STEELFORCE PRO 100 HC User manual

STEELFORCE PRO 100 HC

STEELFORCE

PRO 100 HC

MVL-H11fA1P-0EN-DE-NL

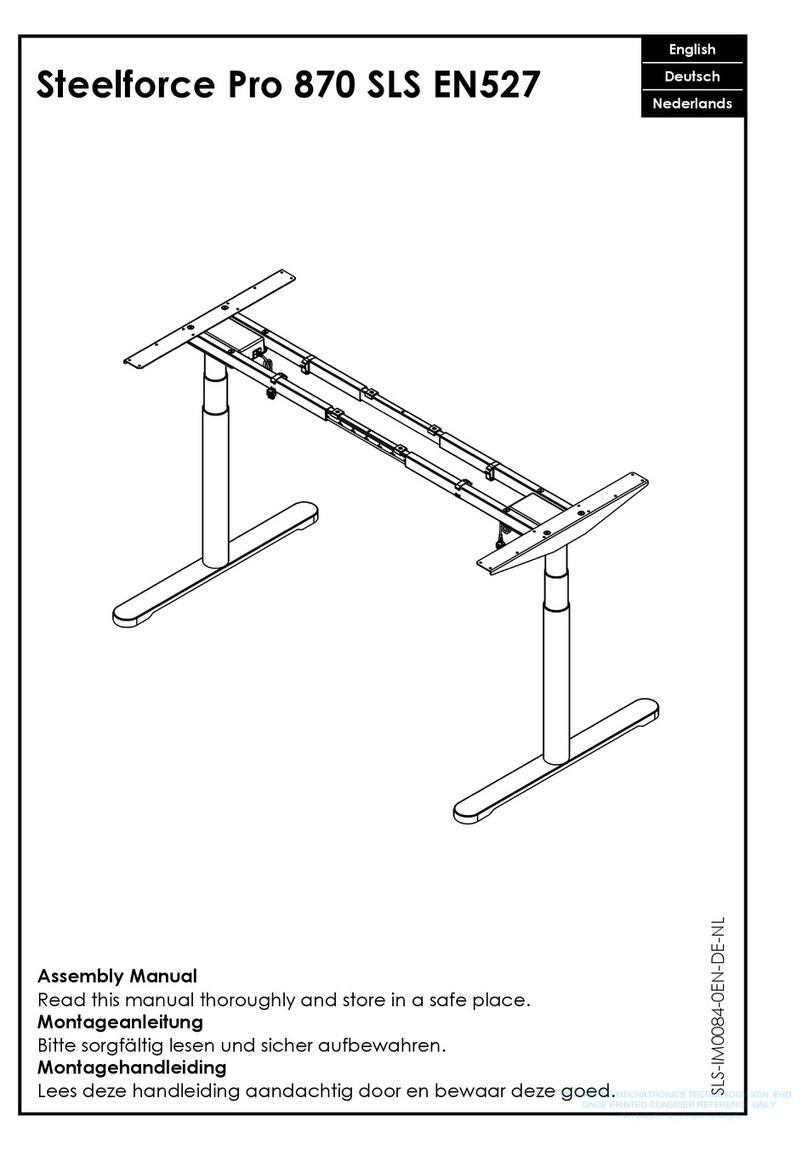

Assembly Manual

Read this manual thoroughly and store in a safe place.

English

Deutsch

Nederlands

STEELFORCE PRO 100 HC

2

Content

1GENERAL ..................................................................................................3

1.1 Local value of the assembly/operating manual .................................3

1.2 Intended use .....................................................................................3

1.3 Improper use.....................................................................................3

1.4 Content box ......................................................................................4

2SAFETY INFORMATION.............................................................................5

2.1 Symbols/warnings.............................................................................5

2.2 Symbols used on the workstation frame............................................5

2.3 Organizational measures ...................................................................5

2.4 Informal safety measures..................................................................5

2.5 Note for those assembling the workstation .......................................5

2.6 Transport and assembly.....................................................................5

2.7 Use of the workstation frame ............................................................6

2.8 Specific dangers ................................................................................6

2.9 Emergency instructions .....................................................................6

2.10 Maintenance and upkeep ...................................................................6

2.11 Cleaning.............................................................................................6

2.12 Persistent risks..................................................................................6

3ASSEMBLY ................................................................................................7

3.1 Checking the items supplied ..............................................................7

3.2 Packaging ..........................................................................................7

3.3 Tightening torques for screws used...................................................7

3.4 Assembly of the workstation .............................................................7

3.4.1 Pre-assembly of the Crossbar......................................................... 7-9

3.4.2 Mounting the Feet........................................................................9-10

3.4.3 Installation of the Wheels / Adjustable Feet........................................11

3.4.4 Mounting the Drive Shaft ................................................................12

3.4.5 Assembly of the Hand Crank ............................................................13

3.4.6 Installation of the Hand Crank .........................................................14

3.4.7 Frame test without Table Top...........................................................14

3.4.8 Assembly of the Table Top ..............................................................14

3.4.9 Assembly of the parts of the Table Top .............................................14

4TECHNICAL SPECIFICATIONS.................................................................15

5OPERATION AND INDICATORS ...............................................................16

6 CUSTOMER SERVICE ...............................................................................16

7 MANUFACTURER.....................................................................................16

8 RECYCLING.............................................................................................16

8.1 Taking the workstation apart...........................................................16

8.2 Recycling .........................................................................................16

STEELFORCE PRO 100 HC

3

1 General

1.1 Local value of the assembly/operating manual

The guiding principle for safe use and trouble-free operation of this workstation frame is

knowledge of basic safety information and regulations. This assembly/operating manual

contains the most important information needed for assembling and operating the work-

station frame safely. This assembly/operating manual, in particular the safety information

contained herein, must be observed by any person building the frame and working on the

finished surface. More importantly, the rules and regulations applying to accident preven-

tion in the locality in which the workstation frame is to be used must be observed at all

times.

1.2 Intended use

The workstation frame must be used only as a height-adjustable workstation for sitting/

standing use in offices or other enclosed areas. The frame must be used for this purpose

only. The workstation frame may be set up and operated solely in office environments. Do

not use the workstation frame in the home. Please observe the provisions of Section 2,

Safety Information. Children may be unaware of the dangers presented by the workstation

frame if unsupervised. Any other use than the above shall be deemed improper. The man-

ufacturer can in no way be held liable for damage arising from improper use.

Intended use shall also include:

Observation of all information from the assembly/operating manual and

Prohibition of any sort of addition to/conversion of the workstation.

1.3 Improper use

Never use the workstation frame to lift people or loads.

Load the table frame only up to the maximum load (see chapter 4 "Technical data").

Do not use the workstation frame in the home; alternatively, use it only in offices.

WARNING: Any changes or modifications not expressly approved by the manufac-

turer could void the user’s authority to operate the equipment.

STEELFORCE PRO 100 HC

4

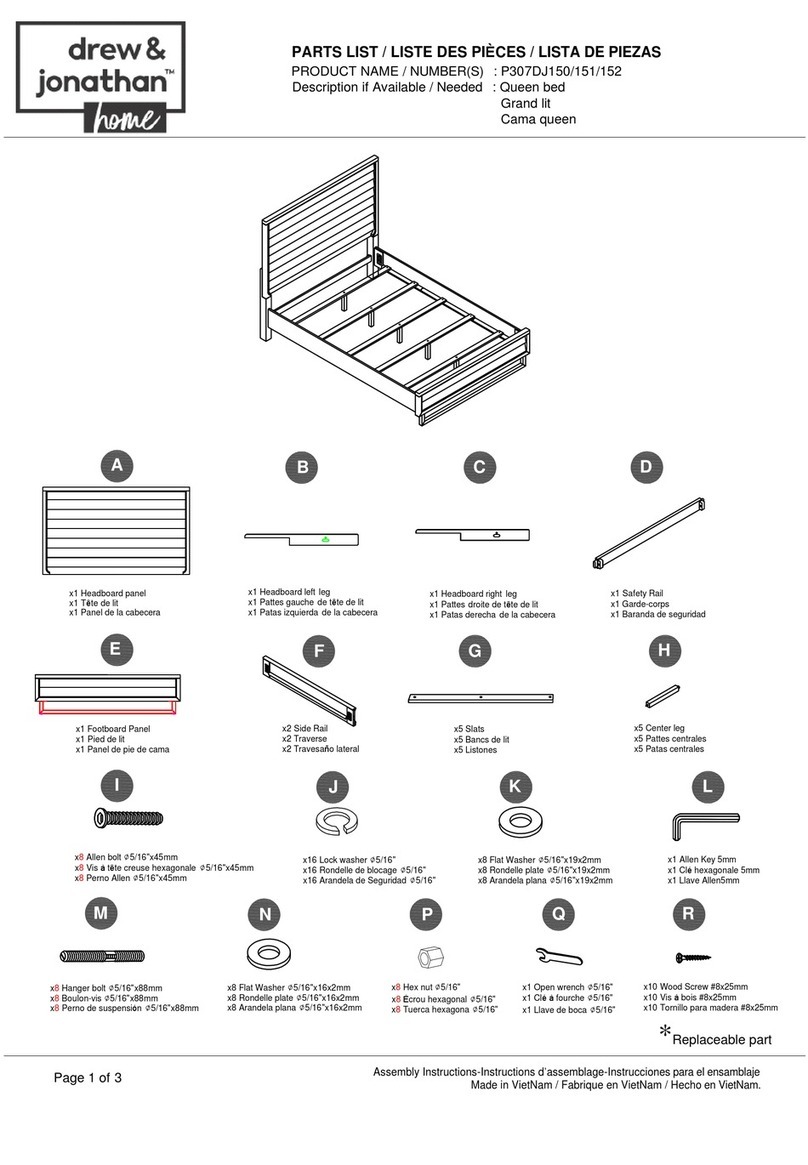

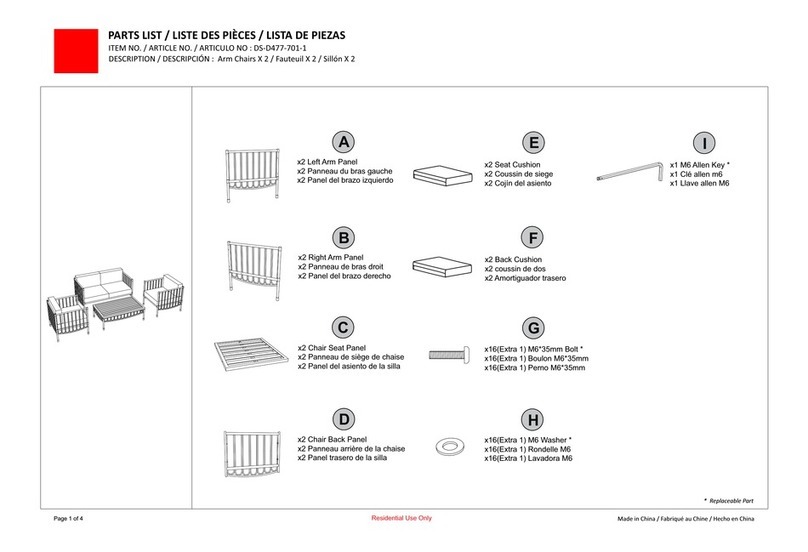

01 02

13.1 8 x M6x25 Bolt

13.2 8 x M6x16 Adjusting Screw

13.3 8 x M6 Collar Nut

13.4 8 x M6 Ring

13.5 2 x M6x6 Set Screw

13.6 10 x Screw 4.5x20mm

13.7 2 x M10 Spanner

13.8 1 x M3 Allen Key

13.9 1 x M5 Allen Key

13.10 1 x Screwdriver

13.11 2x Hexagon-stopper

13.12 4x Cover Cap

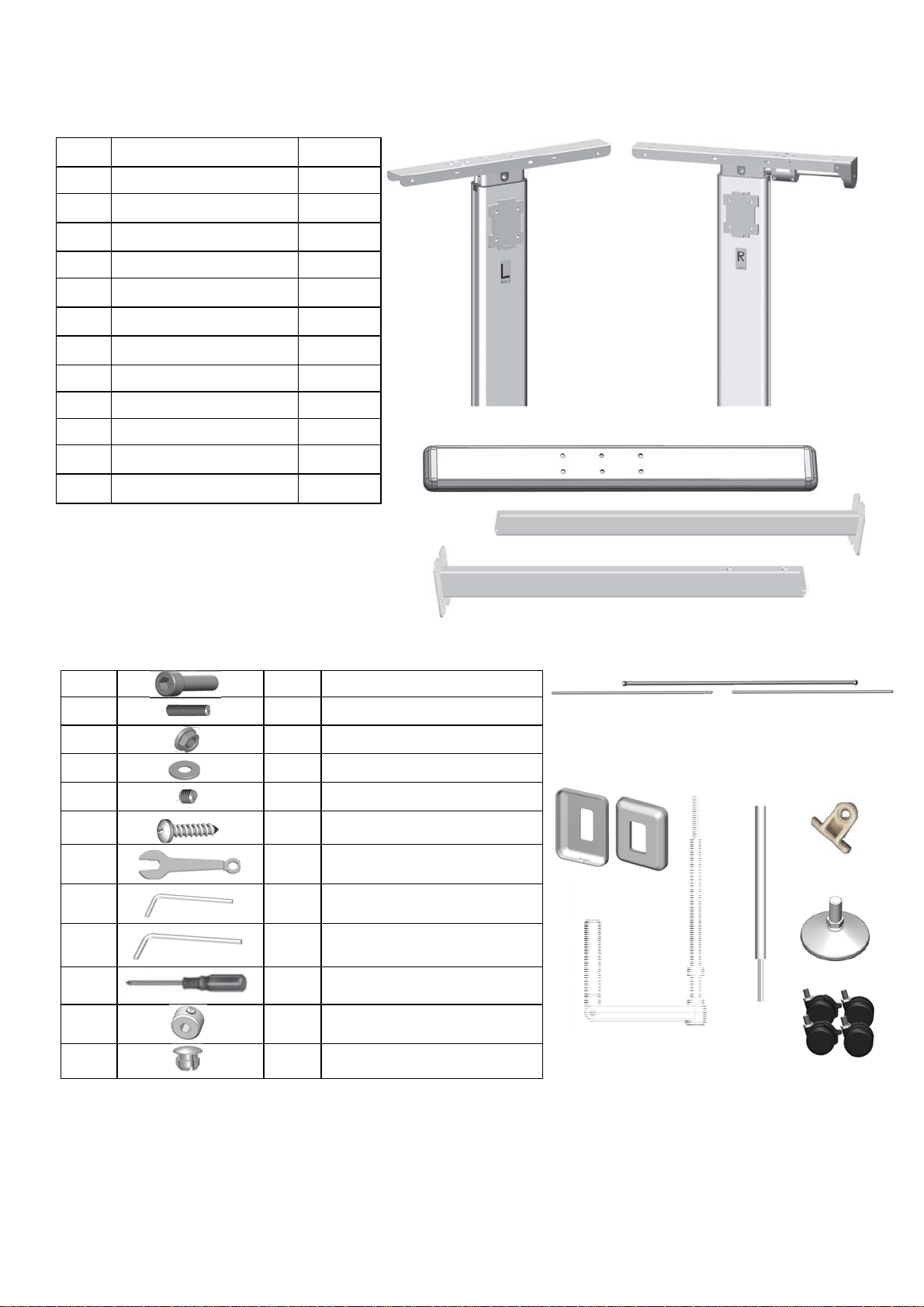

# Description Qty

01 Leg L 1

02 Leg R 1

03 Foot 2

04 Inner Crossbar 1

05 Outer Crossbar 1

06 Drive Shaft Kit 1

07 Cover cap, crossbar 2

08 Hand Crank 1

09 Hand Crank Extension 1

10 Hand Crank Guide 1

11 Adjustable foot 4

12 Wheelset 4

06

1.4 Content Box

08

07 09

12

10

Mounting Material and Tools

11

05

03

04

STEELFORCE PRO 100 HC

5

2 Safety Information

2.1 Symbols/warnings

The assembly/operating manual uses the following terms and signs to indicate dangers:

2.2 Symbols used on the workstation frame

2.3 Organizational measures

The workstation frame can best be assembled by two people. Turning the frame,

once the work surface has been fitted, is a task in particular which requires two

people!

2.4 Informal safety measures

Keep the assembly/operating manual in the place where the workstation frame is

used at all times.

Make sure that all safety information on the table (see Section 2.2, Symbols used

on the workstation frame) is legible, replacing the same if necessary.

2.5 Note for those assembling the workstation

The workstation must be assembled/worked on by persons over the age of 16.

The persons referred to above must have read and understood the assembly/

operating manual.

2.6 Transport and assembly

The workstation frame must be moved by two persons only, and in such cases must

be retracted.

Do not drag or pull the workstation frame over the floor.

Assemble the workstation frame with the supplied tools only. They are the only tools

which ensure that the screws can be tightened to the correct torque.

2.7 Use of the workstation frame

Children may only use the desk under supervision. They may not be aware of the

dangers of the agency. This puts them at serious risk of self-injury, possibly with

fatal consequences.

The desk may only be used in an environment that is suitable for it.

Do not use the desk on an uneven surface. The desk will then not be stable.

This symbol indicates an immediate threatening situation for any person’s

life or health. Failure to adhere to such information may have serious con-

sequences for health, or could even result in life-threatening injury or

death.

This symbol indicates important information. Failure to adhere to such in-

formation could lead to damage to the workstation.

Do not place objects or parts of the body under the workstation frame or

between the cross members. This could cause serious injury.

Do not exceed the maximum permitted load on the workstation frame.

Overloading could lead to breakage and serious injury as a consequence.

STEELFORCE PRO 100 HC

6

2.9 Emergency Instructions

Immediately leave the area around the desk when it starts to move

spontaneously. Do not use the desk. Have the desk repaired by a specialized

company. Do not use the desk again until it has been repaired.

If you notice anything unusual, take the desk out of service immediately. Have

the desk repaired by a specialized company. Do not use the desk again until it

has been repaired.

2.10 Maintenance and upkeep

Always keep the product in good condition. If necessary, have it checked regularly

by a professional.

Do not repair the desk or any of its parts yourself.

Do not make any changes to the worktop or desk construction.

Defective parts may only be replaced with new original parts from the

manufacturer. Only use original replacement parts from the manufacturer. In

doing so, these installation instructions must be observed.

2.11 Cleaning

Once a week, remove the dust from the desk with a dry cloth.

Clean the desk every two weeks with a damp cloth and a mild detergent.

2.12 Persistent risks

This office is built according to the latest state of the art and according to recognized

safety regulations. Nevertheless, its use can

endanger the health and safety of users or third parties and cause damage to the desk

or other parts. The desk may only be used:

for the intended purpose;

if it is completely safe.

2.8 Specific dangers

Adjusting the height of the desk carries the risk of injury. Make sure that no one

else is in the immediate vicinity of the desk.

When mounting the desk, provide enough space to avoid collisions in all possible

directions (e.g. sloping roof, fixed objects, filing cabinets, waste bins, etc.).

Provide sufficient space to avoid collisions if objects such as computers or

peripherals are on the worktop.

Provide a clearance of at least 25mm from all other furniture around the desk

STEELFORCE PRO 100 HC

7

3 Assembly

3.1 Checking the items supplied

Carefully open the cardboard packaging.

In doing so, do not use any long knife blades. They may damage the components

inside.

Check the parts supplied against the list in Section 1.4 Items supplied.

Check the contents for visible transit damage, paying particular attention

to the electrical wiring. In the event of any damage or incorrect components, con-

tact customer service (see Section 6).

Do not attempt to assemble the workstation frame if there is any damage or if

there are any incorrect components.

3.2 Packaging

Remove the packaging. Treat as household waste/paper.

Observe national legislation.

3.3 Tightening torques for screws used

Assemble the workstation frame with the tools supplied only.

3.4 Assembly of the workstation

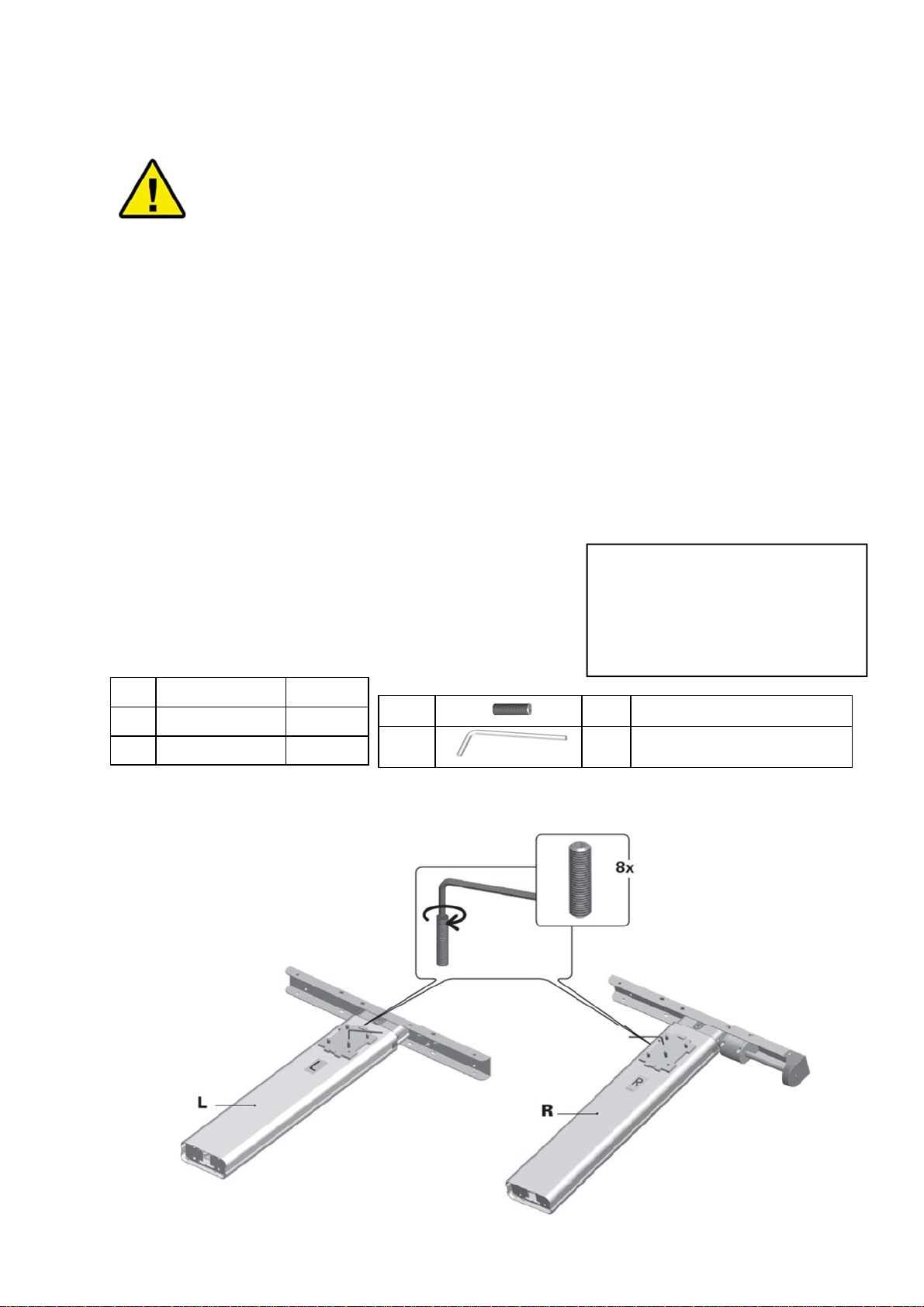

3.4.1 Pre-assembly of the Crossbar

Assemble the following components:

Before attempting assembly, read the safety information in Section

Dimensions Width

Frame Worktop

0,80 m 0,90 cm

1,00 m 1,10 cm

1,20 m 1,30 cm

Place the set screws in the threaded bores.

G Screw the set screws into the threads and tighten them slightly

# Name Qty

01 Leg L 1

02 Leg R 1

13.2 8 x M6x16 Adjusting Screw

13.8 1 x M3 Allen Key

STEELFORCE PRO 100 HC

8

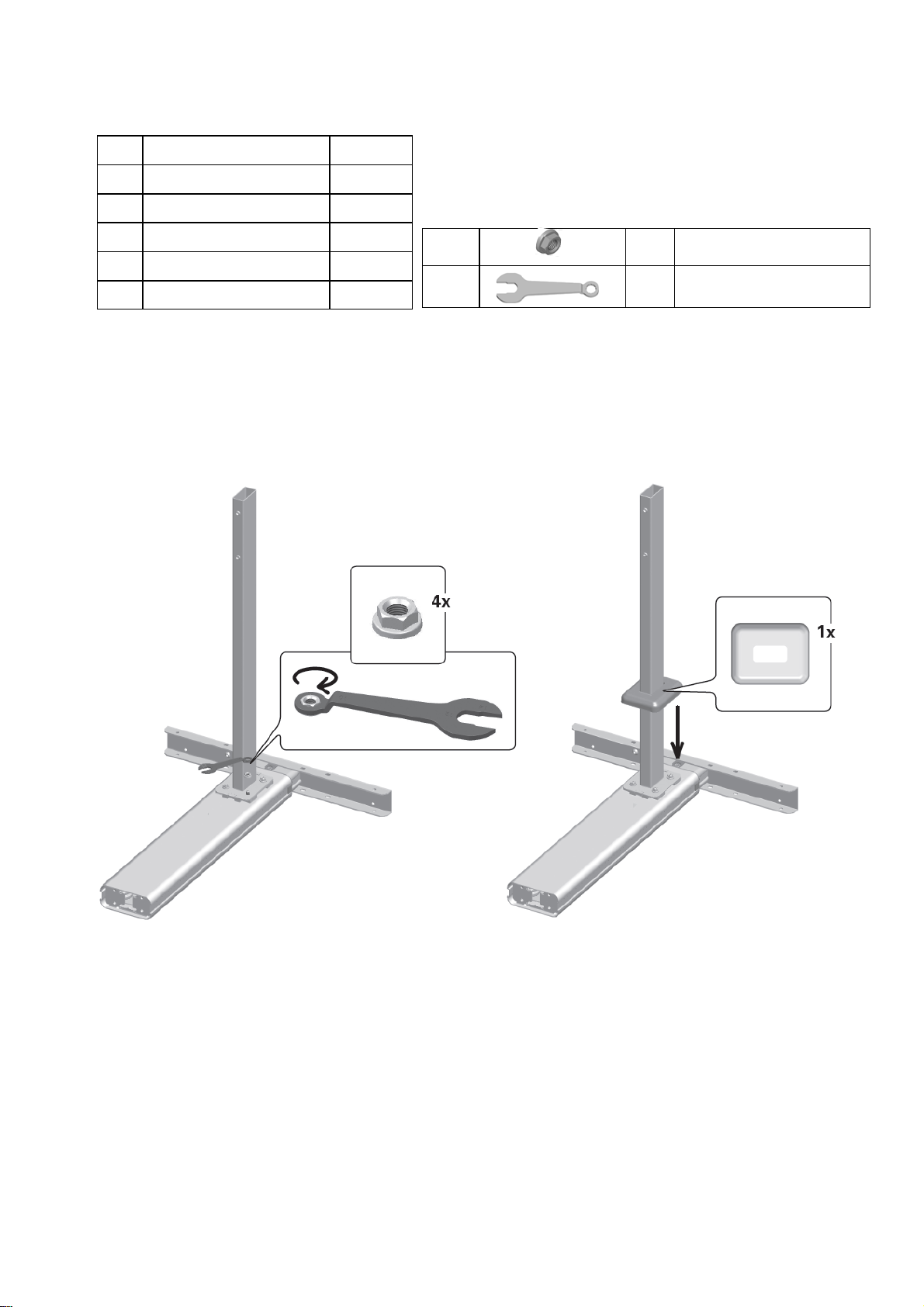

3.4.1 Mounting the Crossbar– Continued

Install the following parts:

13.3 8 x M6 Collar Nut

13.7 2 x M10 Installation Key

# Name Qty

01 Leg L 1

02 Leg R 1

04 Inner Crossbar 1

05 Outer Crossbar 1

07 Cover Cap, crossbar 2

Mount both caps on the ends of the crossbars by pressing them lightly.

Place one leg on the floor in front of you and place the other parallel next to it.

Screw the collar nuts onto the set screws on both legs.

Tighten the collar nuts with the M10 mounting wrench.

STEELFORCE PRO 100 HC

9

13.12 4x Cover cap

3.4.1 Mounting the Crossbar - continued

Install the following parts:

13.5 2 x M6x6 Adjusting screw

Now turn the legs with the crossbar (with two people). The crossbar is now just

above the floor.

Make sure that the legs do not fall over during assembly.

Extend the frame to the desired width.

Screw the studs into the crossbar and tighten them lightly.

A = position of the T-foot

Attach the blanking cap to the location shown

O R

B = position of the C-foot

Attach the blanking cap to the location shown

3.4.2 Mounting the feet

First choose the position of the legs!

STEELFORCE PRO 100 HC

10

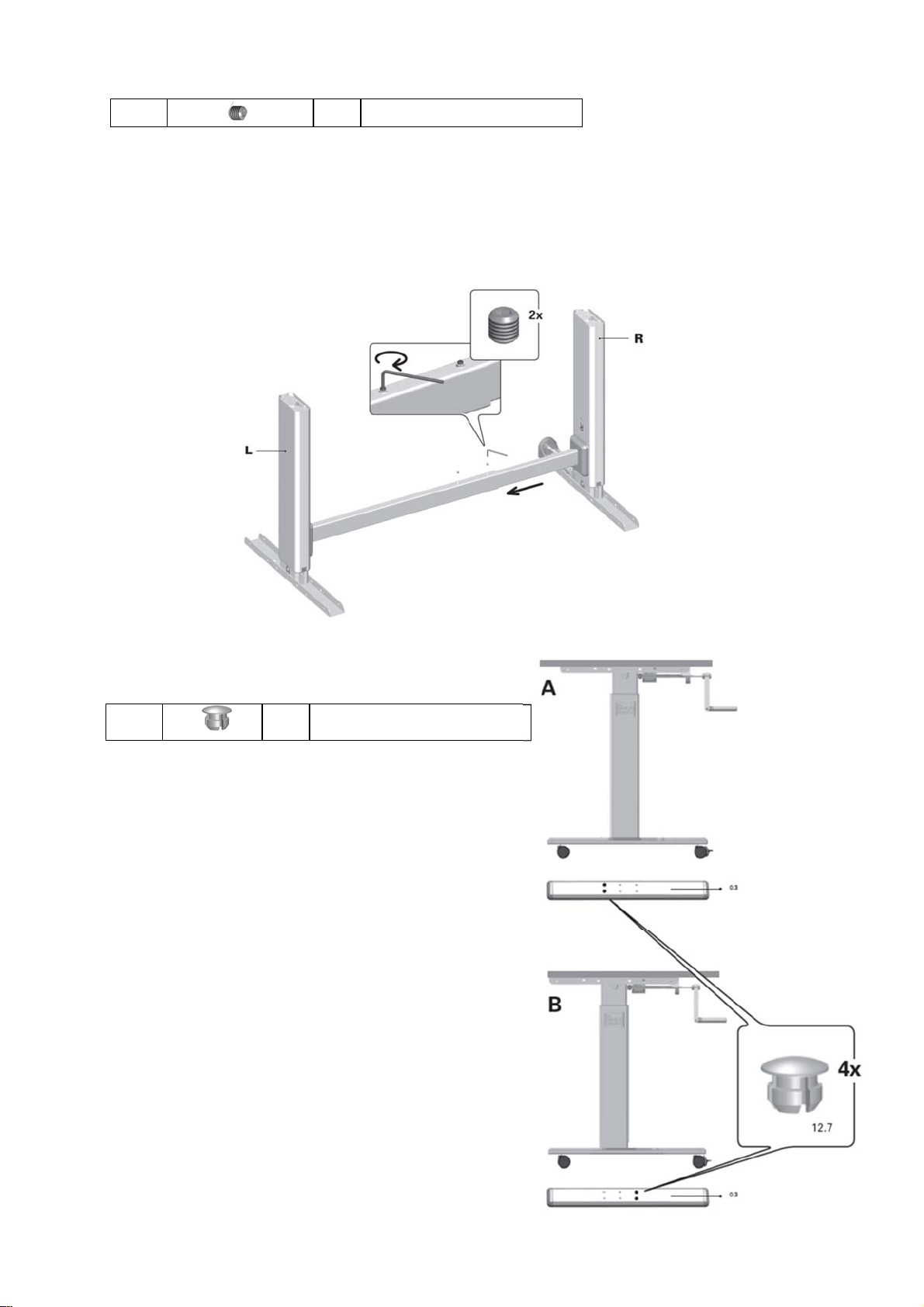

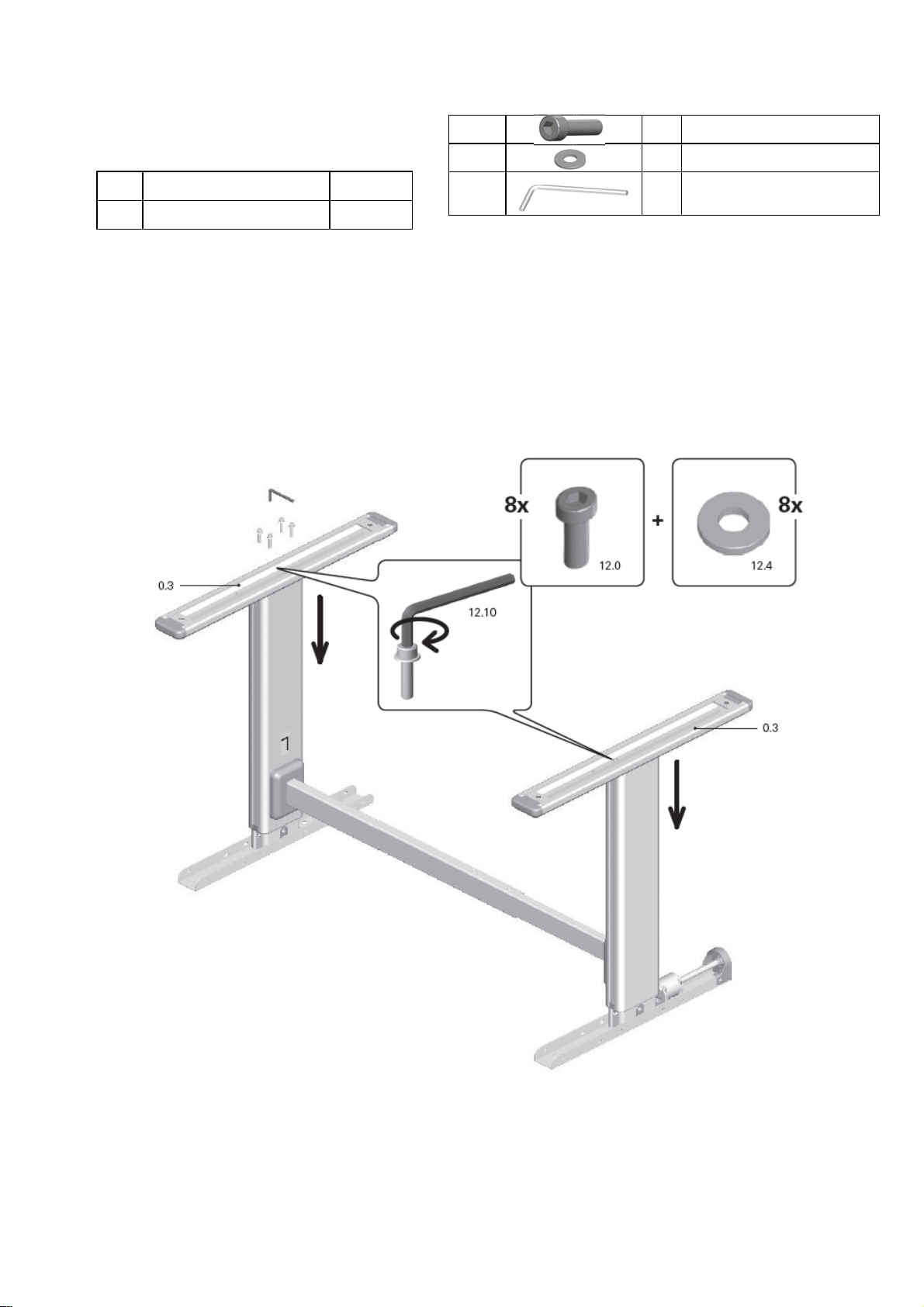

3.4.2 Mounting the Feet —continued

Install the following parts:

# Name Qty

03 Foot 2

13.1 8 x M6x25 Bolt

13.4 8 x M6 Ring

13.9 1 x M5 Allen Key

Mount a foot on each leg. Use four screws and washers for this.

Attach cover caps to the unused holes (as shown on the previous page).

Tighten the eight screws with the Allen key.

STEELFORCE PRO 100 HC

11

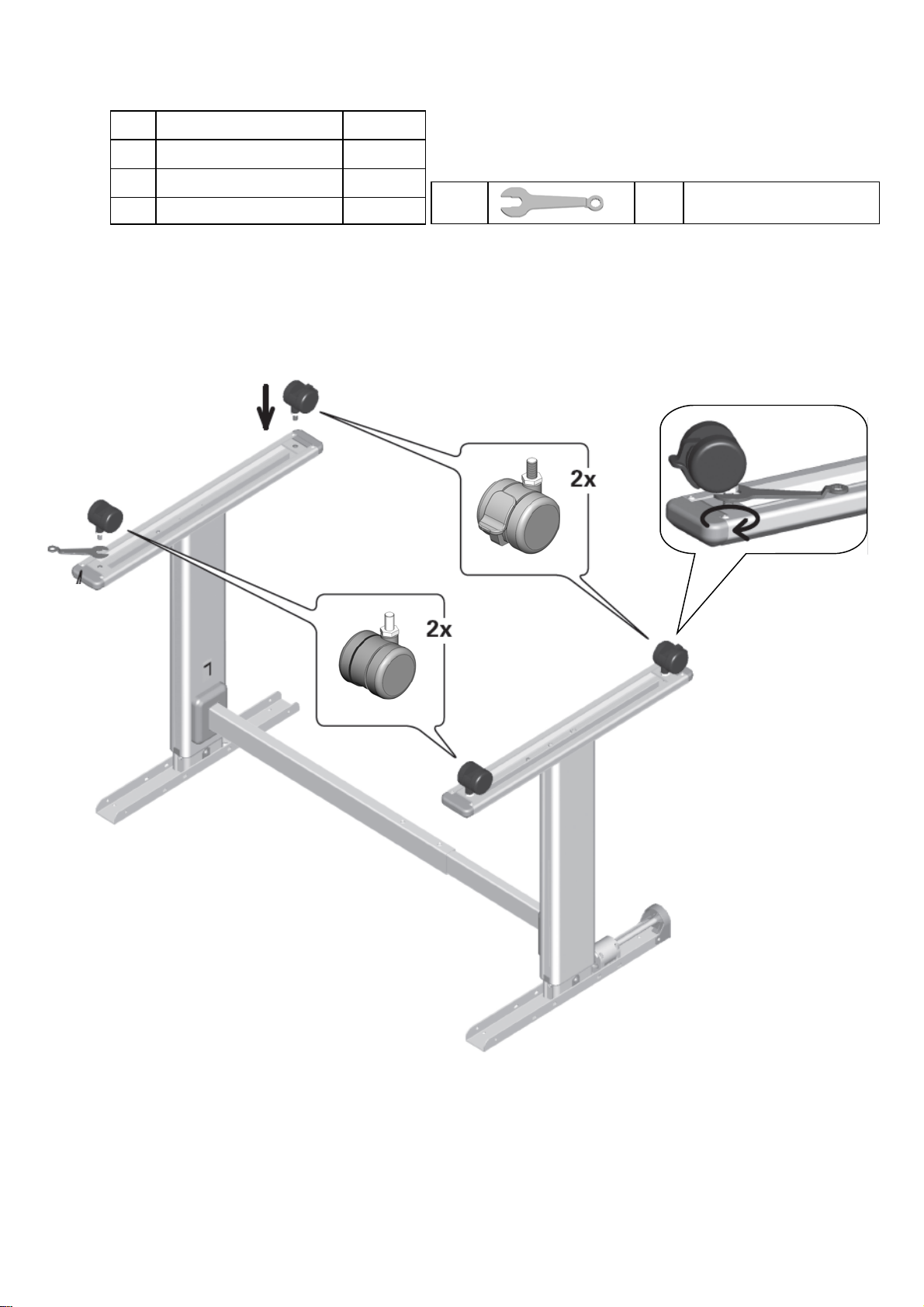

3.4.3 Installation of the Wheels / Adjustable Feet

Install the following parts:

# Name Qty

11 Adjustable foot 4

OR

12 Wheelset 4

Screw either two leveling feet or two wheels into each foot. Use the installation key

for this.

The desk is only stable when the adjustable feet are used. The use of the wheels is

at your own risk!

13.7 2 x M10 Installation Key

STEELFORCE PRO 100 HC

12

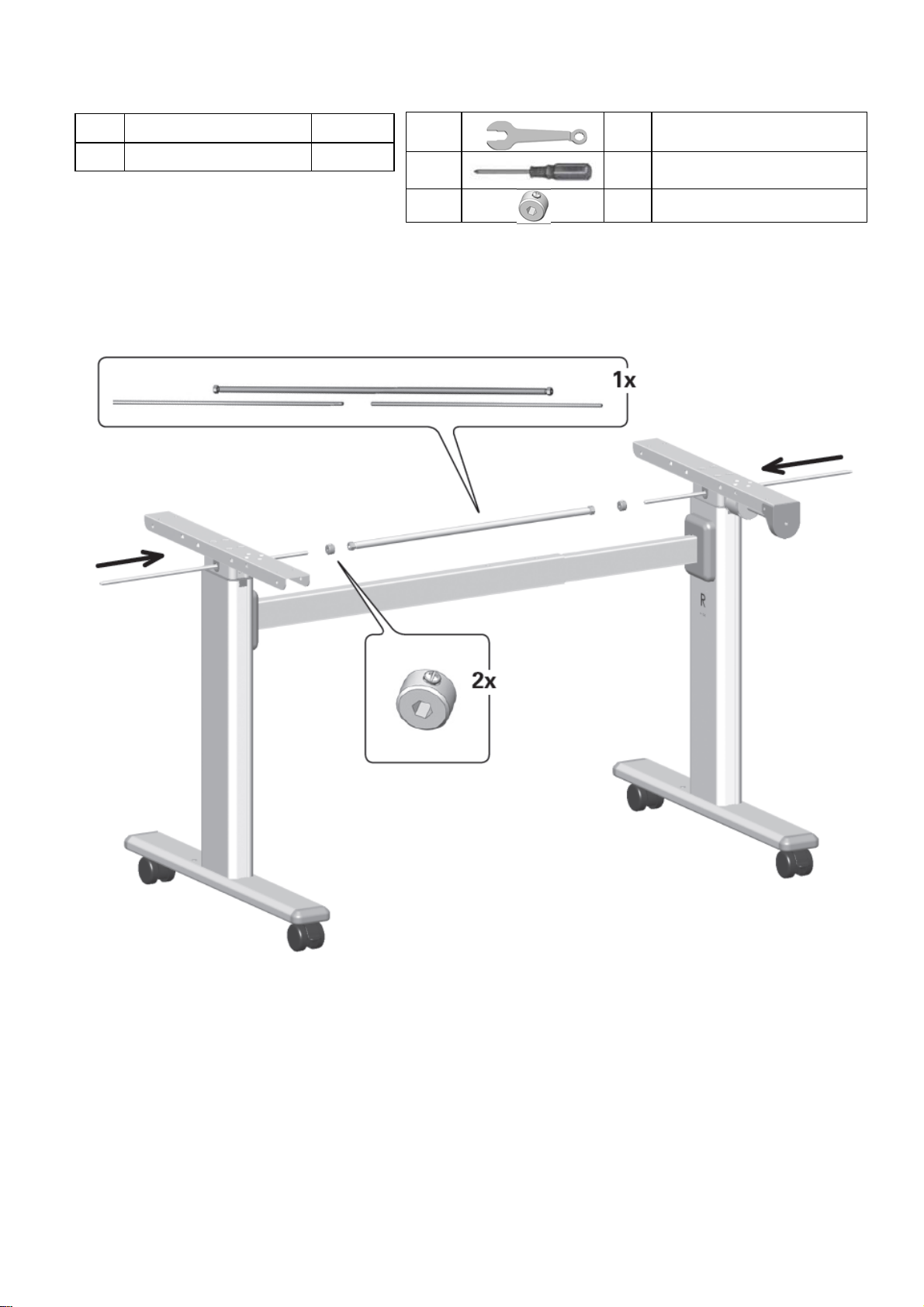

Make sure the legs are in the lowest position (zero position).

Slide the drive shafts (hexagon) from the outside to the inside through the hexagonal

openings in the legs.

Slide the two axles into the frame about 15 cm.

Attach a hex stopper to each axle.

Now slide the two hexagonal shafts into the receiving shaft.

# Name Qty

06 Drive shaft kit 1

3.4.4 Mounting the Drive Shaft

Install the following parts:

13.7 2 x M10 Installation key

13.10 1 x Screwdriver

13.11 2x Hexagon stopper

STEELFORCE PRO 100 HC

13

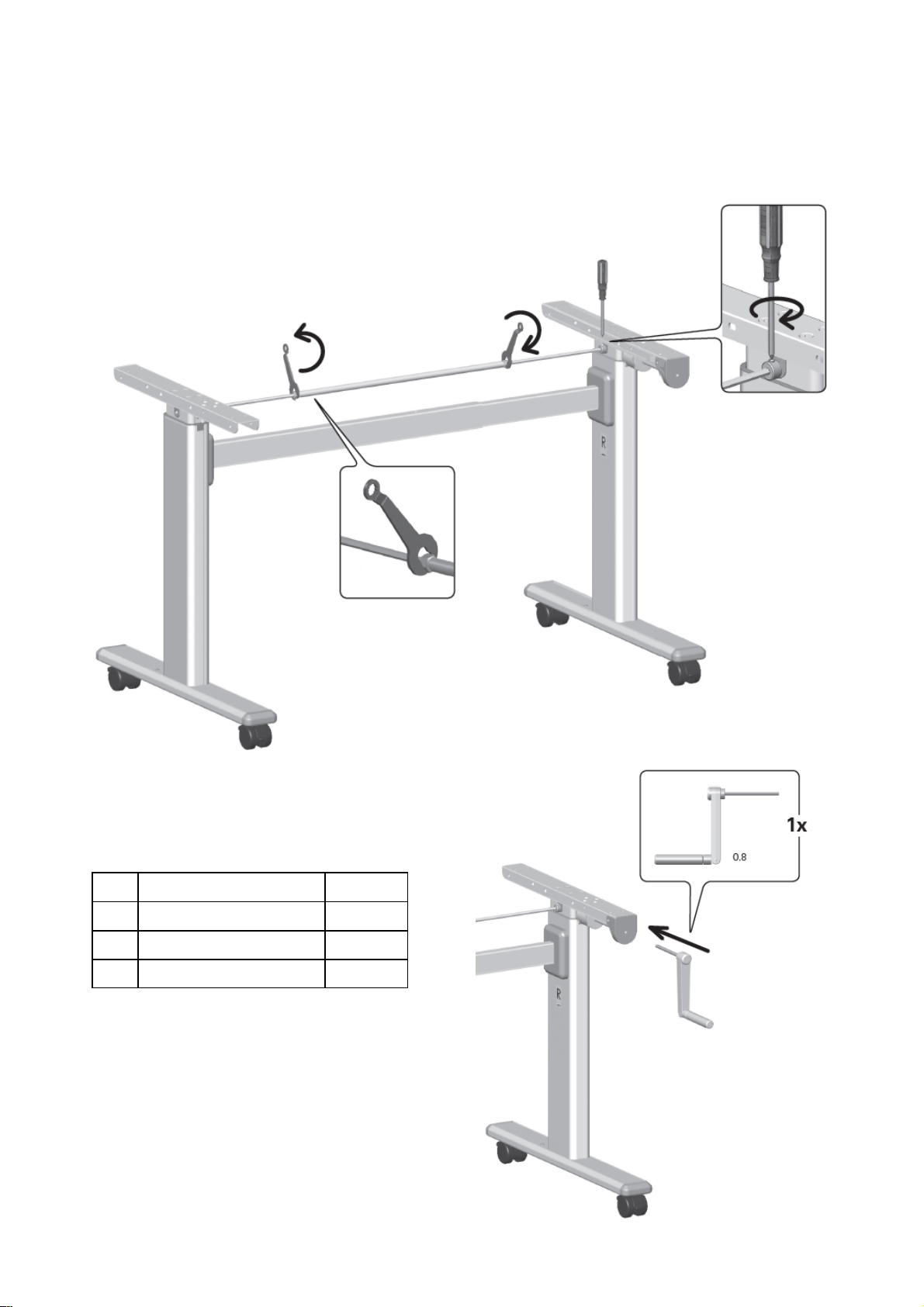

3.4.4 Mounting the Drive Shaft — Continued

Extend the frame to the desired width before beginning the following steps.

Slide both hex shafts into the frame until they touch the outside of the legs.

Now tighten both shafts at the ends with a Phillips screwdriver/slotted screwdriver.

3.4.5 Assembly of the Hand Crank

Install the following components:

When your worktop is in the correct position on the

tray supports, insert the crank into the hexagonal

opening as shown.

# Name Qty

08 Hand crank 1

09 Hand crank extension 1

10 Hand crank guide 1

STEELFORCE PRO 100 HC

14

3.4.6 Installation of the Hand Crank

Install the following components:

If the worktop protrudes far beyond the top supports that the crank has to be extended in

order to adjust the height of the workplace, proceed as follows:

Insert the crank guide into the crank extension.

Insert the crank extension into the hexagonal hole of the blade carrier as shown.

Attach the crank guide to the blade carrier using both # 8x5 / 8 screws.

13.6 2 x Screw 4.5x20mm

# Name Qty

08 Hand crank 1

09 Hand crank extension 1

10 Hand crank guide 1

3.4.7 Frame test without table top

Check the height adjustment function by first moving the frame to the highest position

and then back to the lowest position using the crank.

3.4.8 Assembly of the table top

If you have purchased the frame including worktop, read the loose ones assembly instruc-

tions. The supplied screws (13.6) can only be used in combination with a chipboard with a

thickness of more than 22 mm. Otherwise, follow the instructions in the separate assembly

instructions for the worktop.

3.4.9 Assembly of the parts of the table top

If you have purchased the frame including worktop, read the loose ones assembly instruc-

tions.

STEELFORCE PRO 100 HC

15

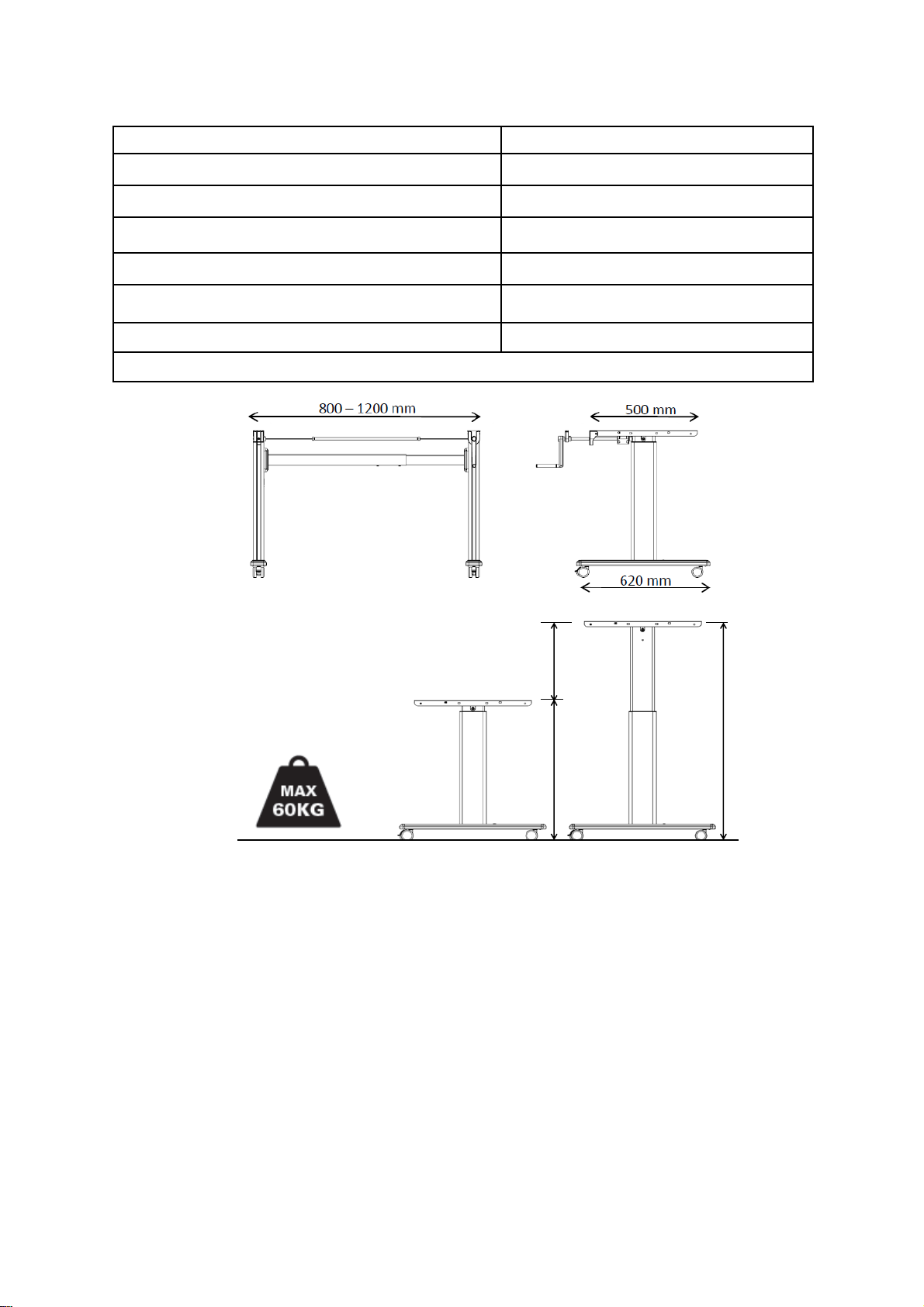

4 Technical Specifications

Frame for a manually height-adjustable sitting / standing workstation

Operating and installation manual version MVL-H11fA1P-0EN-DE-NL

System Single stage, hand crank

Material Steel and plastic

Stroke (max.) 410 ± 10 mm

Frame load (max.) Surface load 60 kg

Frame weight 16 kg

Stroke per revolution of the hand crank 13 mm per pendulum swing

Only for indoor use !!!

Minimum frame height 640 mm 680 mm

Maximum frame height 1050 mm 1090 mm

Maximum stroke 410 mm

Frame width 800 - 1200

Frame depth 620

Minimum worktop depth 500

Maximum frame load / surface load 60

Stroke per revolution 13 mm per pendulum swing

410 mm

mm

mm

mm

kg

680 mm 410 mm

1090 mm

(* Average tolerances= ± 10 mm)

STEELFORCE PRO 100 HC

16

5 Operation and Indicators

6 Customer Service

When contacting the customer service please

8 Recycling

8.1 Taking the workstation apart

In case of de-assembling please follow the manual backwards or contact cus-

tomer service.

8.2 Recycling

Please split all parts to their type of material. Keep notice of National restrictions!

7 Manufacturer

Retailer:

Actiforce International B.V.

Het Steenland 20

3751 LA Bunschoten-Spakenburg

The Netherlands

+31 (0)33 4600120

www.actiforce.com

Please observe the provisions of chapter 2 “Safety Infor-

mation” on page 5, especially:

Children may only use the desk under supervision. They may

not be aware of the dangers of the agency. Because of this,

they are in serious danger of that they may injure themselves,

possibly with fatal consequences. Protect the frame from the

use by children. Provide sufficient space to avoid collisions,

even when objects such as computers, work materials and the

like are on the worktop.

Table of contents

Other STEELFORCE Indoor Furnishing manuals

Popular Indoor Furnishing manuals by other brands

Courtyard Creations

Courtyard Creations RTS009P Assembly instructions

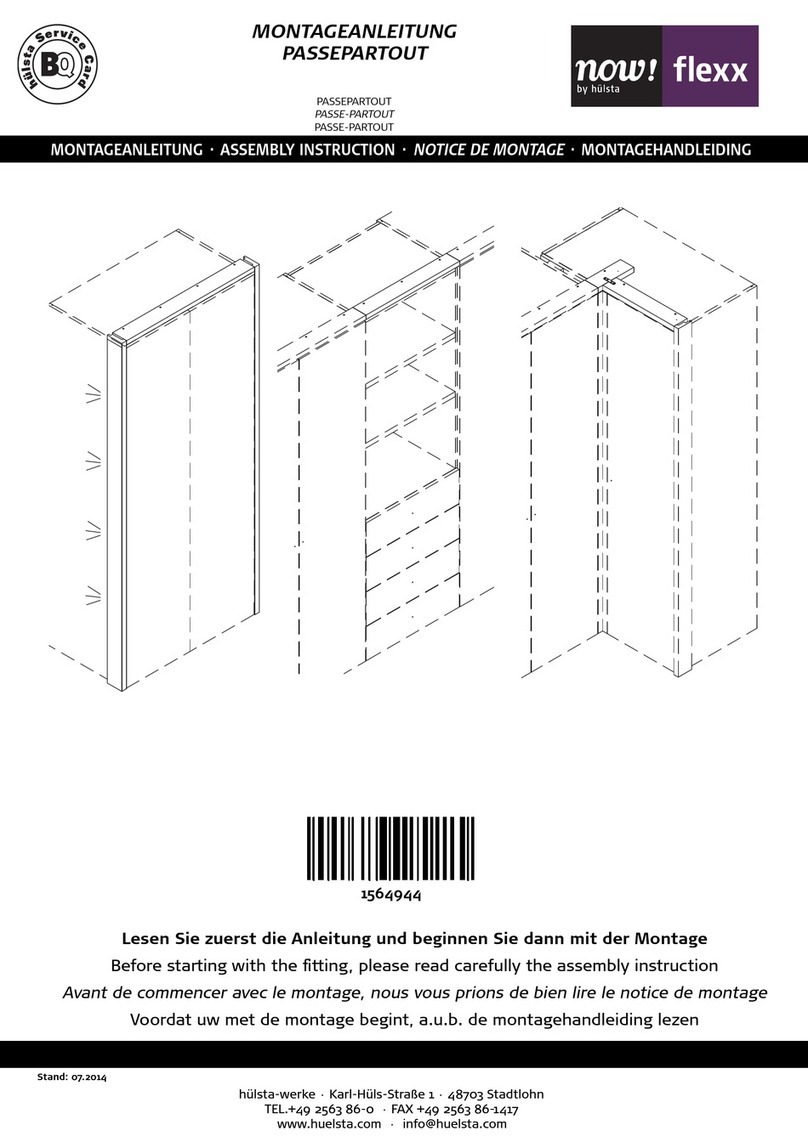

Rauch

Rauch M1793 Assembly instructions

Dentsply Sirona

Dentsply Sirona Hugo operating instructions

Accentrics Home

Accentrics Home DS-D477-701-1 Assembly instructions

Hülsta

Hülsta now! flexx PASSEPARTOUT Assembly instruction

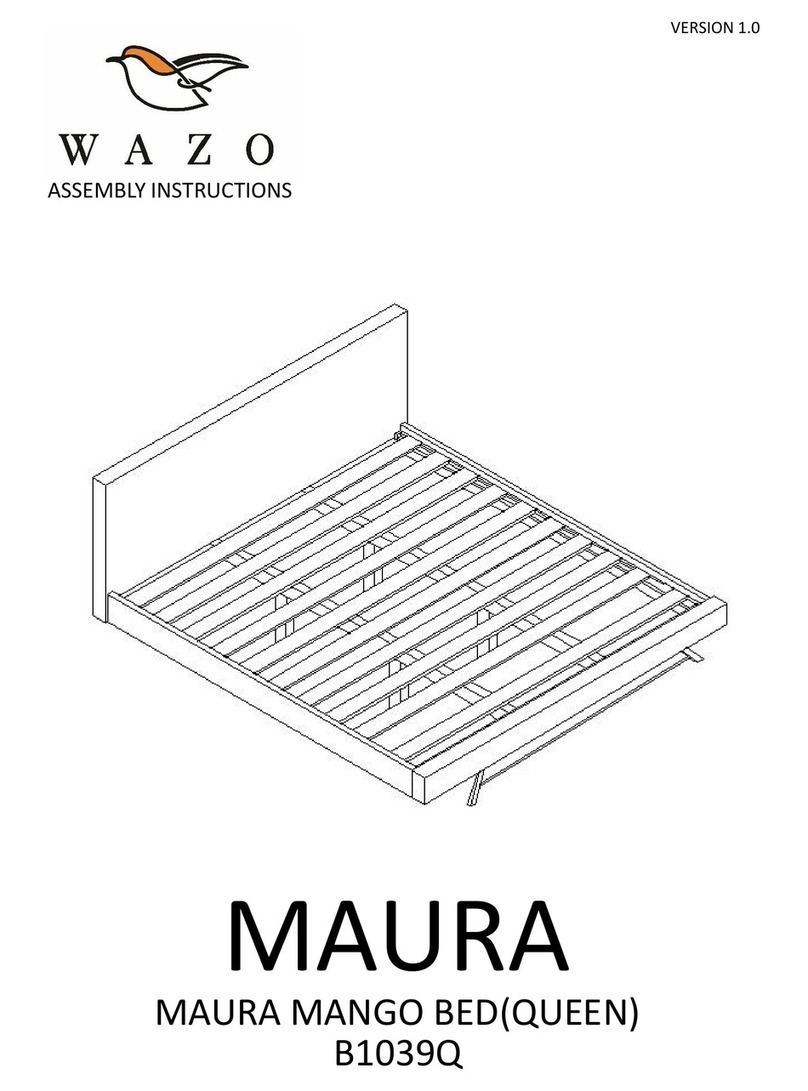

Wazo

Wazo MAURA MANGO B1039Q Assembly instructions