STAUFF SMFS-P-015 User manual

Operating instructions

Translation of the original operating instructions

Mobile filter system

SMFS-P-015

E 03 18-09-2019

To avoid injuries and damage, read these operating instructions thoroughly and attentively.

Retain it for further reference.

SMFS-P-015

www.stauff.com

3 / 32

Table of contents

Table of contents

1

Information about the instructions ........................................................5

1.1

Warnings structure .........................................................................5

1.2

Instructions structure ......................................................................6

1.3

Orientation tools .............................................................................6

2

For your safety.........................................................................................7

2.1

Intended use...................................................................................7

2.2

General safety instructions.............................................................8

2.3

Specific safety instructions .............................................................9

2.4

Tasks and obligations of the operating company...........................9

2.5

Personnel qualification .................................................................10

2.6

Personnel protective equipment...................................................11

3

Machine description ..............................................................................12

3.1

Overview.......................................................................................12

3.2

Function........................................................................................12

3.3

Technical data ..............................................................................13

3.4

Type plate.....................................................................................14

3.5

Display and control elements .......................................................15

3.5.1

Electrical main switch........................................................15

3.5.2

Contamination indicator.....................................................15

3.6

Spare parts and wear parts ..........................................................16

4

Transport and storage...........................................................................17

4.1

For your safety..............................................................................17

4.2

Transport ......................................................................................17

4.3

Storage.........................................................................................18

5

Installation..............................................................................................19

5.1

For your safety..............................................................................19

6

Operation................................................................................................21

6.1

For your safety..............................................................................21

6.2

Starting pumping ..........................................................................21

6.3

Stopping pumping.........................................................................21

7

Maintenance ...........................................................................................22

7.1

For your safety..............................................................................22

7.2

Inspection and maintenance schedule.........................................23

7.3

Cleaning........................................................................................23

7.3.1

Cleaning the pre-filter........................................................23

7.4

Replacing the filter element..........................................................24

Mobile filter system

4 / 32

www.stauff.com

Table of contents

8

Malfunctions...........................................................................................25

8.1

For your safety .............................................................................25

8.2

Troubleshooting procedure ..........................................................25

8.3

Malfunctions table ........................................................................26

9

Decommissioning..................................................................................27

9.1

For your safety .............................................................................27

9.2

Disposal........................................................................................28

10

EC Declaration of Conformity .............................................................. 29

10.1

EC Declaration of Conformity.......................................................29

Index.......................................................................................................30

SMFS-P-015

www.stauff.com

5 / 32

1 Information about the instructions

1 Information about the instructions

These operating instructions includes important instructions and information

on the intended use. Keep the operating instructions where they can be

accessed by the operating personnel.

1.1 Warnings structure

Coloured signal word boxes emphasise the warnings. Always read the full

warning text for effective protection against hazards!

The different colours and signal words of the following boxes designate

various hazard levels:

Ignoring this warning results in serious or lethal injuries.

Ignoring this warning can result in serious or lethal injuries.

Ignoring this warning can result in minor or moderate injuries.

Ignoring this warning can result in damage.

Warnings always have the same structure. They include the signal word,

hazard type and source, consequences of failure to comply and steps to ward

off/avoid hazards.

Example:

Working on electrical equipment

Serious or lethal injuries from voltage

►Only qualified electricians may carry out work on electrical appliances.

►Switch off the machine and secure it against inadvertent reactivation.

►Work on live parts may only be carried out under supervision of a

second person.

HAZARD

WARNING

CAUTION

IMPORTANT

WARNING

Mobile filter system

6 / 32

www.stauff.com

1 Information about the instructions

1.2 Instructions structure

Instructions are a direct request to carry out a task. They are structured in

line with the operation involved. Always carry out the operating steps in the

prescribed sequence.

The instructions are structured as follows and marked with the appropriate

symbols:

►Objective of the instruction

1. Operating step

✓Effect of the operating step to check if the step has been executed

correctly.

2. Additional operating step

Result of the overall instruction

1.3 Orientation tools

The following orientation tools are provided in these instructions:

•Table of contents at the beginning

•Main chapter indicated in the header

•References to other chapters, e.g. to “Information about the instructions”

(chapter 1, p. 5)

•Additional information and tips marked with an “i” symbol

Example for additional information

SMFS-P-015

www.stauff.com

7 / 32

2 For your safety

2 For your safety

2.1 Intended use

The mobile filter system is designed for cleaning hydraulic and lubricating oil

systems in machines and plants or for filling in new oil.

The mobile filter system is only intended for use with commercial mineral

oils.

Intended use includes:

•observing all safety and warning instructions in these operating

instructions (chapter 2.2, p. 8)

•use only within the specifications provided in the “Technical data”

chapter (chapter 3.3, p. 13)

•observing the maintenance intervals and instructions

•(chapter 7.2, p. 23)

No changes, attachments or conversions may be carried out without

consulting the manufacturer. Such modifications can jeopardise the

operating safety and are considered to be a violation of intended use.

Misuse

Any use other than that stated in the „Intended Use“ chapter is not permitted.

The mobile filter system must not be used

•in explosive atmospheres

•in unventilated rooms

The mobile filter system must not be used with the following media:

•explosive substances

•aggressive substances

•toxic substances

•highly abrasive substances

•faeces

The basic contamination of the conveyed liquid must not exceed category

22/20/16 as per ISO 4406.

Mobile filter system

8 / 32

www.stauff.com

2 For your safety

2.2 General safety instructions

Safety instructions help you in avoiding injuries and damage. Ensure that

you have read and understood all the safety instructions in these operating

instructions.

Safe working entails doing more that just reading the general safety

instructions in this chapter. Also read and follow the specific safety

instructions in every chapter affecting your work. Also observe information in

the referenced documents.

The following safety instructions apply in general:

•Observe the applicable national and international health and safety

regulations.

•Only operate the machine …

–in a technically satisfactory condition

–taking into account safety and hazards

–according to the intended use (chapter 2.1, p. 7)

–in compliance with these operating instructions

–with unchanged, complete and correctly installed safety devices and

–with a correctly installed and functioning control unit

•Wear the personal protective equipment (chapter 2.6, p. 11).

•Immediately rectify malfunctions which affect your safety and the reliable

operation of the machine. Disable the machine until the malfunction is

rectified and secure it against reactivation.

•Observe all adjustment, inspection and maintenance intervals, including

the information on replacing parts.

•For maintenance and repair work, switch off the machine and disconnect

the mains plug.

•Work on electrical equipment may only be carried out by qualified

electricians. Work on live parts is only permitted under supervision of a

second person.

•Be aware of possible residual energies in mechanical and electrical

components.

•Use authorised spare parts when replacing components. Non-authorised

spare parts can compromise operating safety.

•Check the electrical equipment regularly. Loose connections and burnt

cables must be removed immediately.

SMFS-P-015

www.stauff.com

9 / 32

2 For your safety

2.3 Specific safety instructions

The product is designed to the state of the art and the recognised safety-

relevant regulations. Nevertheless, its use can entail risks to the life and limb

of the operator and third parties or damage to the product and its operating

environment.

Electric shock from live parts

•Electrical installation and maintenance may only be carried

out by qualified electricians.

•Disconnect the device from the power supply before starting

any work

•Check parts for electrical charge before starting any work

Burns from hot surfaces

•Let hot components cool down before starting any work

•Wear protective gloves

2.4 Tasks and duties of the operating company

In addition to the instructions and information in these operating instructions,

the general, statutory and other mandatory regulations on accident

prevention and environmental protection also have to be observed.

To ensure safety, the operating company has to at least...

•ensure that the machine is only operated as intended, in proper

condition, with all safety devices fully installed and without damage

•establish the area of application and prepare the corresponding

operating instructions

•acquire the regulations applicable for operation in their most recent

version and to familiarise operating personnel with these

•make the operating manual available in a complete and legible form at

the operating location of the machine at all times

•ensure sufficient stability

•avoid trip hazards

•ensure sufficient ventilation and lighting of the work areas

•instruct the personnel in safe working

•ensure that unauthorised persons do not have access to the hazard area

•provide personnel with the required personal protective equipment

•have the electrical installation checked by a qualified electrician at least

annually

Mobile filter system

10 / 32

www.stauff.com

2 For your safety

2.5 Personnel qualification

Any work on the machine may only be carried out by qualified and

authorised personnel. Personnel trained for the respective work and with

appropriate certification are considered to be qualified.

Qualifications

The following qualifications are needed for certain work on the machine:

•Operating personnel have been briefed in operating the machine and in

its functions. They input the data required for the operation and carry out

the required operating steps to operate the machine. They are also

responsible for simple maintenance tasks.

•Setup and maintenance personnel are responsible for commissioning,

decommissioning, setup and configuration of the machine. In addition,

setup and maintenance personnel carry out more extensive maintenance

work and instruct operating personnel in the functions of the machine.

•Qualified electricians are responsible for all work on the electric

components.

•Qualified transport personnel are qualified for the proper and secure

loading and transporting of heavy goods.

Qualified tasks

Certain qualifications are needed for some tasks. Only persons with the

specified qualifications are allowed to carry out the tasks listed.

Task

Qualification

Transporting the machine to the

destination

Qualified transport personnel

Installation

Setup and maintenance personnel

Troubleshooting

Setup and maintenance personnel

Maintenance and troubleshooting on

electrical equipment

Qualified electricians

General inspection and maintenance

work

Setup and maintenance personnel

SMFS-P-015

www.stauff.com

11 / 32

2 For your safety

Safety briefing

All those working on the machine must receive a safety briefing at least once

a year. Indispensable constituents of this briefing are:

•Personnel qualifications and authorisations

•Functionality and operation

•Area of application and ambient conditions

•Personal protective equipment

•Transport to the place of installation

•Regular maintenance work

2.6 Personal protective equipment

To limit risks during work, use the following defined personal protective

equipment:

Symbol

PPE

Life phase

Task

Tight fitting

work clothing

All

All

Safety shoes

All

All

Protective gloves

Operation

When working on

the system before it

has cooled down

Startup

Troubleshooting

Maintenance

Eye protection

Operation

When working on

the system under

pressure

Startup

Troubleshooting

Maintenance

Mobile filter system

12 / 32

www.stauff.com

3 Machine description

3 Machine description

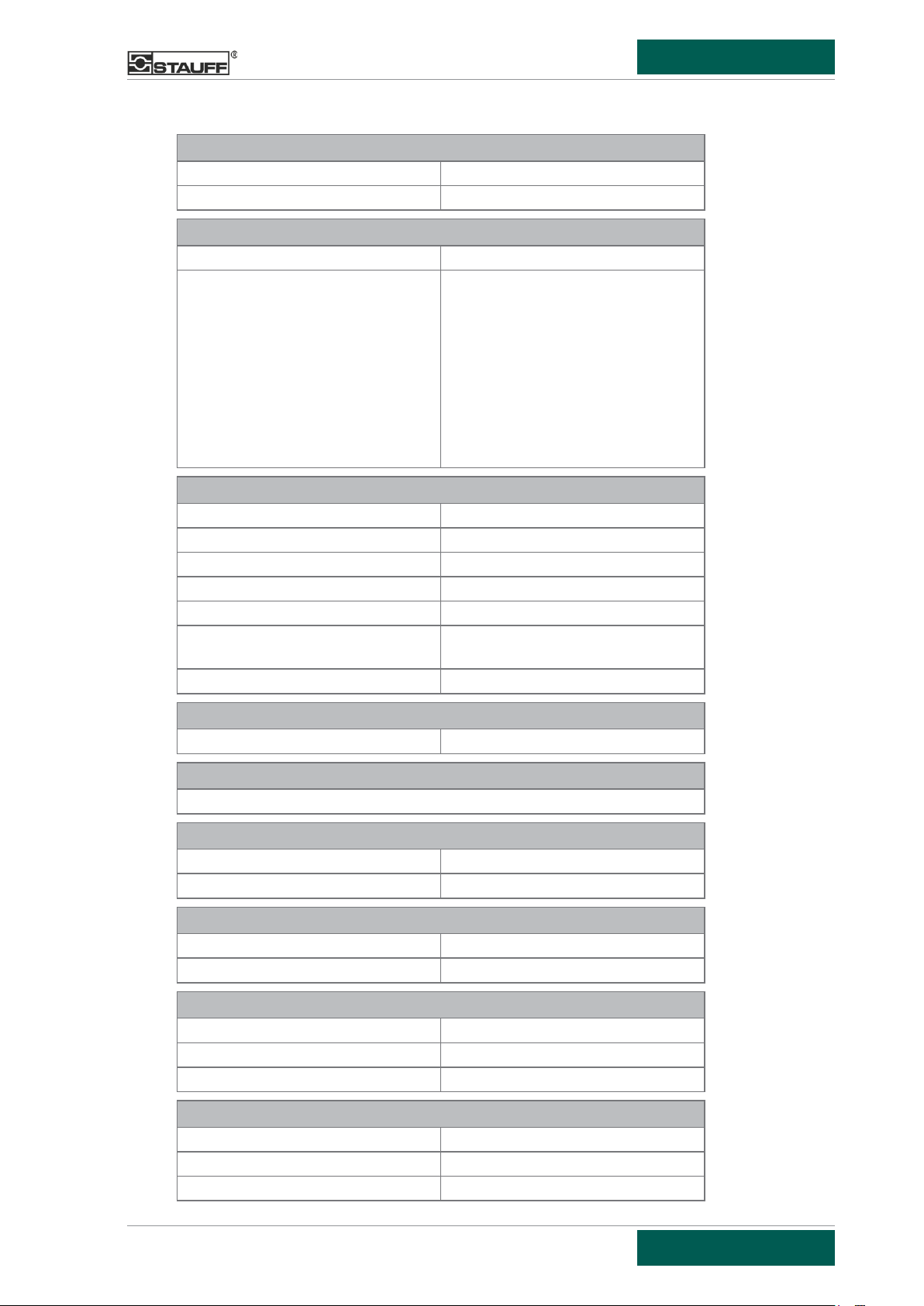

3.1 Overview

Fig. 1: Overview

1

Frame with handle bar

6

Hose on suction side

2

Electric motor

7

Gear pump with pressure limiting

valve

3

Contamination indicator

8

Hose on pressure side

4

Filter housing with filter element

9

Lance

5

Pre-filter

10

Electrical main switch (hidden)

3.2 Function

The mobile filter system is connected to the external power supply after

installation and connection of the hoses at the installation site. After

switching on, the medium is fed in by the pump, cleaned in the filter and

discharged again through the hose on the pressure side.

6

7

5

8

4

9

3

10

2

1

SMFS-P-015

www.stauff.com

13 / 32

3 Machine description

3.3 Technical data

Dimensions and weights

Dimensions (width x depth x height)

258 x 454 x 551 mm

Weight

33 kg

Media compatibility

Suitable for:

Mineral oils

Upon consultation with

Walter Stauffenberg GmbH&Co.KG:

•water, especially drinking water

•food

•flammable liquids

•degreasing liquids

•DOT brake fluids

•phosphate esters (e.g. Skydrol, Hyjet)

•HFDR liquids as per ISO12922 based

on phosphoric acid esters

•HEPG liquids as per ISO15380

based on polyglycol

•MIL-L-7080 E

•caustic liquids

Hoses and lances

Material

PVC, reinforced with internal spiral

Length of hose, suction side

150 cm

Length of hose, pressure side

200 cm

Dimensions, suction side

DN 25

Dimensions, pressure side

DN 25

Mesh size of the integrated coarse filter

(suction side)

Stainless steel filter 200 μm

Lance length

15 cm

Flow rate

Flow rate

15 l/min (depending on viscosity)

Temperature

Medium temperature

-15 °C ... +65 °C

Ambient temperature

-40 °C ... +70 °C

Viscosity

Permitted

10 ... 400 mm²/s

Recommended (with continuous use)

25 mm²/s

Pressure

Operating pressure

2 bar

Switch-off pressure for electric motor

7 bar overpressure

Test pressure

12 bar

Motor with CEE 7/4 connector

Voltage/frequency

230 V AC/50 Hz

Phase

1

Power

0.75 kW

Mobile filter system

14 / 32

www.stauff.com

3 Machine description

Motor with CEE 7/4 connector

Speed

1400 rpm

Motor with CEE connector 3P+N+PE

Voltage/frequency

400 V AC/50 Hz

Rated current

16 A

Phase

3

Power

0.75 kW

Speed

1400 rpm

Emissions

Sound pressure level according to

EN ISO 11202:2009

below 70 dB(A)

Harmful substances

none

3.4 Type plate

The type plate is located on the side of the machine.

SMFS-P-015

www.stauff.com

15 / 32

3 Machine description

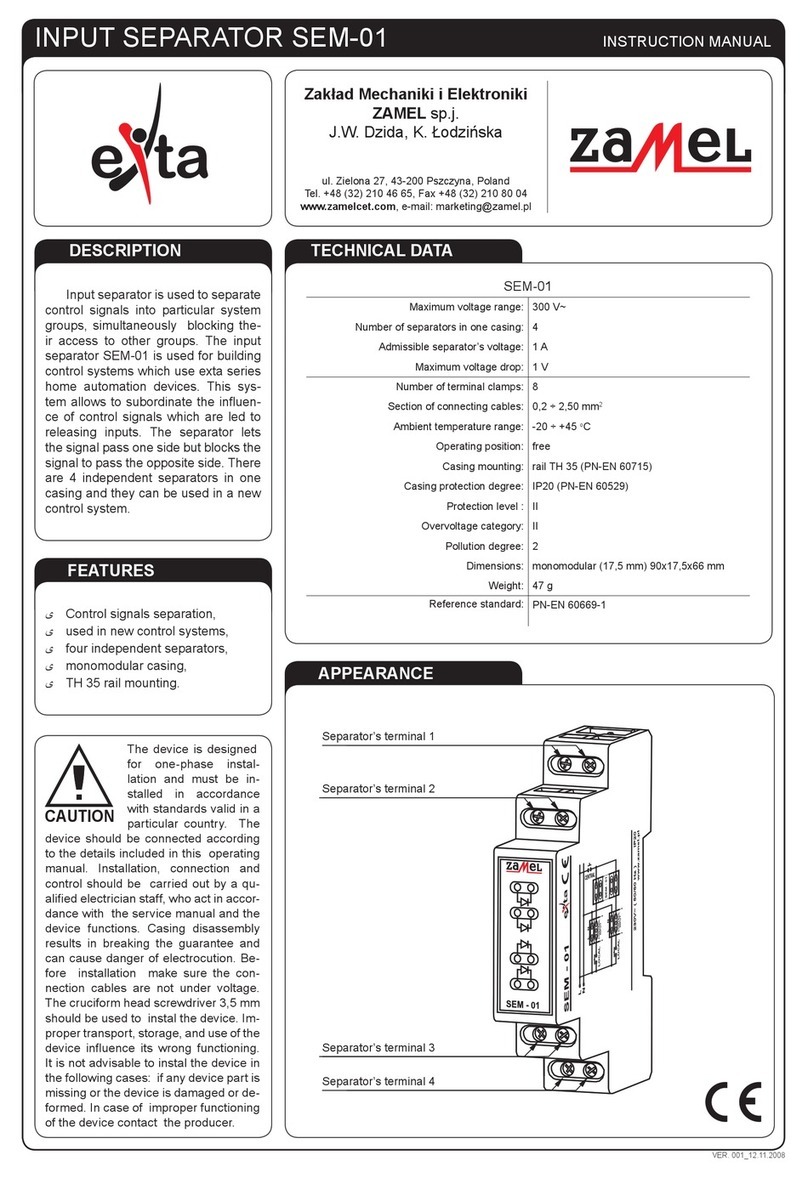

3.5 Display and control elements

The following display and control elements are available for monitoring and

control.

3.5.1 Electrical main switch

Fig. 2: Electrical main switch

The main switch has two positions:

•0 OFF (horizontal): Machine switched off and disconnected from power

supply

•1 ON (vertical): Machine live

3.5.2 Contamination indicator

Fig. 3: Contamination indicator

The contamination indicator shows how contaminated the filter element is

while a medium flows through the filter cartridges.

•Green: The filter element is OK.

•Yellow: The filter element is 75% contaminated.

•Red: The filter element is very contaminated and must be replaced

chapter 7.4, p. 24.

Mobile filter system

16 / 32

www.stauff.com

3 Machine description

3.6 Spare parts and wear parts

Replacing components

Machine damage, malfunctions, faults

►Only Walter Stauffenberg GmbH & Co. KG may carry out work involving

opening up the machine!

►Only authorised setup and maintenance personnel may carry out

maintenance work!

►Only use appropriate tools which are in a good condition!

►Replace components only with genuine spares or those authorised by

the manufacturer!

Lists of authorised spares and wear parts can be had from Walter

Stauffenberg GmbH&Co.KG.

Replacement filter elements:

Spin-on series filter element SFC-35/36

IMPORTANT

SMFS-P-015

www.stauff.com

17 / 32

4 Transport and storage

4 Transport and storage

4.1 For your safety

Lifting loads

Serious or lethal injuries from falling/suspended loads

►Secure all moving components before raising the load!

►Only use undamaged lifting equipment which is permitted for the weight

of the load to be lifted!

►Attach load attachment gear only at the indicated attachment points!

►Never leave loads hanging in the lifting devices without supervision!

►Never stand underneath suspended loads!

Transporting the machine

Serious or lethal injuries from tilting or slipping loads

►Before transporting the machine, secure all its moving components!

►Secure the machine against overturning or slipping out of position

during transport!

►Only use transport vehicles suitable for the weight of the machine!

4.2 Transport

Information an dimensions and weight can be found in the

“Technical data” chapter (chapter 3.3, p. 13) and in the

overview drawings and parts lists.

Note the following during transport:

•Transport may only be carried out by an authorised specialist company

or by qualified personnel.

•Dispose of all packaging material in a proper and environmentally

compatible manner after transport.

•Slide the lances into the respective lance holder for transport.

•Lift the mobile filter system using the handle bar.

WARNING

WARNING

Mobile filter system

18 / 32

www.stauff.com

4 Transport and storage

4.3 Storage

Note the following during storage:

•The storage location has to be clean and dry.

•The ambient temperature has to be at least 5 °C.

•After a storage period of more than one year, all moving parts have to be

checked for sufficient lubrication.

During storage, protect the mobile filter system against the following

influences:

•strong sunshine

•high humidity

•strong vibrations

•extreme temperatures

SMFS-P-015

www.stauff.com

19 / 32

5 Installation

5 Installation

5.1 For your safety

Working on electrical equipment

Serious or lethal injuries from dangerous voltage

►Work on electrical equipment may only be carried out by qualified

electricians.

►Work on live parts is only permitted under supervision of a second

person!

Carrying out installation work

Serious or lethal injuries or machine damage due to incorrect installation

►Installation work may only be carried out by authorised specialist

personnel!

►Only use suitable tools in proper condition!

►Wear your personal protective equipment for all work!

WARNING

WARNING

Mobile filter system

20 / 32

www.stauff.com

5 Installation

The filter element is not included in the delivery.

During initial commissioning, ensure that all filter elements are installed in

the housing and securely attached chapter 7.4, p. 24.

Note the following rules before installation:

•The task may only be carried out by qualified personnel.

•Place the mobile filter system in direct proximity to the tank to be cleaned

or filled.

•Keep space for maintenance work clear around the mobile filter system.

•Place the mobile filter system horizontally onto a level surface.

•Keep access to the main switch clear at all times.

•Keep access to the control elements clear at all times.

•Models delivered with CEE plugs are intended for fields with clockwise

rotation.

►How to install the mobile filter system:

1. Guide the hoses into the corresponding removal or drain reservoirs.

2. Secure the hoses against sliding out.

3. Plug the mains plug into the appropriate socket.

Table of contents

Other STAUFF Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Franklin Water Treatment

Franklin Water Treatment PIF1D Series Installation instructions and owner's manual

Grunbeck

Grunbeck desaliQ Operation manual

Xtralis

Xtralis VESDA VSP-005 Cartridge Replacement Instructions

Pentair

Pentair freshpoint F2000-B2B instruction manual

Hague Quality Water

Hague Quality Water WaterMax H6000 Owner's manual and installation guide

Wilo

Wilo EMUport CORE Series Installation and operating instructions