SteamOvap ACA Series User manual

ACA – COMPRESSED AIR & WATER ATOMIZING

HUMIDIFIER & AIR COOLER

Installation and Operation Manual

Please read and save this manual

steamOvap technologies inc, 9495 Charles de la Tour, Montreal, Qc, H4N 1M5, Canada

Tel.: 1-844-357-4477 • www.steamOvap.com

Rev.191101

ACA

Introduction

Foreword

Thank you for purchasing ACA steamOvap compressed air & water atomizing humidifier.

If you have quesons or comments please contact us:

www.steamOvap.com

1-844-357-4477

Intended use

ACA Compressed air & water atomizing is intended exclusively to produce cold mist from

water at atmospheric pressure for air humidificaon.

Operang condions are specified in this Installaon and Operaon Manual (IOM).

Operaon of this atomizing in the intended use scope requires that all direcons and

informaon contained in this IOM are observed.

Any other use or operaon outside the above design scope without wrien authorizaon

from steamOvap may lead to trouble and hazardous condions and will void warranty.

No alteraon or modificaon to the atomizing must be done without wrien authorizaon

from steamOvap.

Replacement of any defecve components must be done with original component and spare

parts from steamOvap representave.

Installation and Operation Manual Limitation

This IOM is intended for trained and qualified personnel and must be applied along with the

applicable local codes and regulaons.

Any work related to installaon or service for this atomizing must comply with local code and

regulaon regarding safety and prevenon of accidents.

End of life disposition

Ensure that ACA Compressed air & water atomizing humidifier is empty from water, if not

proceed empty all pipes, hoses and valves.

Disconnect ACA Compressed air & water atomizing humidifier from power supply, electrical

control signal, water main supply, ACA Compressed air & water atomizing humidifier can then

be removed from the wall or stand.

ACA Compressed air & water atomizing humidifier is an electrical equipment and as such

MUST not be disposed of in domesc waste.

This humidifier should be returned to the closest steamOvap authorized representave for

proper dismantling, recycling and disposion of components according to local regulaons.

3

Table of content

Introduction................................................................................................3

Table of content.........................................................................................4

Safety warnings.........................................................................................5

Before to proceed to Installation................................................................6

ACA Overview...........................................................................................7

ACA-Distribution panel Dimensions & weight............................................9

Typical installation in-space overview......................................................10

Installation – step 1 ACA Dist. panel positioning & mounting...................11

Installation – step 2 Water supply installation..........................................13

Installation – step 3 Compressed air installation......................................15

Installation – step 5 ACA control panel installation..................................16

Installation – step 6 Control installation....................................................17

Verification before start-up.......................................................................18

Configuration & Operation.......................................................................19

Service....................................................................................................xxi

Warranty.................................................................................................xxii

4

S A F E T Y

Safety warnings

General

Risk of electric shock.

Disconnect power supply before installaon or service.

For safety and warranty reasons, Installaon and service of this humidifier should be

carried out by trained and qualified personnel.

Any work related to installaon and service of this humidifier must comply with local code

and regulaon regarding safety and prevenon of accidents.

Electrical Warning

Risk of electric shock.

Disconnect power supply before installaon or service.

Power supply connecon must be done by a trained and qualified electrician.

Water safety warning

Any work related to water supply, drain connecon or service of such for this atomizing

humidifier must comply with local code and regulaon regarding safety and prevenon of

accidents.

Water supply connecon must be done by a trained and qualified plumber.

Risk of disease: ACA atomizing humidifier should be connected to a clean,

wholesome mains water supply. Installer and user are responsible to ensure that

the water supply system complies with local regulaons in regards to Legionella

prevenon and any other microbiological growth prevenon,

Building owner and end user should carry-out a risk analysis and put in place a prevenon

plan to avoid any microbiological growth such as legionella.

Compressed air safety warning

Any work related to compressed air connecon or service of such for this atomizing

humidifier must comply with local code and regulaon regarding safety and prevenon of

accidents.

Compressed air supply connecon must be done by a trained and qualified plumber.

Others

Risk of flooding. In order to avoid any risk of flooding steamOvap recommends a Hi

limit humidity switch installed in the air duct downstream of the distribuon ramp.

Risk of freezing. Plan an an-freeze system in case of installaon in a locaon that

would be exposed to outside condions and suscepble of freezing.

Risk of malfuncon. Do not block outlet(s).

5

section

0

I N T E N D E D U S E

Before to proceed to Installation

Please read this Installation and Operation manual before to proceed to the Installation

Receiving & Unpacking

1. Upon receipt verify that packaging is complete and not damaged.

In case of damage, and/or missing boxes advise immediately the carrier by wring a

note on the waybill.

2. Verify that model of the humidifier matches the purchase order and that all

accessories are included.

3. Any missing item should be reported as soon as possible to steamOvap or its

representave and within 5 business days aer receipt.

steamOvap will not assume any responsibility for missing item aer this delay.

4. Proceed carefully to unpacking, and check that the humidifier and its accessories are

not damaged. in case of damage please proceed as for point 3

Included in standard delivery of ACA Compressed air &

water atomizing humidifier

1. ACA Compressed air & water atomizing humidifier

2. Mounng brackets

3. ACA Controller

4. This IOM

Depending on model

5. In duct manifold

6. Compressed air hose

7. Water hose

8. RH% sensor

6

section

1

O V E R V I E W

ACA Overview

ACA Compressed air & water atomizing humidifier

Figure 1 – ACA Overview

ACA product designation & name plate

Figure 2 – ACA Name plate

7

section

2

I N S T A L L A T I O N

Product designation

Type Model Nozzle qty Capacity Comment

In space ACA-S2 2 26lb/h

In space ACA-S4 4 53lb/h

In space ACA-S6 6 78lb/h

In duct ACA-DHPP 1 to 6 13 to 78b/h

In duct ACA-NOZZ6 1 13 b/h Nozzle only

Control panel ACA-OCUx n/a n/a For 1 or 2 zones

Electrical rating

Type Model Nozzle

Qty Capacity Rated

power

Voltage &

nb of

phase

Rated

current

In-space ACA-S2 2 26lb/h 15W 24Vdc 0.6A

In-space ACA-S4 4 53lb/h 15W 24Vdc 0.6A

In-space ACA-S6 6 78lb/h 15W 24Vdc 0.6A

In duct ACA-DHPP 1 to 6 13 to 78b/h 15 W 24Vdc 0.6A

-ACA-OCUx - - 15W 120Vac/1p 0.13A

Compressed air requirement

Type Model Capacity Air pressure Air consumpon

In-space ACA-S2 2 26lb/h 87 to 100PSI 4 cfm @ 87PSI

In-space ACA-S4 4 53lb/h 87 to 100PSI 8 cfm @ 87PSI

In-space ACA-S6 6 78lb/h 87 to 100PSI 12 cfm @ 87PSI

In duct ACA-DHPP 1 to 6 13 to 78lb/h 87 to 100PSI 2 to 12 cfm @

87PSI

Water supply requirement

Pressure:

40 to 60PSI [2.8 to 4bar] hammer free

Temperature:

37 to 68°F [3 to 20°C]

Untreated water requirement Pure water requirement

Water supply conducvity: 1 to 156µS/cm

Water supply TDS: 0 to 100 ppm TDS max

Water supply PH: 6.5 to 7.5

Water supply chloride content: 0 to 50ppm

Water supply conducvity: 0.1 to 0.5µS/cm

Water supply TDS: 0.02 to 0.2 ppm TDS min

Water supply PH: 6.5 to 7.5

8

I N S T A L L A T I O N

ACA-Distribution panel

Dimensions & weight

16in

20in

8in

4in

Figure 3 – ACA-Sx dimensions

Model Capacity Nb

Nozzle

Dimensions Weight

W H D

ACA-S2 26lb/h 2 16in 24in 8in 24lb

[11kg]

ACA-S4 53lb/h 4 16in 24in 8in 26lb

[13kg]

ACA-S6 78lb/h 6 16in 24in 8in 28lb

[13kg]

ACA-DHPP 1 to 6 13 to

78lb/h 16in 20in 8in 22lb

[10kg]

ACA maximum ambient conditions & IP rating

Temperature: 38°F to 113°F [+3 to +45°C]

Relave Humidity: 95%RH max (non condensing)

Ingress Protecon for ACA standard enclosure: IP42

9

I N S T A L L A T I O N

Typical installation in-space

overview

General

1. Installaon of this atomizing humidifier should be carried out by trained and qualified

personnel.

2. Any work related to installaon of this atomizing humidifier must comply with local

code and regulaon regarding safety and prevenon of accidents.

WARNING. Risk of electric shock.

Power supply must be disconnected during installaon.

Main power should be connected only aer all installaon steps have been

completed and properly verified.

5

3

4

1

2

Figure 3 –ACA typical installaon

installation steps:

Posioning& mounng of ACA in space distribuon panel

Water supply installaon

Compressed air installaon

ACA control panel installaon

RH% control installaon

10

section

3

I N S T A L L A T I O N

Installation – step 1

ACA Dist. panel positioning &

mounting

General guidelines for positioning

ACA in space distribuon panel should be posioned so that:

Unintenonal weng cannot occur on equipment, material or building surface or

people. A ceiling height of 9 [2.7m] minimum is recommended.

Humidifier is easily accessible for service

CAUTION. Risk of flooding. Ensure that the space where ACA Compressed air &

water atomizing humidifier will be installed is equipped with floor drain.

In case of no floor drain is available; installaon of a water leak detector is required

in order to prevent any flooding in case of abnormal operaon or service.

ACA Compressed air & water atomizing humidifier should be installed in a well-venlated and

dry environment.

If local is subject to below freezing point temperature, an freezing disposion such as heat

trace on any water carrying device and pipe is required.

Clearances

24in

[60cm]

8-1/2

[2.5m]

Figure 4 – minimum clearances

11

I N S T A L L A T I O N

Clearance guidelines

There is no minimum clearance on both side of the ACA distribuon panel, but it is a good

pracce to have a clearance of 4 to 8 in [100 to 200mm] for ease of installaon and service

Allow a minimum clearance of 24in [60cm] with ceiling.

Front clearance of 8-1/2 [2.5m] in front of nozzle is required to avoid any unintenonal

weng on surfaces, equipment, wall, or people.

It is a good pracce to install ACA in space distribuon panel where ceiling height is 9

[2.7m]minimum

Mounting holes positions

Figure 5 – ACA distribuon panel mounng holes posion

General guidelines for Mounting

CAUTION. Risk of malfuncon. ACA distribuon panel must be levelled in X & Z axis.

Installaon on wall

1. Verify that wall structure and strength is appropriate to support the weight of the

ACA distribuon panel.

2. Mark the wall or support according to the holes locaon as per the above figure , and

drill 4 holes to the wall or support as per the size of anchors and/or screws.

3. Use anchors of sufficient size (at least 1/4in [6mm]). Insert those anchors and the 2 top

screws. Then hung the ACA distribuon panel onto the 2 top screws.

Ensure that the humidifier is properly levelled.

4. Insert the 2 boom screws and ghten them up. Re verify the level in the 2 direcon X

and Z axis.

1. Tighten the 4 screws.

12

I N S T A L L A T I O N

Installation – step 2

Water supply installation

Water supply specification& quality:

Water supply pressure: 40 to 60PSI [2.8 to 4bar] – hammer free

Water supply temperature: 37 to 68°F [3 to 20°C]

ACA Compressed air & water atomizing humidifier can accept a wide range of water quality.

Important: the use of untreated water will lead to fine parcles deposit with the atomized

water, resulng is fine powder deposit in surrounding surfaces or air filter.

ACA should be connected to a clean, wholesome mains water supply. Installer and user are

responsible to ensure that the water supply system complies with local regulaons in regards

to Legionella and any other microbiological growth prevenon,

A 1μm sediment filter and a silver ions anbacterial cartridge or UV sterilizer must be installed

on the water supply line.

Untreated water requirement Pure water requirement

Water supply conducvity: 1 to 156µS/cm

Water supply TDS: 0 to 100 ppm TDS

Water supply PH: 6.5 to 7.5

Water supply chloride content: 0 to 50ppm

Water supply conducvity: 0.1 to 0.5µS/cm

Water supply TDS: 0.02 to 0.2 ppm TDS

Water supply PH: 6.5 to 7.5

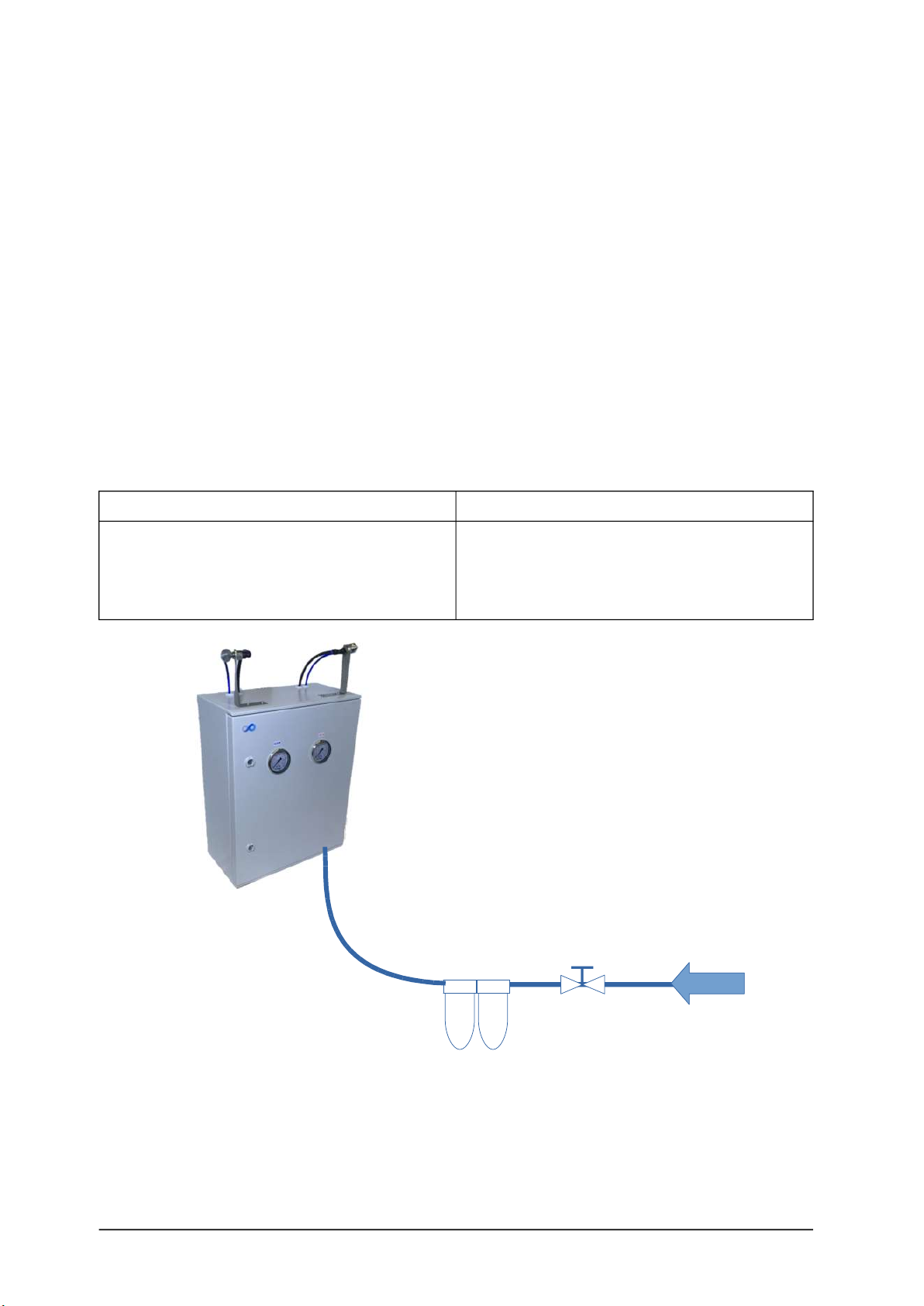

Figure 6 – water supply connecon

13

2 stages filter (1μm)

+ silver ions (anbacterial)

or UV sterilizer

Shut off valve

(by others)

I N S T A L L A T I O N

Water supply connection:

1. Install a manual; shut off valve on the water main line.

2. If ACA distribuon panel is supplied with tap water it is recommended to install a 5µm

sediment filters on the line. This filter will protect internal water components from

clogging.

3. ACA atomizing humidifier is supplied with 2 stages filters 1µm & anbacterial silver

ions cartridge. Install this pre-filter on the water main line downstream of the manual

shut-off valve.

4. Connect water supply to the 3/8in compression fing connecon. located at the

boom of ACA distribuon panel and secure the water line.

5. Ensure that the water line is hammer free and leak free.

Important: In case ACA atomizing humidifier is Off for more than 24hours, user should be

able to isolate the water main supply line and drain the ACA water supply line in order to

avoid any stagnant water and associated risk of legionella growth.

14

I N S T A L L A T I O N

Installation – step 3

Compressed air installation

Compressed air specification& quality:

Water supply pressure: 87 to 100PSI [6 to 7bar]

Air supply should be clean, dry and free from oil.

In case dirt or oil is contained in air supply, an air filter and oil separator should be installed.

Any oil collector should be connected to an oil drain.

To prevent bacterial growth, compressed air piping should be non-corrosive and any joinng

material should be inorganic.

Figure 7 Compressed air installaon

Compressed air connection:

6. Install a manual shut off valve on the compressed air line.

7. Install an air filter and oil separator on the line. This filter will protect ACA internal

component and avoid spraying oil in the air.

8. Connect compressed air to the universal quick coupling M type 1/4 connecon.

located at the boom of ACA distribuon panel and secure the compressed air line.

9. Ensure that the compressed air line is leak free.

15

Air filter & oil separator (by others)

I N S T A L L A T I O N

Installation – step 5

ACA control panel installation

Electrical Warning

Risk of electric shock.

Disconnect power supply before installaon or service.

General guidelines for ACA control panel positioning

ACA control panel should be posioned so that:

Unintenonal weng cannot occur the control panel

Control panel is easily accessible for set-up and control of the ACA distribuon panel

and atomizing

It is protected from sun and rain

Maximum length of cable to ACA distribuon panel and to RH% & Temp sensor is 30

[9m].

Power supply specification:

ACA Control panel is supplied with power cord and standard 120Vac plug.

ACA Distribuon panel is supplied from the ACA control panel at extra low voltage 24Vdc

refer to below diagram for electrical connecon of ACA distribuon panel.

ACA electrical rating

Type Model Rated power

Voltage &

nb of

phase

Rated

current

-ACA-OCU 15W 120Vac/1p 0.13A

In-space ACA-S2, S4, S6, or DHPP 15W 24Vdc 0.6A

16

I N S T A L L A T I O N

Installation – step 6

Control installation

General guidelines for control installation

RHS-P420 should be placed in a locaon where the air is properly mixed and represensave of

the air condion in the room

Connect ACA-Sx or DHPP and RHS-P420 according to below diagram

L

Main supply teminal

120Vac / 1ph

N Gnd

24Vdc +

RH signal

RH & T #1

OCU1

Air & Water

To Dist Pan.

ACA-S or DHPP

Distribuon panel

ACA-OCU1 or 2

Control panel

(by others)

(by others)

+ -

RH1

T1

WATER1 -

WATER1 +

AIR 1 -

AIR 1 +

FAN1

FAN1

B OUT

A OUT

B IN

A IN

Temp signal

4-20mA

signal

AIR +

WATER +

COMMON

RHS-P420

RH% & Temp.

sensor

T V+ RH

Air proving switch

(by others)

Figure 8 – Control connecon

17

I N S T A L L A T I O N

Verification before start-up

Warning

For safety and warranty reasons, Installaon and service of this ACA atomizing humidifier

should be carried out by trained and qualified personnel.

Any work related to installaon and service of this atomizing humidifier must comply with

local code and regulaon regarding safety and prevenon of accidents.

Risk of electric shock.

Disconnect power supply before verificaon.

Risk of floofing: Ensure that the space where ACA Compressed air & water

atomizing humidifier will be installed is equipped with floor drain.

In case of no floor drain is available; installaon of a water leak detector is required

in order to prevent any flooding in case of abnormal operaon or service.

Risk of damage due to weng : Plan for proper clearance in front and below ACA

distribuon panel and nozzle in order to avoid any unintenonal weng on

surfaces, equipment, wall, or people.

Risk of freezing. Plan an an-freeze system (heat trace) in case of installaon in a

locaon that would be exposed to condions suscepble of freezing.

Risk of malfuncon. Do not block nozzle orifice(s).

Check list

Mounng

oCheck mounng to verify that the ACA distribuon panel is level and securely

supported before filling with water.

oVerify that ACA control panel and RH% and /or Temperature sensor are

installed and connected.

Water supply

oVerify that all piping connecons have been completed as recommended and

that water pressure is available.

oEnsure that 2 stages Pre-filter 1µm + an-bacterial silver ions cartridge is

installed.

oOnce water shut off valve is open, verify for any possible leak.

Compressed air

oVerify that compressed air piping have been completed that Air pressure is

available.

oEnsure that an air filter and oil separator have been installed on the line.

oOnce Air shut off valve is open, verify for any possible leak.

Power supply

oVerify that 120Vac electrical is available for the supply of ACA control panel

oCheck that ACA distribuon panel and RH% and/or Temperature sensor have

been wired to the ACA control panel.

Control circuit

oVerify that safety controls such as Hi limit humidistat and/or enable switch

and/or floor leak detector have been connected.

oVerify that RH% and Temperature sensor is connected to the control terminals.

Once all above verificaon has been completed and found sasfactory you can powered up

the ACA atomizing humidifier.

18

section

4

C O N F I G U R A T I O N & O P E R A T I O N

Configuration & Operation

Control panel overview

Figure 9 – Control panel

Control panel allows you to set-up and control the ACA Compressed air & water atomizing

humidifier.

Control panel standard set-up

Steps Screen Descripon

01 When powered the display will indicate actual RH% and

Temperature.

02 By pressing Right arrow LCD display will indicate the

RH% set point

03 Pressing right arrow again will display the on/off pulse

of the air and water valves

04 Pressing right arrow will display the password request

to enter programming mode

19

section

5

C O N F I G U R A T I O N & O P E R A T I O N

Programming mode

Steps Screen Descripon

Default password is 12345 Press enter once value is entered

A Press 1, for User mode

B Enter desired Set point and press enter

C

You can select by pressing the down arrow between:

‘’No’’ or ‘’with’’, then press enter

Pulses are recommended for smaller space

DIf With pulses is selected

enter the Pulse ON period in seconds

E Enter then the Pulse OFF period in seconds

F

Air valve closing should be delayed by 10 to 20 seconds

aer water valves

this period can be adjusted depending on the water hose

length, longer the hose length is londer the delay should

be.

This delay can be set-up in the technician mode.

The Delay On should be set a 0sec, Delay Off will delay the

closing of the Air valve to the desired valu.

Once all sengs have been entered, you should put the control panel off by switching

the main switch to Off for few seconds and put it back On

Once back On, press for few second on the buon ‘’i’’ unl the ‘’SYSTEM’’ is

displayed.

Press enter , then press le arrow unl ‘’RESET’’ is displayed, press again enter

.

Controller will perform a reset. Once reset is complete, press on the right arrow 2

mes to verify that the seng are recorded.

Make sure that the flip switch ‘’A/M”” located inside the control panel beside the control

terminal is on the ‘’A’’ posion for Automac

Operation mode

Once Control panel is ON, press on the ON/OFF green push buon to put the ACA atomizing

humidifier on Automac mode.

20

This manual suits for next models

6

Table of contents

Other SteamOvap Humidifier manuals