Steamist HC-9 User manual

HEAVY COMMERCIAL

STEAMBATH GENERATOR

OWNERS MANUAL

Models HC-9 Thru HC-18

3/98 Pub. No. 400- G

TABLE OF CONTENTS

I. Plumbing Installation...............................................................................................................1

A. Plumbing Pre-Installation ..................................................................................................1

B. Plumbing Rough-In .............................................................................................................1

C. Steam Generator Plumbing Installation............................................................................2

Title Page

11. Electrical Installation ...............................................................................................................2

A. Electrical Pre-Installation ...................................................................................................2

B. Electrical Rough-In .............................................................................................................2

C. Steam Generator Electrical Installation............................................................................2

III. CP-1 Control Package Installation and Operation ................................................................4

A. Pre-Construction Considerations .......................................................................................4

B. CP-1 Control Package Rough-In ........................................................................................5

C. CP-1 Control Package Installation .....................................................................................5

D. Steam Solenoid Valve ...........................................................................................................6

E. Operation ..............................................................................................................................6

IV. Auto Blowdown and Automatic ON/OFF Time Clock............................................................8

V.Steam Generator Operation......................................................................................................8

VI. Steam Generator Maintenance..................................................................................................8

A. Manual Blowdown ................................................................................................................8

B. Periodic Inspection ...............................................................................................................8

LIST OF ILLUSTRATIONS

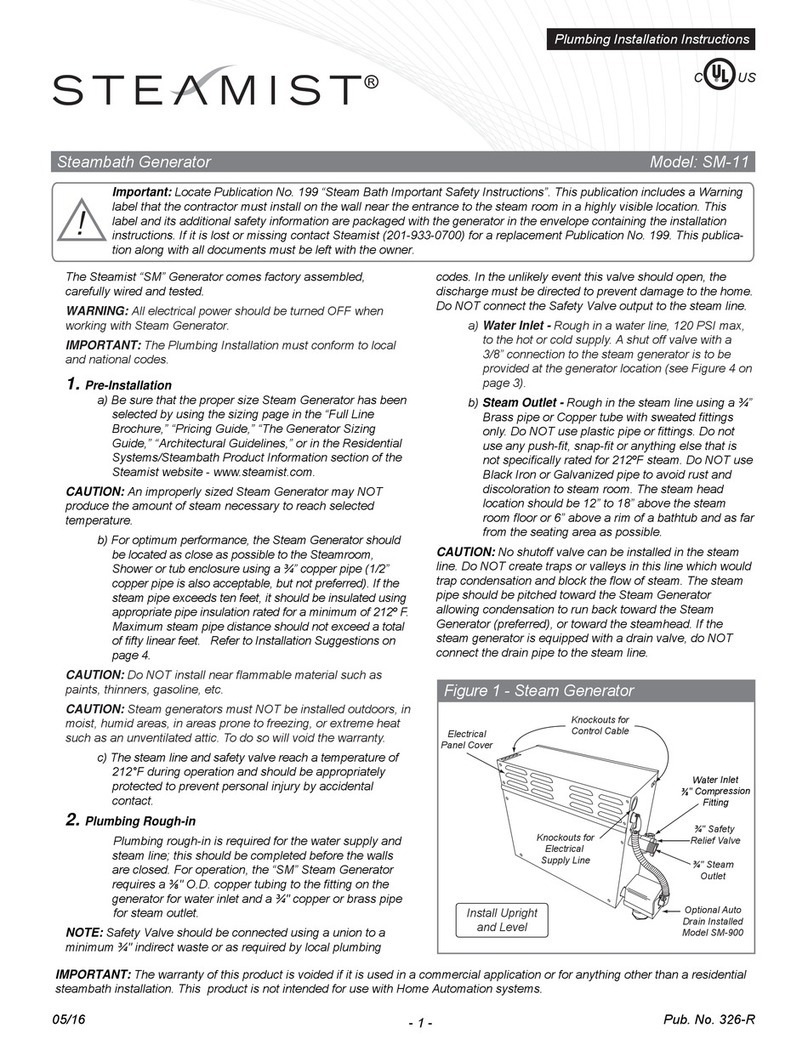

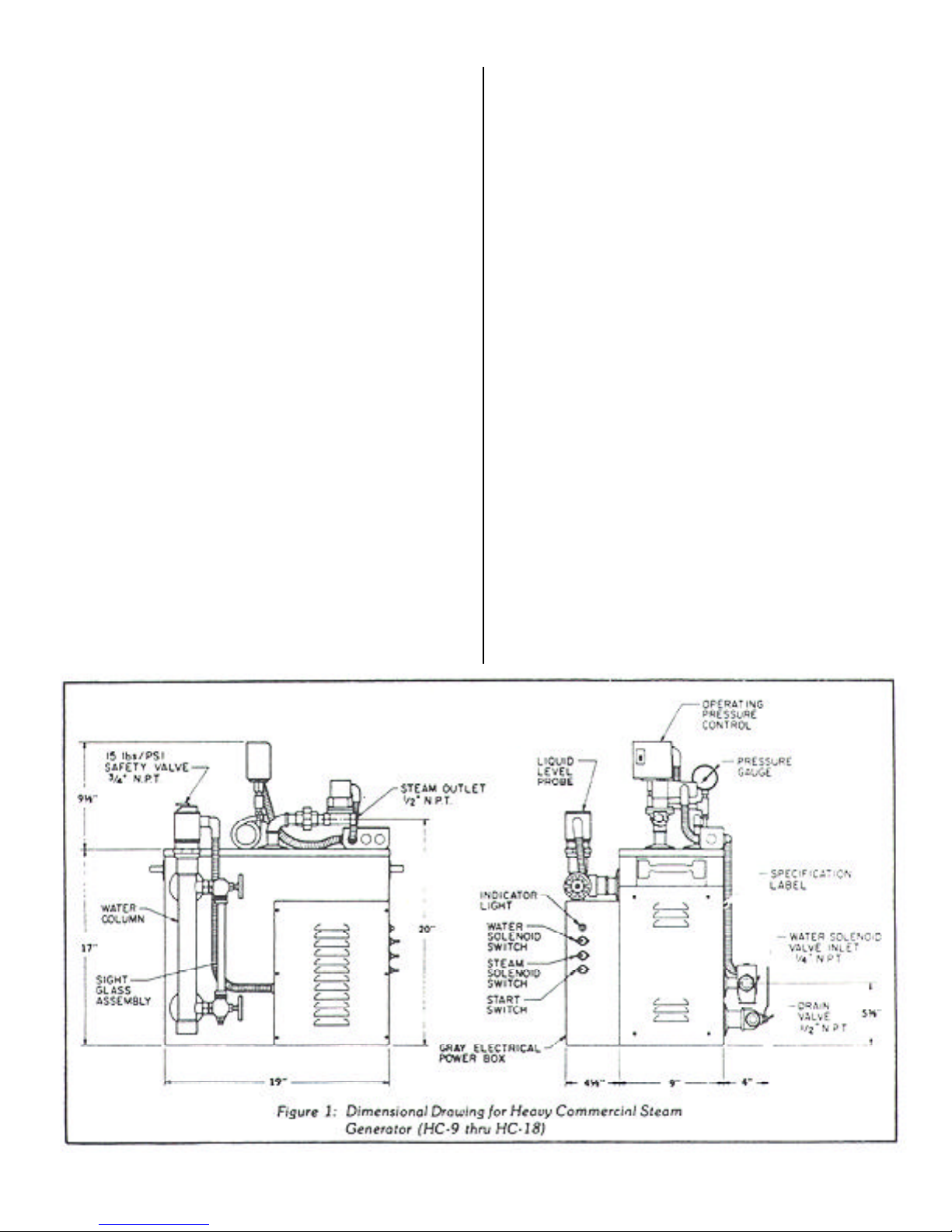

1. Dimensional Drawing for Heavy Commercial

Steam generator (HC-9 thru HC-18) ....................................................................................1

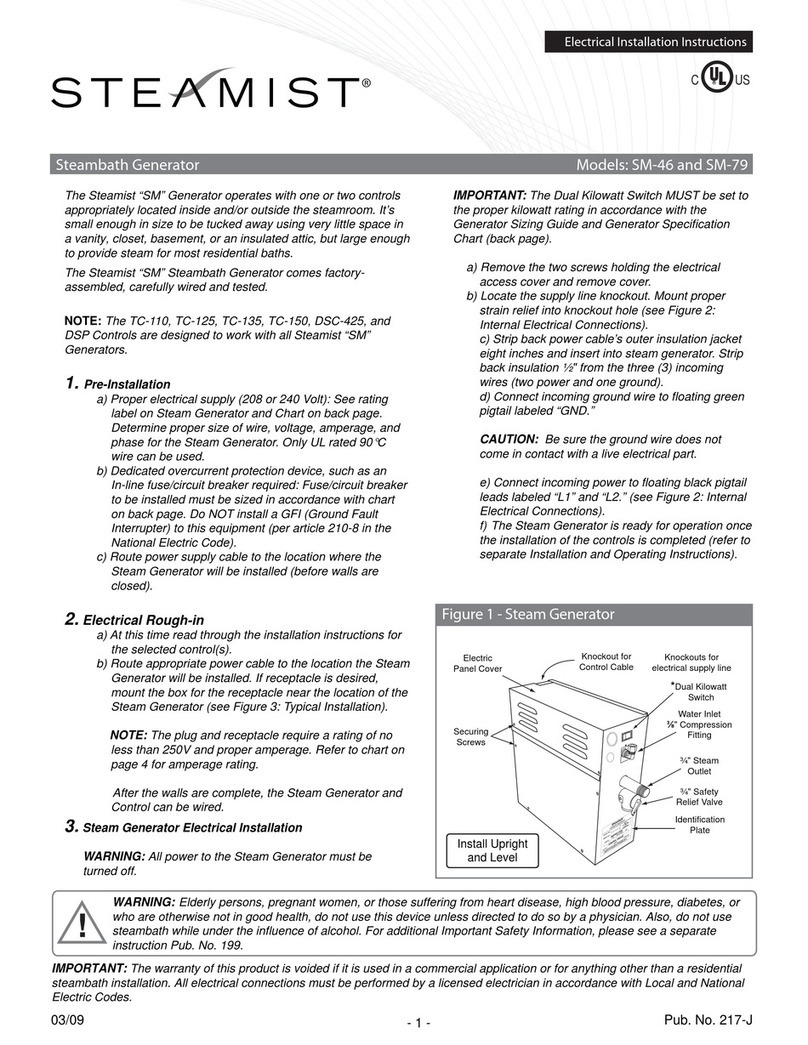

2. Typical Steam generator Installation ........................................................................................3

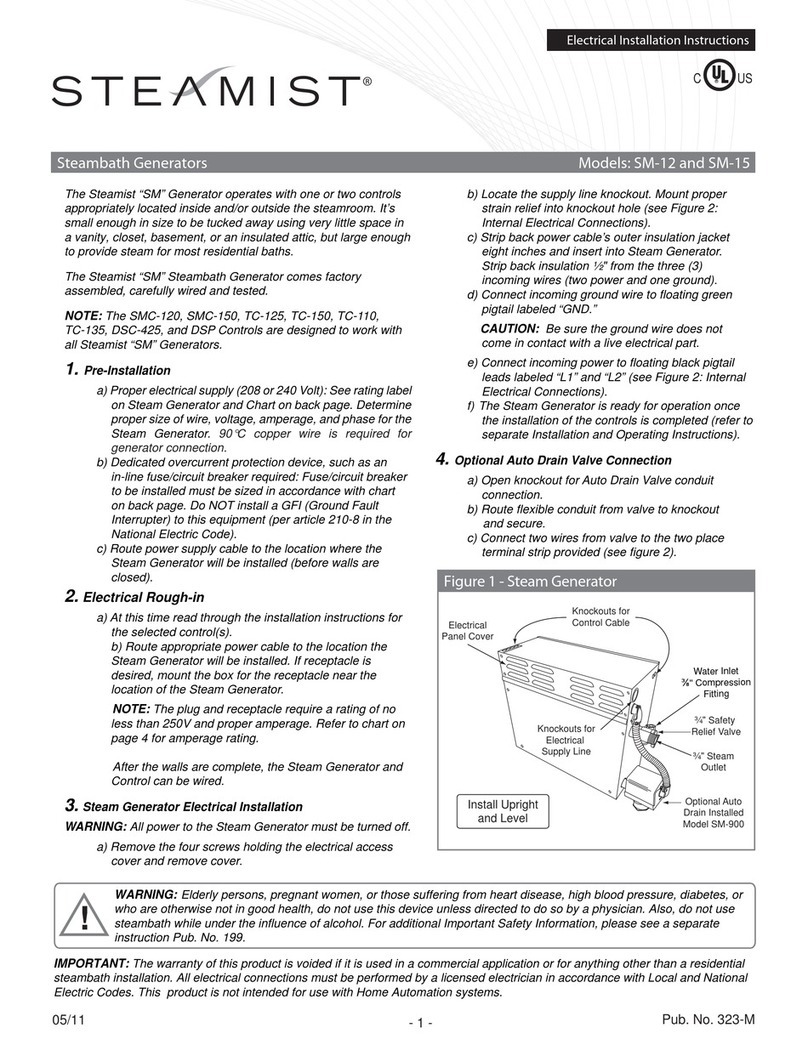

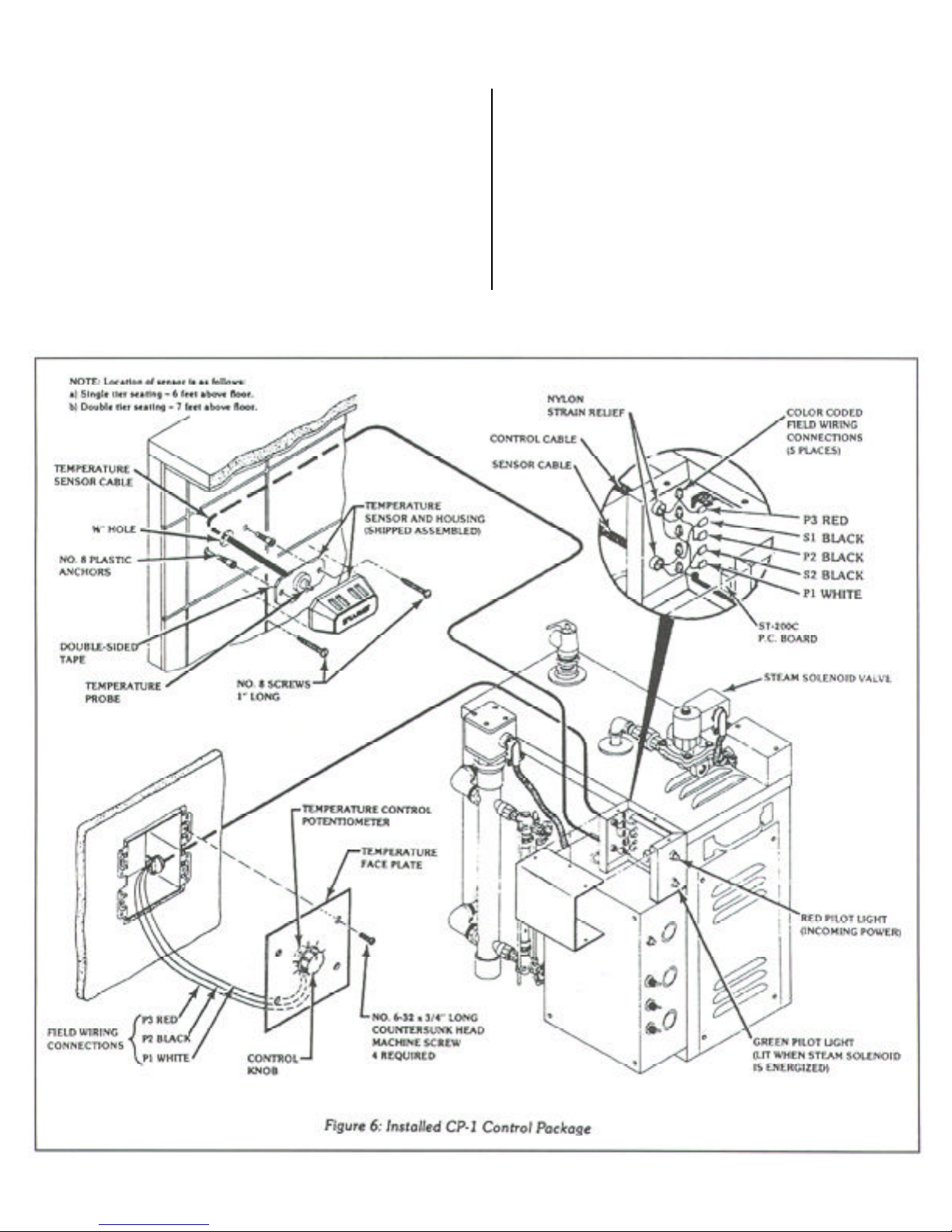

3. ST-200C Temperature Sensor Installation ...............................................................................4

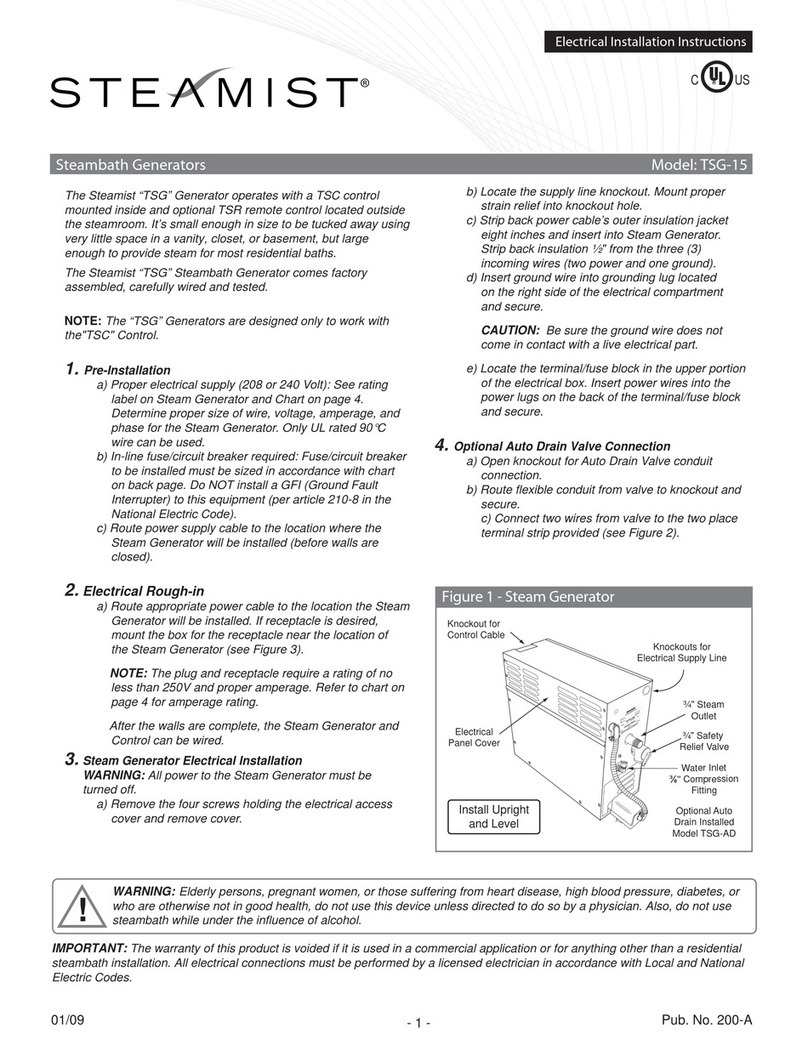

4. ST-200C Temperature Control Installation .............................................................................5

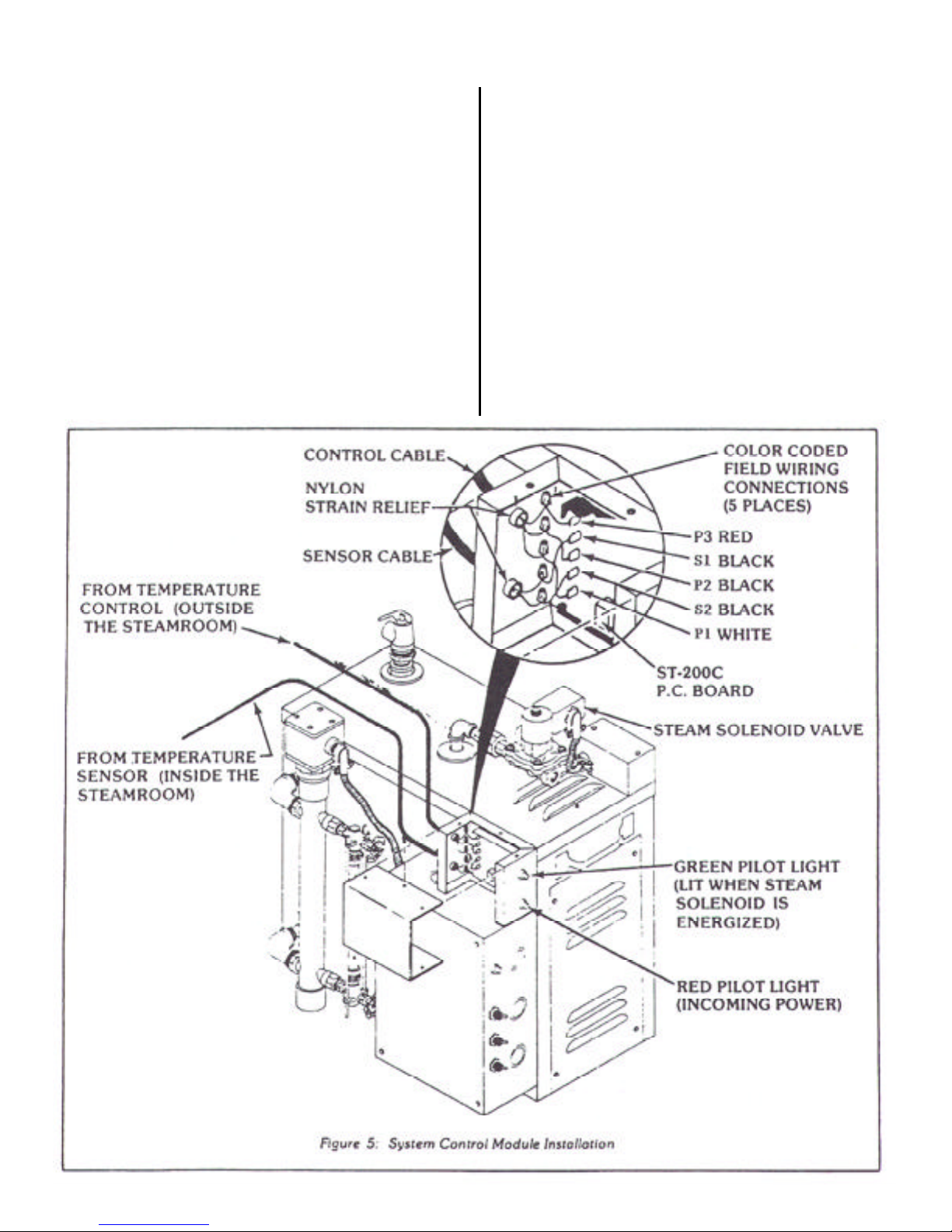

5. System Control Module Installation .........................................................................................6

6. Installed CP-1 Control Package...............................................................................................7

7. Automatic Blowdown and Automatic ON/OFF Time Clocks...... ............................................9

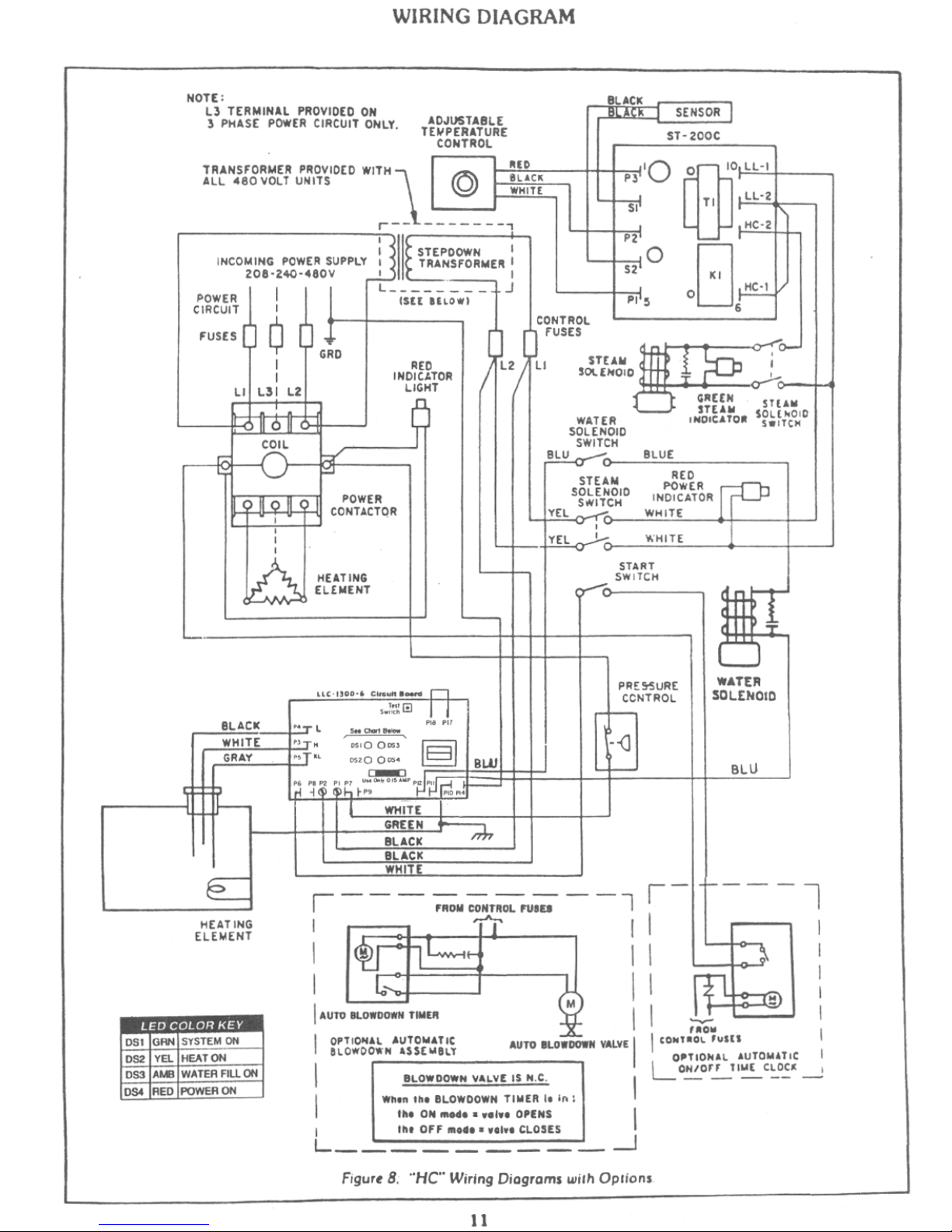

8. “HC” Wiring Diagram with Option..........................................................................................11

IMPORTANT: Read all instructions before installing equipment

Steamaster Company Inc., 1998

Figure Page

System Control Module Installation

PLUMBING INSTALLATION

The Heavy Commercial Steam Generator (HC-9 thru

HC-18) comes factory assemblect, carefully wired, and

tested.Allworkmustconformtolocalandnationalcodes.

All power must be OFF to the steam generator when

Installing or servicing the unit.

WARNING - Elderly persons, pregnant women, or those

suffering from heart disease, high blood pressure,

diabetes, or not in good health must not use this device

unlessdirectedbyaphysician. Also. steambathing should

be avoided while intoxicated.

I. PLUMBING INSTALLATION

A. Plumbing Pre- Installation

Allow sufficient room (30" minimum) for

access to the unit in the event service is

required. Do not keep flammable materi-

als such as gasoline, thinners, paints, etc.

In the same area as the steam generator.

The steam generator must be located as

close as possible to the steamroom. If the

steam generator is more than ten feet from

Insure that the model steam generator

unit you have purchased is sized ad-

equately for your steamroom.

1)

2)

3)

the steamhead, Insulate the steam pipe.

The serial number plate should be vis-

ible. Refer to Figure 2 for Installation

drawing. Do not Install outdoors or an

area where parts may freeze or corode.

Also, do not install near combustible

materials, i.e., paints, thinners, chlorine,

etc.

The steamroom must be completely sealed

on all sides. top, and bottom. Floor. walls,

and ceiling should be completely covered

with waterproof material. In the event that

the walls or ceiling are exposed plaster.

sheetrock, or plaster board, a waterproof

paint must be applied to seal the surfaces.

4)

B. Plumbing Rough-in

The Heavy Commercial “HC” Steam Generator

req,tires the following connec. tions: 1/2" NPT

piping for water inlet. 3/4" NPT brass or 3/4"

(I.D.)copper tubing for steamoutlet. and 3/4" NPT

safety valve should be piped to an indirect waste

line. A 3/4" minimum indirect waste line must be

installed for the drain. This should be completed

before wa!ls are installed.

Before connecting the water line it is important to

make sure the line is thoroughly clean and free of

foreign matter.

Rough-in a water line from hot (prefer-

ably) or cold water pipe; brass pipe or

1)

1

ELECTRICAL INSTALLATION

copper tubing is recommended. A shut-

off valve should be convenicnitly placed

in the water feed line.

Rough- in the steam line using 1/2" NPT

brass pipe or 3/4 " I. D. copper tubing. Do

not use iron pipe. it will rust and discolor

wall of steamroom. For a steam line that

is longer than 10 feet, insulation must be

used. The stearnhead location should be

approximately 12” to 18" above the

steamroom floor.

CAUTION: NO shut-off valve should be

installed on the steam line. Do not create

trapsor valleys in thisline which would trap

condensation and block the flow of steam.

Thesteampipeshouldbepitchedawayfrom

thestearnhead allowingcondensation to run

back into steam generator (Preferably) Or

pitched toward the steamhead.

Rough- in a 3/4" indirect waste line to be

used for the safety valve and drain. The in-

direct drain must be in accordance with lo-

cal plumbing codes.

2)

3)

C. Steam Generator Plumbing Installation

Care must be taken when installing the steam

generator. Leave proper access for servicing

(30'’ minimum each side). (Refer to Figure 2

for typical steam generator installation.)

CAUTION: The steam generator is designed

to be used ONLY in an upright and level posi-

tion ; to do otherwise would damage the unit

and void the warranty.

If needed mount the steam generator on a

platform to allow draining into a basin or

into previously installed indirect waste line.

NOTE: Optional automatic blowdown must

be piped into the 3/4" indirect waste line.

Connect the 3/4" NPT safety valve into ihe

previously installed indirect waste line.

In areas where high water pressure may be

a problem a water hammer arrestor should

be installed. Connect the water supply to

the steam generator connection marked

“water inlet”. (See Figure 1.)

Connect the steam line from the preViously

roughed-in location to the steam solenoid

valve on the generator marked .. steam out-

let”. (See Figure 1.)

1)

2)

3)

4)

In the steamroom. place the center of the

escutcheon onto the steam pipe and Screw

the stearnhead into place. Care must be

taken not to Scratch the stearnhead or es-

cutcheon with a wrench. Be Sure the steam

slot in the stearnhead is facing down.

After the plumbing connections are complete

the electrician may finish the wiring and test

the unit.

II. ELECTRICAL INSTALLATION

Electrical Pre- Installation

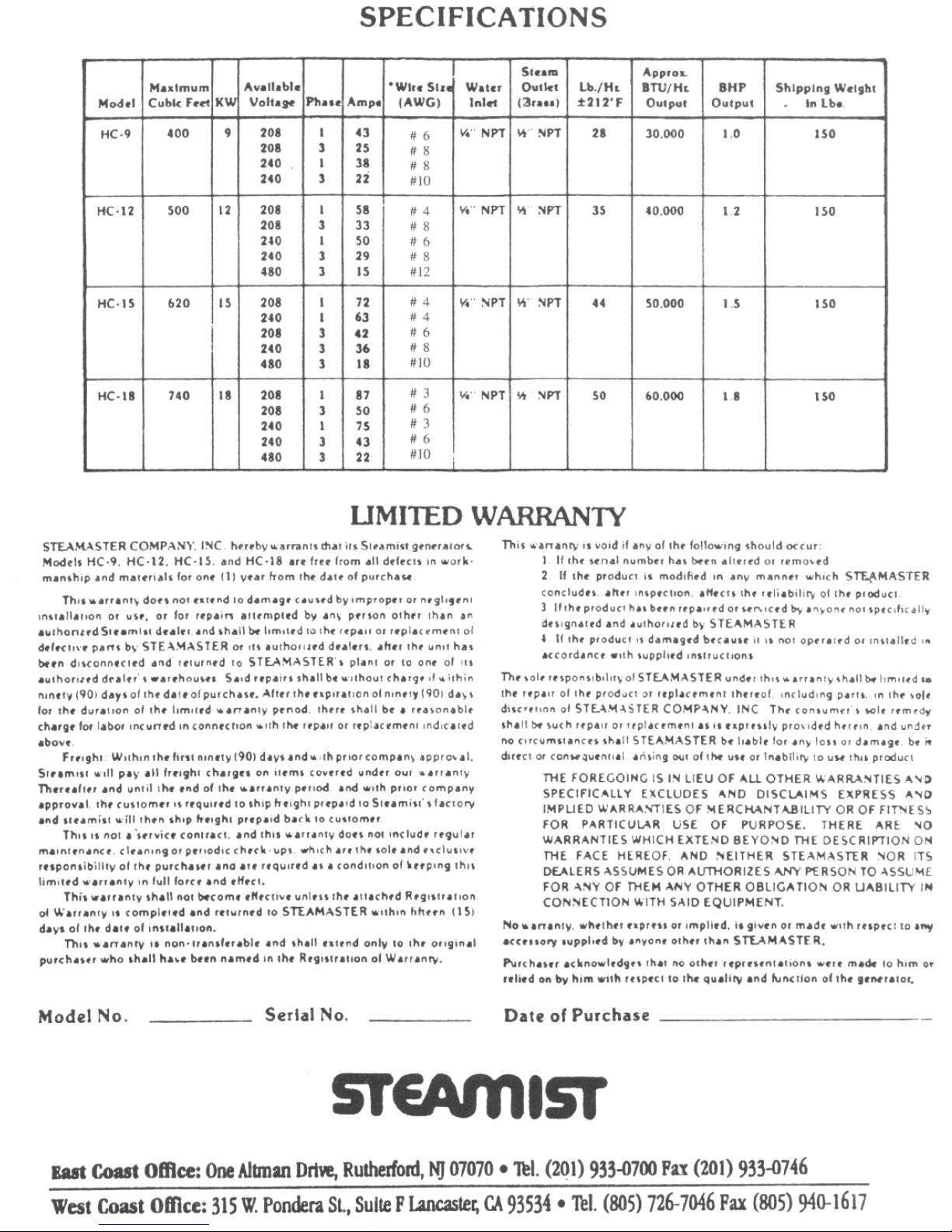

Proper electrical supply: see specification

label located above the drain valve (see Fig-

ure 1)Determine proper size of wire,voltage,

amperage. and phase for the steam genera-

tor.

Inline fuse/circuit breaker required: fu or

circuit breaker sized in accordance with

specification label. Do not install a (GFI)

Ground Fault interrupter to this equip-

ment.

B. Electrical Rough-In

Route power supply cable to the location the

steamgenerator will beinstalled before walls

are closed.

C. Steam Generator Electrical Installation

WARNING ALL POWER TO THE STEAM

GENERATOR MUST BE TURNED OFF.

Locate appropriate knockout found on top

of the steam generator. Mount proper stain

relief into knockout hole.

Strip back the power cable’ s outer insulat-

ingjacket twelve inchesand insert intosteam

generator. Strip back insulation 1/2" from

the incoming wires; single phase (two power

and one ground). 3 phase (three power and

one ground).

Insertgroundwireintogroundingluglocated

on the lower left side wall of the gray elec-

trical power box.

CAUTION: Insure ground wire does not

come in contact with live electrical connec-

tions.

Locate the fuse block. found in the upper

part of the gray power box. Insert power

wires into the proper power lug terminals

on top of the fuse block and secure.

5)

A.1)

2)

1)

2)

3)

4)

5 )

2

Locate and remove six (6) screws securing

the access cover to the gray electrical power

box. (See Figure 1.)

1)

ELECTRICAL INSTALLATION

Replacecoverandsecure screws removed

in step 1

6)

NOTE: Steam Generator will not operate

without water.

3

If connections are made properly the indi-

cator lamp will illuminate when the

7)

generator is heating.

CP-1 CONTROL PACKAGE

CP-1 CONTROL PACKAGE INSTALLATION

AND OPERATION

The CP-I Control Package is completely automatic in

operation... room temperature is thermostatically con-

trolled by the Steamist ST-200C Solid State Temperature

Control System in conjunction with the generator’s steam

solenoid valve. No attendant required... set it, forget it.

The “rapid response” ST-200CTemperature Control Sys-

tem is made up of three components: Temperature Sensor

Probe (Figure 3), Temperature Control Panel (Figure 4),

and System Control Module (Figure 5). After installation

of the ST200C is complete the steamroorn temperature

will automatically be maintained within 1-1/2 F of the

desired setting.

NOTE: This control is not an ON/OFF switch, it is used

in conjunction with the Steam Solenoid Valve. The steam

generator cannot be turned OFF with this device.

A. Pre - Construction Considerations

Choose a location to mount the Temperature Con-

trol Panel. If only a manager or limited group will

be in charge of controlling the steambath tempera-

ture, a utility area may be appropriate.

If steambathers will be permitted to adjust the tem-

perature, choose a convenient location outside the

steamroom door.

Mount the Temperature Control Panel OUTSIDE

the steamroom. Mount the Temperature Sensor

Probe INSIDE the steamroom.

WARNING: Allelectrical powerto the steam gen-

erator MUST be turned OFF before proceeding

with installation.

B. CP-1 Control Package Rough-in

The 3 wire cable for Temperature Control Panel to

be used during installation of the ST200C Solid

State Temperature Control System is low voltage;

18 or 22 AWG wire recommended. Every attempt

should be made to match the color wire of the Tem-

perature Control Potentiometer lead wires (P1

white, P2 black, and P3 red) to the 3 wire cable.

Install a metal two-gang switch box rotated 90

(refer to Figure 4). Install an inverted strain re-

lief clamp and feed the 3 wire cable into the

two -gang box. Run the 3 wire came from the

switch box to the steam generator’s location.

1)

STEPS TO INSTALL SENSOR

SEPARATE TWO WIRES OF CABLE (COMING THRU

WALL FROM GENERATORS ST 200C CIRCUIT

BOARD, TERMINAL #2 AND #4) APPROX. 2", STRIP

AND TWIST APPROX. 1/2" OF BARE WIRE.

TAKE NEW SENSOR ASSEMBLY AND TWIST WIRES

TO WALL CABLE AND SECURE WITH WIRE NUTS.

PEEL OFF ADHESIVE BACKING FROM SENSOR.

CAREFULLYAPPLYSILICONESEALANTAROUND

REAR EDGE.

FEED WIRES BACK INTO WALL AND PRESS SENSOR

FIRMLY TO WALL (BE CAREFUL TO ALIGN PLATE

HOLES WITH ANCHOR HOLES).

INSTALLSCREWS,AND SNAPCHROME COVERBACK

IN PLACE.

TEMPERATURE SENSOR ASSEMBLY MUST FORM A

100%WATER TIGHT SEAL TO THE WALL USING SILI-

CONE SUPPLIED.

1)

2)

3)

4)

5)

6)

7)

Note: Location of sensor is as follows:

a) Single tier seating - 6 feet above floor.

b) Double tier seating - 7 feet above floor.

III

4

CP-1 CONTROL PACKAGE

Install the cable from the area of the Tem-

perature Sensor (Probe) to the steam

generator’s location. The Temperature Sen-

sor (Probe) MUST be located inside the

steamroom. In steamrooms with singletier

seating the Sensor should be located 6 feet

abovethe floor, withtwo tier seating it should

be 7 feet above the floor and in either case

away from the steamhead and steamroom

door. The connector end of the wire must be

installed inside the steamroom. NOTE: A

5/8 inch hole should be provided so that the

connector can be passed through the wall for

installation found later in these instructions.

2)

CP-1 System Control Package Installation

Temperature Sensor (Probe ) (for installation

inside the steamroom)

C. 1)

Locate the 2 wire cable described in the

Rough-in section.

a.

Keeping the 5/8 inch hole centered, drill two

1/4 inch holes 2 inches apart. Insert 2-No. 8

plastic anchors into drilled holes.

b.

c. Follow Figure 3.

Temperature Control Panel (for installation out-

side the steamroom )

2)

Attach the 3 wires (P1, P2, and P3) from the

Temperature Control Potentiometer to the 3

wire cable in the two-gang box. Note the

colors of wire P1, P2, and P3 are attached to

match the colors of the 3 wire cable to the

potentiometer wire colors.

a.

Secure Temperature Face Plate to the two-

gangbox usingfour (4) machine screws. (See

Figure 4.) Important: Care must be taken

to mount Temperature Face Plate properly.

b.

5

CP-1 CONTROL PACKAGE

3) System Control Module

Remove screws securing cover to Sys-

tem Control Module and remove cover

(Figure 5).

a.

Feed the 3 wire cable through the top

strain relief. three inches into the control

module. Attach wires as shown in the

blowup (Figure 5).

Feed the 2 wire cable through the lower

strain relief, three Inches into the control

module. Attach wires as shown in the

blowup (Figure 5).

Check that all connections are made

b.

c.

d.

in accordance with Wiring Diagram

(See Figure 7.)

e. Replace control module cover.

D. Steam Solenoid Valve

There is no installation required for the steam

solenoid valve. it is factory installed and

wired.

E. Operation

The temperature of the steambath is regu-

latedautomatically by the ST-200CTempera-

tureControl System whichturns “On orOff”,

the Steam Solenoid Valve located on the

steam generator allowing steam to enter the

room.

6

CP-1 CONTROL PACKAGE

To INCREASE the temperature, turn the knob on

the Temperature Control Panel clockwise; the

HIGHER THE NUMBER, THE HIGHER THE

SETTING (numbered 1 to 10).

To DECREASE the temperature, turn the knob

counterclockwise.

Once a desired temperature setting has been estab-

lished there should be no further need for additional

adjustments.

IMPORTANT.

To check the function, two lights are provided on

the exterior of the System Control Module located

on the steambath generator. The “Red Light” indi-

cates there is electrical power to the Temperature

Control Module. The “Green Light” indicates the

Steam Solenoid Valve is energized.

If a malfunction should occur in either the incom-

ing electrical power supply “Red Light” or the

Steam Solenoid Valve “Green Light” then the ap-

propriate light will not be lit. However, the “Green

Light” will cycle “ON and OFF” to indicate mode

of the Steam Solenoid Valve.

7

AUTOBLOWDOWNANDAUTOON/OFFTIMECLOCKS

The “HC” steam generator, with an optional auto blowdown sys-

tem, will automatically purge the steam boiler. Working in con-

junction, the Time Clock and electrically motorized valve, which

allows blowdown on boilers, prevents excessive mineral and scale

build-up.

IV.

A. Installation

1. Auto Blowdown Drain Valve (plumbing)

Attach the main blowdown drain valve to 3/4" indirect drain

(most local codes require a blowdown tank). A strainer must

not be used with the valve. Note: the drain line must be angled

downward, allowing gravity to properly drain the machine.

2. Auto Blowdown (electrical)

All wiring is done at the factory so that no special electrical

wiring is necessary.

B. Operation

First decide the TIME OF DAY you require the boiler to

blowdown. It is recommended to select a time while the boiler

is in use, but under low demand. For best results program the

Timer to blowdown every day of use for a period of 5 minutes.

The blowdown will begin with the Timer “ON” command and

end with the Timer “OFF” command. See Page 9 and 10.

C. SETTING AUTOMATIC ON/OFF TIME CLOCK

The Steam Generator will turn ON with the Timer “ON” com-

mand and OFF with the timer “OFF” command. See Page 9

and 10.

IMPORTANT. The Auto Blowdown Timer and Auto On/Off

Timer are two separate timers. If your steam generator only

has one timer, then only one of these two options can be pro-

grammed. Check with the installer to see which option has

been purchased.

V. STEAM GENERATOR OPERATION

A. Place START, WATER SOLENOID, and STEAM SOLE-

NOID switches in the ON position. The Water Solenoid Valve

will open and the boiler will fill to its proper level (one-half to

two-thirds of the sight glass full) and automatically shut-off.

B. When there is adequate water in the boiler the power contactor

will energize and the red power light will illuminate indicating

that the boiler is heating up.

NOTE: This boiler is equipped with a Solid State Liquid Level

Control System. Water level is maintained in the boiler, by a

ground potential signal between each stainless steel water level

probe and the boiler, and operates by sensing the electrical resis-

tance of water.

Both the water feed and low water cut-off functions are regulated

bya low voltage electrical signal that activates the control relay(s),

depending on the water level within the boiler which, in turn,

energizes the water solenoid valve and/or power contractor.

C. When adequate steam has been generated from the boiler

and the desired temperature reached in the steamroom the

steam solenoid valve will close: when controlled by the ST-

200C. The steamroom is now ready for use. Note: When the

steam solenoid valve closes the red pilot light above the toggle

switches will go out only after steam pressure builds to ap-

proximately 8 to 10 PSI within the boiler.

The boiler will maintain an 8 to 10 PSI steam pressure by use

of a pressure control which is supplied as standard equipment.

The pressure control will cycle the unit ON and OFF auto-

matically when the steam solenoid valve is OFF and the room

temperaturecontrol is satisfied.If the solenoidvalve is OPEN,

the pressure in the boiler will drop and the red light will stay

ON.

D. If a ST-200C Temperature Control System (Thermostat) is

provided, set the dial to the desired TEMPERATURE (Dial

Calibration: 1 to 10 setting for comfort level). (Refer to Sec-

tion III for Operating Instructions.)

E. If an Automatic ON/OFF Time Clock is provided, set “the

timer cycle” in order to operate the steambath generator.

VI. STEAM GENERATOR MAINTENANCE

A. MANUAL BLOWDOWN (Only if not equipped with

Automatic Blowdown)

The boiler should be blown down on a daily basis to purge the

vessel of mineral deposits and possible scaling. For effective

blowdown, the STEAM, WATER, and START switches must

be placed in the OFF position. The drain valve should be

opened completely, allowing the boiler water to exit through

your drainage piping into an indirect drain. Now, place the

water solenoid switch in the ON position allowing the system

to flush through for approximately 5 minutes. Close the drain

valve and allow the boiler to fill with water until the proper

level has been reached. The generator is again ready for use,

place the START and STEAM switches in the ON position.

B. PERIODIC INSPECTION

CAUTION: Disconnect all power to boiler before servicing.

Service should be performed by a qualified person.

Check electrical connections periodically, to ensure that

they are tight.

Remove flange-type element to clean any scale that might

have built up on sheath of heating element(s). Be careful

when cleaning heating element, not to deform the rods.

1.

2.

3.

8

Remove Liquid Level Probe periodically to check for

deposits.Check that thebottom union,which attaches

the water level probe assembly is clean of deposits. If

necessary, clean stainless steel probes and teflon insu-

lated tubing by removing all foreign matter. Extreme

care should be exercised so that porcelain insulators

are not damaged during the removal of Liquid Level

Probe. This will ensure proper conductivity and op-

eration of boiler.

Digi 20 Series

One Circuit Electronic

24 Hour or 7 Day Time Switches

FIGURE 7. Auto Blowdown and Auto ON/OFF Timeclock

Digi 20A

(surface mounting)

Operating Instructions

APPLICATION

Time based control of lighting, ventilating, heating, cooling or other electrical loads in commercial and industrial applications. The Digi 20 time

switches are programmable for 24-hour or 7-day schedules.

The Digi 20A is intended for either surface or rail mounting. The control is completely enclosed in a plastic housing and includes a terminal

cover and sub-base for installation and hard wiring.

The Digi 20E is intended for flush (panel) mounting.

All units are supplied with a clear plastic dust cover.

TECHNICAL DATA

Output-1 SPDT relay with dry contacts

Switch Rating: 16A/277VAC resistive

1 OOOW tungsten @ 240VAC; 50OW @ 120VAC

1/2 hp @ 120VAC; 1 hp @ 240VAC

100 hour capacitor back-up of memory and display

Supply voltages: Separate Models - 24VAC/DC, 120VAC,

208/240VAC, all 50/6OHz (refer to product label)

Shortest switch time-1 minute

Ambient Temperature Range -20 F to 140 F ( 28 C to 60 C)

VA required: 120V & 240V models: 4VA

24V model: 2VA @ 24VAC, 1VA @ 24VDC

Screw terminal connections (Digi 20A)

1/4" quick connects (Digi 20E)

Accuracy ± 4 minutes per year

WIRING

1. Disconnect the power.

2. Wire input to timer M to the proper

voltage marked on the unit. Wiring to

incorrect voltage will avoid the warranty.

3. Connect wiring according to the wiring

diagram. The terminals on the Digi 20A

sub base will accommodate 10 to 24 AWG

wire.

Mechanical Timer Shown

9

Other manuals for HC-9

2

This manual suits for next models

9

Table of contents

Other Steamist Inverter manuals

Popular Inverter manuals by other brands

Parkside

Parkside PSE 2800 A1 Operation and safety notes

Mitsubishi Electric

Mitsubishi Electric FR-A700 Series Technical manual

CONPO

CONPO SDC-20A instruction manual

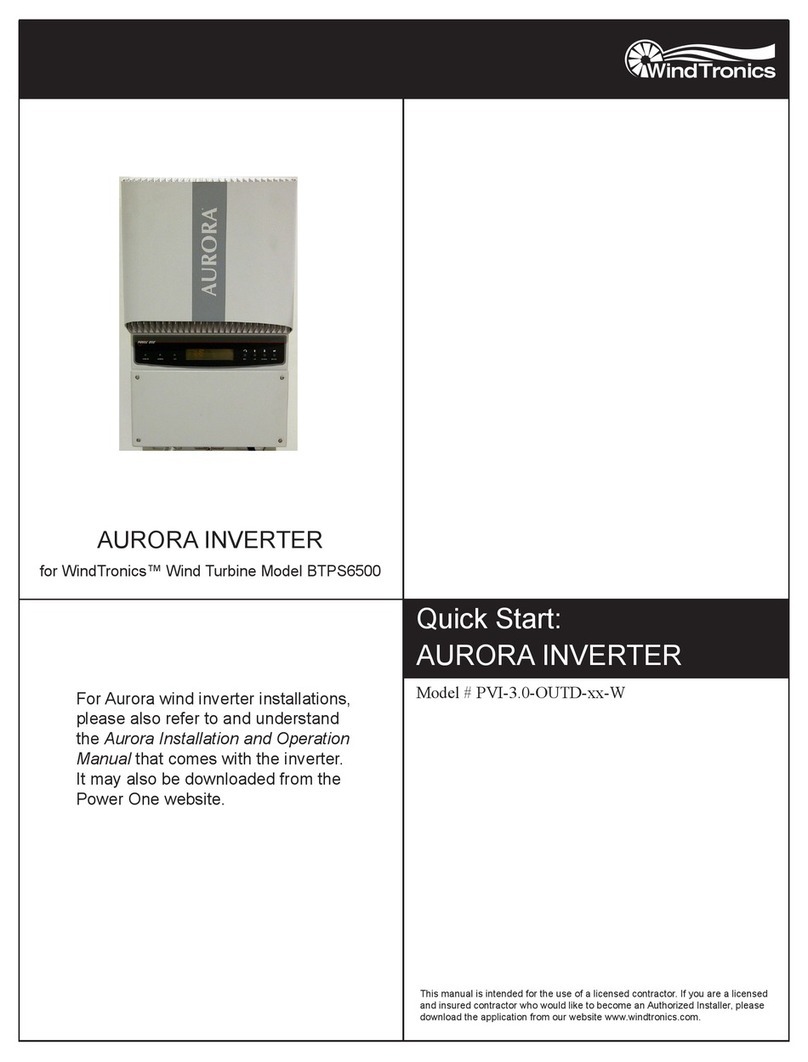

WindTronics

WindTronics AURORA PVI-3.0-OUTD-W quick start guide

UnitedPower

UnitedPower IG3600S instruction manual

Growatt

Growatt SPF3000 Installation and operation manual

SMA

SMA SUNNY ISLAND 4.4M Quick reference guide

Endress

Endress ESE 30YW/RS Original operating manual

Mitsubishi Electric

Mitsubishi Electric FR-A8AP instruction manual

Growatt

Growatt SPH TL BL-UP Series installation manual

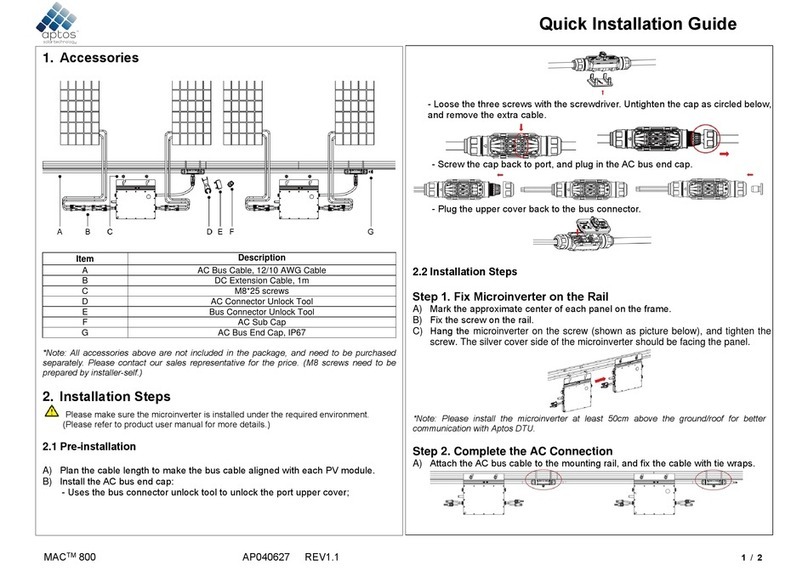

aptos

aptos MAC 800 Quick installation guide

Trotec

Trotec AIROZON 10000 Original instructions