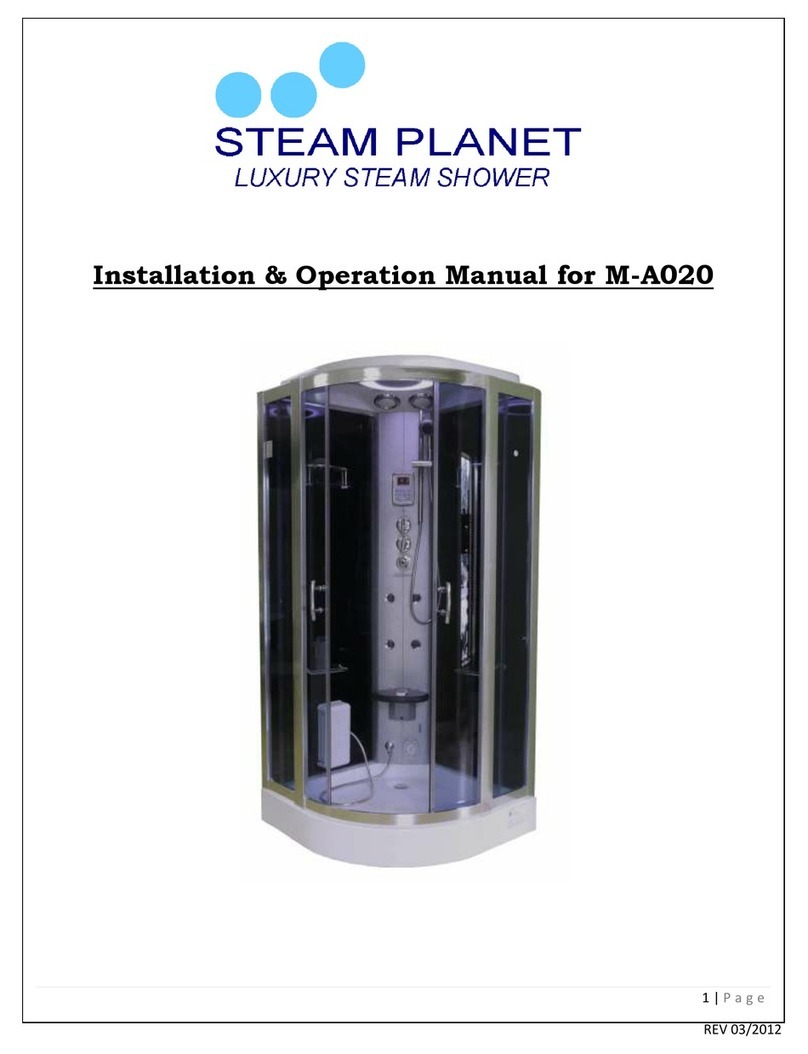

Steam Planet M-A021 User manual

1 | P a g e

REV 03/2012

Installation & Operation Manual for M-A021

2 | P a g e

REV 03/2012

Table of Contents

Specification Page …………………………………………… 3-4

Unit Parameters …………………………………………… 5

Drain Disclosure …………………………………………… 5

Tools Need for Installation …………………………………………… 6

Packing List …………………………………………… 7

Installation Manual …………………………………………… 8-13

Troubleshooting …………………………………………… 14

Replacing Door Rollers …………………………………… 15

Cleaning & Maintenance …………………………………………… 16

Shower Control Panel …………………………………………… 17

Remote Control …………………………………………… 18

Function Instructions …………………………………………… 19-20

Technical Data ……………………………...…………… 21

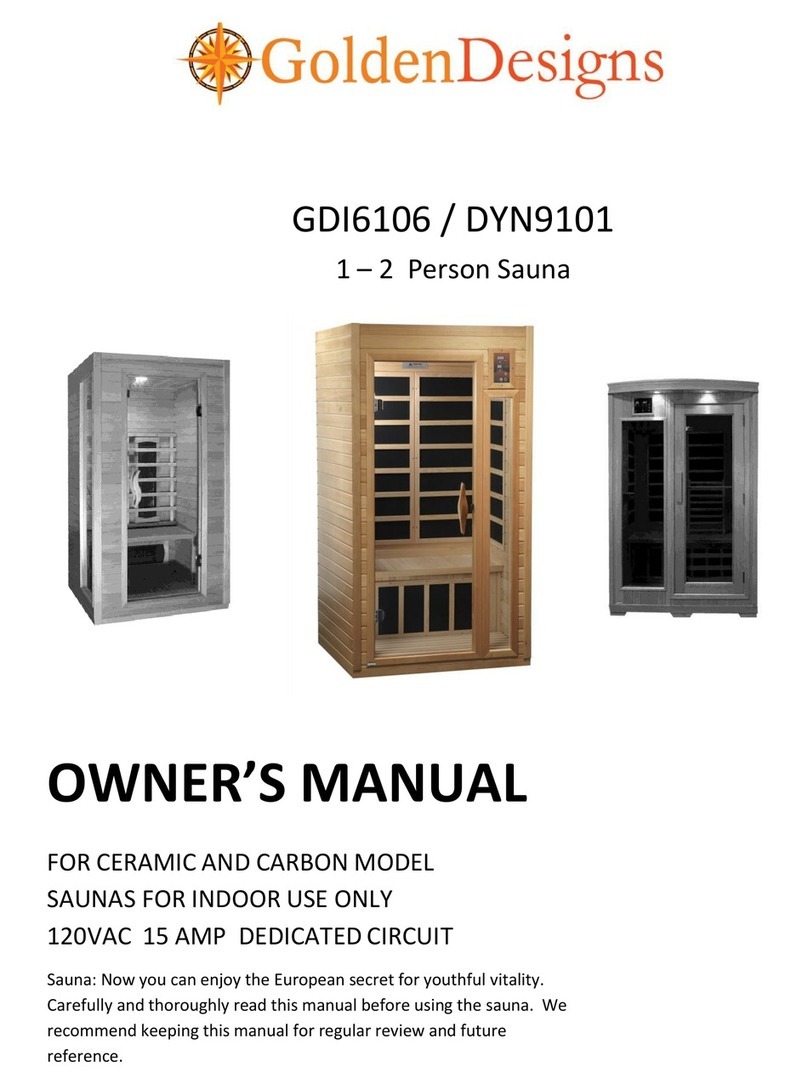

Thank you for selecting Steam Planet Corp Computerized Steam Room, we hope that our

exquisite design will meet your life’s needs; it’s our honor to promote your health and

longevity with comfortable enjoyment.

In order to operate and use the product well, please read carefully and follow all

instructions provided in this User’s Manual. We are dedicated to providing satisfied service

for you.

Our company reserves the right to change the Manual. The manual takes effect since the

date it is published. This manual shall prevail if there’s any difference between this and

previous documents and manuals.

Thanks for your support.

3 | P a g e

REV 03/2012

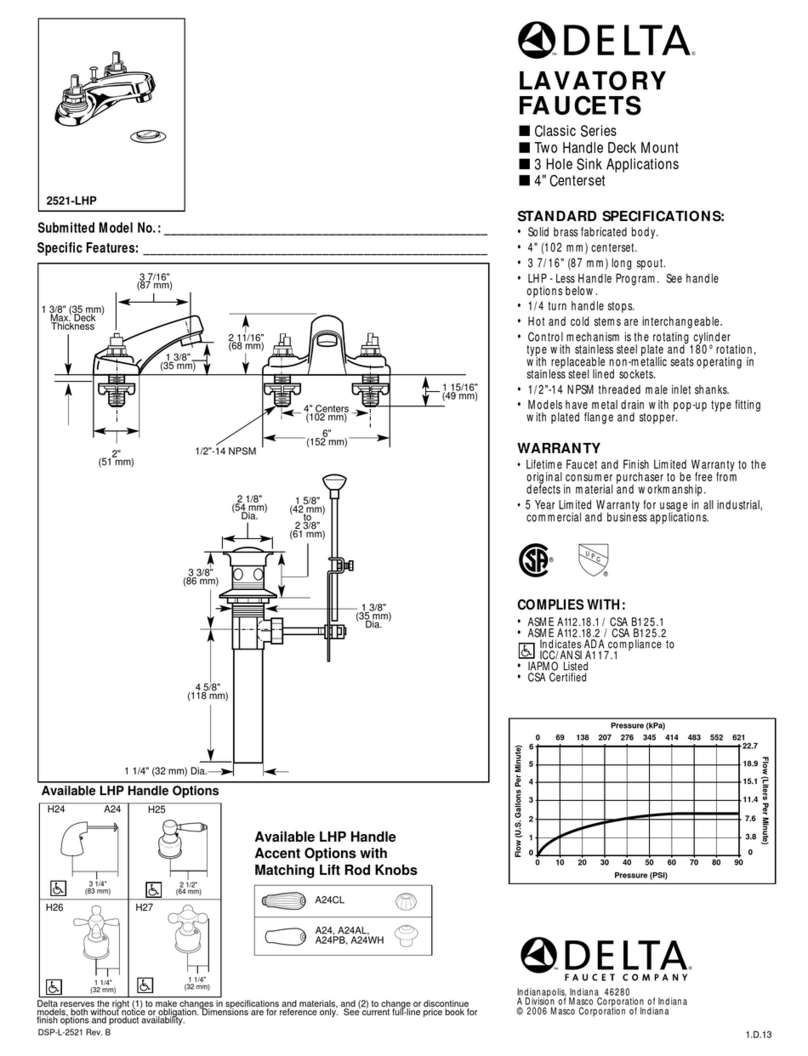

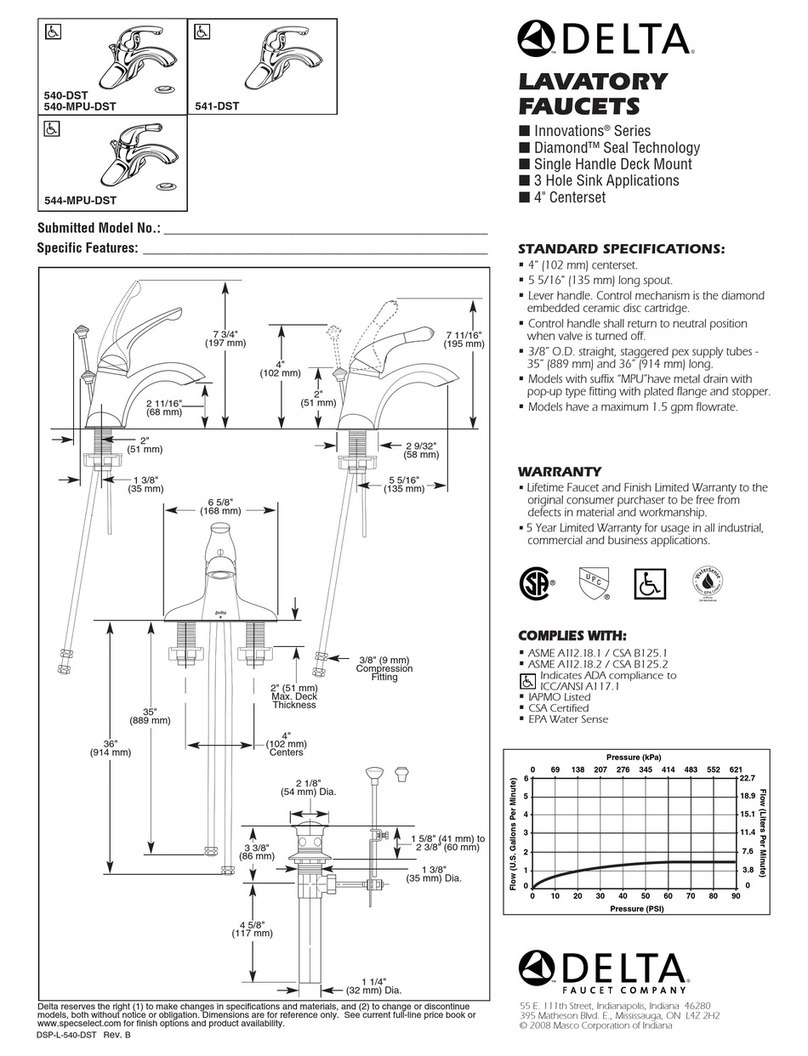

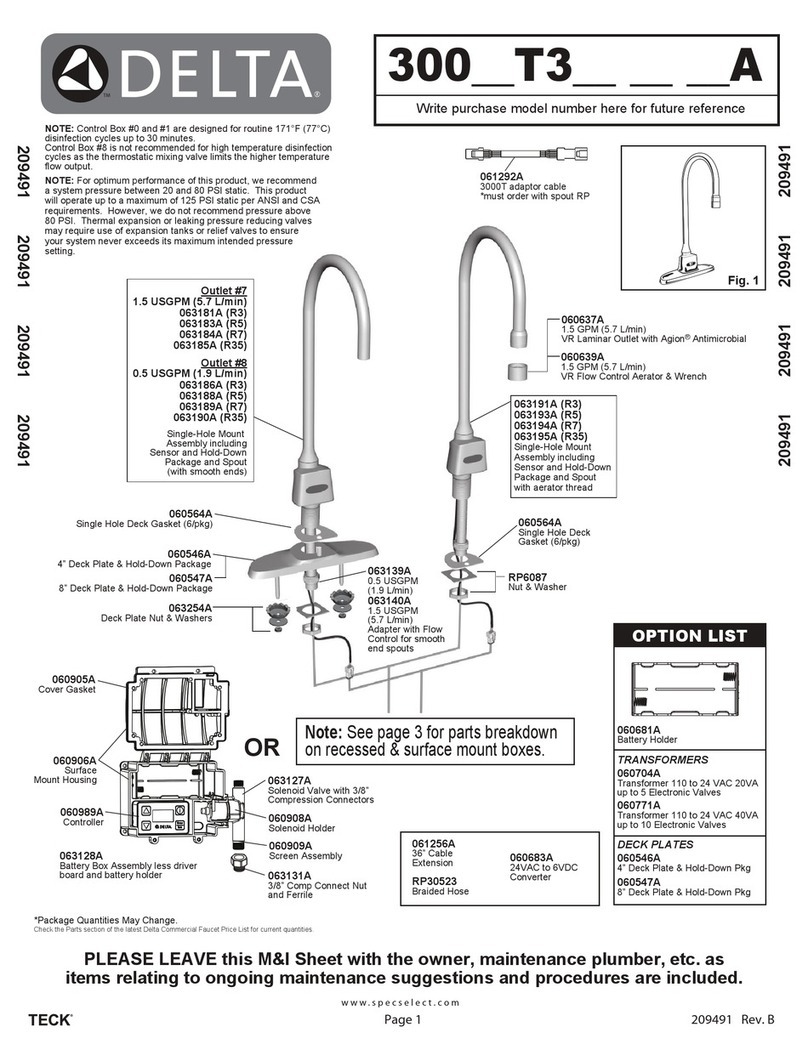

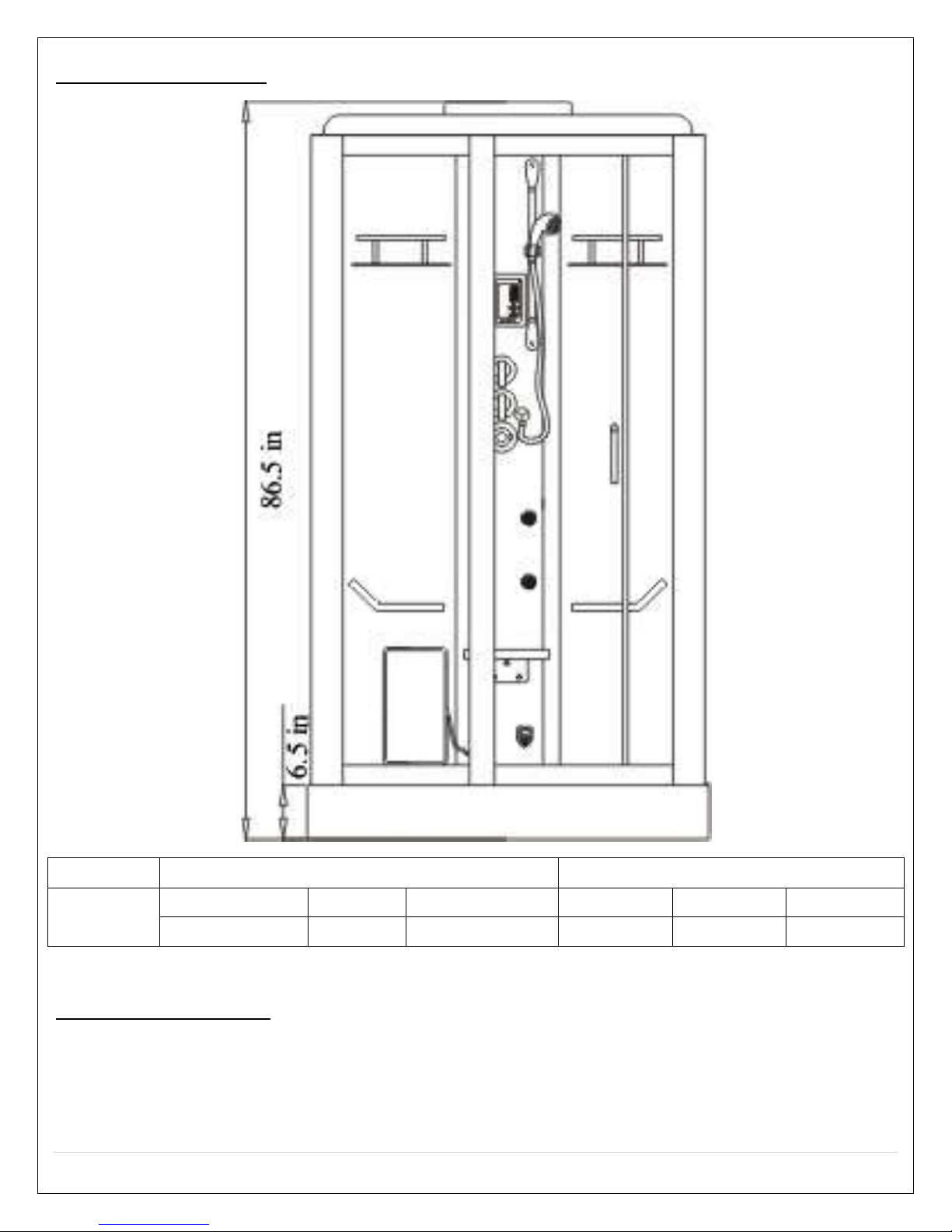

TECHNICAL INFORMATION

Materials: Acrylic, Aluminum, Tempered Glass

Power Supply: 220V

Steam Ready: 2-5 MIN

Dimensions: 47 x 33 x 87 IN

ELECTRICAL INFORMATION

1 dedicated 12-2 line for steam (line 1, line 2, and ground)

220 volt, 20 amp GFCI breaker

There is a length of wire from the control box supplied to connect to power source.

PLUMBING REQUIRMENTS

The unit is equipped with hot and cold, metal braided ½ inch water supply hose with ½ national pipe

thread.

Need to install hot and cold shutoffs with ½ -male national pipe thread (not included).

Supply hoses are to connect from the faucet manifold on the unit to the shutoff valves.

All water jet features are pre plumbed with reinforced braided flexible supply hose

All fixtures and fittings must be checked for tightness as they may have been loosened during

transport.

Access panel area recommended.

Note: The flexible drain hose included with this unit is for installation into a floor drain only.

Substituting the existing drain setup for a setup of the installers’ choice will not void the warranty of

the unit as long as there is no evidence of misuse or damage to the base. If the substitute drain

system is used, a 3/8 in stub must be added to the main shower drain line to connect the steam

generator’s automatic flushing drainage hose.

Please call the manufactured for updated drain info 1-866-STEAM-61

M-A021

FEATURES

Factory tested

Polished Finish

Blue tinted doors/sides and

solid black rear walls

Phone

Auxiliary RCA input

Steam Aromatherapy Cup

Towel bar

Accessory rack

Door slides from right to left

Foot Massage

Body Massage Jets

Rainfall Shower Head

Folding Seat

Hand-held Shower w/ Height-

Adjustable Bracket

Water control valve

Adjustable Time & Steam

Temperature Settings

Control Panel with Remote

Circulation Fan

Mood Light

2.5kW Self-Cleaning Steam

Generator

Tempered Glass

Pressure Balance Valve

(optional extra)

FM Transmitter (optional

extra)

4 | P a g e

REV 03/2012

GENERAL INFORMATION

Units come broken down in panels and are assembled with screws, nuts and bolts on site. All seams &

joints to be caulked with 100% silicone at room temperature (no latex caulking)

Note: All shower bases need to be leveled in its final resting position, mark the placement, then pull

base out and begin assembly. It is advised to have base onsite before preparing drain location. Access

panel area recommended.

Access panel near controls panel and jets recommended.

Manufacturer reserves the right to change specs or features at anytime. Please check to

confirm details. 1-866-783-2661.

5 | P a g e

REV 03/2012

Unit Parameters

System

Electric Data

Size (mm/inch)

M-A021

Voltage

Power

Frequency

Length

Width

Height

220V

2.5kW

50~60Hz

47

33

87

Drain Disclosure

NOTE: a flexible drain hose is provided with the unit. We strongly recommend taking off the flex

drain hose and hard pipe the unit into existing drain. This will not void the warranty. Call 866-

STEAM-61 for any questions.

6 | P a g e

REV 03/2012

Attention: do not put anything in the safe area, the distance between the top shower cover

and ceiling should be greater than the safe area. Room must be left clear on both sides of the

shower.

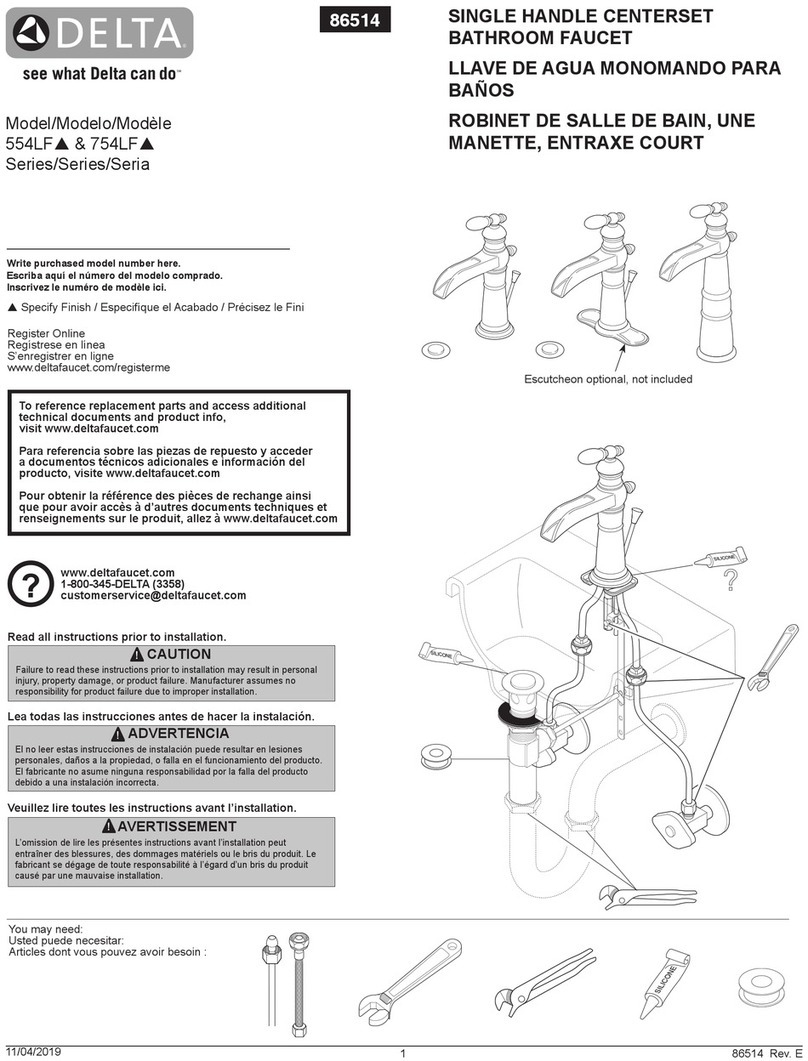

Tools Needed for Installation

7 | P a g e

REV 03/2012

Packing List

1. Check the unit as soon as it arrives. Note if there is any shipping damages, then

notify the distributor.

2. Check the water and the electronic system and ground are suitable for

installation.

3. At least two people will be needed for installation.

4. The following parts should be in the packaged boxes:

8 | P a g e

REV 03/2012

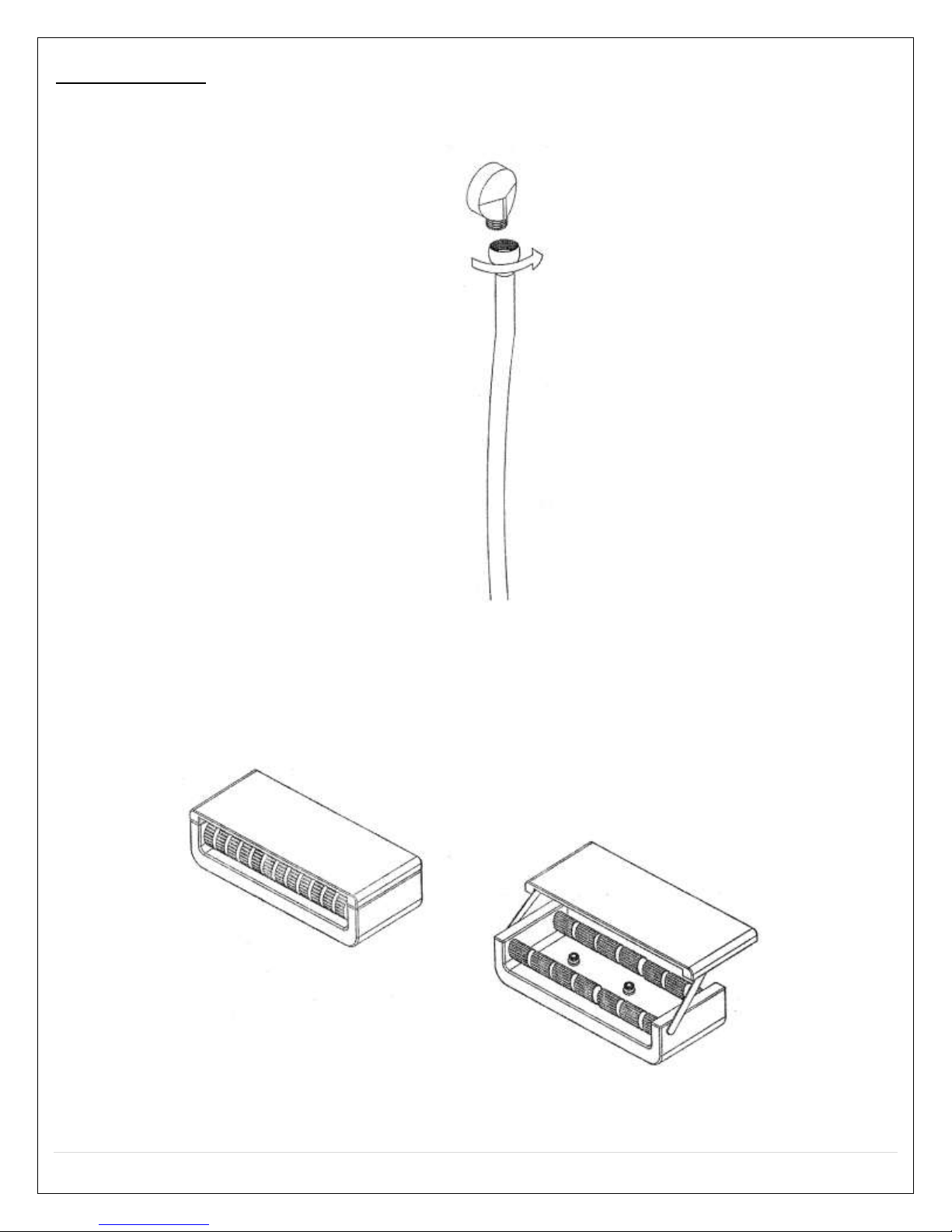

Installation

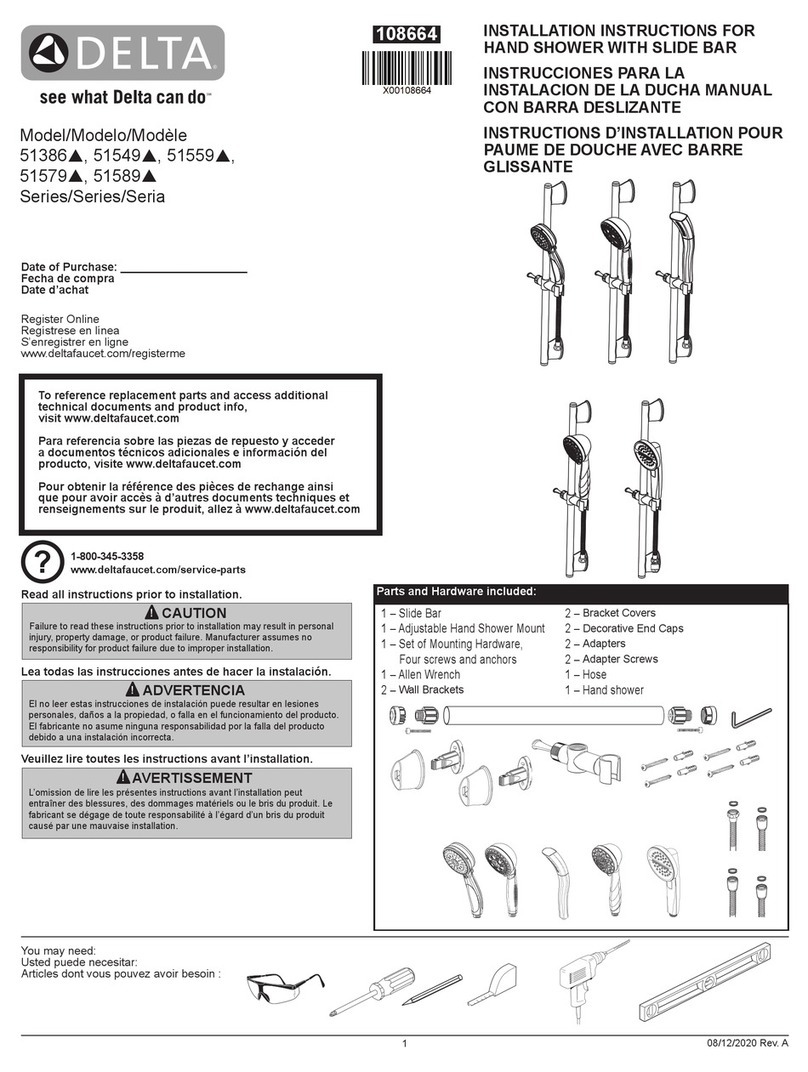

1. Connect the shower hose with shower outlet (on the back panel), then put the hand-

held shower on the sliding bar.

.

2. When using the foot massage, open the cover first.

9 | P a g e

REV 03/2012

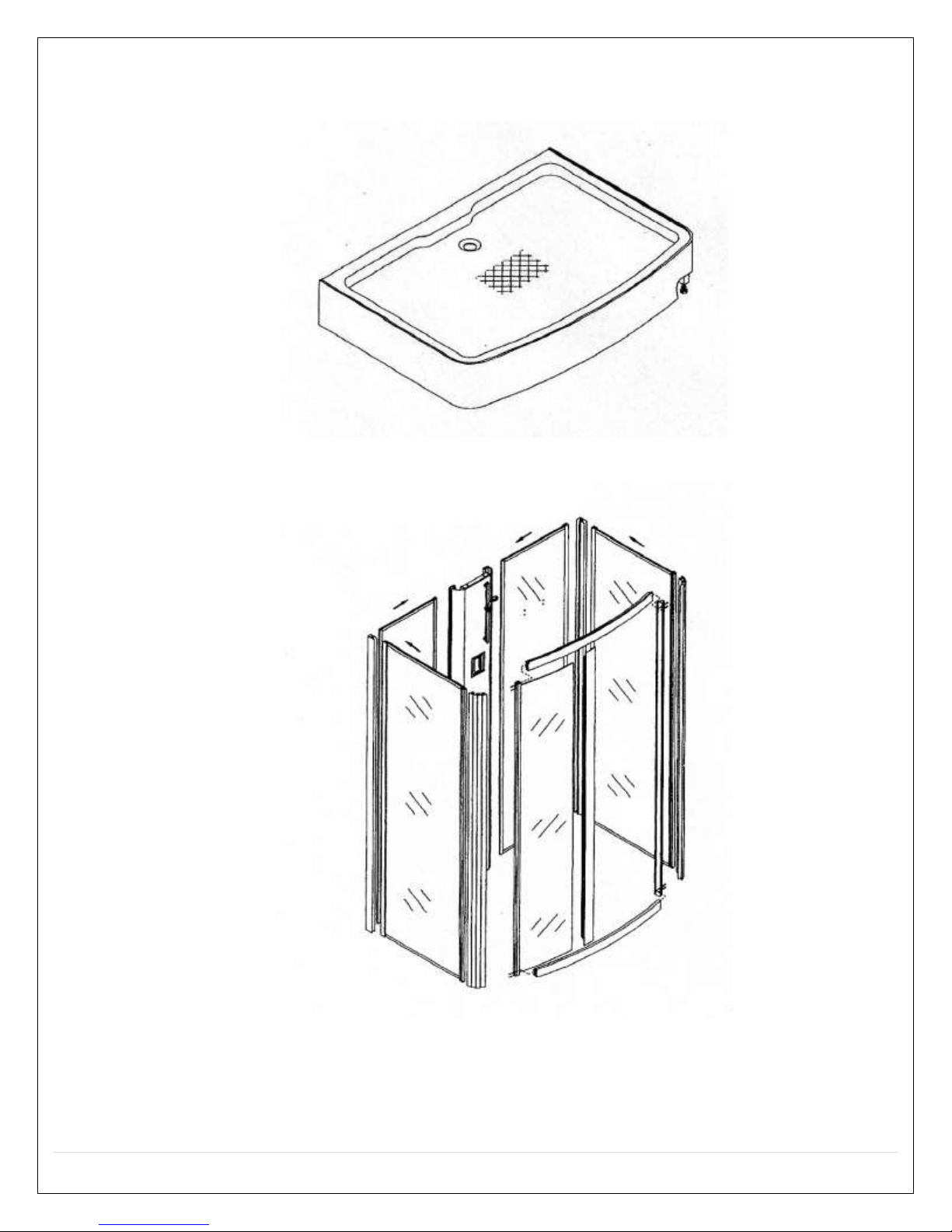

3. Put the shower tray on the selected area (using are of this product), check whether it

is leveled, then adjust the foot screws (under the shower tray) to make sure it is

leveled. Note: level all feet on the supporting bar.

4. Slide the left and right fixed glass into the aluminum column, just as shown in the

diagram.

Note: Please use 100% silicone caulk on all seams, joints, and check all fittings and

connections for tightness.

10 | P a g e

REV 03/2012

5. Place all the glass onto the acrylic shower base.

6. Place the roof of the unit on top of all glass and attach it with ST4x10 to glass doors;

M6x25 screws are used to attach top with control column and shower tray.

11 | P a g e

REV 03/2012

7. Attach shelf and rail as shown.

8. Connect the pipes in the package with the drain outlet on the steam generator and

the drain exit; fasten it with the M4X16 round head screw; as shown.

9. Pull the top shower pipe through hole on the top cover. Connect to the shower head.

12 | P a g e

REV 03/2012

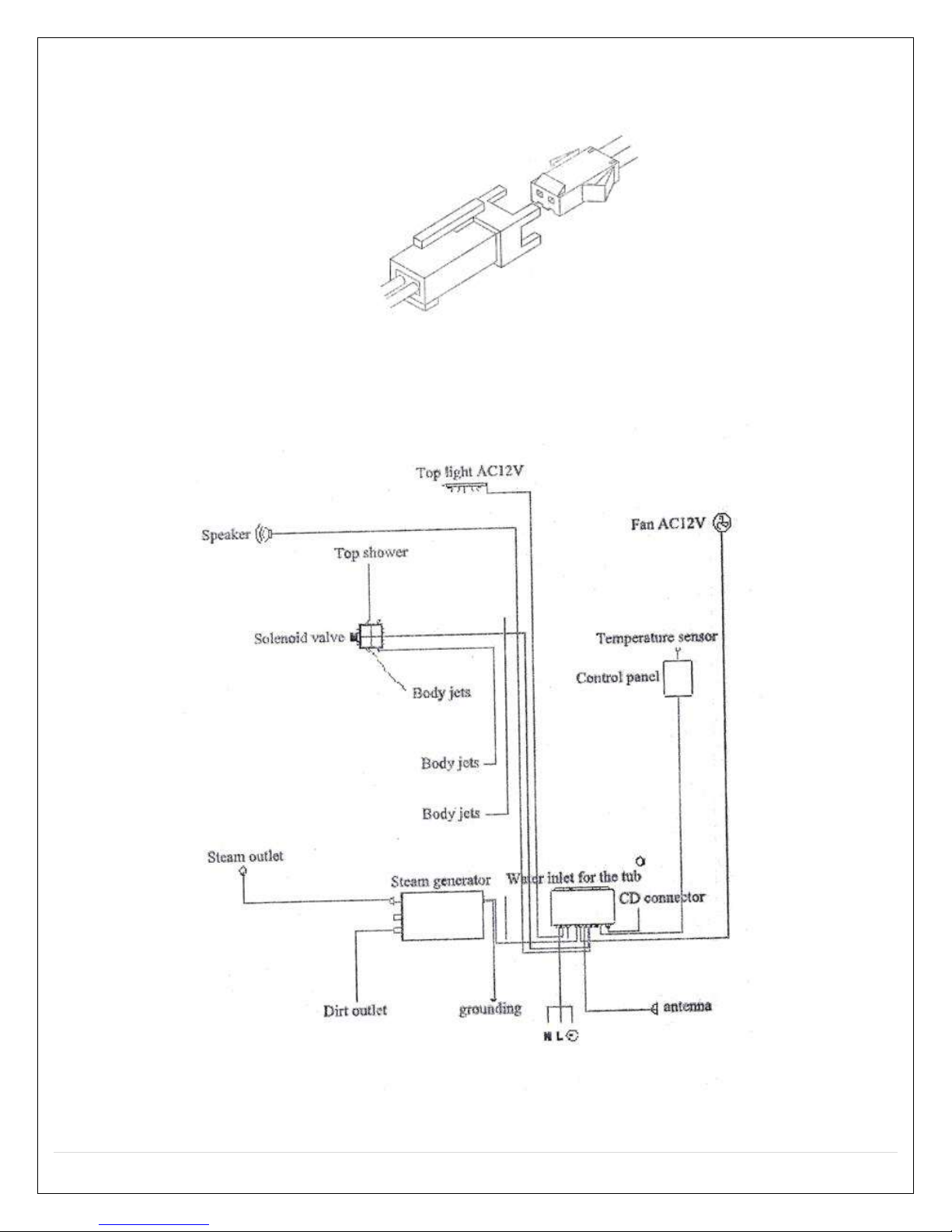

10. Please, refer to the labels on the wires; connect the wires sharing the same

sign.

11. Connect the braided cold and hot water hoses, the red one is for hot water,

blue is for cold.

12. Seal the connection with Teflon tape.

220V

50-60Hz

13 | P a g e

REV 03/2012

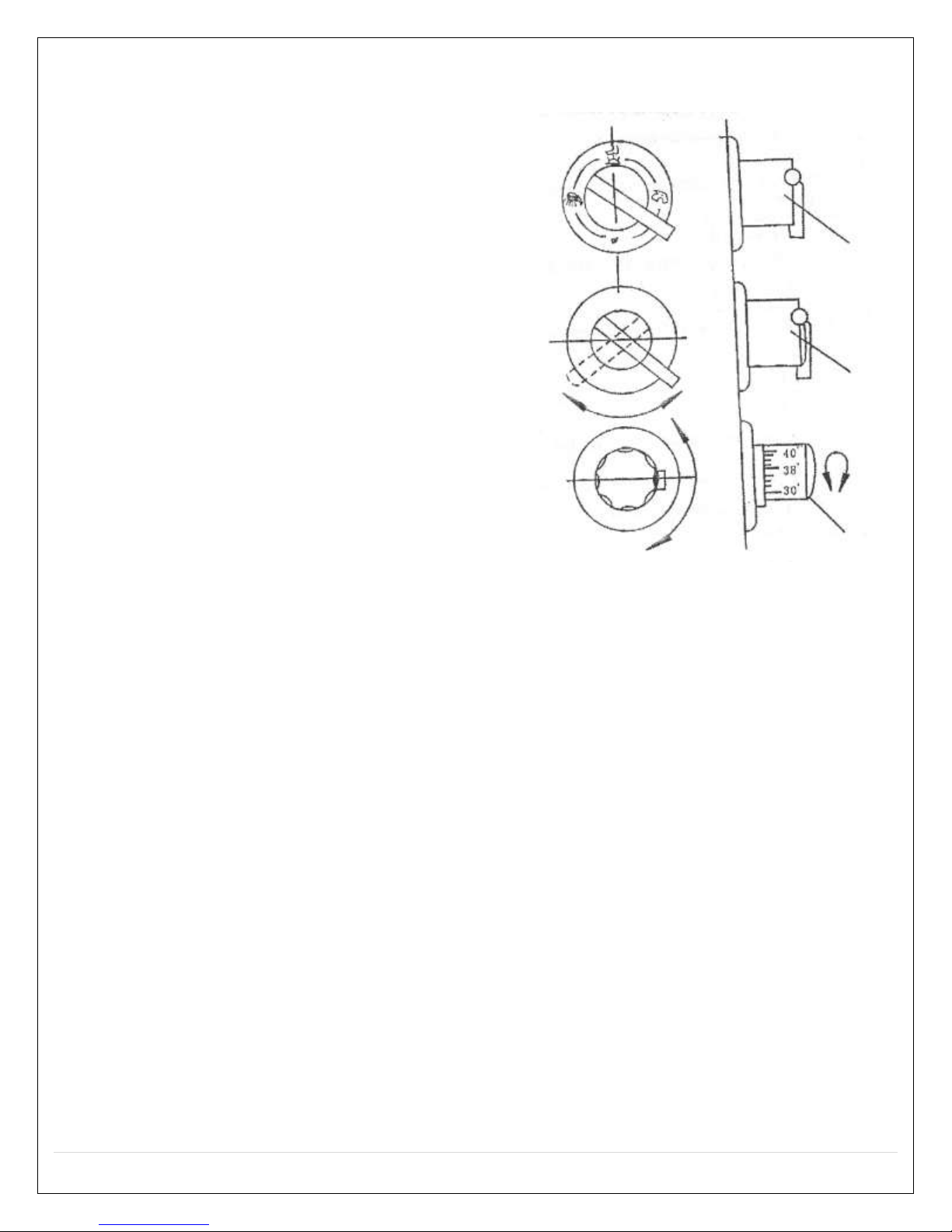

After connecting the hot and cold water,

rotate the temperature knob, in accordance

with the temperature scale in the dial, you

can adjust the different temperature, rotate

the middle knob, this shuts the water on

and off. Rotate the water diverter function

knob; you can use the different shower

functions.

The thermostatic valve faucets are different

with the general faucet, when using the

thermostatic valve faucet, the desired results

can only be achieved after the following

terms and conditions are available.

The water pressure of the hot and cold water

should remain consistent

If a relatively large water heater has been

equipped, the heat required should be

satisfied

Specific methods of operation

Thermostat valve adjustment

oIf the temperature control faucet has

been equipped in the steam room, a sudden change of water temperature

which may leads to burn the body by hot water, or stimulate the skin by cold

water will be eliminated, the function is controlled by the Italian thermostat

valve-core which uses the advance shape alloy memory technology (SAM) to

control the water temperature. On thermostat adjusting hand wheel, the 30°-

50° temperatures are marked there, the temperature within the scope are

optional for the users. If the user rotates the wheel at 38°, it will be locked,

and the water will always flow at 38°. If the user wants to change the

temperature, he/she can press the position lock bar on the thermostat

adjusting hand wheel, and then adjust the temperature to the desired value.

Note: the temperature setting of the hot water tank and the cold water will vary the

temperature valves on the control. Seasonal temperature change will affect the

temperature also.

14 | P a g e

REV 03/2012

Troubleshooting Guide

Situation

Malfunction

Display

Possible Failure Reason

Solutions

Will not run

No display on the

monitor

1. Power line not connected or no

power supply

2. Insufficient power

3. 2A fuse damaged

4. Circuit breaker or OFT switch

damaged.

1. Correctly connect or wait for the

electricity supply to resume.

2. The power must reach the required

standard.

3. Replace the 2A fuse.

4. Replace or reset breaker

Switch failure

Power off right after

turned on

1. Leakage protection switch

damped or damaged

2. Short circuit

1. Replace the switch

2. Recheck the circuit for shorts

Shut off

spontaneously

Indicating light is on

1. Inlet or outlet valve damaged

2. The drainage of the outlet valve

got stuck

1. Replace the inlet or outlet valve

2. Clean out the drain pipe

Indicating light is off

1. Electronic components damaged

2. Cables loose

1. Repair or replace the relevant

component

2. Reconnect the cables

No steam coming

out

1. No water coming in the steam

generator

2. Water pressure too low

3. Heating element in the steam

generator is broke

4. Lack of water

5. Steam pipe is blocked

6. Haven’t reached the required

heating time

7. The indoor temperature is higher

than the set temperature

1. Wait for the water pressure to build

up

2. Install booster on the main water

pipe

3. Replace with a new one

4. Check the inlet valve

5. Remove the obstruction or replace

the pipe

6. Wait for a while (2-3minutes)

7. Set a higher temperature or wait for

it to cool down

Self protection

1. Lack of water pressure

2. Inlet or outlet valve got stuck

3. Drain pipe blocked

4. Steam pipe blocked

1. Install booster

2. Clean out the obstruction

3. Same as above

4. Clean the steam pipe

Overheating

1. The set temperature is too high

2. Temperature sensor fails to work

1. Set a lower one

2. Replace with new one

Steam cut off

1. Set time’s up

2. Set temperature is too low

3. Electronic component (heating

element) damaged

1. Reset the time

2. Set a higher one (cannot be lower

than the temperature in the room)

3. Repair or replace

Water leaks from the

steam outlet

1. Water sensor is out of control

2. The circuit in charge of checking

the water level is out of control

1. Check the water sensor

2. Check the components of that circuit

No sound comes

from the speaker

Monitor is working

1. No FM signal

2. No sound

3. Speaker damaged

4. Antenna is loose

1. Readjust the channel

2. Increase volume

3. Replace a new one

4. Reconnect it and adjust the position

Monitor is not working

1. Circuit or electronic components

damaged

2. Cable loose and/not connected

1. Replace it

2. Reconnect it or replace it

Attention: within the warranty time, do not break the seal on the electrical box and the steam generator on your own. Do

not repair or replace the circuit on your own. If any problems occur, please contact the local distributor.

15 | P a g e

REV 03/2012

Replacing Door Rollers

1. Remove plastic cover from roller

2. Loosen the nut

3. Turn the 6 sides plastic cover Left or Right for release the door on Top and Bottom of

door. Note: the roller is off set to loosen or tighten the door to the frame

4. Take down the door

5. To install new door repeat steps 4,3,2, and 1

16 | P a g e

REV 03/2012

Cleaning and Maintenance

1. When it comes to daily cleaning, liquid detergent and soft cloth should be used. DO

NOT sterilize it with acetone and ammonia detergents. Do not use detergent with

formic acid or formaldehyde. Do not use any abrasive cleaners.

2. To apply with some wax to polish it will bring you the glossy surface back.

3. The blotch on the surface can be wiped away by soft cloth with toothpaste.

4. The scale on the surface can be cleaned out by soft cloth with lemonade or heated

vinegar.

5. To deal with slight scratches, wet sand with citric acid 1200 sand paper, and then

polish it with polishing paste.

6. After every 20 times of using the unit, we strongly suggest you to clean the steam

generator. When you start to clean it, make some solution mixed with 1.5-1.7 liter of

warm water and 5-10grams of citric acid. Pour the solution into the steam generator

through the water inlet. Switch it on after 8 to 10 hours, wait for it to be discharged

as gas.

7. When your water is hard, we strongly suggest you lean the whirlpool devise twice a

year, as described below:

a. Fill 40°C hot water in the tub to the necessary water level (right to the level that

can ensure to get the tub working)

b. According to the proportion of mixing 2 gram of liquid detergent into 1 liter of

water, put certain amount of detergent into the water, and switch the system

on for 5 minutes.

c. Switch if off, drain out the water.

d. Fill cold water in the tub, switch on the system and keep it working for 3

minutes.

e. Switch it off, drain out the water and clean the tub.

Tips:

1. User’s power facilities must meet national safety standard, voltage and frequency.

Power supply shall be consistent with the value marked on the product, the power

supply should be installed a RCD which is the current under 30 MA, assure grinding

protection facilities are effective.

2. Power cord shall be permanent fixed wire and 3-core wire is required, section of every

core shall exceed 2.5mm (3.*2.5mm)

3. Drain water for about 10 minutes for newly built or remodeled house to remove

debris from water line before connecting the water line.

4. After using, cut off power supply and water supply.

5. The ground should be connected to the system, for example the smooth surface of a

metal water pipe wire.

6. We strongly advise to use a filtration system for the steam generator unit.

Recommended filtration system is Whirlpool WHKF-DWHV.

17 | P a g e

REV 03/2012

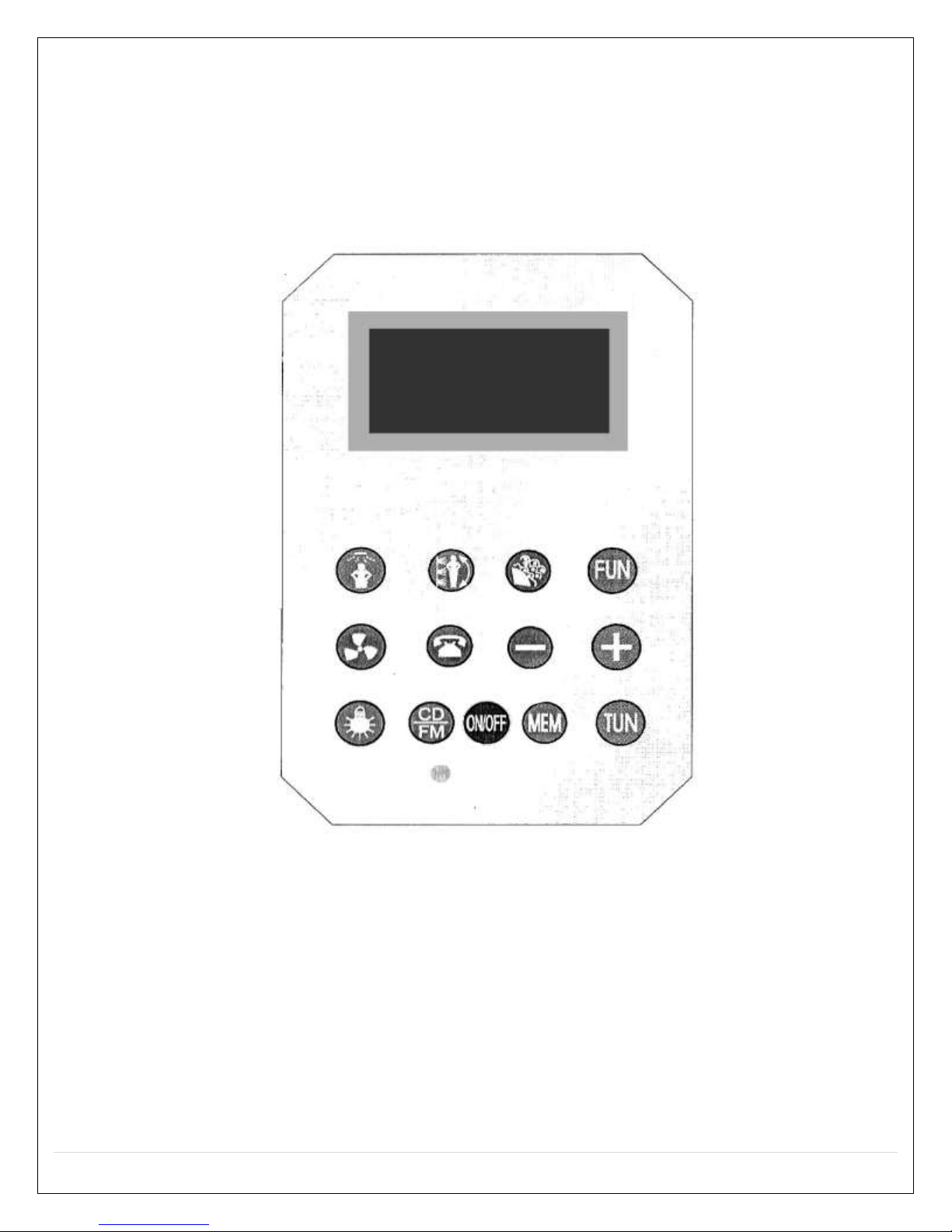

User Manual for BF1102

(Fits Models: M-A020 & M-A021)

18 | P a g e

REV 03/2012

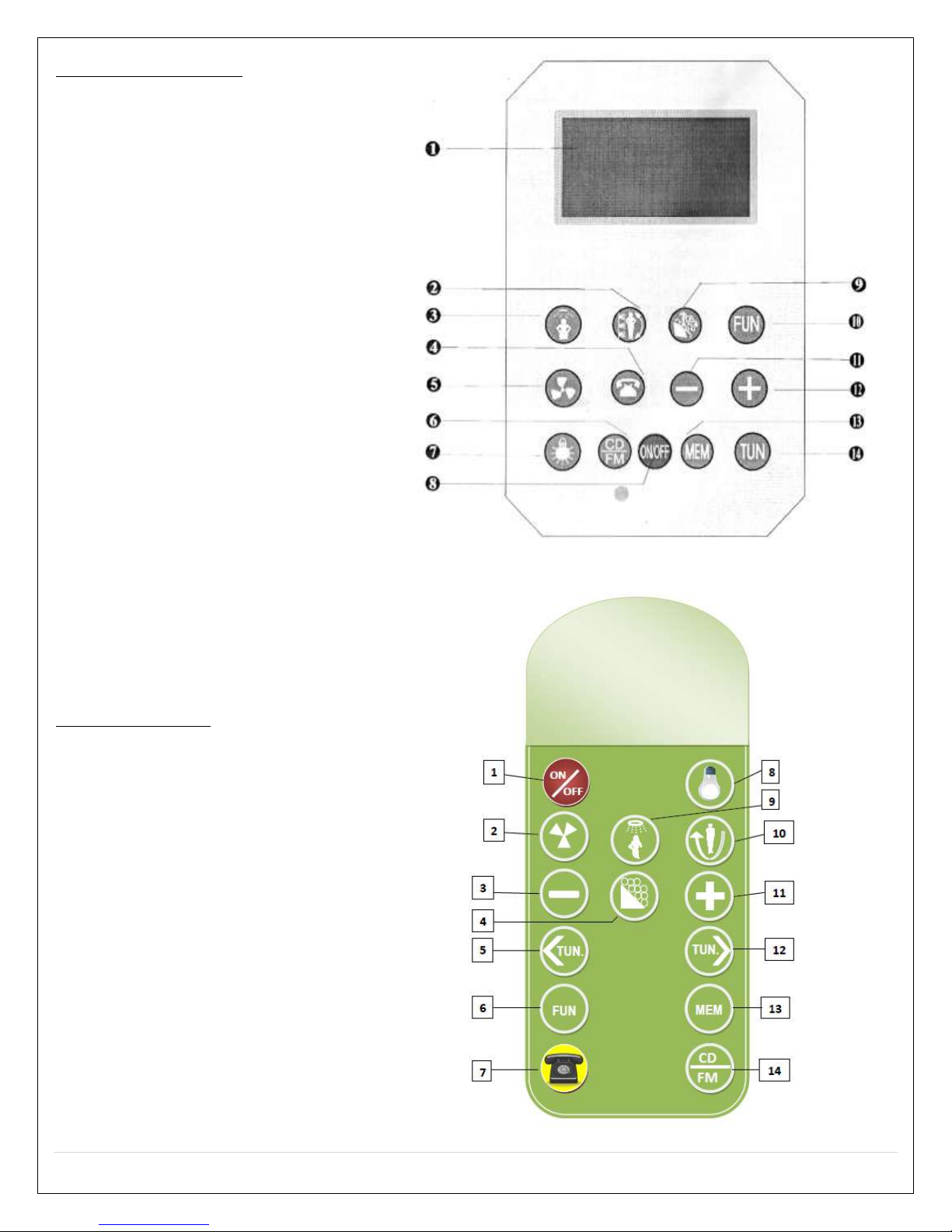

Main Control Panel

1. LCD

2. Massage Jets Function

3. Rainfall Shower Head

Function

4. Telephone Function

5. Fan Function

6. Radio / CD Function

7. Top Light Function

8. ON/OFF

9. Steam Function

10. Function Key

11. –Key

12. + Key

13. Band Storage Key

14. Radio Frequency

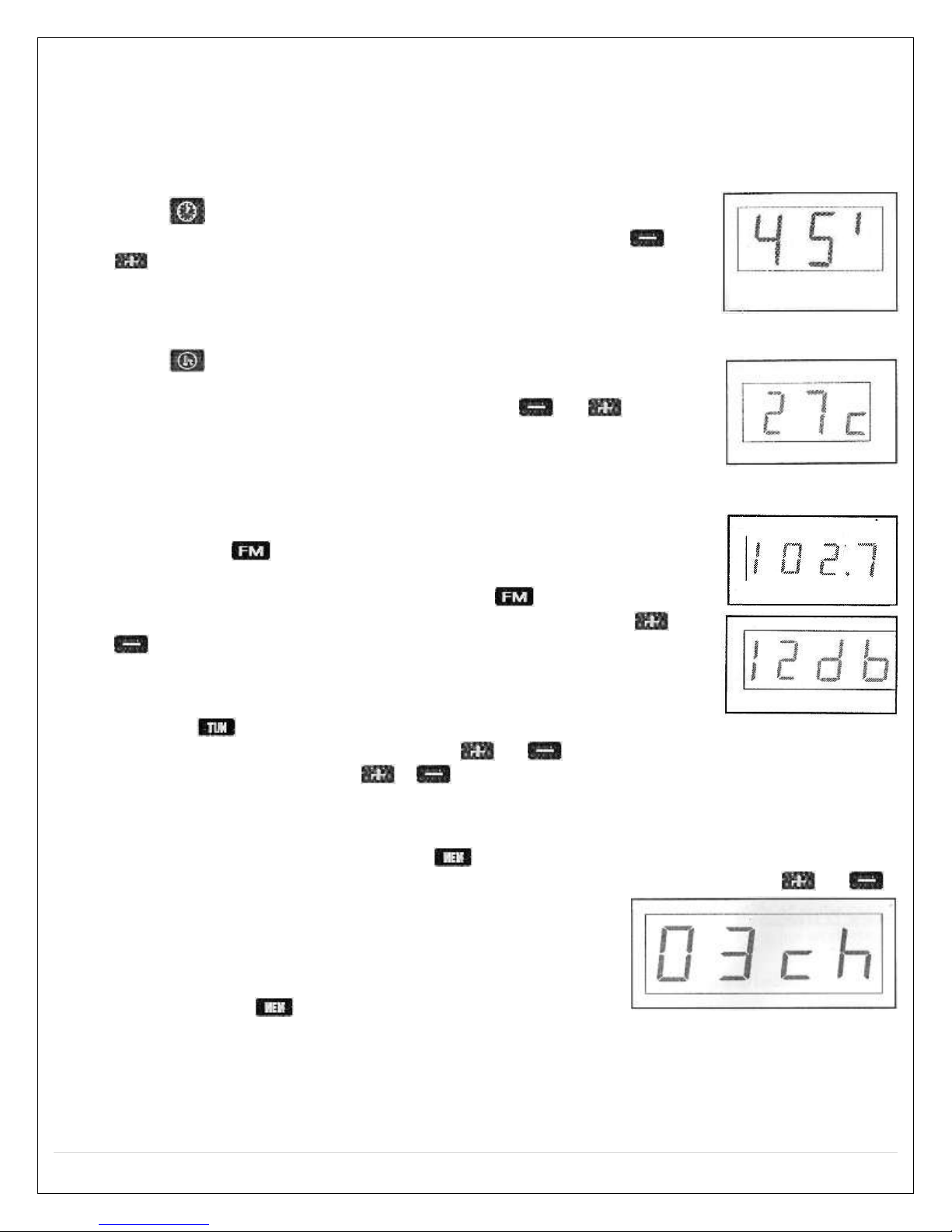

Remote Control

1. ON/OFF

2. Circulation Fan

3. Decrease Key

4. Steam Function

5. FM Tuning (-)

6. Function Key

7. Phone Key

8. Light Key

9. Rainfall Shower Key

10. Body Massage Jets

11. Increase Key

12. FM Tuning (+)

13. Memory Key

14. Radio / CD Switch

19 | P a g e

REV 03/2012

Introduction to Functions

1. ON/OFF

2. Light Lamp Function

3. Circulation Fan Function

4. Steam Function

5. Steam Time Function

6. Steam Temperature Function

7. Radio Function

Description of Functions

1. ON/OFF Key

Under ON state, press key on the panel or remote control key to start the

system, the top light will come on, and functions will be activated and illuminated on

the LCD display. The LCD display will show the environment temperature, press

key again to shut down the system.

Press other keys except on the panel or remote control key under standby

by and OFF state, the backlight of keys will be illuminated, if the system is not

turned on, the backlight will automatically shut-off in 30 seconds.

2. Light Lamp

Top light will be turned on when the system is activated, press on the control

panel or remote to turn on or off the top light.

Caution: The light power must be under 12V, and the power has to be less than or

up to 10W. The temperature system will be in danger is the light’s power is too high.

3. Circulation Fan

Press key on the panel to start the fan, the same icon will show on the LCD

panel. To shut off the fan, press key again.

4. Steam

Press key on the panel or remote control to control the steam system. When the

steam ON/OFF, LCD will display “S-ON” / “S-OF”. This will be displayed only for 5

seconds. See examples bellow:

When the steam generator does not have water, LCD display will flash “S-ON”, until

the steam generator is full or water or cut down, the flashing will stop and come back

to the original state. The other function also can be operated when the steam

machine does not have water and the LCD will redisplay the “S-ON” after operating

for about 4 seconds.

20 | P a g e

REV 03/2012

Caution: Setting aroma jar must screw the nut when the testing line from control

box and connect to the water level probe of Aroma jar. If the nut is too loose,

between the inside of the probe and the jar wall, the probe will not work during

testing. Without water creates a dangerous situation!

5. Steam Time Settings

Press key on the panel or remote control, LCD panel will

move into time setting state. See sample display. Press or

key to set duration. Time setting range is 1 –99 minutes,

default time is 45 minutes.

6. Steam Temperature Settings

Press key on the panel or control remote, LCD panel will

display the steam temperature setting state, see sample icon. To

increase or decrease the temperature, press or key. The

temperature range is between 25°C – 60°C, default temperature

is 45°C. When the temperature is more than the setting time

1°C will be cut down, if less than 1°C – the steam will come on.

7. Radio Function

Pressing the key on the panel or remote control will start

the radio function; LCD panel will display the current radio

frequency, see sample icon. Pressing the key for the second

time will turn off the radio. When the radio is on, press or

on the panel or remote control can adjust volume, and the

volume number will be displayed on the LCD panel, see sample

icon.

Pressing key on the panel or remote control can enter into or exit the FM

frequency. When in FM mode, press or on the panel or remote control can

adjust frequency. Holding or will skip to the next available frequency. If a

radio station cannot be found in 5 seconds, the system will exit the FM. The screen

will stop flashing.

When the radio is on, pressing the key on the panel or remote control can enter

into channel switch if the current radio is not in searching mode. Press or

to adjust channels, the range is 1 –25. If it cannot

find a radio channel within 2 seconds, it will turn back

to the channel display status. Entering in to channel

switch status, the channel will add 1, see sample.

When pressing more then 1.5 seconds, the

current radio station will be memorized as a favorite channel. The LCD panel will

flash the FM channel for hinting.

Table of contents

Other Steam Planet Plumbing Product manuals