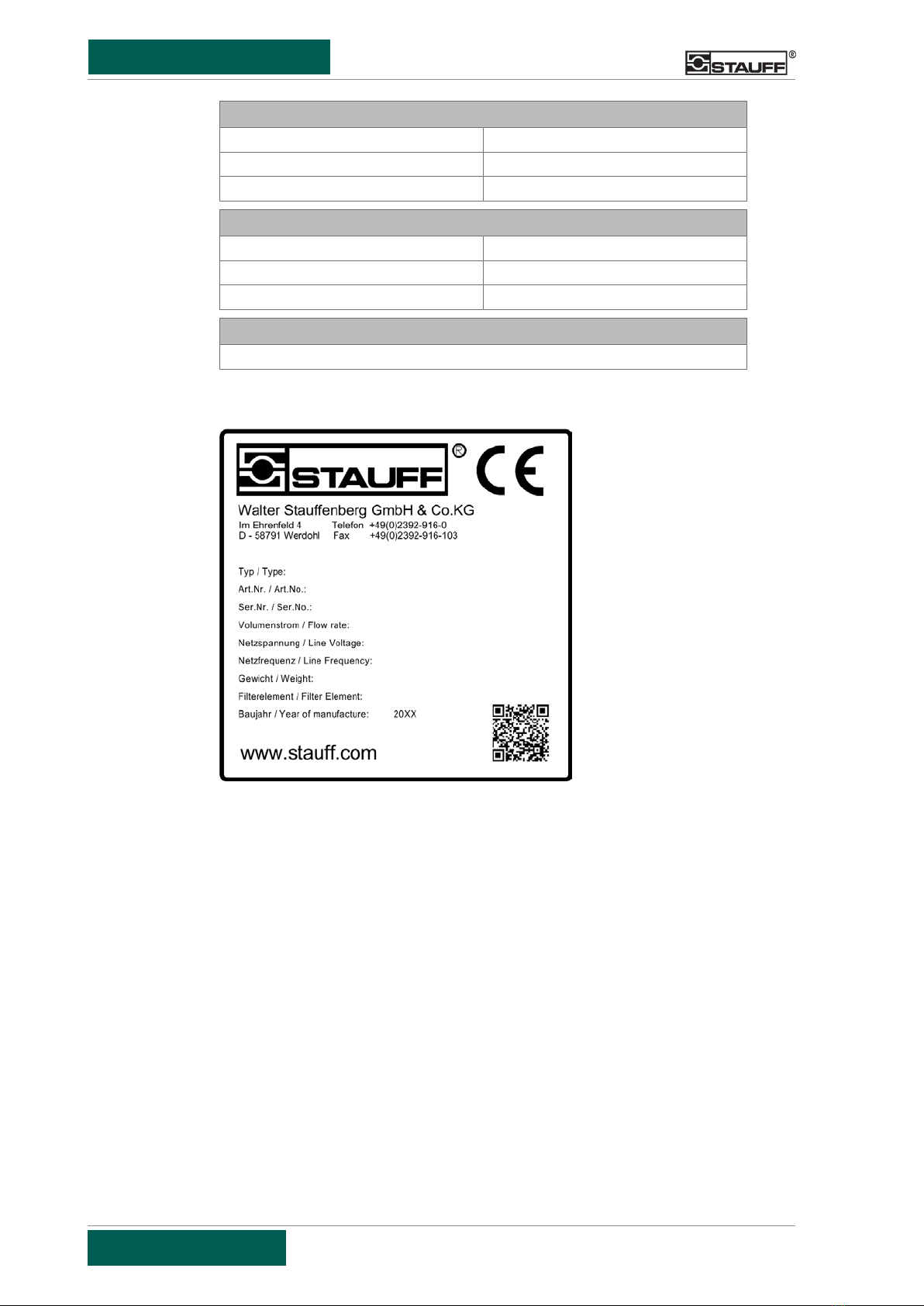

3.4 Type plate

The type plate is located on the side of the machine.

3 Machine description

SMFS-U-CM-110 15 / 40

www.stauff.com

3.5 Display and operating elements

The following display and operating elements are available for monitoring

and control.

3.5.1 Electrical main switch

Fig.2: Electrical main switch

The main switch has two positions:

• 0 OFF (horizontal): Machine switched off and voltage-free

• 1 ON (vertical): Machine under electrical voltage

3.5.2 Clogging indicator

Fig.3: Clogging indicator

The clogging indicator shows how clogged the filter element is while a

medium flows through the filter cartridges.

• Green: The filter element is OK.

• Yellow: The filter element is 75% clogged.

• Red: The filter element is very clogged and has to be replaced

Section 7.4, P. 32

3 Machine description

16 / 40 Mobile Filter System

www.stauff.com

3.6 Spare and wear parts

NOTICE

Replacing components

Machine damage, malfunctions, faults

► Work which involves opening up the machine may only be carried out

by Walter Stauffenberg GmbH & Co. KG!

► Maintenance work may only be carried out by authorised setup and

maintenance personnel!

► Only use appropriate tools in proper condition!

► Replace components only with genuine spare parts or those authorised

by the manufacturer!

Lists of authorised spare and wear parts can be obtained from Walter

Stauffenberg GmbH & Co. KG.

Replacement filter elements:

Filter element NR-630E series

4 Transport and storage

SMFS-U-CM-110 17 / 40

www.stauff.com

4 Transport and storage

4.1 For your safety

WARNING

Lifting loads

Severe injury or death from falling / oscillating loads

► Attach all load moving parts before lifting!

► Use only undamaged lifting devices that are approved for the weight of

the load to be lifted!

► Attach slings only to the designated lifting points!

► Do not let loads unattended while suspended from the lifting device!

► Never walk under suspended loads!

WARNING

Transporting the machine

Severe injury or death due to tipping over or slipping load

► Fix all movable components of the machine before transport!

► Secure the machine against tipping over or slipping during transport!

► Only use transport vehicles that are approved and/or licensed for the

weight of the machine!

4.2 Transport

Dimensions and weight information are provided in the section

“Technical data” ( Section 3.3, P. 13) and in the overview

drawings.

Note the following during transport:

• Transport may only be carried out by an authorised specialist company

or by qualified personnel.

• Dispose of all packaging material in a proper and environmentally

compatible manner after transport.

• Use the handle bar to lift the mobile filter system.

• Secure the mobile filter system against rolling away and, on inclines,

against tipping over.

• The design allows for the attaching of suitable lifting equipment. The

attachment positions must be selected carefully by the operator.

4.3 Storage

Observe the following principles when storing:

4 Transport and storage

18 / 40 Mobile Filter System

www.stauff.com

• The storage location must be clean and dry.

• The ambient temperature must be at least 5 ° C.

• After a period of more than one year, all moving parts must be tested for

sufficient lubrication.

During storage, protect the mobile filter system from the following influences:

• strong sunlight

• high humidity

• strong vibrations

• extreme temperatures

5 Installation

SMFS-U-CM-110 19 / 40

www.stauff.com

5 Installation

5.1 For your safety

Installation principles:

Note the following rules before installation:

• The task may only be carried out by qualified personnel.

• Place the mobile filter system in direct proximity to the tank to be cleaned

or filled.

• Keep space for maintenance work clear around the mobile filter system.

• Place the mobile filter system horizontally on a level surface.

• Keep access to the main switch clear at all times.

• Keep access to the control elements clear at all times.

• Models delivered with CEE plugs are intended for fields with clockwise

rotation.

WARNING

Work on electrical equipment

Serious or fatal injury due to dangerous voltage

► Work on electrical equipment may only be carried out by qualified

electricians!

► Work on live parts may only be carried out under the supervision of a

second person!

WARNING

Execution of installation tasks

Severe injury or death or machine damage due to faulty installation

► Installation tasks must only be executed by authorised and qualified

personnel!

► Only use suitable tools that are in faultless condition!

► For all tasks, wear your personal protective equipment!

5 Installation

20 / 40 Mobile Filter System

www.stauff.com

5.2 Initial commissioning

Fig.4: Main switch

CAUTION

Hot machine parts

Burns on hands and arms

► Never let the pump run dry for longer than 2 to 3 minutes.

► Before carrying out any maintenance work, let components which have

become hot during operation cool down.

► Wear your personal protective gear for all work carried out on the

machine.

The filter element is not included in the delivery.

uNote the following steps during Initial commissioning:

1. Ensure that all filter elements have been installed in the housing and

securely attached to the filter housing Replacing the filter element.

2. Before the pump is switched on, the tube ends of the hoses have to

be immersed into the vessels to be drained/filled and secured against

sliding out or held in place by someone.

3. Plug the connector into the appropriate socket.

4. Turn the main switch to I.

5. Note that the unit takes about 10 to 15 seconds to completely fill the

filter elements, depending on the pumping height and viscosity.

Shortly afterwards, the pumped medium has to be emitted on the

discharge hose.

Table of contents

Other STAUFF Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Keating Of Chicago

Keating Of Chicago Top-Side 1-800 owner's guide

PoolCop

PoolCop PoolCop installer and user manual

Hydrofarm

Hydrofarm Three Stage Reverse Osmosis instruction manual

Eaton

Eaton DCF-3000 Installation operation & maintenance

Du Pont

Du Pont WFQT27000 installation instructions

Emerald

Emerald HOME 20 OFFICE B DEVICE operating manual