SteamOvap ISE30 User manual

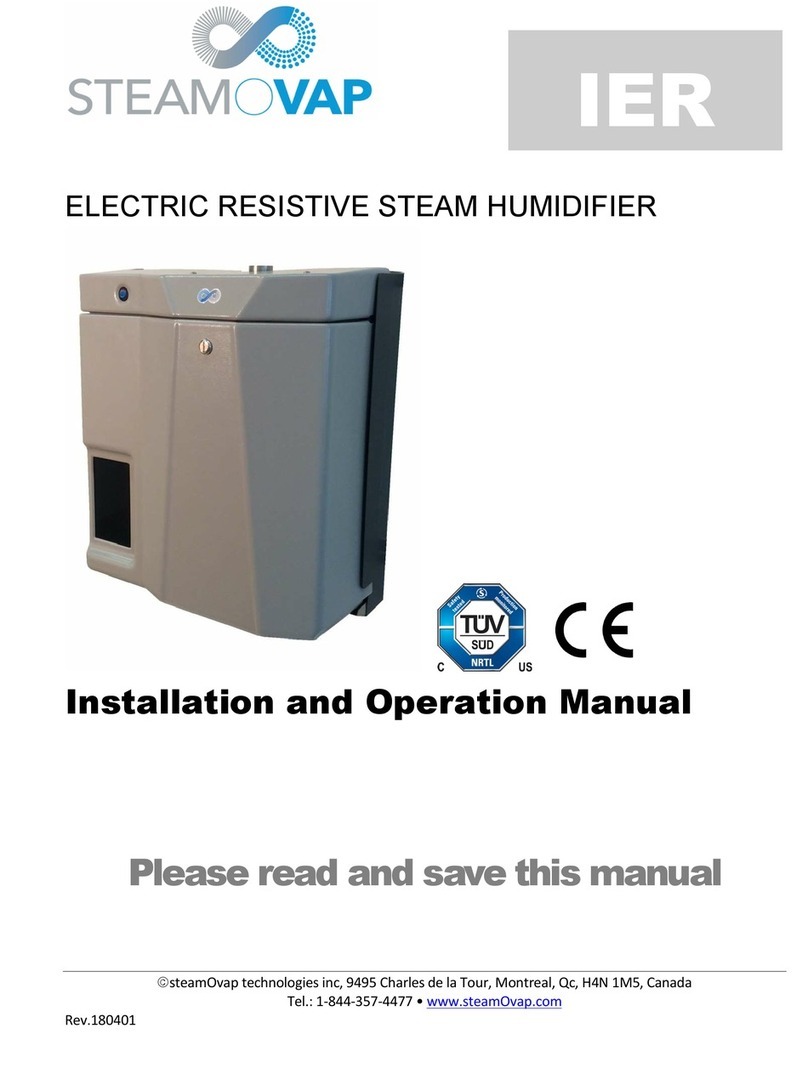

STEAM EXCHANGE HUMIDIFIER

Installation and Operation Manual

Please read and save this manual

steamOvap technologies inc, 1490 Mazuree, Montreal, Qc, H4N 1H2, Canada

Tel.: 1-844-357-4477 • www.steamOvap.com

Rev.200701

ISE

I N T R O D U C T I O N

Introduction

Foreword

Thank you for purchasing ISE steamOvap Steam Exchange Humidifier.

If you have quesons or comments please contact us:

www.steamOvap.com

1-844-357-4477

Description

ISE steam exchange humidifier is a steam generator that uses

pressurized steam heat exchanger to produce pure and sterile

steam at atmospheric pressure that is distributed in air

handling unit or venlaon duct, or directly into space.

ISE humidifier can be supplied with tap or treated water such

as reverse osmosis water or deionized water without alteraon

or addional required opon.

When tap water is used, the scale will come off the heat-

exchanger by the natural contracon and expansion of its

coiled shape tube . Scale pieces then accumulate at the

boom of the cylinder without the risk of clogging the drain

outlet.

Regular maintenance consists in opening and removing the

cylinder and cleaning the accumulated scale off.

ISE unique & patent pending vercal heat-exchanger allows for

very easy regular maintenance that consists in opening and

removing boom part of the cylinder and cleaning the

accumulated scale off without the need of any tool or

consumable.

Main features

Very accurate +/-1% and constant steam producon whatever water condion.

Fully modulang humidifier.

Drain water automacally cooled down at 140°F [60°C].

Pre-heang funcon for quick reacon upon demand.

Steam producon reducon opon.

Permanent stainless steel cylinder with thermal insulaon.

Easy and quick regular maintenance with no tool required.

Log of events and alarms easy to export.

Modbus RTU remote communicaon

Oponal remote communicaon BACnet (RS485)

Three year warranty (when installaon is commissioned by steamOvap authorized

service representave)

3

I N T R O D U C T I O N

Intended use

ISE steam exchange humidifier is intended exclusively to produce steam from water at

atmospheric pressure for air humidificaon.

Operang condions are specified in this Installaon and Operaon Manual (IOM).

Operaon of this humidifier in the intended use scope requires that all direcons and

informaon contained in this IOM are observed.

Any other use or operaon outside the above design scope without wrien authorizaon

from steamOvap may lead to trouble and hazardous condions and will void warranty.

No alteraon or modificaon to the humidifier must be done without wrien authorizaon

from steamOvap.

Replacement of any defecve components must be done with original component and spare

parts from steamOvap representave.

Installation and Operation Manual Limitation

This IOM is intended for trained and qualified personnel and must be applied along with the

applicable local codes and regulaons.

Any work related to installaon or service for this humidifier must comply with local code and

regulaon regarding safety and prevenon of accidents.

End of life disposition

Ensure that ISE steam exchange humidifier is empty from water, if not proceed same way as

for a standard drain for service.

Disconnect ISE steam exchange humidifier from power supply, electrical control signal, water

main supply, Steam line, and drain. ISE steam exchange humidifier can then be removed from

the wall or stand.

ISE steam exchange humidifier is an electrical equipment and as such MUST not be disposed

of in domesc waste.

This humidifier should be returned to the closest steamOvap authorized representave for

proper dismantling, recycling and disposion of components according to local regulaons.

4

Table of content

Introduction................................................................................................3

Table of content.........................................................................................5

Safety warnings.........................................................................................6

Before to proceed to Installation................................................................7

ISE Overview.............................................................................................8

Installation overview................................................................................11

Installation – step 1 Positioning & Mounting............................................12

Installation – step 2 Water supply installation..........................................17

Installation – step 3 Drain installation......................................................19

Installation – step 4 Pressurized steam & condensate installation...........21

Installation – step 5 Steam line installation..............................................23

Installation – step 6 Power supply installation..........................................30

Installation – step 7 Actuated valve connection.......................................31

Installation – step 8 Control installation....................................................32

Verification before start-up.......................................................................34

Configuration & Operation.......................................................................36

Warranty..................................................................................................48

5

S A F E T Y

Safety warnings

General

Risk of electric shock.

Disconnect power supply before installaon or service.

For safety and warranty reasons, Installaon and service of this humidifier should be

carried out by trained and qualified personnel.

Any work related to installaon and service of this humidifier must comply with local code

and regulaons regarding safety and prevenon of accidents.

Electrical Warning

Risk of electric shock.

Disconnect power supply before installaon or service.

Power supply connecon must be done by a trained and qualified electrician.

Any work related to power supply installaon or service of this humidifier must comply

with local code and regulaon regarding safety and prevenon of accidents.

Water safety warning

Any work related to water supply, drain connecon as well as steam lines and condensate

returns lines installaon or service of such for this humidifier must comply with local code

and regulaon regarding safety and prevenon of accidents.

Water supply connecon must be done by a trained and qualified plumber.

Risk of malfuncon. Steam lines should not have any restricon or blockage that

may cause a burst of pressure in the steam line.

Others

Risk of flooding. In order to avoid any risk of flooding steamOvap recommends a Hi

limit humidity switch installed in the air duct downstream of the steam distribuon

ramp.

Risk of freezing. Plan an an-freeze system in case of installaon in a locaon that

would be exposed to outside condions and suscepble of freezing.

Risk of malfuncon. Do not block steam outlet(s).

6

section

0

I N T E N D E D U S E

Before to proceed to Installation

Please read this Installation and Operation manual before to proceed to the Installation

Receiving & Unpacking

1. Upon receipt verify that packaging is complete and not damaged.

In case of damage, and/or missing boxes advise immediately the carrier by wring a

note on the waybill.

2. Verify that model of the humidifier matches the purchase order and that all

accessories are included.

3. Any missing item should be reported as soon as possible to steamOvap or its

representave and within 5 business days aer receipt.

steamOvap will not assume any responsibility for missing item aer this delay.

4. Proceed carefully to unpacking, and check that the humidifier and its accessories are

not damaged. in case of damage please proceed as for point 3

Included in standard delivery of ISE steam exchange

humidifier

1. ISE steam exchange humidifier

2. Water supply hose

3. Collar(s) to secure steam hose on steam outlet of ISE

4. 1-1/4in flexible hose for easy connecon to the drain outlet

5. Actuated control valve for pressurized steam input

6. Strainer to be installed on pressurized steam inlet upstream the actuated control valve

7. Float & Thermostac condensate trap for condensate return fro heat exchanger.

8. This IOM

Depending on other accessories ordered

9. Steam ramp(s)

10. Steam hose

11. Condensate hose

12. RH% sensors for duct or room

13. HI Limit RH% switch

14. Air flow switch

15. Condensate temperature switch

7

section

1

O V E R V I E W

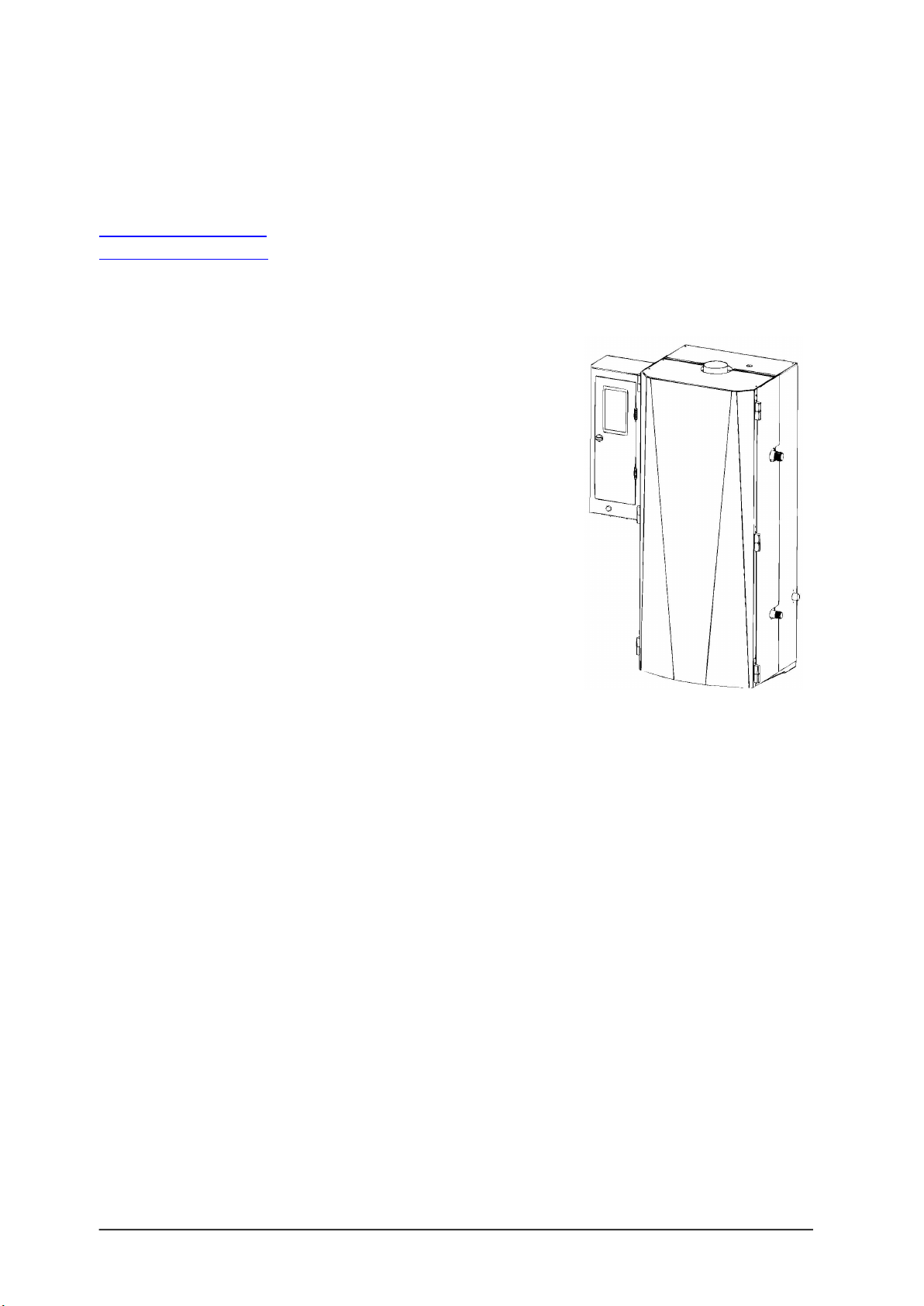

ISE Overview

ISE steam exchange humidifier

Figure 1 – ISE Overview

ISE product designation & name plate

Figure 2 –ISE Name plate

8

section

2

O V E R V I E W

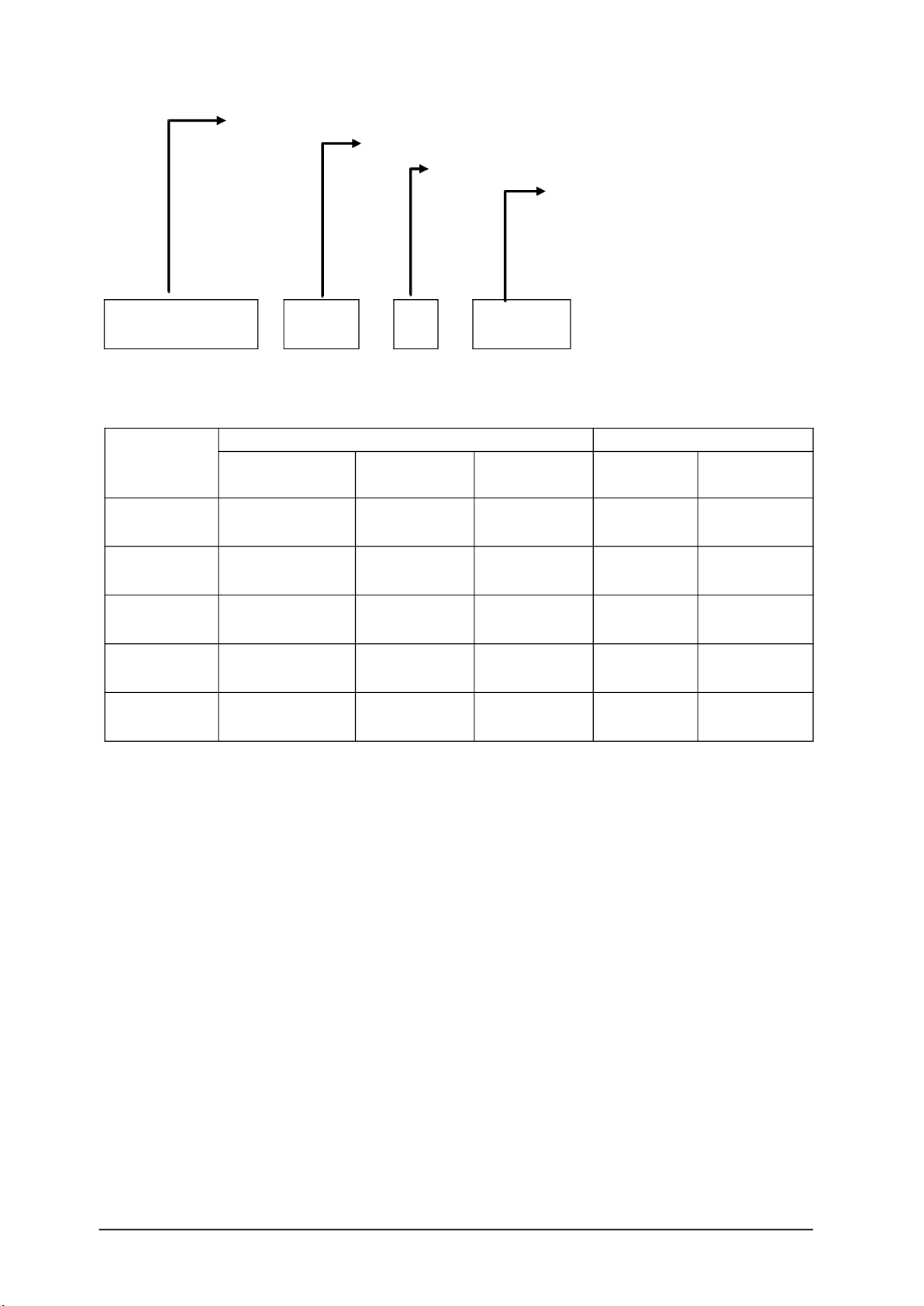

Model designation and options codification

Type & Model

Nominal Voltage

Nb of Phase

Opons

MB Mounng Bracket

FS Floor Stand

BBACnet RS485

RT Roof top enclosure

ISE 100 - 120 / 1 - MB

ISE capacity & power requirement

Model

Steam Capacity Power requirement

5PSI

[34kPa]

10PSI

[69Kpa]

15PSI

[103kPa] Power Voltage

ISE30 4lb/h

[1.8kg/h]

15lb/h

[6.8kg/h]

30lb/h

[13.6kg/h] 100W 120Vac/1ph

or 240/1ph

ISE60 7b/h

[3.2kg/h]

30b/h

[13.6kg/h]

60b/h

[27.3kg/h] 100W 120Vac/1ph

or 240/1ph

ISE100 12b/h

[5.4kg/h]

50b/h

[22.7kg/h]

100b/h

[45.4kg/h] 100W 120Vac/1ph

or 240/1ph

ISE200 24lb/h

[10.9kg/h]

100lb/h

[45.4kg/h]

200lb/h

[90.9kg/h] 100W 120Vac/1ph

or 240/1ph

ISE400 48lb/h

[21.8kg/h]

200lb/h

[90.9kg/h]

400b/h

[181.8kg/h] 2x 100W 120Vac/1ph

or 240/1ph

9

O V E R V I E W

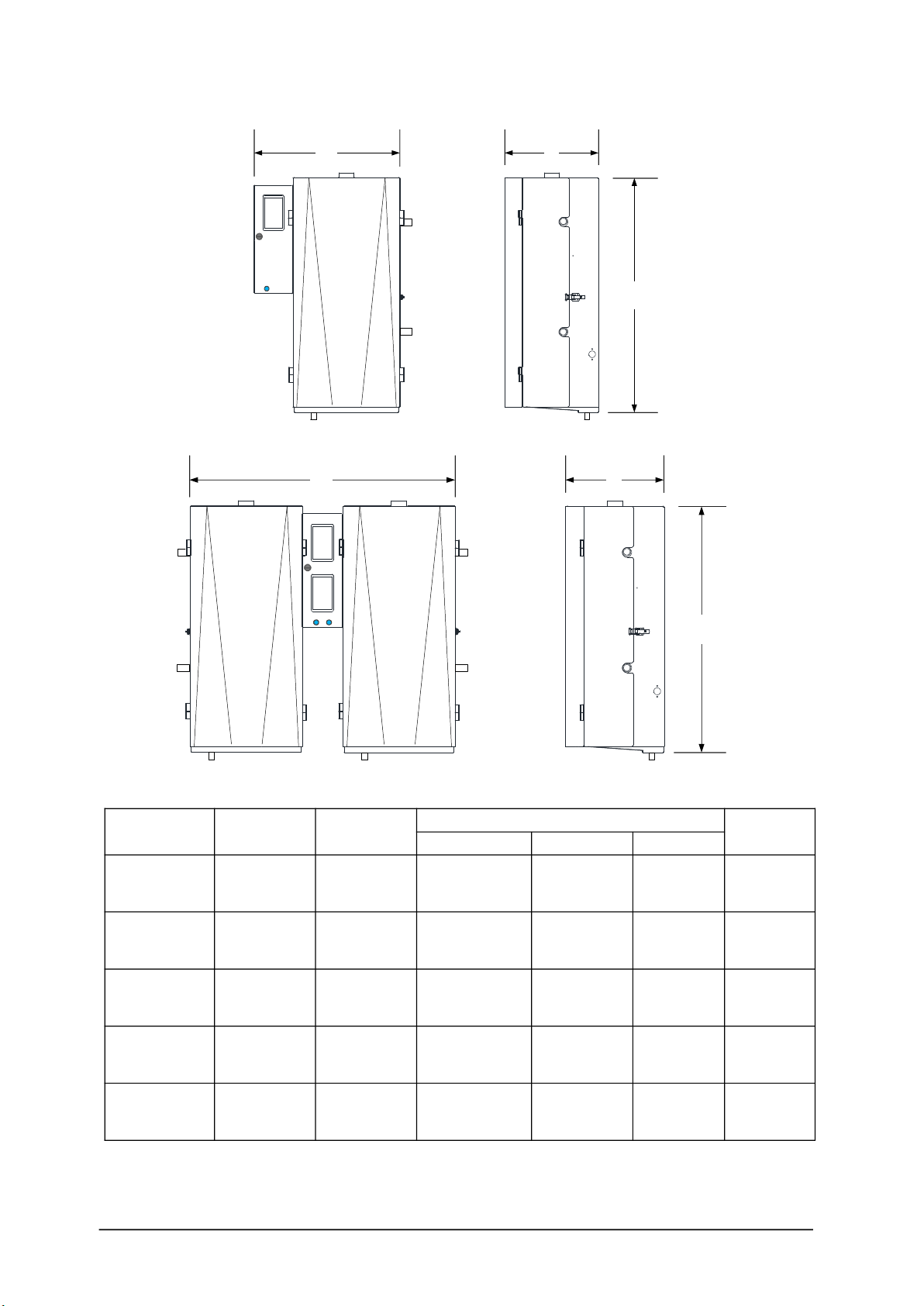

ISE Dimensions

W

H

D

Figure 3 – ISE Dimensions , single module

W

H

D

Figure 4 – ISE Dimensions , two modules , model ISE400

Model Nb Cyl

+ size

Nb Steam

Outlet + Ø Dimensions Net

weight

W H D

ISE30 1x

small

1x 2in

[DN40]

27-1/4in

[682mm]

35in

[875mm]

18-1/4in

[456mm]

80lb

[36kg]

ISE60 1x

medium

1x 2in

[DN50]

27-1/4in

[682mm]

35in

[875mm]

18-1/4in

[456mm]

85lb

[38kg]

ISE100 1x

medium

1x 2-1/2in

[DN65]

27-1/4in

[682mm]

40in

[1000mm]

18-1/4in

[456mm]

100lb

[45kg]

ISE200 1x

large

1x 3-1/2in

[DN90]

27-1/4in

[682mm]

46in

[1150mm]

18-1/4in

[456mm]

120lb

[55kg]

ISE400 2x

large

2x 3-1/2in

[DN90]

27-1/4in

[682mm]

46in

[1150mm]

18-1/4in

[456mm]

270lb

[122kg]

10

I N S T A L L A T I O N

Installation overview

General

1. Installaon of this humidifier should be carried out by trained and qualified personnel.

2. Any work related to installaon of this humidifier must comply with local code and

regulaon regarding safety and prevenon of accidents.

WARNING. Risk of electric shock.

Power supply must be disconnected during installaon.

Main power should be connected only aer all installaon steps have been

completed and properly verified.

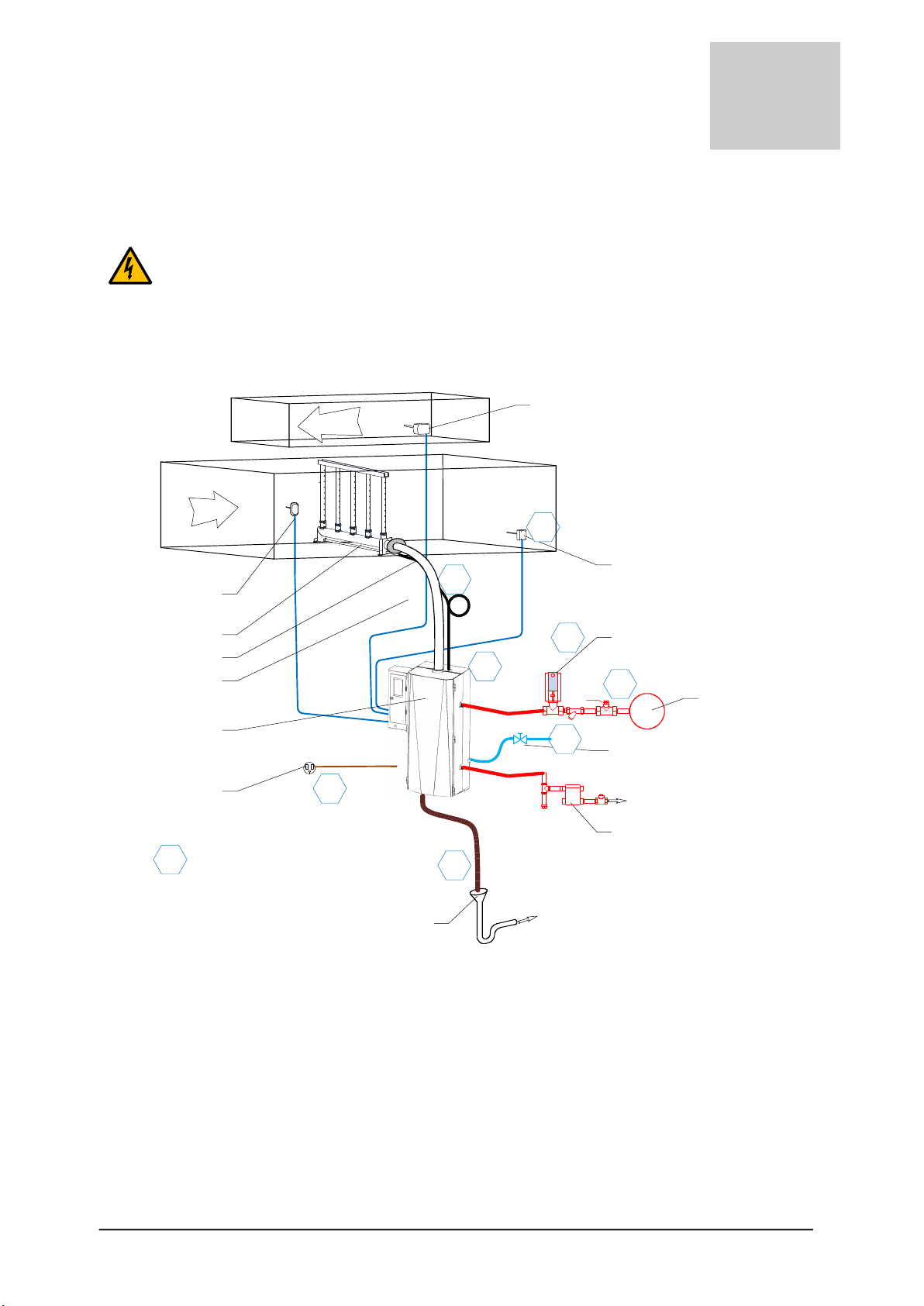

Typical installation with steam ramp

Air

RETURN

RH% Sensor

HI-Limit RH% switch

ISE Steam exchange

Humidifier

Open & deported Drain

with P Trap

Air flow switch

Power supply

Shut-off valve on

water supply line

SOS Mul-ramp

Steam line (hose) 1

2

3

4

5

8

0Installaon steps

Air

SUPPLY

Condensate line

(hose)

6

Control valve

Pressurized steam

(raw steam)

Steam trap

Non pressurized

condensate

Main drain

(waste water)

7

Figure 5 – installaon overview

Typical installation steps:

1. Posioning & mounng of ISE steam exchange humidifier

2. Water supply installaon

3. Drain installaon

4. Pressurized steam & condensate return lines installaon

5. Atmospheric steam line installaon for duct humidificaon

6. Power supply installaon

7. Actuated control valve connecon

8. Safety & RH% control installaon

11

section

3

I N S T A L L A T I O N

Installation – step 1

Positioning & Mounting

General guidelines for positioning

ISE steam exchange humidifier should be posioned so that:

Length of the steam line (or hose) is as short as possible,

In case steam hose is used, the bend radius of 12in (300mm) is ensured

Humidifier is easily accessible for service

CAUTION. Risk of malfuncon due to vibraon. Do Not mount ISE steam exchange

humidifier directly on venlaon duct.

CAUTION. Risk of flooding. Ensure that the local where ISE steam exchange

humidifier will be installed is equipped with floor drain.

In case of no floor drain is available; installaon of a water leak detector is required

in order to prevent any flooding in case of abnormal operaon or service.

ISE steam exchange humidifier should be installed in a well-venlated and dry environment.

If local is subject to below freezing point temperature, acvaon of ant freezing funcon of

the ISE steam exchange humidifier is required.

For outdoor installaon please contact your steamOvap representave to order and install

special outdoor oponal enclosure for IER.

ISE maximum ambient condions:

Temperature: 41°F to 113°F [+5 to +45°C]

Relave Humidity: 90%RH max (non condensing)

Ingress Protecon for ISE standard enclosure: IP20

12

I N S T A L L A T I O N

Clearances

[ ]

[ ]

Min. 36in

900mm

Figure 6 – minimum clearances

Clearance guidelines

There is no minimum clearance on le side of the ISE steam exchange humidifier, but it is a

good pracce to have a clearance of 4 to 8 in [100 to 200mm] for ease of installaon and

service.

Right side clearance of 36in (900mm) minimum is required to the steam exchanger

connecon to steam supply and condensate return piping.

In case of a 2 modules ISE [model ISE400] same clearance, 36in [900mm], is required on both

side of the ISE humidifier.

Allow a minimum clearance of 24in [610mm] with floor to allow for proper drain slope and

drain pipe column.

Top clearance is required of 12in [300mm] for access and proper steam connecon

Front clearance of 30in [762mm] is required for access to the ISE steam exchange humidifier

13

I N S T A L L A T I O N

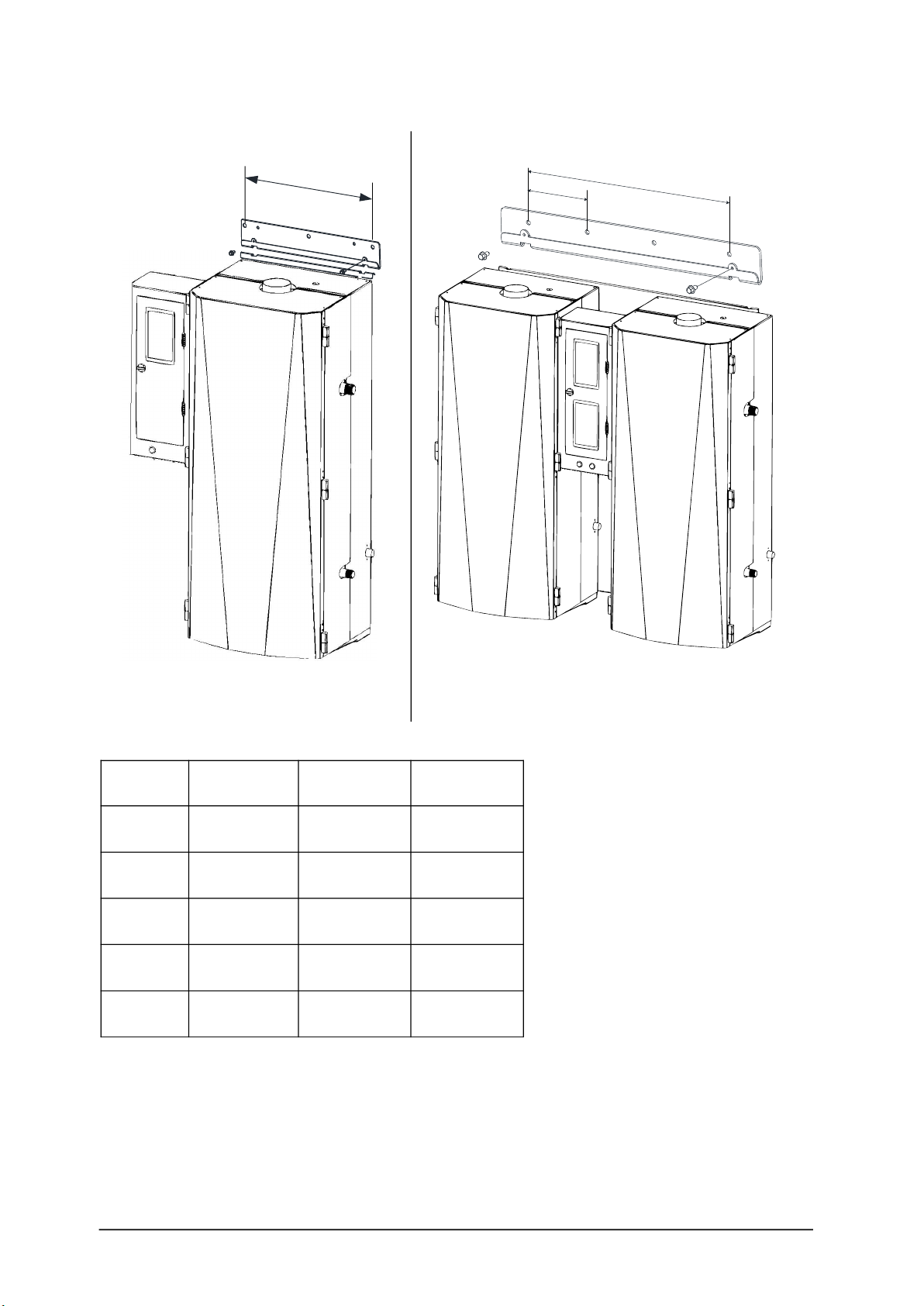

Wall Mounting bracket & weight

15in

[381mm]

Figure 7 mounng bracket for single

module (ISE30 to 200)

36-1/2in [913mm]

12in

[300mm]

Figure 8 – 2 modules mounng bracket

(ISE400)

Weight

Model Nb Cyl + size Net Weight Oper. Weight

ISE30 1x

small

80lb

[36kg]

145lb

[66kg]

ISE60 1x

medium

85lb

[38kg]

159lb

[72kg]

ISE100 1x

medium

100lb

[45kg]

200lb

[91kg]

ISE200 1x

large

120lb

[55kg]

240lb

[109kg]

ISE400 2x

large

270lb

[122kg]

506lb

[230kg]

14

I N S T A L L A T I O N

General guidelines for Mounting

CAUTION. Risk of malfuncon. ISE steam exchange humidifier must be levelled

in X & Z axis.

Installaon on wall, with mounng bracket

1. Verify that wall structure and strength is appropriate to support the operang weight

of the ISE steam exchange humidifier.

In case that wall is not solid enough to support operang weight of ISE humidifier,

install it on a floor stand (FS opon is available to your steamOvap representave).

2. Mark the wall or support according as per below drawing, Drill holes to the wall or

support to aach the mounng bracket to the wall as per the size of anchors and/or

screws.

Distance between the 2 holes in Mounng bracket is 15in [381mm] for ISE30 to ISE200

36-1/2in [913mm] for ISE400

3. Use anchors of sufficient size (at least 3/8in [9m]). Install the mounng bracket to the

wall or support.

Ensure that the mounng bracket is properly levelled.

4. With front cover removed, hung the ISE humidifier onto the mounng bracket.

5. Install the 2 supplied screws to avoid the ISE steam exchange humidifier to move up

from the mounng bracket.

Installaon on Floor Stand (opon FS)

1. Ensure that the floor structure and strength is appropriate to support the operang

weight of the ISE humidifier.

2. Aach the floor stand to the floor or structure to avoid any movement of the ISE

humidifier.

You can use bolt or screws to aach this one to surrounding structure or to the floor.

3. Install Humidifier (with front cover removed) hung the ISE humidifier onto the FS floor

stand and secure it with supplied bolts.

4. Re-install the front cover to the humidifier.

15

I N S T A L L A T I O N

Installation – step 2

Water supply installation

Water supply specification & quality:

Water supply pressure: 15 to 80PSI [1 to 5bar]

Water supply temperature: 37 to 105°F [3 to 40°C]

ISE steam exchange humidifier can accept a wide range of water quality.

Untreated water will lead to scale deposits that will need to be regularly removed from steam

chamber.

Use of addives such as scale inhibitor or corrosion inhibitors, disinfectants or other can

impair the normal operaon of the humidifier and are not allowed.

Water supply conducvity: 1 to 1500µS/cm

Water supply hardness: 0 to 16grains/gallon [0 to 15°gH][268mg CaCO3/l]

Water supply PH: 6.5 to 7.5

Water supply chloride content: 0 to 50ppm

( µ – [ ]

)

[ ]

3/8'

3/4

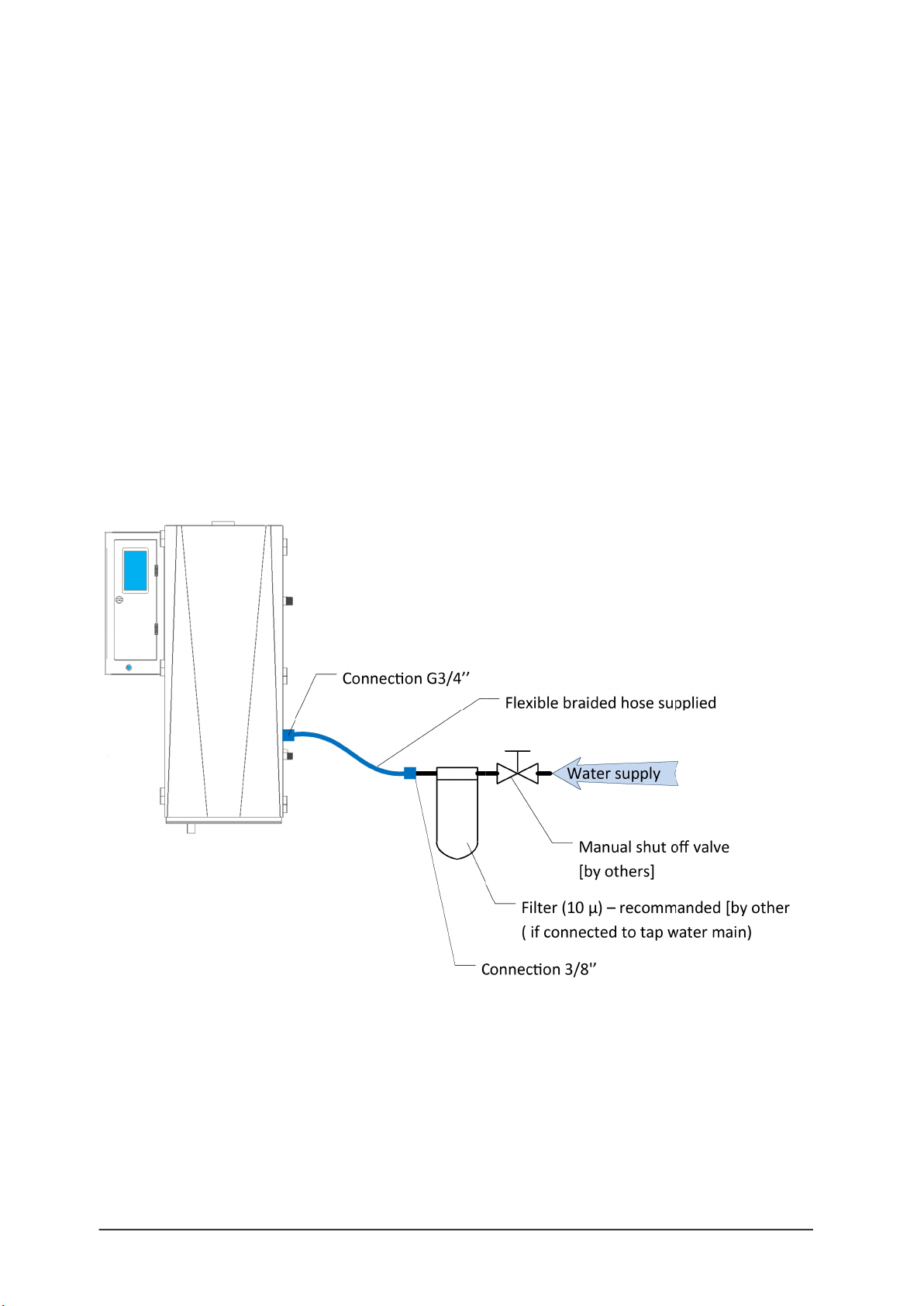

Figure 9 – water supply connecon, single module

16

I N S T A L L A T I O N

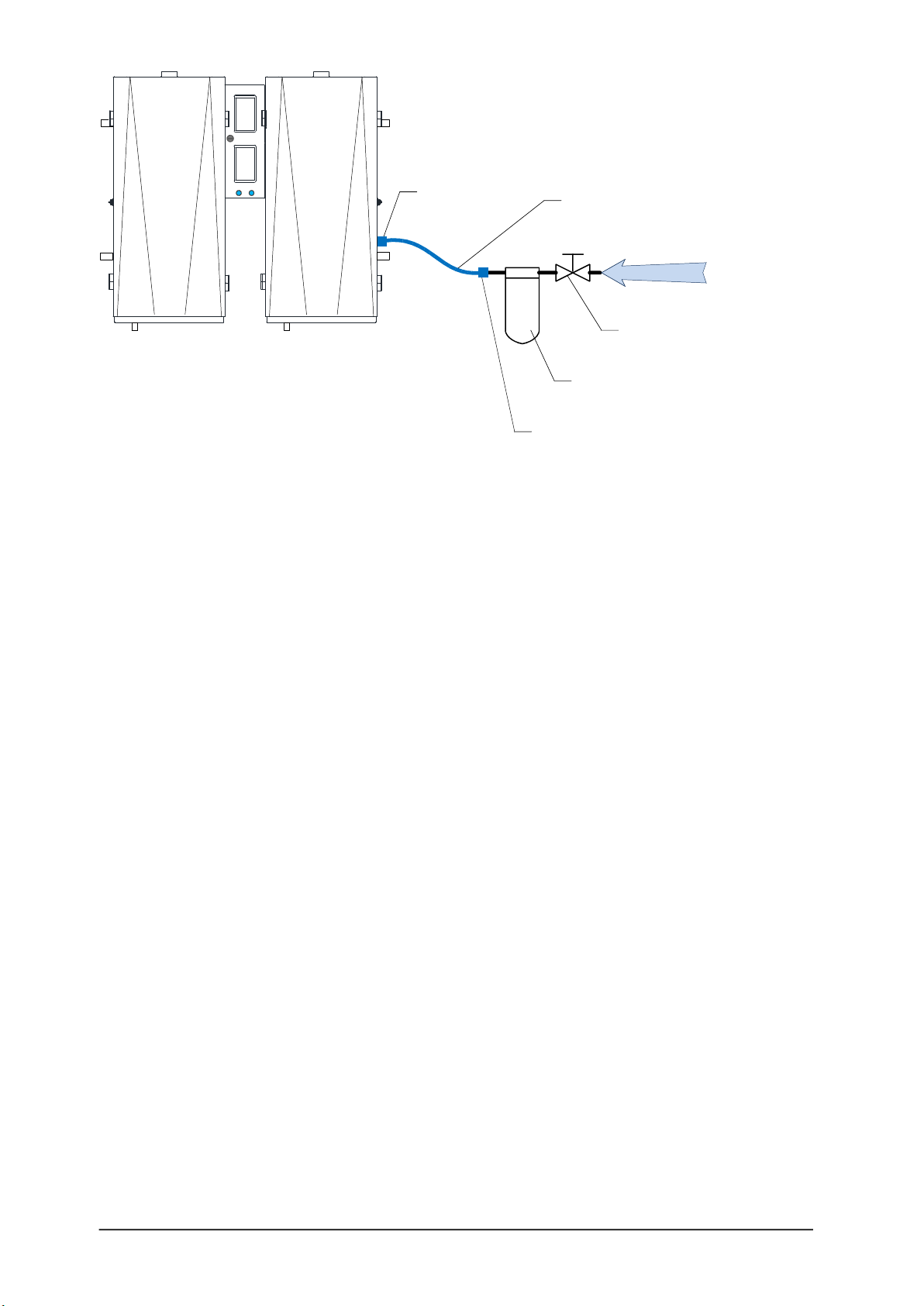

Flexible braided hose supplied

Water supply

Filter (10 µ) – recommanded [by others]

( if connected to tap water main)

Manual shut off valve

[by others]

Connecon 3/8'’

Connecon

NPT½ female

Figure 10 – water supply connecon, 2 modules ISE400

Water supply connection:

1. Install a manual; shut off valve on the water main line.

2. If ISE humidifier is supplied with tap water it is recommended to install a 10µ sediment

filter on the line. This filter will protect internal water fill valve from clogging.

3. A flexible braided hose is supplied for an easy and secure connecon to the water

supply inlet.

17

I N S T A L L A T I O N

Installation – step 3

Drain installation

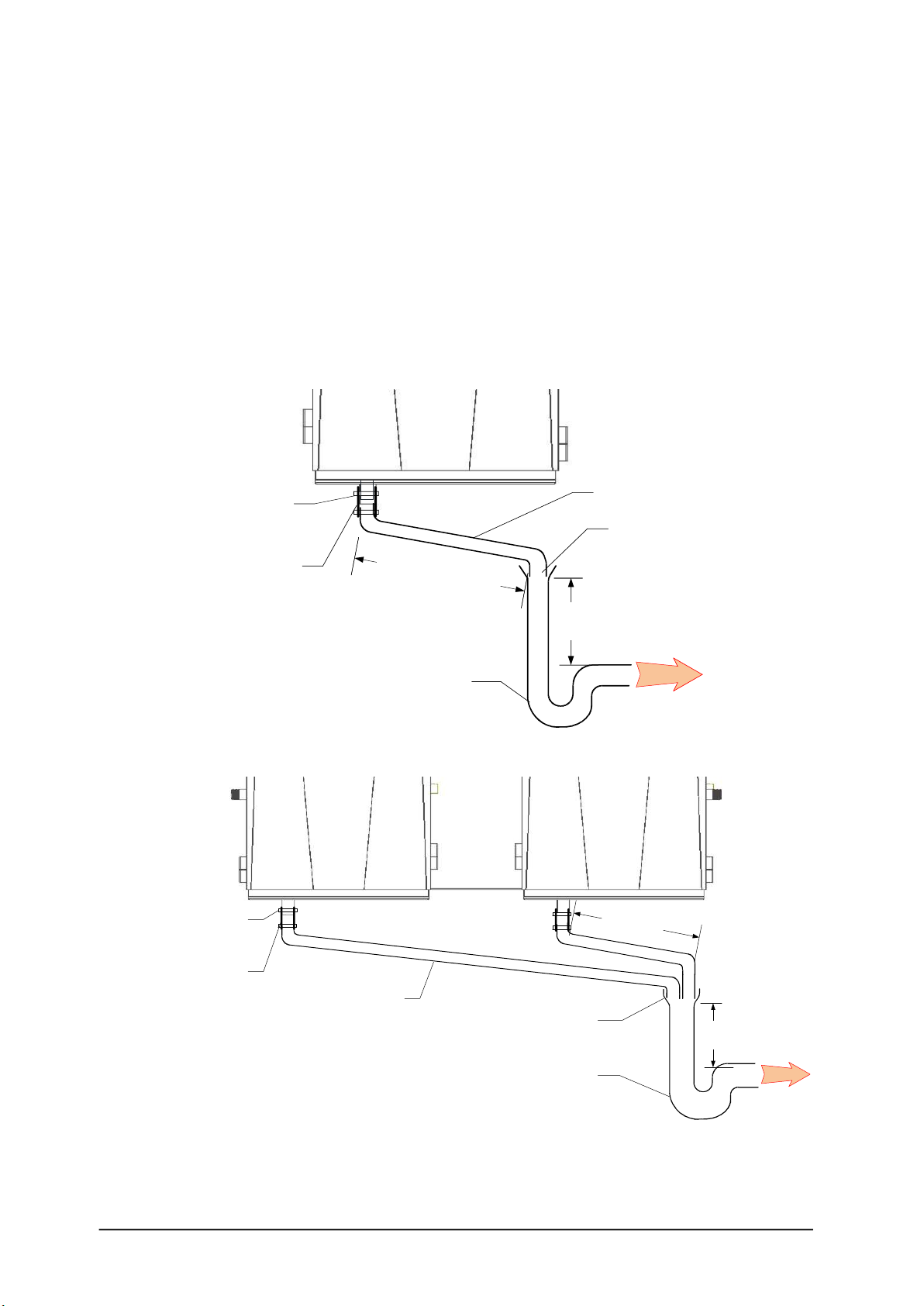

Water drained specification:

Drained water maximum temperature: 140°F [60°C]

when supplied with cold water supply

Drained water flow rate: 6.6 GPM [25 l/min]

Drain outlet dimension: ISE30 to 200: (1x)1-1/4in [32mm]

ISE300 & 400: (2x)1-1/4in [32mm]

ISE Humidifier

Drain

Connecon sleeve

1-1/4in [DN32] (supplied)

Slope minimum 5°

P trap

Open drain offset from ISE

1-1/2in [DN40] minimum

2 collars

(by others)

12in

[30cm] minimum

Vercal Length 18in

[45cm] minimum

Figure 11 – water drain connecon, single module

Connecon sleeve

1-1/4in [DN32] (supplied)

2 collars

(by others)

Drain

Slope minimum 5°

P trap

Open drain offset from ISE

2in [DN50] minimum

12in [30cm]

minimum

18in [45cm]

minimum

ISE Humidifier

Module 2Module 1

Figure 12 – water drain connecon, 2 modules ISE400

18

I N S T A L L A T I O N

Installation steps:

1. Ensure that an Open drain with a P-trap is installed offset from the ISE humidifier.

IMPORTANT: Risk of malfuncon. A minimum slope angle of 5 degree of the drain

hose or pipe and a minimum length of 12in [30cm] must be provided between the

drain outlet of the ISE humidifier and the open drain inlet.

A minimum of 18in [45cm] vercal run before P trap or obstrucon must be provided

2. If required, install a connecon sleeve 1-1/4 [32mm] at the drain outlet of the ISE

humidifier to the drain pipe, and secure it with 2 collars.

19

I N S T A L L A T I O N

Installation – step 4

Pressurized steam & condensate

installation

Pressurized steam supply piping must conform to local codes and regulaons.

Risk of damage to ISE humidifier. Steam piping should be supported to avoid stress to

steam components and/or ISE humidifier heat exchanger.

Pipes should be free from dirt.

Pressurized steam line installaon should be performed by a qualified installer.

Nipple & union (by others)

Electric actuated control

valve (supplied)

Strainer (supplied)

Manual shut-off valve (by others)

Raw steam supply

Nipple & union (by others)

F&T steam trap (supplied)

Check valve (by others)

Non-pressurized condensate return

Vacuum breaker (by others)

ISE steam exchange

humidifier

Figure 13 – Pressurized steam & condensate connecon

Pressurized steam installation:

ISE humidifier heat exchanger is designed for a maximum steam pressure of 15PSI (105kPa).

Pressurized steam line must be sized to provide design pressure and flow at the CV valve at

full output. Pressure losses in the steam supply line will reduce ISE pure steam capacity.

Actuated steam control valve should be lted to reduce the heat transfer from steam pipe to

the electric actuator. Please refer to below illustraon.

It is a good pracce to install the following components:

•Strainer (supplied) and a manual shut-off valve upstream to the control valve .

•Manual shut-off valve and pressure gauge (by others) upstream to the actuated

control valve.

•Vacuum breaker (by others) between actuated control valve and ISE heat exchanger

inlet and at any high point of the pressurized steam piping

•nipple and union (by others) to the inlet and outlet of the ISE heat exchanger for ease

of service.

20

This manual suits for next models

4

Table of contents

Other SteamOvap Humidifier manuals

Popular Humidifier manuals by other brands

Nordmann

Nordmann ES4 Installation operation & maintenance

Steba

Steba LB 5 Instructions for use

Levoit

Levoit OasisMist LUH-O451S-WUS user manual

Honeywell

Honeywell HCM 800 - PermaFresh Cool Moisture... user manual

HygroMatik

HygroMatik Basic-DS manual

Field Controls

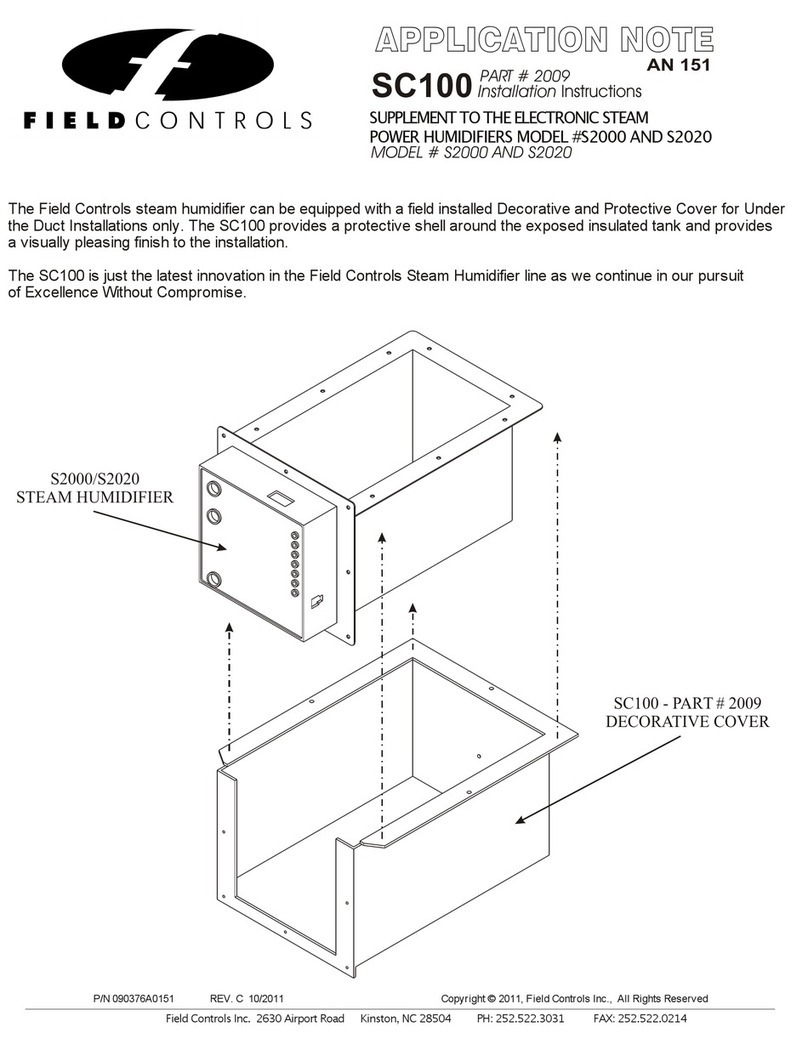

Field Controls SC100 installation instructions