Steel Core 40809 User manual

*Actual product may vary slightly

Please carefully read and save these instructions before attempting to assemble, maintain, install, or operate this product.

Observe all safety information to protect yourself and others. Failure to observe the instructions may result in property

damage and/or personal injury. Please keep instructions for future reference.

For warranty purchases, please keep your dated proof of purchase. File or attach to the manual for safe keeping.

For Customer Service, Call 1-800-348-5004

This product contains or, when used, produces a chemical

known to the State of California to cause cancer and birth

defects or other reproductive harm.

(California Health & Safety Code § 25249.5, et seq.)

WARNING

11GA COIL ROOFING NAILER

40809

Z87

Fig.1

Fig.2

Fig.3

BC

A

WARNING: W hen using pneumatic tools, basic safety precautions

should always be followed to reduce the risk of personal injury,

There are certain applications for which this to ol was designed. we

strongly recommends that this tool NOT be modified and /or used for

any application other than for which it was designed. If you have any

questions relative to its application, please contact with our dealer.

including the followin g:

READ AND F OLLOW ALL INS TRUCTIONS.

IMPORTANT SAFETY INSTRUCTIONS

1. KEEP WORKING AREA CLEAN.

2. DON'T ALLOW CHILDREN KEEP AT

THE WORKING AREA.

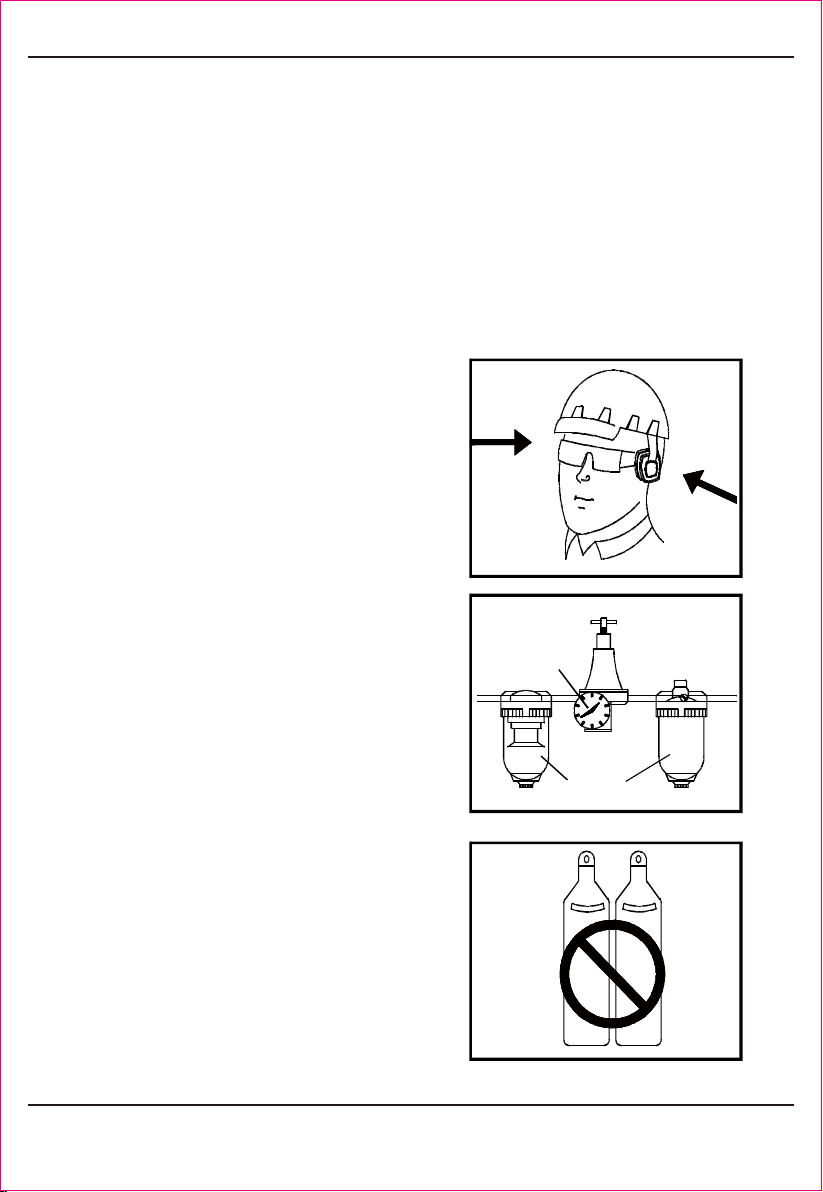

3. USE SAFETY GLASSES.

4 . U S E E A R PRO T E CT I ON .

5. DRESS SAFELY.

6. O NLY U SE CL EAN , D RY AND

REGULATED

C l u t t e r e d a r e a s i n v i t e i n j u r i e s .

Don't let them

To prevent

eye injuries, the tool operator and all

persons in the working area must wear

s a f e t y g l a s s e s w i t h p e r m a n e n t l y

attac hed, rigid, plastic side shields.

These safety gla sses must conform to

ANSI Z87.1 requirements (approved

glasses have “Z87” printed o r stamped

T he

working area may be exposed to high

noise levels that can lead to hearing

Protective gloves

and nonskid footwear or safety shoes

are recommended when working with

and operating this tool. Don't wear loose

clothing or jewelr y. They can get caught

in moving parts. Also, wear a protective

hair covering to prevent long hair from

compressed a ir at 70 to

handle the tool.

on them).

damaged.

getting caught in the tool.

120 PSI (4.8 t o 8. 3 BA R) .

Fig.4

Fig.6

1

2

3

Fig.5

7. NEVER USEOXYGEN, CARBON

DIOXIDE,

8.DO NOT CONNECT TOOL

9. ONLY US E AIR HOSETHAT IS

RATED

10.DON'T OPERATE TOOL NEAR THE

COMBU ST IB LE ,

11 DISCONNECT TOOL FROM AIR

S U PPLY H OSE

12.O N L Y D I SCO N N ECT Q U I C K

CON N EC TOR B E IN G C ONNE C TED

13.REPLACE PARTS AND ACCESSO-

R I ES.

combustible gases or any

otherbottled gas asapower source for

to pressure

thatpotentially exceeds180PSI(12.3

for 150% o f the m aximu m

systempressure.

.

or a ny o th er easy

explosive material and don't operate the

tool under easy producing corrosion,

r u s t and h a v i n g h e a v y p o w d e r

.

before doi n g t o o l

m a i n t enanc e , c l e a r i n gaj a m m e d

fastener, leaving work area, moving tool

to another location, or handing the tool

with the connector of the body tail

portion air inlet, no compressed air can

be guaranteed when disconnecting. If

operating is not correct, thetool can

remain charged with air afterbeing

disconnected and still be able to drive a

Onlyallo w u s e s a m e

rep la cem e nt p arts w hile s erv ic i ng.

Approved accessories andreplacement

Please try to useahose

o f I D 3/8”conn e c t i n g nai l e r w i t h

this tool.

BAR).

environment.

to another person.

parts are available.

fastener, causing personal injury.

Compressor.

Fig.10

Fig.9

Fig.8

Fig.7

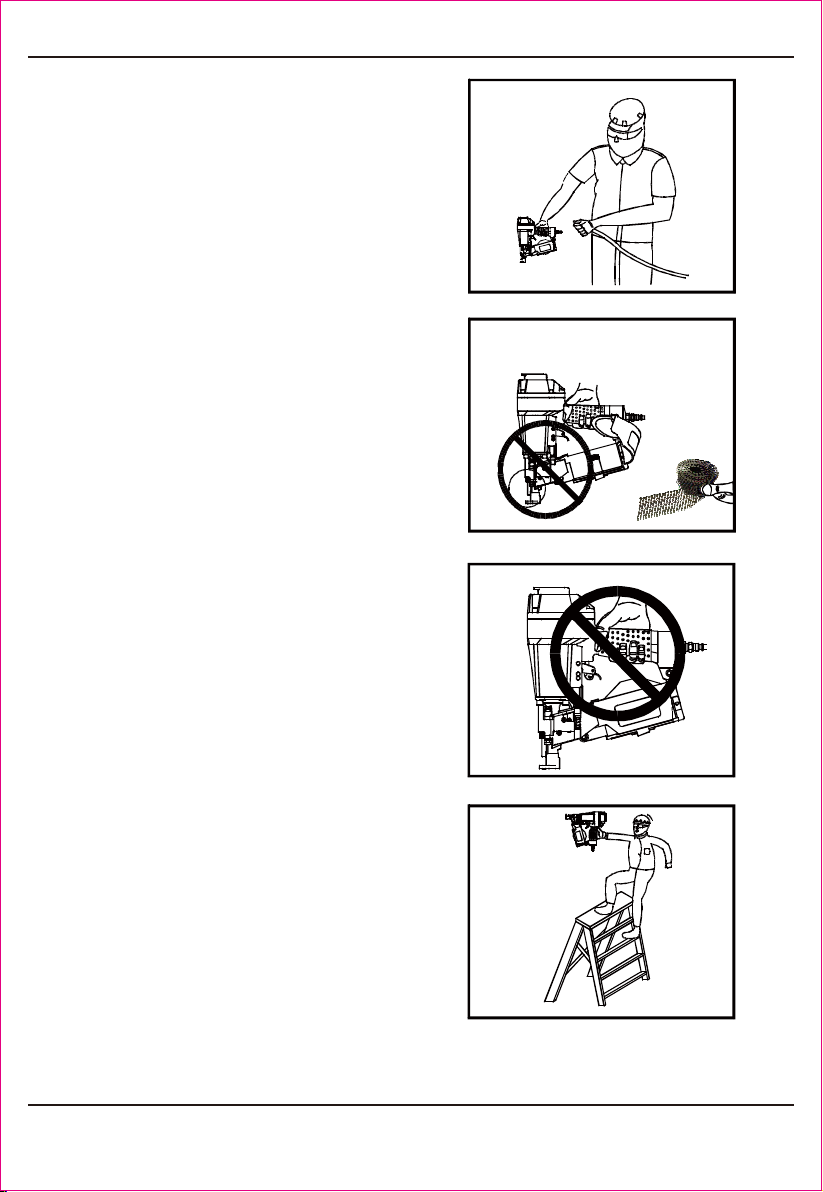

14. BEFORE USING TOLL,

15. NEVER USE TOOL

1 6 . O N L Y U S E P A R T S A N D

FASTEN ERS,

17. CONNECT TOOL TO AIR SUPP LY

BEFORE

1 8 .A LWAYS A S S UM E T HE TO O L

C ONTAI NS FA STENE RS.

19. DO NO T LOAD FASTENERS

20. REMOVE FINGER FROM TRIGGER

21. DON'T OVER REACH .

carefully

check if there is any part damaged to

obt ain ideal results. Do not use the tool

i f th e t o o l h a s a n y a ir le a k e d ,

uncompleted, damaged par ts and n eed s

if safety, trigge r

o r s pr in g i s i no per ab le , missin g o r

damaged. Do not alter or remove safety,

t ri g g e r o r s p r i n g s . M a k e d a i l y

inspe ctions f or f re e movement of trigge r

re commende d by us .

loading fasteners, to prevent a

f a s t e n e r f r o m bei n g f i re d du r i n g

connection. The tool dri ving mechanism

may cycle whe n tool is connected to the

air supply. Wh en not in use remove all

Keep the tool

poi nted awa y from yourself and others

at all times. No hor seplay. Respect the

with

trigger or safe ty depressed, to prevent

u n in te nt io nal f ir i n g o f a f as ten e r.

when not drivi ng fasteners. Never carr y

tool with finger on tr igger: tool will fire a

faste ner if sa fe ty is b umpe d whi le trigge r

Keep prope r

footing and balance at all times when

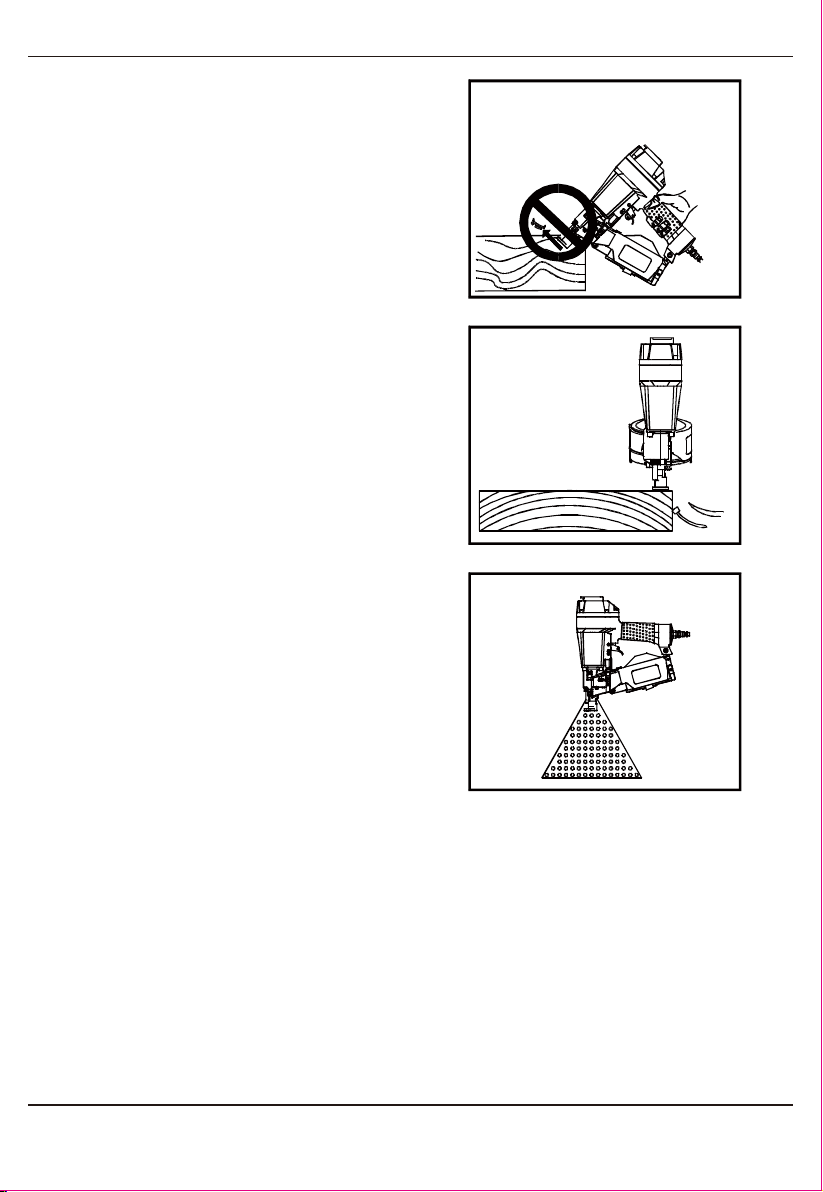

22. FIRE FASTENERS INTO WORK

SURFACE ONLY: NEVER into materials

repairing.

and safety me chanism .

fasteners from the nail housing.

tool as a working implement.

is depressed.

using or handing the tool.

too hard to penetra te.

Fig.13

Fig.11

Fig.12

23. GRI P TOOL FIR MLY TO MAINTAI N

CONTR OL

24. DO NOT DRIVE FASTENERS

2 5 . D O N O T DR IVE FA S T E N ER S

CLOSE

26. KEEP ALERT.

27. KEEP HANDS AND BODY PARTS

28. T HIS TOOL IS EQU IPED W IT H

AD JU S TER

29. WHEN NOT IN USE,

while allowing tool to recoil

away from work surface as fast ener is

driven. If safety bracket is allowed to

co nta ct wor k su rf ace agai n b ef or e

t ri gger i s re l e a s ed, a n un w a n t ed

on

top of other fasteners, o r with the tool at

too steep an an gle: the fasteners can

to the edge of the workpiece.

The work piece is likel y to split allowing

the fastener to fly free or ricochet

Watch what you are

doing. Use common sense. Do not

operate any tool when you are tired.

away from area shown in Fig. 13, to

that ca n ad ju st dri vi ng

depth. When adjusting the driving depth,

first disconnect from air supply, rota te

the knob of the adjuster by hand until it

tool should be

cleaned and put it back into the packing

box. For safety, ke ep out of reach of

children.

fastener will be fired.

ricochet causing persona l injury.

causing personal injury.

avoid injury.

is satisfactoy.

Employer m ust enforce compliance with the safety warningsand all

Keep this manual available for use by all people assigned to use this

For personal safety and properoperation of this tool, read and follow all

EMPLOYER’S RESPONSIBILITIES

other instructions contained in this manual.

tool.

of these instructions carefully.

1-800-348-5004

DESCRIPTION

Roofing coil nailer

S5 Hex Key

S4 Hex Key

S3 Hex Key

Air Tool Oil

Safety glasses

Operating instruction

Q'ty

1

1

1

1

1

1

1

PACKING LIST

TECHNICAL PARAMETER

CHARACTERISTIC

Compressed Air pressure

Outline Dimension (L H W)

Nail Length Range

Too l Weight

Air Inlet

Air Consumption

× ×

VALUE

70-120PSI (4.9-8.3bar)

11.5 "

/ "-1 /

5

1/4 NPT

0.11ft /cycle at 100psi(at pressure

6.9bar, 3.1 litre/ cycle)

" 11.5 5"

"

"

× ×

7 3

3

8 4

.58 Ibs (2. 53K g)

1-800-348-5004

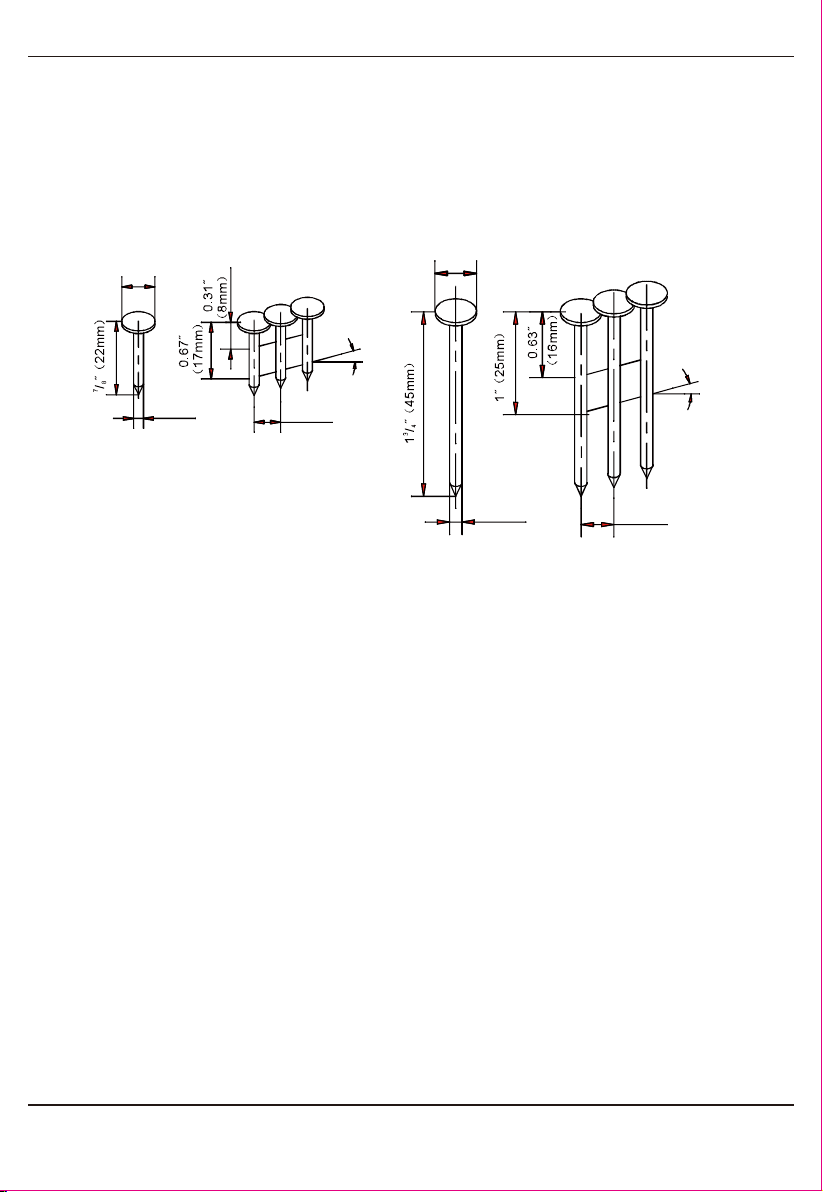

FASTENERS SPECIFICATIONS

Only use recommended the fasteners.

OPERATING INSTRUCTIONS

FOREWORD

POWER SOURCE

It’s a he avy duty, coil fed, pneumatic roofing nailer, u sing

compressed air as power source. It is designed to install / ˝-1 / ˝or

0.12˝diameter roofing nails of various lengths. It is widely used for

connection of roofing frame and connection of roofing frame and felt.

This tool is designed to operate on clean, dry, compressed air at

regulated pressures between 70 and120 PSI (Pounds per Square Inch).

The preferred system w ould include a filter (C) Fig.2, a pressure

regulator (A) Fig.2, andautomatic oiler (B) Fig.2 located as close to the

tool as possible (within15 feet is ideal).

All compressed air contains moisture and other contaminates that a re

detrimental to internal components of the tool. An air-line filter will

remove most of these contaminates and significan tly p rolong the life of

the tool. I f an in-line oiler is not available: place five or six drops of oil,

into the tool’s air inlet at the beginning of each workday.

Only disconnect quick connector being connected with the connector of

the body tail portion air inlet, no compressed air can be guaranteed

when disconnecting.

7 3

8 4

Ø

Min.

0.39φ˝

( )φ10mm

3.05mmφ( )

0.12φ˝0.31˝

( )8mm

15 -16

o o

Max.

0.39φ˝

( )φ10mm

15 -16

o o

3.05mmφ( )

0.12φ˝0.31˝

( )8mm

1-800-348-5004

PREPARING THE TOOL BEFORE DRIVING

CAUTION:

1. After reading and unders tanding this entire manual, connect tool to

air supply.

Keep tool pointed away from yourself and others at all

times.

Always conne ct tool to air supply before loading fasteners.

Do not load fasteners w ith trigger or safety depressed.

Always we ar Z87 approved safety glas ses, and he aring protection

when preparing or operating the tool.

Never use a tool that leaks air or needs repair.

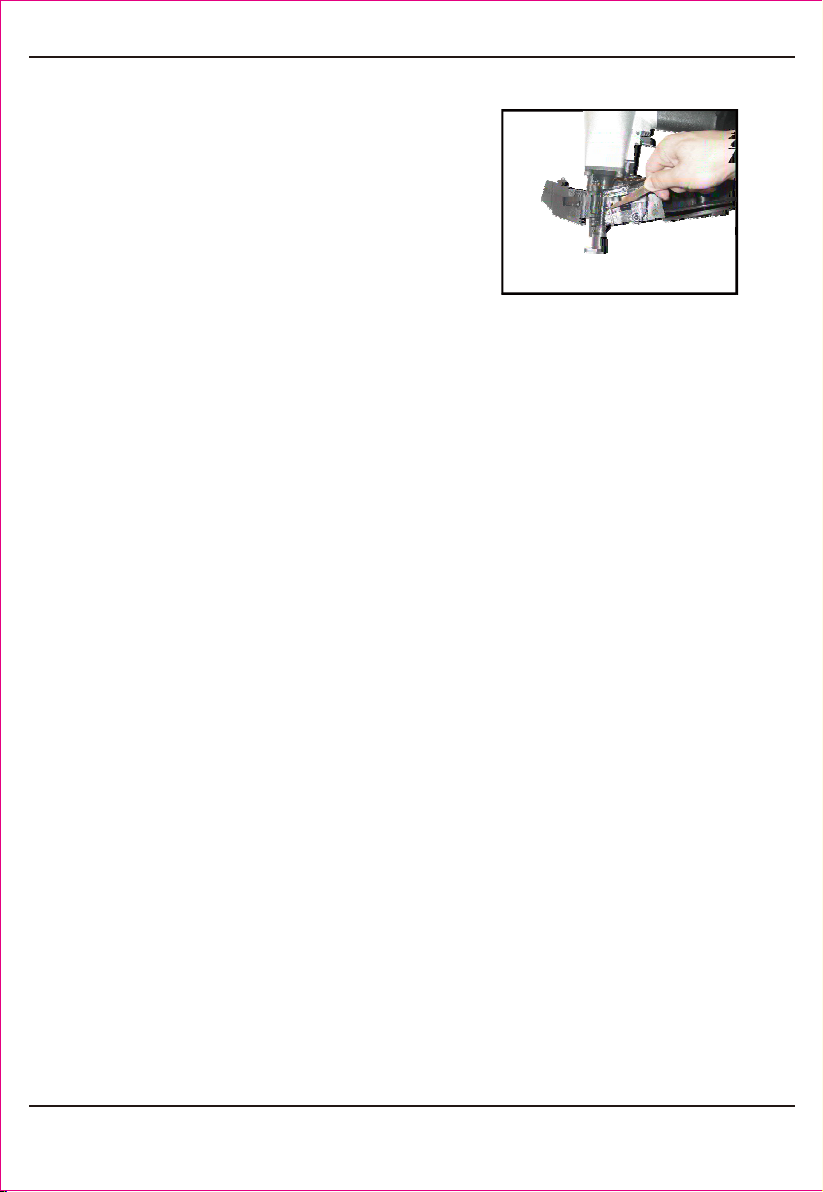

2. Depress HANDLE (See A Fig. 14 ) and open t he LATC H. R otate the

UPPE R NAIL HOUSING to the side of the BODY.

3. The ADJUSTER PLATE can be move d up and down when twisting the

ADJUSTE R NUT(see B Fig.15) . According to the length of nail, the

ADJUSTE R PLATE should be adjusted correctly to t he position

Indicated inside LO WER NAIL HOUSING.

4. Place a coil of nails over the LOWER NAIL HOUSING . Uncoil enough

nails to reach the F EED HO OK and place the second nail betwee n the

teeth on the FE ED HOOK. (see Fig. 16).

5. Close the UPPER NAIL HOUSING and depress the LATCH (see Fig.

17).

6. Adjust directional EXHAUST deflector (s ee F ig. 18), so that the

exhaust air blast will be directed aw ay from the operator. Grasp the

deflector and rotate it to the desired position for the current application.

CAUT ION : All line co mponents (ho ses, co nnectors, filters,

regulators, etc.) must meet 150% of the maximum system pressure.

Please try to useahose of ID 3/8”connectingnailer with compressor.

Do not connect this tool to a system with maximum potential. Only

disconnect quick connector being connected with the connector of

the body tail portion air inlet, no compressed air can be guaranteed

Disconnect tool from air supply before performing maintenance,

clearingajammed fastener, leaving work area, moving tool to

when disconne cting .

ano ther location, or handing the tool to another person.

1-800-348-5004

Fig.16

Fig.14

A

Fig .15

B

Fig .17

Fig.18

A

Fig.19

A

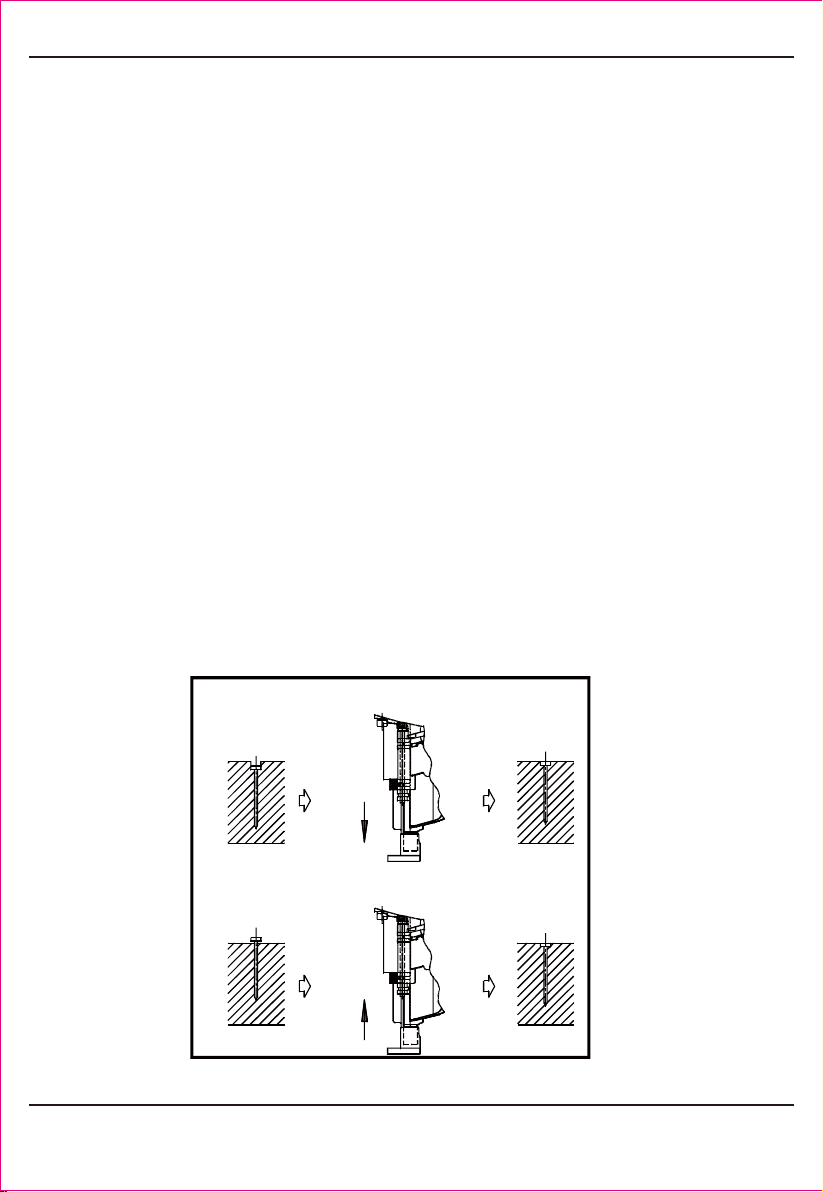

USING THE TOOL

There are two methods of operation to drive nails with theis

tool: Contact Fire and Single Sequential Fire (Black trigger)

Contact Fire

This tool is set up at the Contact Fire mode

1. P ull the trigger with th e tool off the work piece

2. Depress the safety ag ainst the work piece to drive a nail

3. Move the tool along the work piece with a boun cing motion. Each

depression of the safety w ill drive a nail. As soon as the desired number

of nails has been driven, remove your finger from the trigge r.

1-800-348-5004

Single Sequential Fire

1. Position the nail outlet on the work piece with finger off the trigger

2. Depres s the safety firmly until it is comple tely depressed.

3. Pull the trigger to drive a nail

4. Remove finger from the trigger.

To continue nailing in a separate location, move the tool along the

wood, repeating steps 2 - 4 as required.

Remove finger from trigger whe n not driving fasteners.

Never carry tool with finger on trigger: tool will fire a fastener if

safety is bumped.

Keep tool pointed in a safe direction at all times.

Never attempt to drive a fastener into material that is to o hard, or at

too steep an a ngle, or near the edge of the workpiece. The fastener

can ricochet causing personal injury.

Disco nnect tool from air supply before performing maintenance,

clearing a jammed fastener, leaving working area, moving tool to

another locatio n, or handing the tool to another person.

Clean and inspect tool daily. Carefully chec k for proper operation of

trigge r and safety mechanism. Do not use the tool unless both the

trigger and the safety mechanism are functional, or if the tool is

leaking air or needs any other repair.

3. Driving depth will be adjusted by adjusting adjuster (A) Fig.19 .

Test fire a fastener an d check depth. If the nail is driven too deep,

rotate the adjuster to ma ke safe bracket do wnw ard. Whereas,

CAUTION:

Fig.20

1-800-348-5004

Fig.21

1. Disconnect tool from air

2.Open latch, rotate lower housing and

remove the nails of the lowe r housing.

3.Use a slender, soft steel rod to drive the

drive blad e to its uppermost position. U se

needle nose pliers to remove the jammed

CAUTION:

fastener (see Fig.21).

supply .

4.Follow instructions in PREPARING THE TOO L BEFORE DRIVING to

reload fa steners.

CLEARING A JAMMED

FASTENER

Disconnect tool from air supply before cleaning and

Ad d pneumatic tool oil into the oiler regularly to remain the moving

components of the tool fine lubrication. Check the filter of the

compressor weekly and s witch off manual valve to drain water and

Wipe the tool clean. Blow the tool clean by high compressed air, then

use non-flammable cleaning solutions to wipe exterior of tool only if

necessary. Do not soak tool with cleaning solutions. Su ch solutions can

damage internal parts. The expose d portion of the small piston rod and

Inspect triggerand safety mechanism to assure system is complet e and

functional: no loose or missing parts, no binding or sticking parts shall

Ke ep all screws tight. Loose screws can cause personal injury or

Check if there are worn and damaged parts. If any, please repl ace

If tool is used without an in -line oiler: place 5 or 6 drops of porter-cable

air tool oil into the air inlet of the tool at the beginni ng of each workday.

CAUTION:

MAINTENANCE

CLEAN AND INSPECT DAILY

inspection. Correct all problems before operating.

contaminations out.

feed hook must be kept clean.

be found.

dama ge t ool.

immediately.

1-800-348-5004

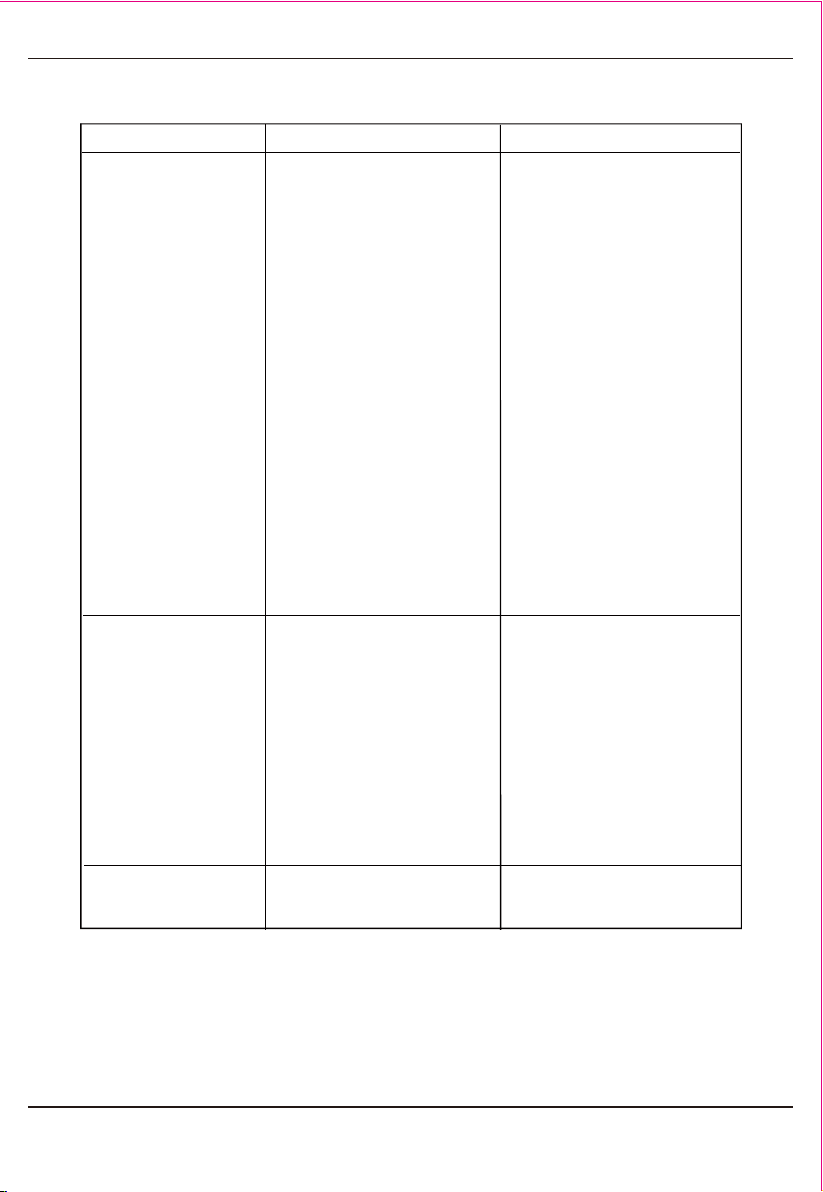

TROUBLE SHOOTING

CAUTION: Disconnect tool from air supply before performing

any Service Procedure.

PROB LEM

CA USE

SOLUTION

Air le aking at trigger area

1. O-ring in trigger valve stem

is worn and damaged.

2. O-ring in trigger valve head is

worn and damaged.

3. Having foreign matters.

1.Che ck/re placeO -ring/lubricate.

2.Che ck/re placeO -ring/lubricate

3.Clean the tool/lubricate

Air leaking at the body

lower portion and nose

1.Screw is loose at connecting

portion of the nose and body.

2.O-ring is damaged between

body and nose.

3.Bumper is damaged.

4.Having the foreign matters at the

contacting portion of t he bumper

and body.

1.Tighten screw/recheck

2.Che ck/re placeO -ring/lubricate

3. Replace the bump er.

4. Disasse mble an d clean

Air leaking a t the body

upper portion and nose

1.Screw is loose at the connecting

portion of the cylinder and body.

2.O-ring is damaged.

3.Gasket is damaged.

1. Tig hten t he screw and recheck.

2. Check/replace0-ring/lubricate

3. Replace the gasket.

Failure to start tool.

1.Tool dry, lack lubrication.

2.The spring in the cylinder cap is

damaged.

1. Use pneu matic too l oi l

2.Replace the spring in the

cylinder cap.

Blade driving fasteners

too deeply

1.Safe bracket poison is not

correct.

2.Air pressure is too high.

1.Rotate knob of the adjuster to

move safe bracket down.

2.Decrease air pressure.

All quality tools eventually require servicing of rep lacement of parts due

to wear from normal use. Some user servicea ble components are

described in the TROUBLE SHOOTING Section. All repairs made by

local agencies are fully guaranteed against defective material and

workmanship. We cannot guarantee repairs made or attempted b y

Should your have any questions about your tool, please contact with us

at any time. In any communications, please give all information shown

on the nameplate of your tool (model number, type , serial number, etc.)

SERVICE AND REPAIRS

anyone other than these ag encies.

1-800-348-5004

Skippin g

fastene rs/feeding

intermittently

1.Having the foreign matters

between the small piston and

small cylinder.

2.O-ring on the small piston is

worn and damaged.

3.Tool dry and lack lubrication.

4.The spring on the small piston is

damaged.

5.Air pressure is lower.

6.Connecting screw of nose and

body is loose.

7.Stopped hook ca n't stop the

fasteners.

8.Bent fasteners.

9.Wrong size fasteners.

10.Gasket is damaged.

11.Small piston bumper is worm

and damaged.

12.Feed hook is binding.

13.Nail length is not correct with

loading space of nail housing.

14.Weld wires in nail coil is broken.

1.Disassemble/ clean/lubricate.

2.Che ck/replaceO-ring/lubricate

3.Use pneumatic tool oil.

4.Rep lace small piston the spring.

5.Increase the air pressure, but

don't exceed 120 PSI (8.3 bar).

6.Tighten all screw.

7.Rep lace taper spring of the

stopped hook.

8.Use recommende d fasteners.

9.Use recommende d fasteners

10.Re place gasket/tighten screw.

11.Replace bumperand lubricate

small piston.

13.Clean feed hookand torsion

spring.

13.Adjust adjuster plate at the nail

housing tail portion according to

the recommended nail length to

make arrow on the nail housing

tail pointing to correct direction.

14.Stop using.

PROBLEM

CAUSE

SOLUT ION

Ru ns slowly or has power

loss

1. Tool dry, lack lubrication

2. The spring in the cylinder cap is

damaged.

3.Having foreign ma tters between

piston assembly andcylinder.

4.Have not assembled the cylinder

to home position.

5.O-ring on the valve is dry after

disassemble.

6.Air pressure is too lower.

7.Driver is worn (sort)

8.Inner diameter of used hose is

small.

1.Use pneumatic tool oil.

2.Replace the spring in the

cylinder cap.

3.Disassemble/clean/lubricate.

4.Reassemble after

disassembling.

5.Reassemble after lubricating

6.Increase the air pressure, but

don't exceed 120 PSI (8.3 bar).

7.Replace piston assembly.

8.Use bigger inner diameter o f

the hose.

Fasteners are jammed

1.Fasteners are wrong size.

2.Weld wires in nail coil is broken.

1.Use recommended fasteners.

2.Stop using.

1-800-348-5004

PART LIST

Description

Screw M5*20

Bushing

Exhaust Cover

Washer

Screw M5*30

Spring Washer

Cylinder Cap

Gasket

O-ring 36.3*2.5

O-ring 55.4*3

Spring

Valve

O-ring 40.2*2.3

Seal

Valve Seat

Stopped Washer

Washer

O-ring 43.3*3.5

Piston Assembly

Cylinder

O-ring 50.5*2.5

Restrictive plate

Cylinder sleeve

Bumper

Protective Piece

Soft Spacer

Body

O-ring 46*1.3

Restrictive Washer

Nose

Screw M6*25

Bracket

Spring

Adjuster

Bracket Assembly

Nut M3

Spring pim3*28

Safe Bracket Guide

Cylinder

O-ring 76.36*2 .62

Spring Washer

O-ring 7.5*1.5

Screw M6*35

Washer

Latch

Pin

Washer

Pin

Handle

Stopped Hook

Spring

Block Plate

Spring Washer

Description

Cover

Pin 2.5*18

Ball

Spring

Backing plate

Lower Nail Housing

Screw M4*12

Pin

Shaft

Spring

Protector

O-ring 10.3*1.9

O-ring 20.3*1.5

Valve set

Trigger Valve Guide

Spring

O-ring 9.5*1.9

O-ring 20.3*2.5

O-ring 12.8*1.9

Trigger Valve Head

O-ring 5.5*1.5

Spring

Trigger Valve Stem

Trigger Assembly

Pin

O-ring 24.3*2.8

Feed Hook

Washer

Feed Hook Pin

Torsion Spring

Piston

O-ring 12.3*1.9

Piston Bumper

Spring

Locking Washer

Upper Nail Housing

Adjuster Nut

Adjuster Plate

Washer

Adjuster Stem

Adjuster Bushing

Pin

Screw M4*10

Nut M6

Connected plate

Support

Braket

Screw M6*10

Soft Grip sleeve

O-ring 65.4*2.5

End Cap

Air plug

Item

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

I

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

tem

97

98

99

100

101

102

103

104

Limited Manufacturer Warranty

FOT makes every effort to ensure that this product meets high quality and durability

standards. FOT warrants to the original retail consumer a 1-year limited warranty

from the date the product was purchased at retail and each product is free from

defects in materials. Warranty does not apply to defects due directly or indirectly

to misuse, abuse, negligence or accidents, repairs or alterations, or a lack of

maintenance. FOT shall in no event be liable for death, injuries to persons or

property, or for incidental, special or consequential damages arising from the

use of our products. To receive service under warranty, the original manufacturer

part must be returned for examination by an authorized service center. Shipping

and handling charges may apply. If a defect is found, FOT will either repair or

replace the product at its discretion.

DO NOT RETURN TO STORE

For Customer Service:

Table of contents

Other Steel Core Nail Gun manuals

Popular Nail Gun manuals by other brands

Campbell Hausfeld

Campbell Hausfeld IN729000AV operating instructions

Hitachi

Hitachi NT 32AE2 Instruction and safety manual

Senco

Senco FinishPro 35 Specification sheet

Metabo HPT

Metabo HPT NT 1865DMA Instruction and safety manual

Hitachi

Hitachi NT 50AE2 Instruction and safety Instruction and safety manual

Freeman

Freeman PFBC940 user manual