for horizontal wall mounting, rotate 90°.

Note 3: The brake nameplate states mounting

position; “horizontal, vertical above or vertical

below.” The brake must be mounted in that

position. Horizontal brakes rated 35 lb-ft and

less do not require modification to be mounted

vertical below.

Note 4: A dimple drilled into the motor shaft for

the hub set screw (16S), 90° from the key is

recommended for vertical mounting.

F. Position hub (16) and key (by customer)

on the motor shaft so outboard face of hub

will protrude approximately 1/32” to 1/16”

beyond face of last outboard friction disc.

(Position may be determined by assembling

friction disc(s) and stationary disc(s) onto

hub, noting hub position, and removing

disc(s).

Torque set screw (16S) as follows: 5/16

diameter - 13 ft-lb, 3/8 diameter - 24 ft-lb

and 1/2 diameter - 52 ft-lb. If brake utilizes

vertical mounting springs, do not assemble

them when measuring for hub location.

G. Reassemble friction disc (be sure friction

discs slide freely), spring (if vertical),

stationary discs, and pressure plate in

correct sequence and position. All parts

must slide freely. The universal mounting

pressure plate presently used has three

tapered reliefs on outboard face. However,

some older brakes used a pressure plate

with a single tapered

relief marked top, which must be installed

with relief facing manual release rod (146).

H. Mount support plate assembly, torque

screws to 50 in-lbs in endplate. Conical

spring washer installed under the screw

head. Flat washer used under the conical

spring washer only with aluminum support

plate. Be sure that assembly is mounted

with the solenoid in a vertical position

(plunger above frame) as shown when

brake is horizontal. If release rod (146) is

not in manual release position and has

allowed the mechanism to overadjust, it will

have to be reset before mounting support

plate. In this case, the lever arm (17) throat

will be near, or touching, the pinion (32)

teeth. Refer to Figure 6 and Self-Adjust

Maintenance. Loosen pressure spring cap

screw (19) until pressure spring (11) is free,

mount support plate assembly to endplate

and retighten spring cap screw until snug.

Do not overtighten! Torque to a maximum

of 8 ft-lbs.

I. Manually lift solenoid plunger to maximum

travel, and release. Complete electrical

connection. (See Section on Electrical

Connection of Brake.) Depress solenoid

plunger manually or electrically, and allow

it to snap up. Repeat this process several

times to set air gap on solenoid. (Check

Self-Adjust Maintenance Section for proper

gap measurement, or corrective action of

improper gap.)

J. Replace housing, nuts and manual release

knob.

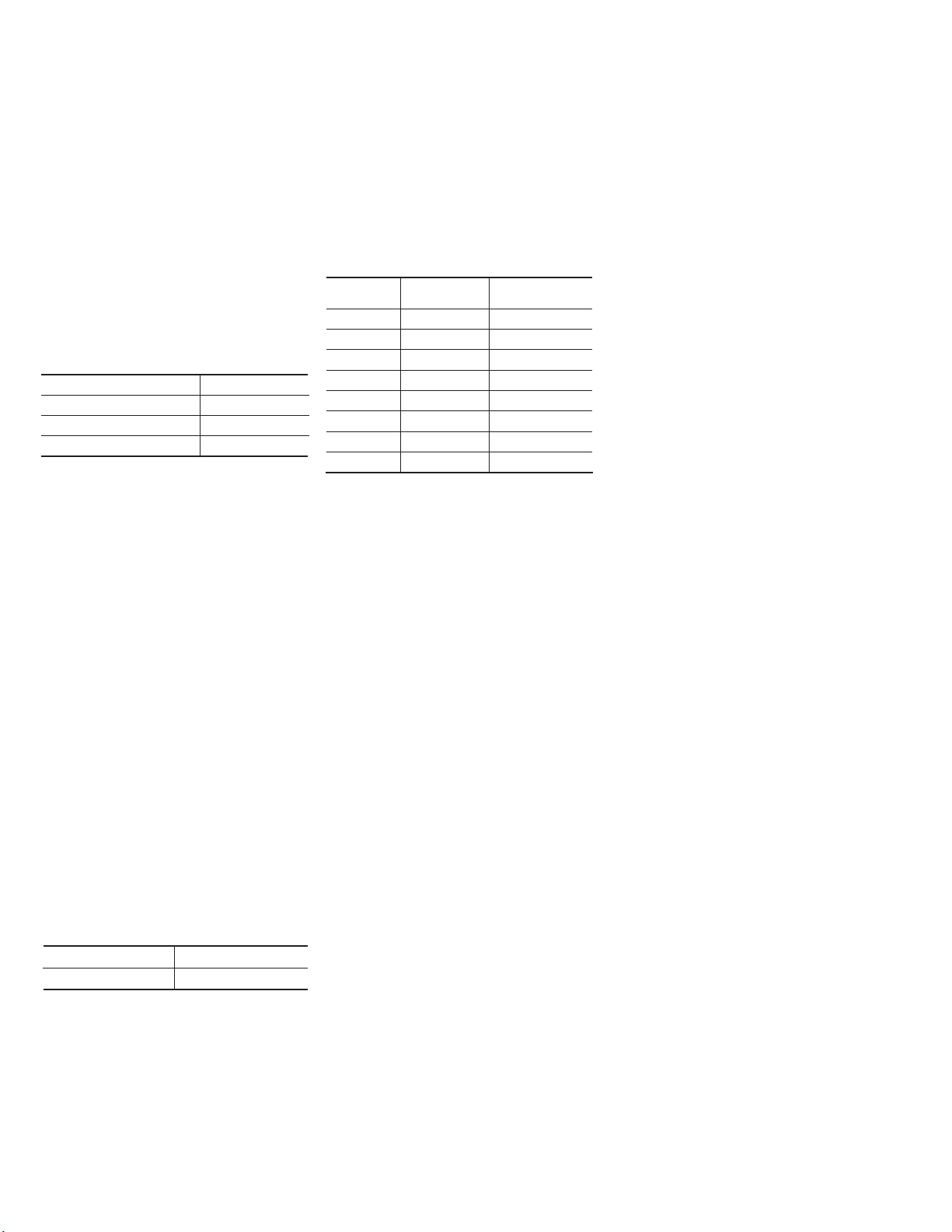

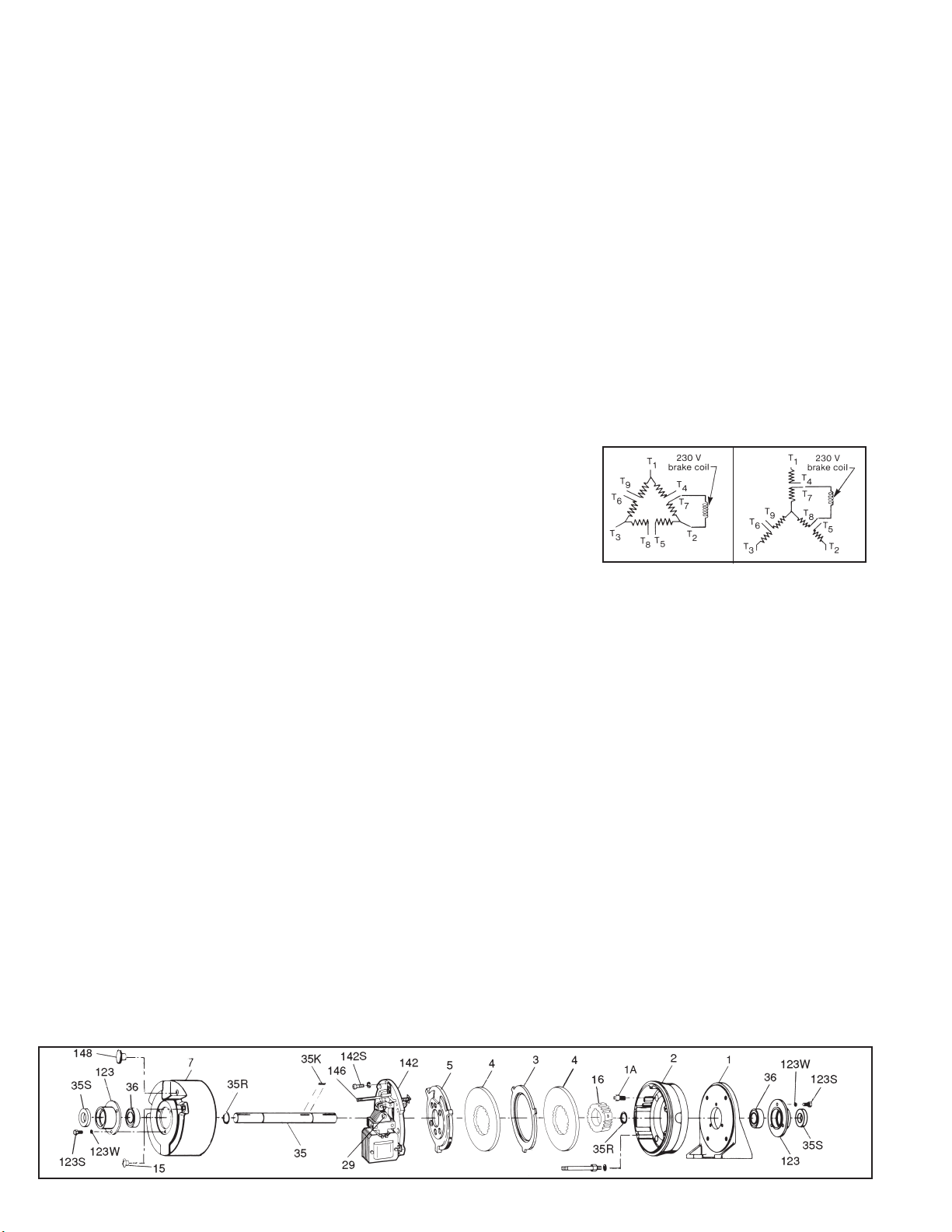

II. Installation Procedure - 87,200 (See

Figure 1A)

As shown in the exploded view, Figure 1A,

the 87,200 Brake is very similar to the motor

mounted 87,000 Series. It is, however, a

self-supported, foot mounted unit, with an

integral bearing supported through-shaft. Since

disassembly is not required prior to mounting,

installation is simplified.

A. Bolt foot mounting bracket (34) to foundation

uses four 3/8-16 cap screws and lock

washers (not supplied). Torque cap screws

to 110 ft-lb specifications. Dowels are

recommended to maintain alignment.

B. For reference purposes, the endplate

mounting bolts, 1A, are torqued to 100-110

lb-ft for cast iron endplates; or 45-50 lb-ft for

aluminum endplates.

C. Do not exceed maximum overhung, or side

load ratings on output shafts. 100 lbs. on

housing end of brake, 150 lbs. on endplate/

foot stand end of brake. (Measured at 1”

from end of shaft).

D. See Section Electrical Connection of Brake.

Note:To remove housing for servicing of the

brake it is necessary to loosen the eccentric

bearing sleeve. Loosen the set screw on

the sleeve (35S) and, using a 3/16” drift pin,

rotate the sleeve on the shaft until loose

(about ±20°). Remove the housing nuts

(15) and release knob (148), and slide the

housing off the shaft. Reverse the procedure

for re-assembly.

III. Electrical Connection of Brake - All

Models

CAUTION 1: Inverter Motor and Special

Control Systems. This brake contains either

a single phase AC coil or DC coil that requires

instantaneous power within ± 10% of rating at

the coil. A separate power source is required

when this brake is used in conjunction with a

motor or control system that limits voltage or

current input (i.e. inverter motors) or causes a

ramping of the power supply.

CAUTION 2: Class H coils with terminals. Do

not bend lead wire crimp connection as this

causes a fatigue in the metal which may break

under vibration.

Note 1: Brake coil connections described

here cover common motor connections. For

nonstandard motor or control connections,

contact respective supplier or Stearns Div.

Note 2: Be sure lead wires to coil are not tight

or pinched, and that leads will not be rubbed

by friction disc, trapped between solenoid

plunger and frame, caught between lever arm

and endplate, or by linkage.

Note 3: On brakes with spacer heater, connect

to appropriate power source. Heater is to be

energized continuously, even during storage or

rusting may occur.

A. AC coils, single or dual voltage

1. Dual voltage coils may be factory precon-

nected for high voltage with wire nuts.

Checking coil connection is suggested. On

the 87,200 only, coil lead wire termination

is accessible at lead wire outlet of endplate

(2). Four lead style are marked on leads

for connection per Figure 4. Two unmarked

leads mean preconnection made for high

voltage. If reconnection of a dual voltage

coil is required (two unmarked leads) on the

87,200, housing (7) must first be removed

per Section and Figure 1A. Reconnect coil

for appropriate voltage as shown in Figure 4.

Bring out line leads.

2. On single voltage coils, connect coil to any

two leads on single or three-phase motors

of the same voltage as the brake. Refer to

brake nameplate and coil number for correct

voltage and frequency. See Figure 4 for dual

voltage coil connection and connect to any

two leads of single or three-phase motor of

the same voltage. The brake can also be

wired to external switch contacts providing

proper voltage other than that used to

control the motor. Normally, the motor and

brake contacts are interlocked.

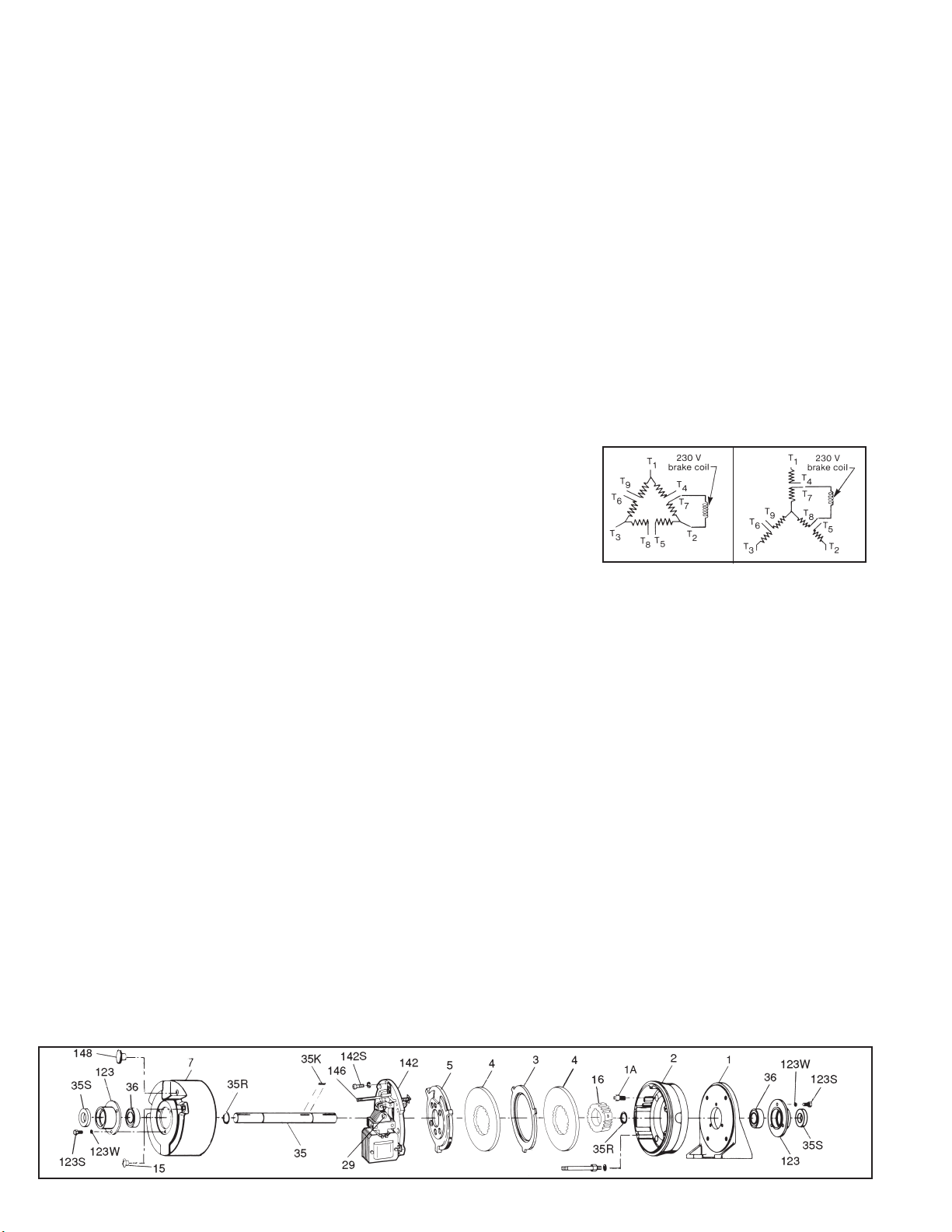

B. Connecting AC solenoid coils on dual

voltage 230/460 three-phase motors

To use a 230 volt coil (or a 230/460 dual

voltage coil connected for 230 volts) with a

230/460 dual voltage three-phase motor, the

brake leads are connected across two motor

terminals as shown in Figures 2 and 3 or other

equivalent combinations. If a 230 volt brake coil

is connected as shown in Figures 2 and 3 the

motor can be operated on either 230 volts or

460 volts with no effect on brake operation.

AC Voltage Coil Connection

C. DC coils - all models

1. All Stearns DC coils are single voltage

dual winding. A high current pull-in winding

is initially energized to start the plunger

movement, while a low current holding

winding is momentarily shunted from the

circuit until the plunger has pulled in. The

older design incorporated a mechanical

switch mounted to the solenoid frame and

actuated by an arm mounted to the plunger

to bring the holding winding into the circuit.

In addition, coils over 48 Vdc have an arc

suppression module in parallel with the

switch contacts to protect the contacts

from arc erosion and suppress EMI. The

polarity of the incoming power supply is

immaterial with the mechanical switch. The

new electronic switch design incor-porates

an electronic timing circuit to allow the

plunger to pull in, then electrically switch to

the holding winding. Polarity of the power

supply to the electronic switch and coil must

be maintained. Refer to Figure 5 for proper

wiring.

Caution! Never use a series resistor to drop

power supply voltage to the coil as brake

malfunction will result.

2. Due to high initial current demands of a

DC solenoid, a separate DC power source

Figure 1A

Figure 2 Figure 3