Steamist TSG-15 User manual

01/09 Pub. No. 200-A

- 1 -

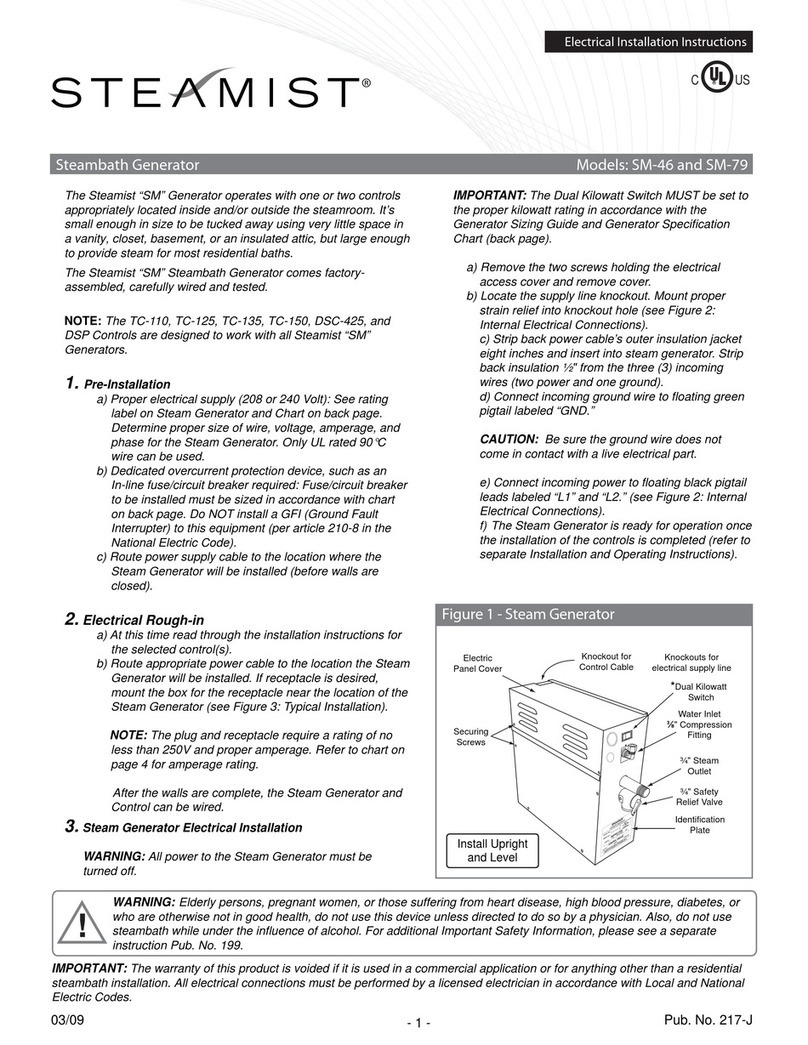

Optional Auto

Drain Installed

Model TSG-AD

Water Inlet

⅜" Compression

Fitting

¾" Safety

Relief Valve

¾" Steam

Outlet

Electrical

Panel Cover

Knockouts for

Electrical Supply Line

Knockout for

Control Cable

Install Upright

and Level

®

CUS

®

WARNING: Elderly persons, pregnant women, or those suffering from heart disease, high blood pressure, diabetes, or

who are otherwise not in good health, do not use this device unless directed to do so by a physician. Also, do not use

steambath while under the influence of alcohol.

!

IMPORTANT: The warranty of this product is voided if it is used in a commercial application or for anything other than a residential

steambath installation. All electrical connections must be performed by a licensed electrician in accordance with Local and National

Electric Codes.

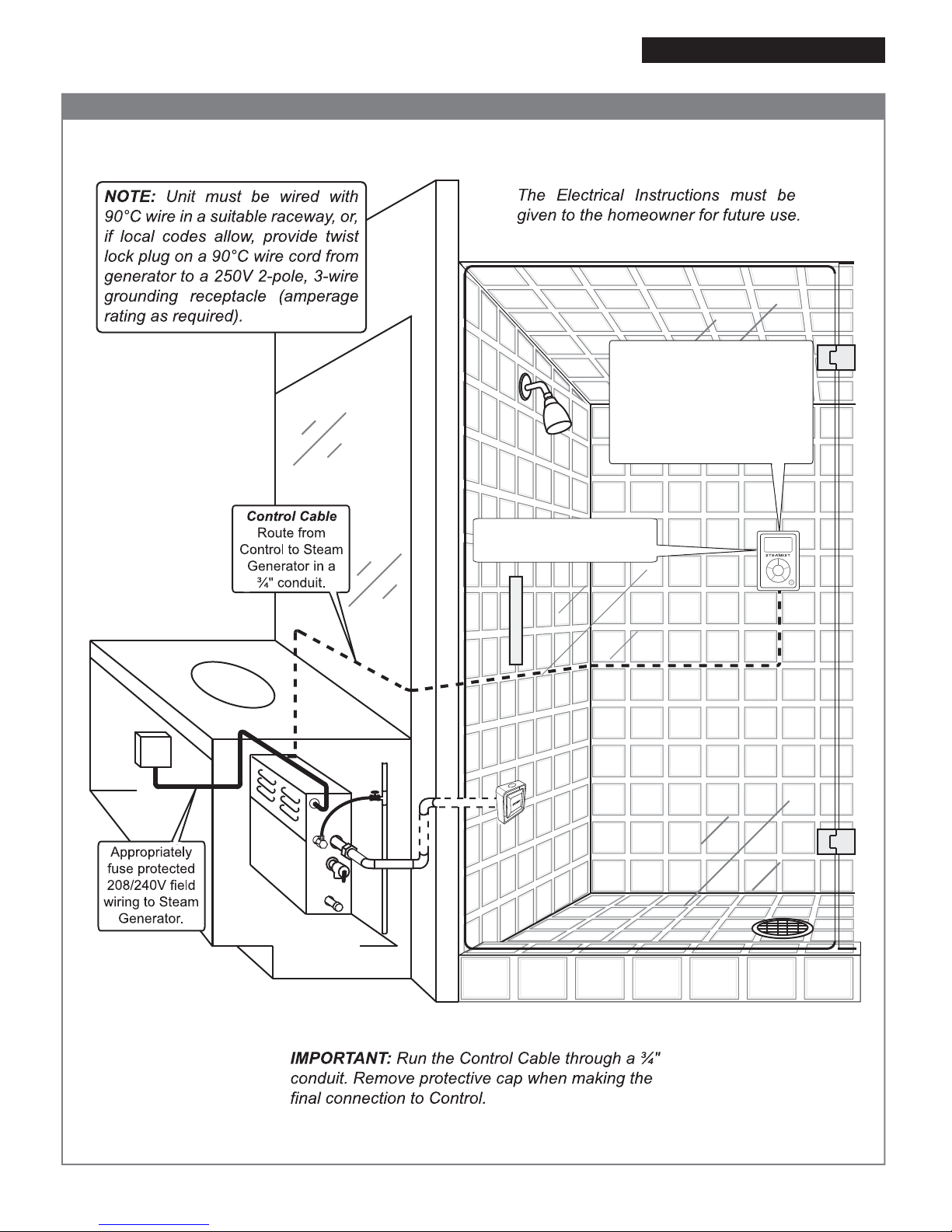

Electrical Installation Instructions

Steambath Generators Model: TSG-15

The Steamist “TSG” Generator operates with a TSC control

mounted inside and optional TSR remote control located outside

the steamroom. It’s small enough in size to be tucked away using

very little space in a vanity, closet, or basement, but large

enough to provide steam for most residential baths.

The Steamist “TSG” Steambath Generator comes factory

assembled, carefully wired and tested.

NOTE: The “TSG” Generators are designed only to work with

the"TSC" Control.

1. Pre-Installation

a) Proper electrical supply (208 or 240 Volt): See rating

label on Steam Generator and Chart on page 4.

Determine proper size of wire, voltage, amperage, and

phase for the Steam Generator. Only UL rated 90°C

wire can be used.

b) In-line fuse/circuit breaker required: Fuse/circuit breaker

to be installed must be sized in accordance with chart

on back page. Do NOT install a GFI (Ground Fault

Interrupter) to this equipment (per article 210-8 in the

National Electric Code).

c) Route power supply cable to the location where the

Steam Generator will be installed (before walls are

closed).

2. Electrical Rough-in

a) Route appropriate power cable to the location the Steam

Generator will be installed. If receptacle is desired,

mount the box for the receptacle near the location of

the Steam Generator (see Figure 3).

NOTE: The plug and receptacle require a rating of no

less than 250V and proper amperage. Refer to chart on

page 4 for amperage rating.

After the walls are complete, the Steam Generator and

Control can be wired.

3. Steam Generator Electrical Installation

WARNING: All power to the Steam Generator must be

turned off.

a) Remove the four screws holding the electrical access

cover and remove cover.

b) Locate the supply line knockout. Mount proper

strain relief into knockout hole.

c) Strip back power cable’s outer insulation jacket

eight inches and insert into Steam Generator.

Strip back insulation ½" from the three (3)

incoming wires (two power and one ground).

d) Insert ground wire into grounding lug located

on the right side of the electrical compartment

and secure.

CAUTION: Be sure the ground wire does not

come in contact with a live electrical part.

e) Locate the terminal/fuse block in the upper portion

of the electrical box. Insert power wires into the

power lugs on the back of the terminal/fuse block

and secure.

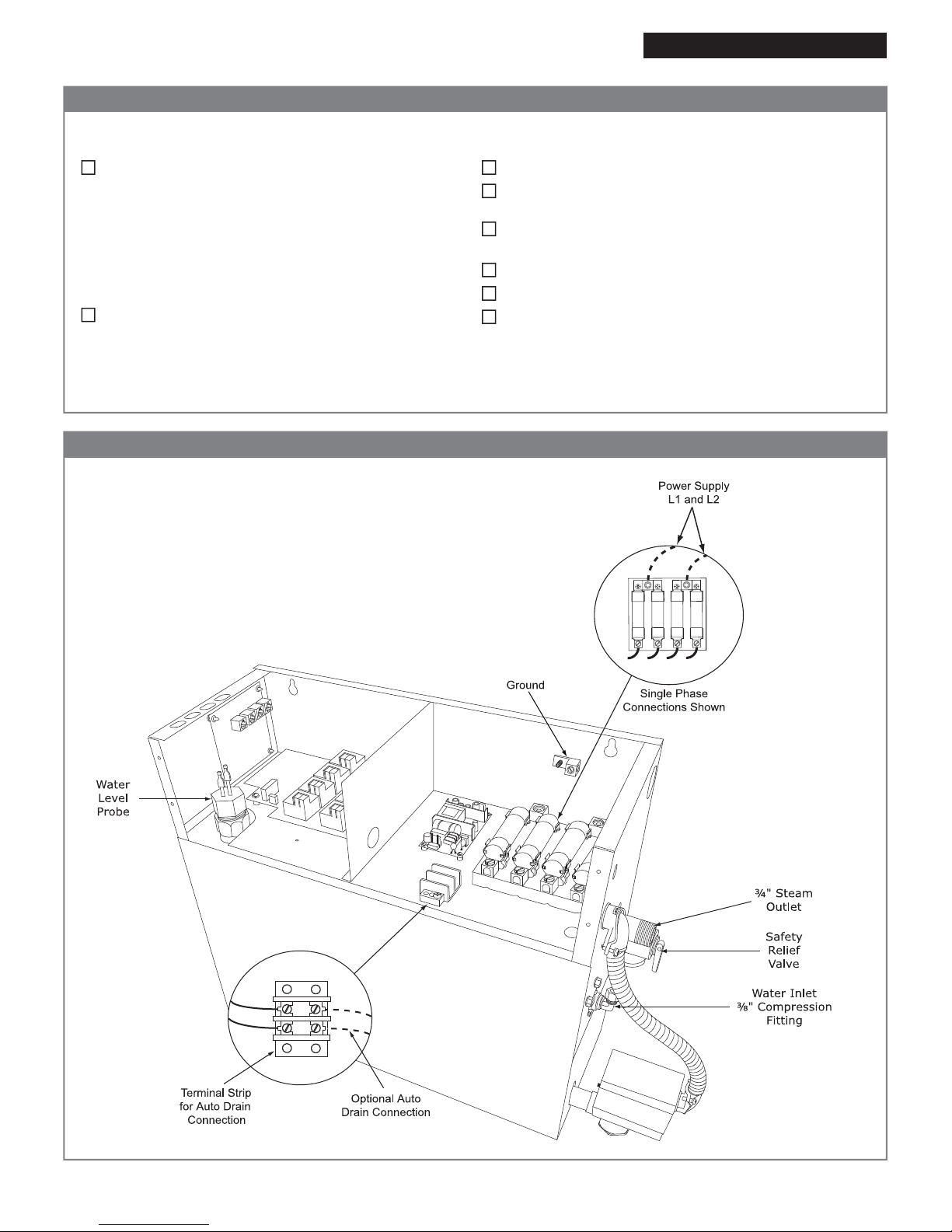

4. Optional Auto Drain Valve Connection

a) Open knockout for Auto Drain Valve conduit

connection.

b) Route flexible conduit from valve to knockout and

secure.

c) Connect two wires from valve to the two place

terminal strip provided (see Figure 2).

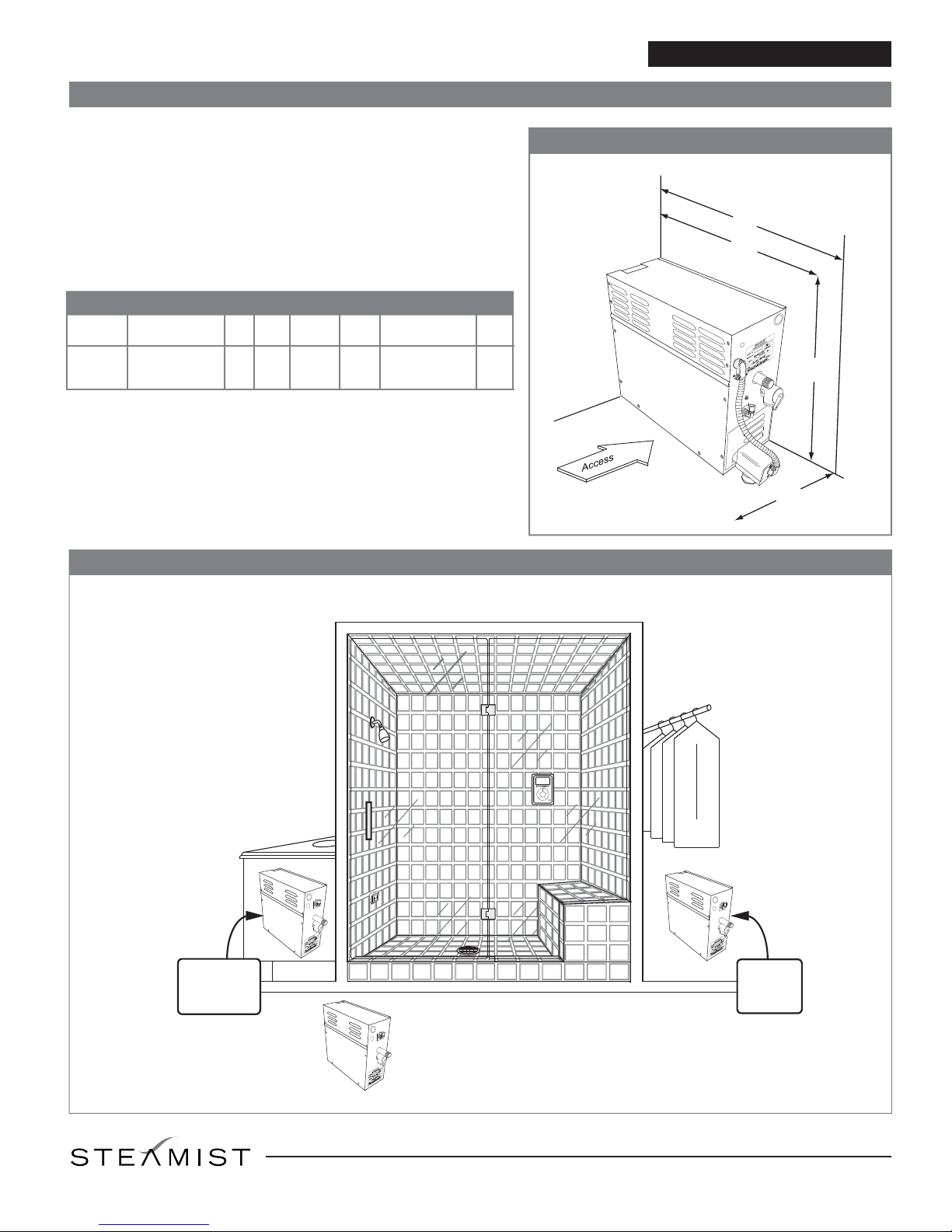

Figure 1 - Steam Generator

®

01/09 Pub. No. 200-A

- 2 -

®

®

The Steam Generator is installed in an upright position.

The proper sized 90°C wire and circuit breaker have

been used.

The circuit breaker is NOT a GFI (Ground Fault

Interrupter) type.

The Steam Generator is properly grounded.

The circuit breaker or disconnect switch is on.

Water supply is open to the Steam Generator.

Electrical Installation Instructions

Checklist Models: TSG-15

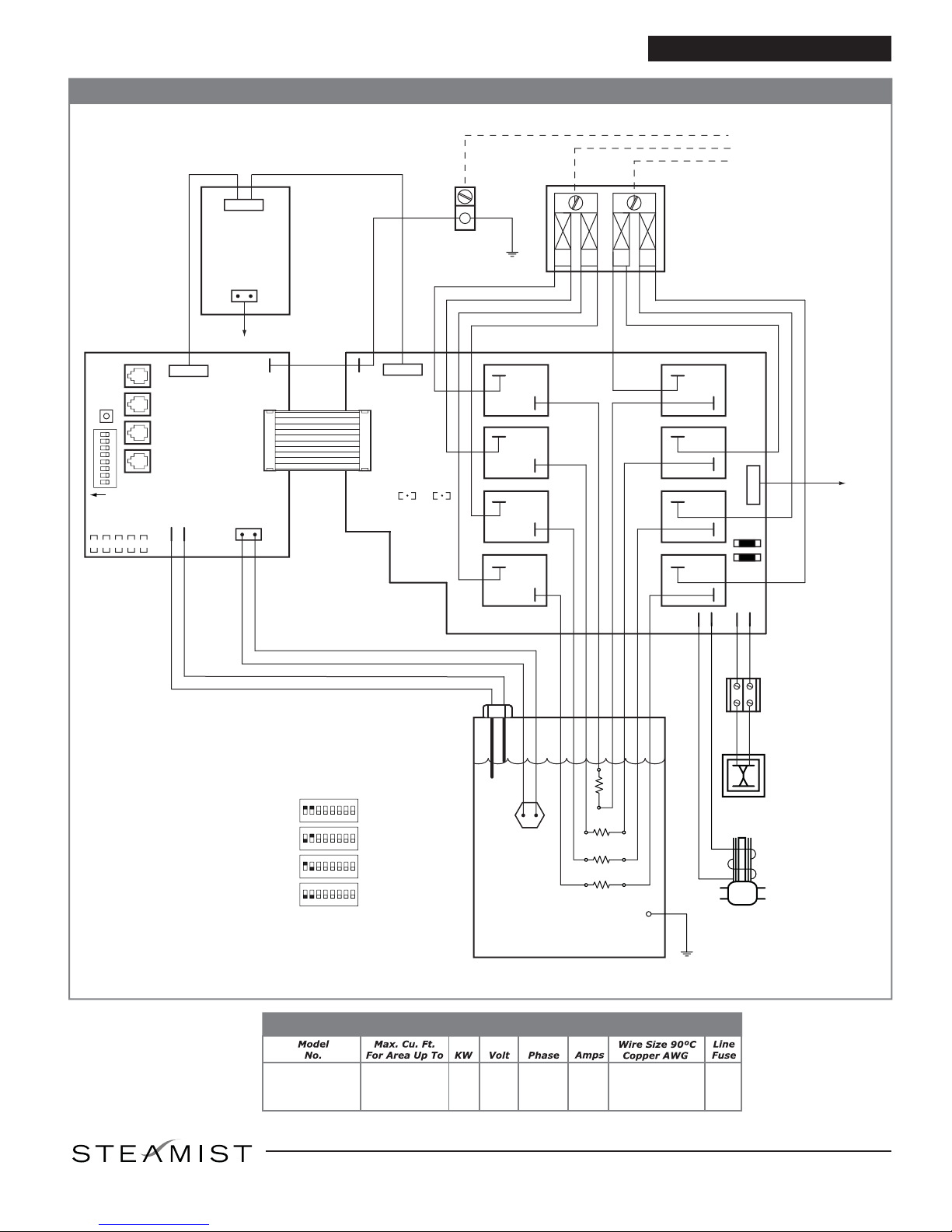

Figure 2 - Internal Electrical Connections

Before starting, insure that the conditions of the following checklist have been met:

The proper size Steam Generator has been selected by

using the sizing page in the “Full Line Brochure,” “Pricing

Guide,” or “The Generator Sizing Guide” in the Residen-

tial Systems/Steambath Product Information section of

the Steamist website - www.steamist.com.

CAUTION: An improperly sized Steam Generator will

NOT produce the amount of steam necessary to reach

selected temperature.

The proper voltage Steam Generator has been selected

(i.e., 208V or 240V). A 208V Generator operating on

240V will damage the heating element, and a 240V

Generator operating on 208V will result in a 25%

loss of power.

01/09 Pub. No. 200-A

- 3 -

^

^

MENU

^

^

^

^

12

®

Electrical Installation Instructions

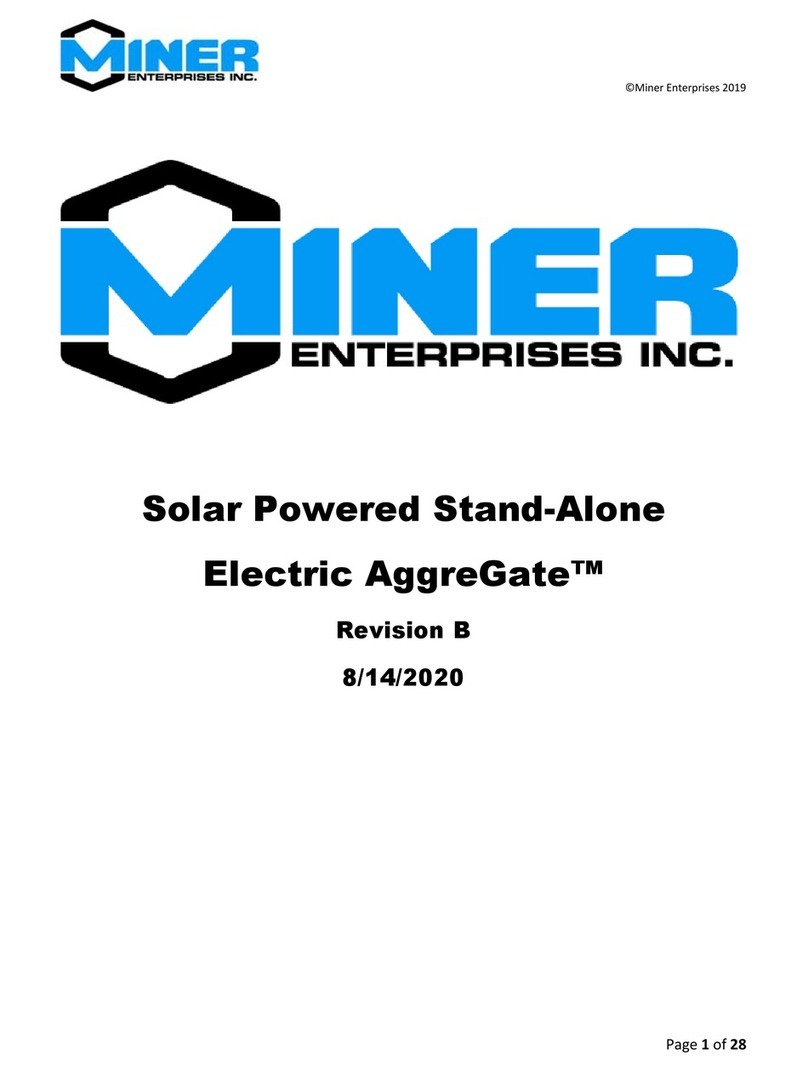

Figure 3 - Typical Installation Models: TSG-15

The TSC Control MUST be

installed inside (Required).

Inside Installation

Control should be mounted

four feet from the floor. Select a

location convenient to the

bather but not in a direct line of

Shower or Body sprays and not

directly above the steam head.

- 4 -

®

01/09 Pub. No. 200-A

®

Dip Switch Settings for Multiple Steam Generators on

Processor Board:

Generator 1 = 1 and 2 up

Generator 2 = 1 down and 2 up

Generator 3 = 1 up and 2 down

Generator 4 = 1 and 2 down

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

Electrical Installation Instructions

Board

Interconnect

A C Relay

Board

Board

Interconnect

Sensor

Probe

15VDC

15 VDC

Power Supply

250VAC

From 240

A C Relay PCB

240VAC

To 250VAC

on P/S Board

Note: Ground must be

on a heater flange

bolt.

Water

Solenoid

Valve

Terminal

Block

Optional

Auto Drain

Valve

Water Level Probe

Fuse Block

WH

GY

GN

BL

BL

BN

BN

BK

BK

Ground

Lug

RH2_L1

RH3_L1

RH4_L1

RH1_L1

RH2_L2

RH3_L2

RH4_L2

RH1_L2

F1

F2

Heating

Elements

Sensor

L1

L2

GND Field

Connections

P1P2

RD

RD

RD

RD

RD

RD

RD

BK

BK

BK

RD

BK

BK

BK

BK

BK

15VDC

15VDC Out

Tank

Frame

GND

Processor

Board

P1

P2

P3

P4

0.5

AMP

Wiring Diagram Model: TSG-15

TSG-15 550 15 240

208 1

163

72 4

480

90

Specication Chart

1 2 3 4 5 6 7 8

UP

GN

GN

P3

GND

Fill

Light Drain

Light

Test

Switch

DS1

DS2

DS3

DS4

DS5 WDT FAIL

COM FAIL

SYS FAIL

TEST

SYS OK

25 E. Union Ave., East Rutherford, NJ 07073 • Tel: 800-577-6478 • Fax: 201-933-0746

West Coast Office: 315 W. Pondera St., Suite F, Lancaster, CA 93534 • Tel: 800-355-6478 • Fax: 661-940-1617

®

02/09 Pub. No. 201-A

- 1 -

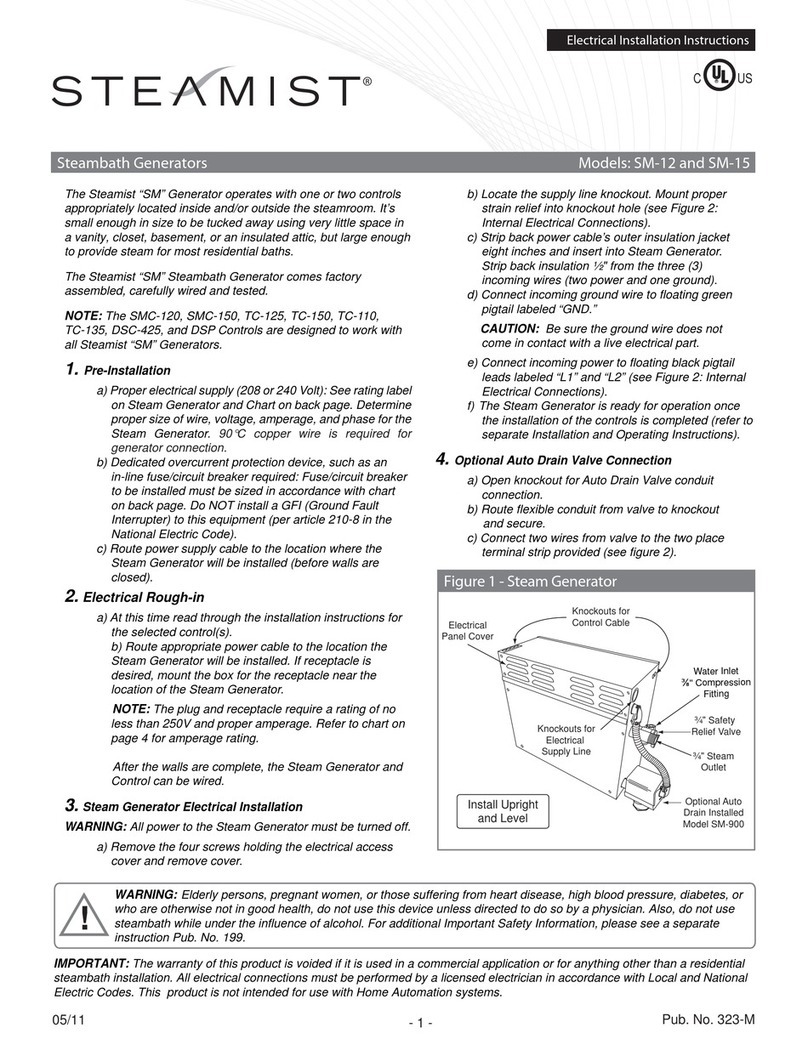

Optional Auto

Drain Installed

Model TSG-AD

Water Inlet

⅜" Compression

Fitting

¾" Safety

Relief Valve

¾" Steam

Outlet

Electrical

Panel Cover

Knockouts for

Electrical Supply Line

Knockout for

Control Cable

Install Upright

and Level

®

®

®®

C US

®

WARNING: Elderly persons, pregnant women, or those suffering from heart disease, high blood pressure, diabetes, or

who are otherwise not in good health, do not use this device unless directed to do so by a physician. Also, do not use

steambath while under the influence of alcohol.

!

IMPORTANT: The warranty of this product is voided if it is used in a commercial application or for anything other than a residential

steambath installation.

Plumbing Installation Instructions

Steambath Generators Model: TSG-15

The Steamist “TSG” Generator comes factory assembled,

carefully wired and tested.

The Plumbing Installation must conform to local and national

codes. All electrical power should be turned OFF when working

with Steam Generator.

1. Pre-Installation

a) Be sure that the proper size Steam Generator has been

selected by using the sizing page in the “Full Line

Brochure,” “Pricing Guide,” “The Generator Sizing

Guide,” “Architectural Guidelines,” or in the Residential

Systems/Steambath Product Information section of the

Steamist website - www.steamist.com.

CAUTION: An improperly sized Steam Generator may

NOT produce the amount of steam necessary to reach

selected temperature.

IMPORTANT: Refer to page 4 for model required for

cubic foot rating.

b) The Steam Generator should be located as close as

possible to the Steamroom/Shower or tub enclosure.

Steam pipe should NOT exceed twenty-five feet in length.

If the steam pipe exceeds ten feet, use an appropriate

pipe insulation rated for a minimum of 212°F. Possible

locations include Vanity, Closets, or Basement near bath

area. The serial number plate should be visible and the

Steam Generator should be accessible for service. Refer

to Installation Suggestions on page 4. Do NOT install

Generator outdoors, in a moist, humid area, or in an area

where parts may freeze or corrode. Also, do NOT install

near flammable materials such as paints, thinners,

gasoline, etc.

c) The steam line and safety valve reach a temperature of

212°F during operation and should be appropriately

protected to prevent personal injury by accidental

contact.

2. Plumbing Rough-in

Plumbing is required for the water supply and steam

line this should be completed before the walls are

closed. For operation, the “TSG” Steam Generator

requires a ⅜" O.D. copper tubing to the fitting on the

Generator for water inlet and a ¾" copper or brass

pipe for steam outlet.

NOTE: Safety Valve should be connected to a minimum ¾"

indirect waste or as required by local plumbing codes. In

the unlikely event this valve should open, the discharge

must be directed to prevent damage to the home.

a) Water Inlet - A water line should be roughed in

from existing ½" hot or cold water pipe. Using a ½"

x ⅜" tee, cut and solder tee into the existing water

line (see Figure 4 on page 3). Solder a piece of ⅜"

copper tubing into tee. Rough-in for water supply is

now complete.

b) Steam Outlet - Rough in the steam line using a

minimum of a ¾" copper or brass pipe; do NOT

use black iron or galvanized pipe; it will rust and

discolor the wall of the steambath. The steamhead

location should be 18" above the shower floor or 6"

above the rim of the bathtub, as far from the

seating area as possible.

CAUTION: No shutoff valve can be installed in the steam

line. Do NOT create traps or valleys in this line which would

trap condensation and block the flow of steam. The steam

pipe should be pitched allowing condensation to run back

toward the Steam Generator (preferred), or toward the

steamhead.

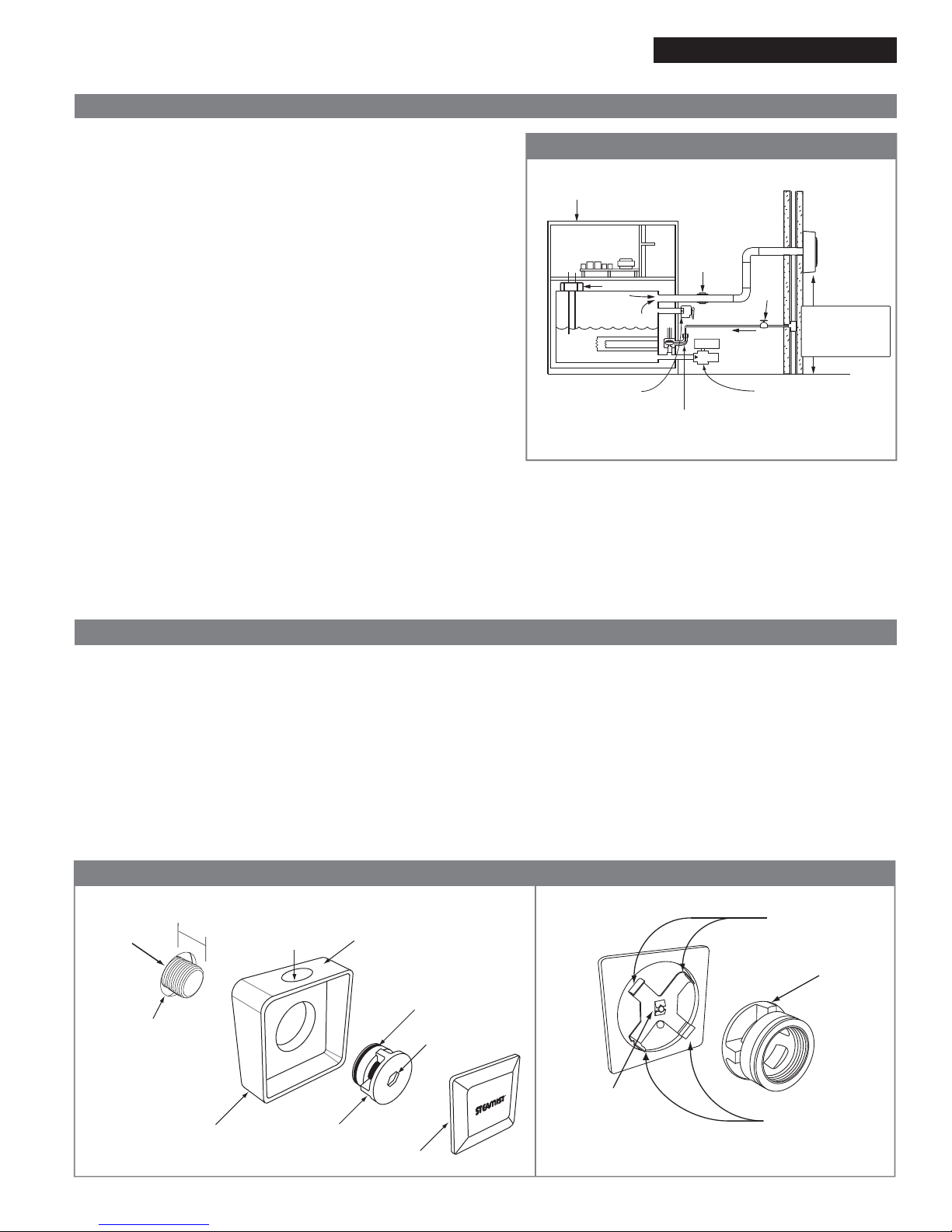

Figure 1- Steam Generator

®

02/09 Pub. No. 201-A

- 2 -

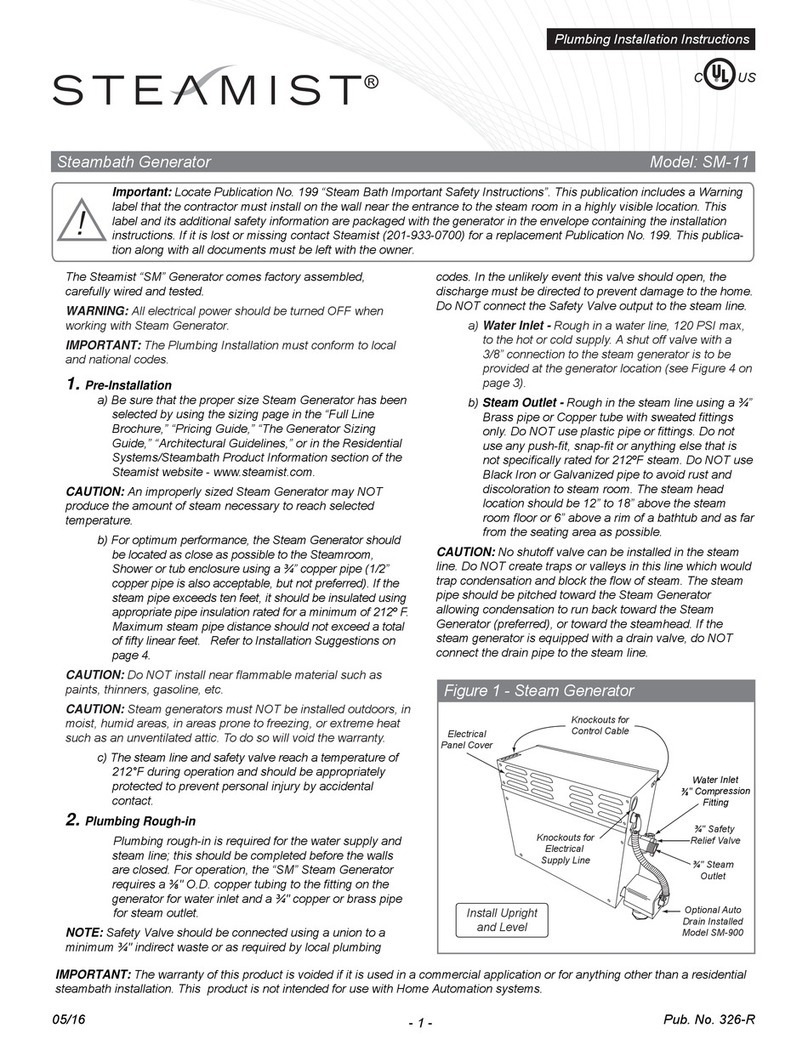

Apply a small

amount of

silicone to

prevent

movement.

Apply a small

amount of

silicone to

prevent

movement.

IMPORTANT:

Install top first

MUST be vertical

After inserting the top,

snap in the bottom.

Cover

Plate

Aromatherapy

Reservoir

Back Plate

O-Ring MUST

seal to inside of

the Back Plate.

Center

Hub

¾" NPT

(Brass Pipe)

Must use sealant

tape.

Apply silicone around

the back edge of the

Back Plate to seal and

prevent movement.

⅜" Hex Key

Hole

Apply silicone

around the steam

pipe to form a

water-tight seal.

½"

Figure 3 - Steamhead Installation Figure 3a - Center Hub Installation

®

Steam Generator

Water Level Probe

Hot or Cold

Incoming Water

Supply

Shutoff

Valve

Union

(Required)

Free-Flowing

Steam Line

Pressure Safety Valve

Connect to Indirect Waste

or As Required by Local Codes.

IMPORTANT: Install

steamhead 18" above

the shower floor or 6"

above the rim of the

bathtub.

Optional Auto Drain Valve

Connect to Indirect Waste

or As Required by Local Codes.

Water Solenoid Valve

®

Plumbing Installation Instructions

3. Steam Generator Installation

The Steam Generator should be mounted in a location convenient

for hook-up and service by the plumber and electrician.

CAUTION: The steam generator is designed to be used ONLY in

an upright and level position, to do otherwise would damage the

unit and void the warranty.

a) The Steam Generator can be mounted to a wall or set

on the floor. However, the unit must be secured. To

secure the unit to a vertical wall, loosen the two screws

holding the electrical access cover, remove cover (see

Figure 1). Located inside the cabinet near the top left

and right corners are mounting holes. Place top cover

back and secure.

b) Connect the 3/8" water supply, described in Section 2, to

the Steam Generator by first soldering a 3/8" valve into

the previously installed water line. The valve must be

kept in an open position during normal operation. In

areas where high water pressure may be a problem a

water hammer arrestor or a pressure regulator should

be installed. Complete water supply by connecting 3/8"

copper tubing from the valve to the water inlet compres-

sion fitting. Refer to Figure 2.

IMPORTANT: Do NOT use a “saddle valve” or piercing

type valve for water connection.

c) Connect the steam line from rough-in location described

in Section 2 to the ¾" nipple on the Steam Generator

using a union.

d) In the shower, place the center of the escutcheon

onto the steam pipe and screw the steamhead into

place. Care must be taken not to scratch the

steamhead or escutcheon with wrench. After the

plumbing connections are complete the electrician

may finish wiring the unit.

Figure 2 - Plumbing Diagram

Installation Instructions

3199 Series Steamhead Installation Instructions

Models: TSG-15

Figure 3

1. Make sure the ¾" nipple protrudes beyond the tile

approximately ½". (See Figure 3)

2. Wrap the nipple with pipe sealant tape.

3. Put a bead of silicone around the outer edge of the Back

Plate (see Figure 3) and center the Back Plate over the pipe

in an upright position. While holding it in place, screw the

Center Hub onto the nipple, using a ⅜" hex key to tighten.

4. The Center Hub MUST be aligned with the four walls in the

vertical and horizontal position (See Figure 3a). Make sure

the steamhead O-ring is fully seated into the Back Plate.

If the nipple is sticking out too far the O-ring will not make

a proper seal and the nipple must be adjusted.

5. Apply a small amount of silicone at the back center point

of the Cover Plate.This will aid in preventing movement

of this plate. (See Figure 3a)

6. Place the Cover Plate over the Center Hub. This is

accomplished by first hooking the top and then snapping

the bottom into place.

7. Adjust the Back Plate and Cover Plate to line up

squarely, and clean excess silicone with rubbing alcohol.

02/09 Pub. No. 201-A

- 3 -

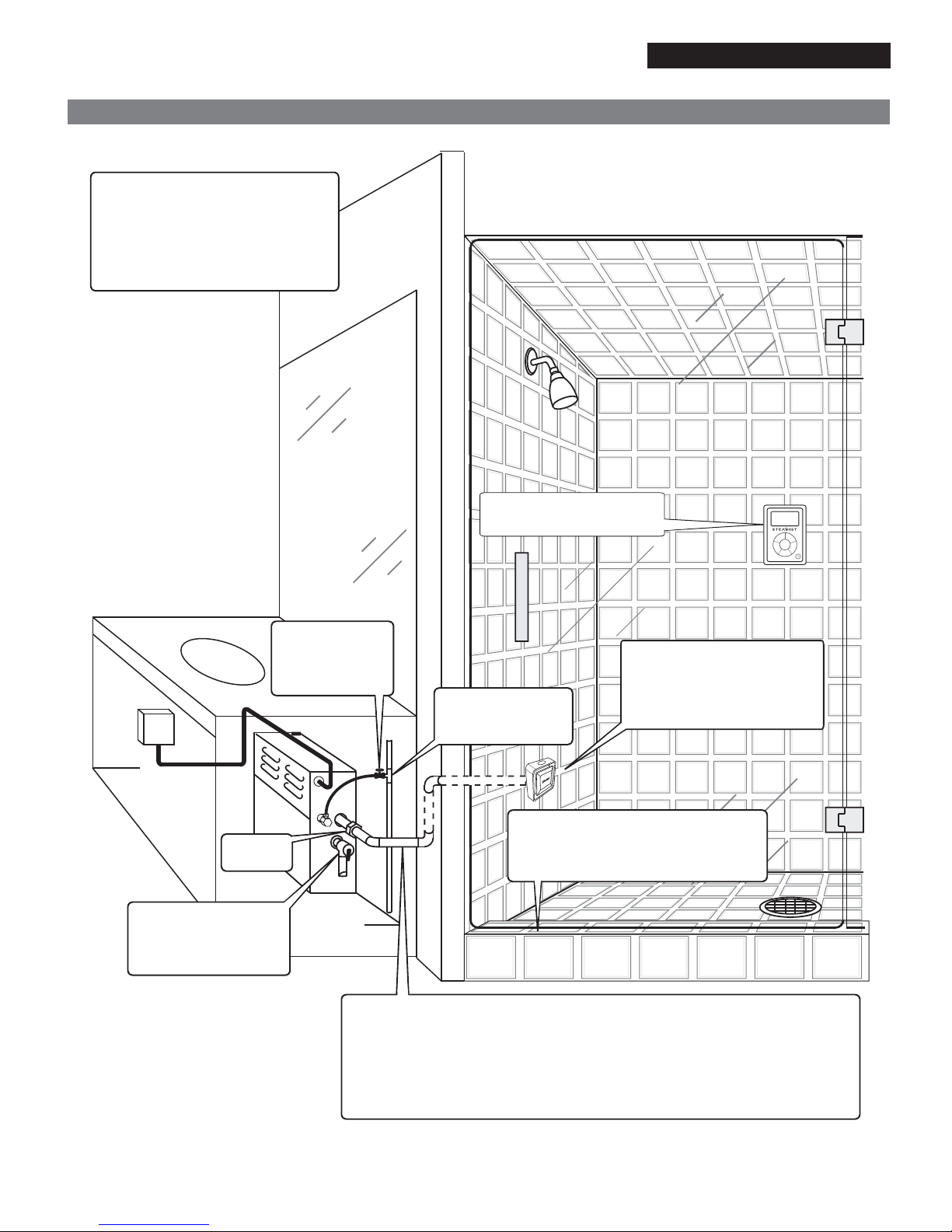

The Plumbing Instructions must be

given to the homeowner for future use.

Slope ceiling 2" per foot

A ⅜" air gap is recommended below the

door and the door should incorporate a

splashguard. The top and sides of the

shower opening must be sealed.

⅜" Shutoff Valve

Keep in open

position during

normal operation.

Steamhead Installation

Steamhead should be mounted

18" above the finished floor or

6" above the rim of the tub as

far from the bather as possible.

½" x ½" x ⅜" Tee.

Using existing Hot or

Cold water supply.

Union

Required

Safety Valve

Connect ¾" pipe to an

indirect waste or as

required by local codes.

WARNING: If installing the

Steamist Unit in conjunction with

an acrylic modular tub/shower unit,

please consult the “manufacturer

of the module” for location of the

steamhead.

Steam Outlet Pipe - Use a minimum of a ¾" Copper or Brass pipe.

CAUTION: Do NOT install a shutoff valve on the steam outlet pipe. Do NOT

create traps or valleys in this line which would prevent the flow of steam.The

steam outlet pipe should be pitched toward the Steam Generator (preferred),

allowing condensation to run back into the Steam Generator or toward the

steamhead. If the steam pipe exceeds ten feet, use an appropriate pipe

insulation rated for a minimum of 212°F.

^

^

MENU

^

^

^

^

12

®

The TSC Control MUST be

installed inside (Required).

®

Plumbing Installation Instructions

Figure 4 - Typical Installation Models: TSG-15

02/09 Pub. No. 201-A

- 4 -

Use 35" with

Optional Auto Drain

35"

28"

25"

18"

®

CAUTION: Do NOT install the steam generator in an attic location.

Alternate Basement Location

(Insulated and Dry)

Steam

Generator

in Vanity

Alternate

Closet

Location

^

^

MENU

^

^

^

^

12

®

Plumbing Installation Instructions

Select a location for mounting the Steam Generator that is

accessible for installation and service. The access requirement

indicates the minimum space for convenient access to Steam

Generator.

CAUTION: All models must be installed INDOORS, in a DRY,

NON-FREEZING location away from flammable materials such

as: Gasoline, Paints, Thinners, Etc.

IMPORTANT: Steam Generator must be installed upright and level.

Figure 5

Access Requirements Model: TSG-15

Installation Suggestions

Model

No. *Max. Cu. Ft.

For Area Up To KW Volt Phase Amps Wire Size 90ºC

Copper AWG Line

Fuse

*Refer to the Steamist Sizing Guide for actual Cu. Ft. capacity.

TSG-15 550 15 240

208 1

163

72 4

480

90

Specication Chart

East Coast Office: 25 E. Union Ave., East Rutherford, NJ 07073 • Tel: 800-577-6478 • Fax: 201-933-0746

West Coast Office: 315 W. Pondera St., Suite F, Lancaster, CA 93534 • Tel: 800-355-6478 • Fax: 661-940-1617

®

Table of contents

Other Steamist Inverter manuals

Popular Inverter manuals by other brands

Omron

Omron SYSDRIVE 3G3EV SERIES user manual

ABB

ABB PVS-175-TL Series Quick installation guide

Generac Power Systems

Generac Power Systems ECOGEN 005818-0 Features & specifications

Cobra

Cobra CPI 450 operating instructions

Miner

Miner AggreGate manual

Generac Power Systems

Generac Power Systems 004912-0, 004912-1, 004913-0, owner's manual