STEELTEC 52CC User manual

2

STEELTEC MULTITOOL

CONTENTS OF BOOKLET

Warnings Check List Page 3

What Is In Your Box/Assembly Page 4

Blade Assembly/Air Filter AƩachment Page 5

Blade Assembly/Air Filter AƩachment Page 6

Pole Assembly And AƩaching Page 7

OperaƟng The Pruner/Installing The Bar And Chain Page 8

AdjusƟng The Chain Page 9

Chain Oiler/Filling The Oil Resvoir/AdjusƟng The Oil Flow Rate Page 10

Typical ApplicaƟons Standard Cut Page 11

Steps For StarƟng Your Machine Page 12

How To Mix The Fuel Page 13

AdjusƟng The Idle Screw On Your Machine/Fuel Mixture Screw Adjustment Page 14

Maintenance On Your Pole Pruner Page 15

AƩaching Blades/AƩaching Nylon CuƩer And Bracket Onto Guard Page 16

How To Open And Close Whipper Snipper Head Page 17

Cuƫng OperaƟon/Maintenance Of Your Machine Page 18

Hedge Trimmer AƩachments Page 19

Installing The Hedge Trimmer Cuƫng Assembly/AdjusƟng The

ArƟculated Hedgetrimmer Cuƫng Assembly Page 20

AdjusƟng The Hedgetrimmer Cuter Assembly For Desired Cuƫng Angles/AdjusƟng

The CuƩer Assembly For Storage Or TransportaƟon/How To Use Hedgetrimmer AƩachment Page 21

Daily Maintenance Page 22

3

BEFORE USING THIS UNIT:

Please Read the Operator’s manual carefully.

Check that the Cung equipment is correctly assembled (please

read and follow instrucons on Page 5)

Start the Unit and check the carbureor adjustment (Please check

Page 11 for this step if needed)

Always Wear Eye, Head and Ear Protectors when

Using This Unit.

Keep all Children, bystanders and helpers 15m (50) away from

Unit. If anyone approaches you, stop the engine and cung

aachment immediately.

Gloves, Safety Goggles and ear muffs and Slip and Sturdy Footwear

should be worn at all mes when operang

tools or Machinery.

ALWAYS MAINTAIN THIS MULTITOOL ACCORDING TO THE OWNER’S

MANUAL AND FOLLOW THE RECOMMENDED SCHEDULED

MAINTENANCE.

NEVER MODIFY OR DISABLE ANY OF THE POLE PRUNER’S

SAFETY DEVICES.

ALWAYS USE GENUINE PARTS AND ACCESSORIES WHEN REPAIRING

OR MAINTAINING THIS MACHINE. DO NOT MAKE UNAUTHORIZED

MODIFICATIONS OR SUBSTITUTIONS TO THE GUIDE BAR OR CHAIN

NEVER ALLOW THE ENGINE TO RUN AT HIGH RPM WITHOUT A

LOAD. DOING SO COULD DAMAGE

THE ENGINE.

WHEN TRANSPORTING THE PRUNER IN A VEHICLE, TIE IT DOWN

SECURELY TO PREVENT DAMAGE AND FUEL SPILLAGE.

ALWAYS CLEAR YOUR WORK AREA OF TRASH OR HIDDEN DEBRIS

TO HELP ENSURE GOOD FOOTING.

KEEP THE SAW CHAIN SHARP AND PROPERLY ADJUSTED

KEEP THE PRUNER AS CLEAN AS POSSIBLE. KEEP IT FREE OF LOOSE

VEGETATION, MUD ETC.

15m (50ft)

4

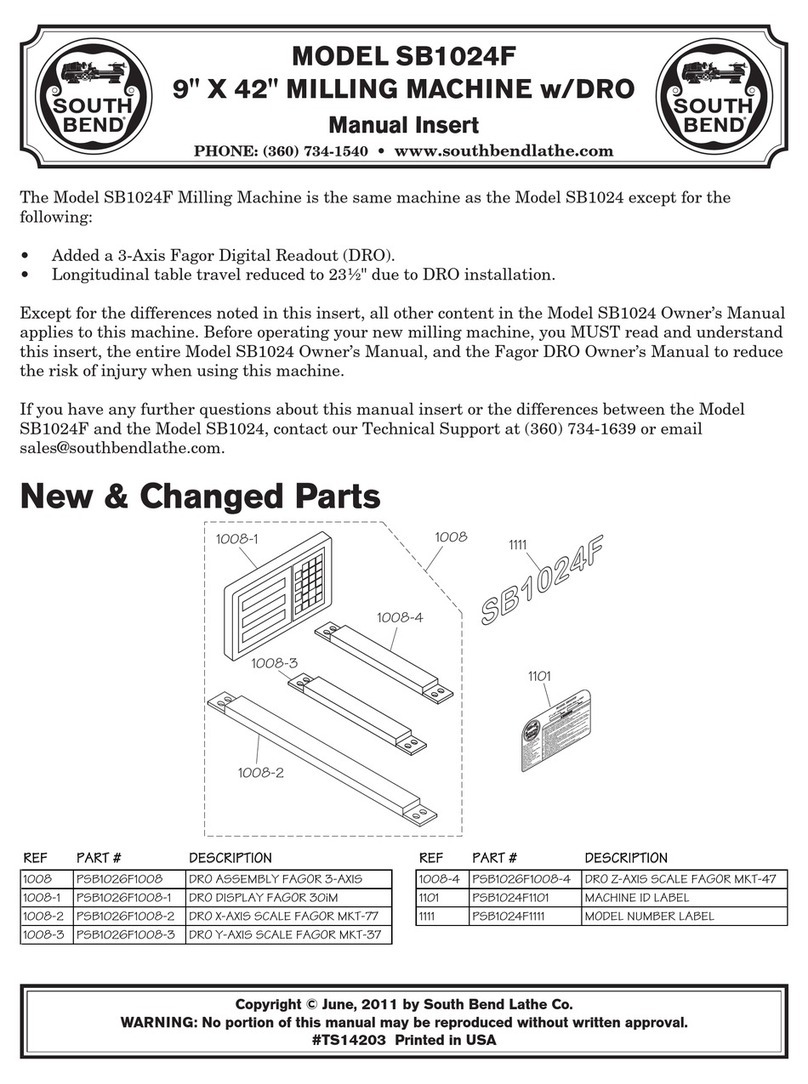

ACCESSORIES:

G1. 12” Chain cover

G2. 12” Guide Bar

G3. 12” Chain

J2. Poles

2,3 or 4 Poles vary depending

on product.

M. Hedge Trimmer

H. Coupler

K. Chain Head

N. Brush Cuer

i1. Airfilter

D. Hex screw for Air filter on the motor

L. Shoulder Strap

O. D Handle

G3

G1

G2

H

J2

J2

M

K

N

O

P

L

H

i

D

G2

G

G

G

G

G

G

G

G

G

J2

J2

J

2

J

J

M

M

M

M

M

M

M

M

H

H

K

K

K

K

K

K

K

K

N

N

N

N

N

N

N

N

N

i

i

i

L

STANDARD COMPONENTS

A. 4x Hex Screws & Nuts (Handle)

B. Nylon Cuer

C. Nylon Cuer Scew

D. 2 plasc es

E. Hex for Air filter on the motor

F. Tools

WHAT IS IN YOUR BOX

B

C

E

D D

F2 F2

F2

A

A

F

F

F

5

HANDLE ASSEMBLY:

STEP 1

Rubber sleeve should already be on pole.

STEP 4

Place the top segment of the handle as seen above.

STEP 2

Insert nuts into the boom segments of the handle as

seen above.

STEP 3

Place the boom segment of the handle into the groove

of the rubber sleeve.

STEP 5

Insert hex screws provided.

6

D

i

ATTACHING THE AIR FILTER TO YOUR MACHINE:

BLADE ASSEMBLY

EIGHT TOOTH

FOURTY TOOTH

THREE TOOTH

FOUR TOOTH

(please note that quanes of blades will vary per model - 5in1, 6in1, 7in1, 8in1)

TWO TOOTH

PLASTEC

7

POLE ASSEMBLY & ATTACHING

1ΉAach Coupler/Joiner (H) to the end of the pole that does

not have the pre-drilled inxdex hole. Phsical holes are

not neccessary for aaching the joiner. Screws on

coupler or joiner are pressure aached against pole.

3ΉPlace pole into joiner with index hole facing upwards.

Adjust/Rotate the hole unl it firmly clicks into place.

2ΉVisible holes at the base of the pole are

4ΉPush down the safety shield firmly unl it locks into

place. Once down ghten the T-handle unl its firm (to

protect the release mechanism).

5ΉRELEASE

Release the safety sheild and push down on the release

clip while gently rotang and removing pole.

H

H

BASE OF POLE

Index hole facing up

TOP OF POLE

Coupler Attaches this end

SCREWS

Screw in Hex screws until

firm against pole.

H

H

H

H

H

H

H

H

H

H

8

Hook the strap hook to the outer pipe on the sha

of the machine

Wear the strap so that the hook stays at your right hand side.

Adjust the length of the strap so that it is comfortable and at the

correct length whilst operang the pruner.

In emergency situaons unhook the metal clasp, this will release

the machine from the strap.

Please View Mega Machine Warehouse Help Videos For Installation.

of Poles and Starting Sequence For Operation Of This Machine.

OPERATING THE PRUNER

INSTALLING THE BAR AND CHAIN

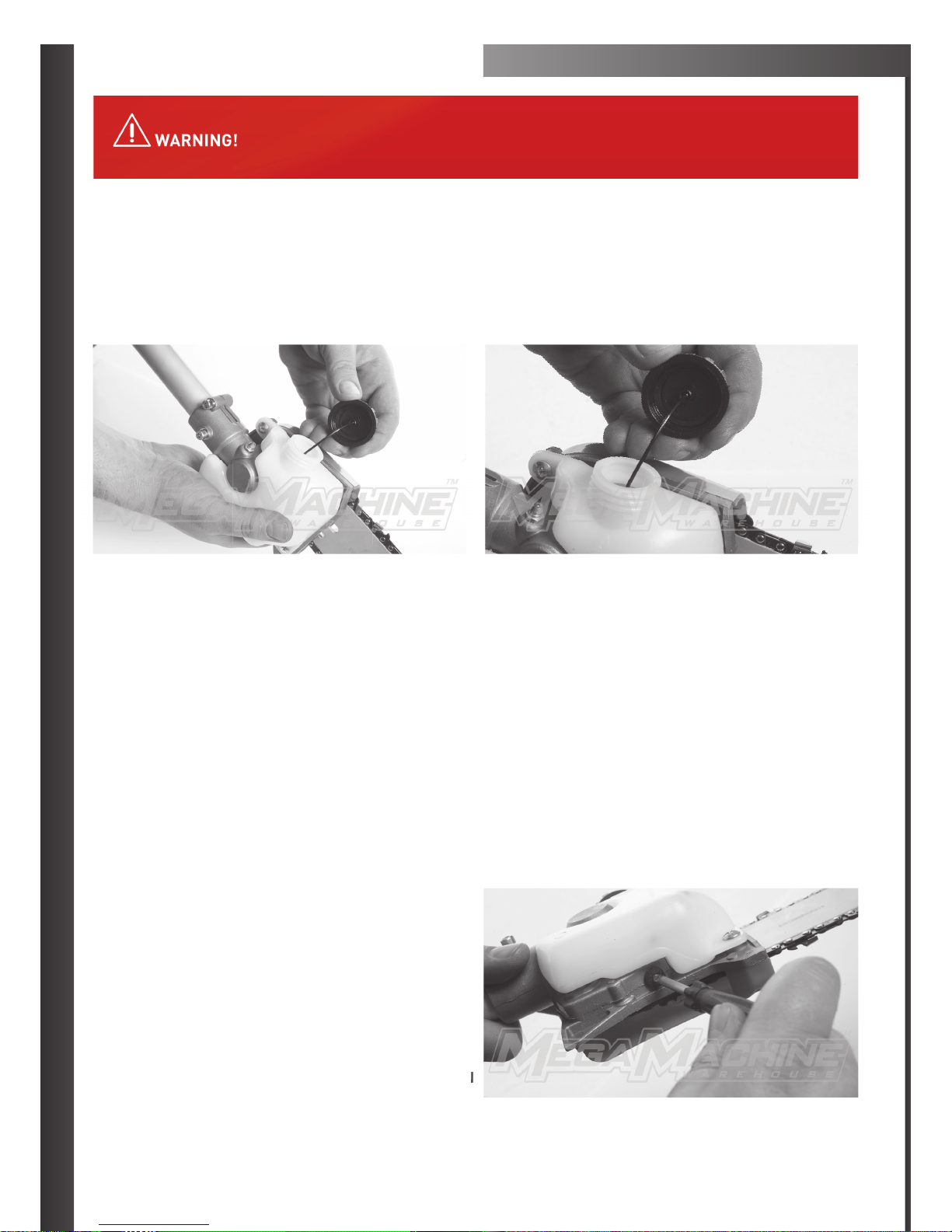

NEVER ATTEMPT TO INSTALL, REPLACE, OR ADJUST THE CHAIN WITH THE ENGINE RUNNING!

WARNING! THE SAW IS VERY SHARP. WEAR GLOVES TO PROTECT YOUR HANDS WHEN HANDLING.

1ΉUsing the small end of the plug wrench remove sprocket

cover nut (turn counterclockwise to remove).

3ΉInstall the chain loop over the drive links within the guide bar groove, and then align the chain over the drive sprocket.

Make sure the cuer are properly oriented as shown in the picture below.

2ΉPlace the guide bar over the guide bar adjustment stud

on the cung head assembly. Align the chain tension pin

with the hole in the guide bar.

4ΉInstall the sprocket cover over the bar stud.

Using finger-pressure only, install the

sprocket cover nut.

9

IMPORTANT

Proper chain adjustment is essenal for maximum performance, long chain life, and operator safety. Always inspect chain tension before

operang the pole pruner.

1ΉLoosen the sprocket cover nut with a Plug wrench.

2ΉLithe nose of the guide bar while turning the chain tensioning screw

Clockwise to ghten the chain Counterclockwise to loosen the chain.

3ΉPull the Chain by hand along the top of the guide bar several mes from the engine to the bar’s p. The chain should feel sung

but sll pull freely.

4ΉTighten the sprocket cover nut securely while liing the p of the guide bar.

5ΉInspect the chain for correct adjustment (more frequently with a new chain). The chain should feel snug but sll pull freely.

ADJUSTING THE CHAIN

NEVER ATTEMPT TO INSTALL, REPLACE, OR ADJUST THE CHAIN WITH THE ENGINE RUNNING. WARNING! THE SAW CHAIN IS VERY SHARP.

WEAR GLOVES TO PROTECT YOUR HANDS WHEN HANDLING.

CAUTION! A LOOSE CHAIN CAN JUMP OFF THE GUIDE BAR CAUSING DAMAGE TO THE CHAIN AND ASSOCIATED EQUIPMENT. ALWAYS MAKE

SURE THE CHAINS IS PROPERLY ADJUSTED; CHECK MORE OFTEN WHEN YOU ARE BREAKING IN A NEW CHAIN.

10

CHAIN OILER

FILLING THE OIL RESEVOIR

The oil reservoir has a capacity sufficient to provide about 40 minutes of cung me (when set to deliver the minimum flow rate)

1ΉPlace the pole pruner on a clean, flat surface with the oil filler cap facing up.

Wipe offany debris from the oil cap and from around the oil filler neck.

2ΉRemove the oil filler cap and fill the reservoir with bar and chain oil, then replace the cap.

3ΉWipe up spilled oil from the unit before restarng the pole pruner.

ADJUSTING OIL FLOW RATE

The guide bar and chain are lubricated automacally by a pump that operates whenever the chain rotates, the pump is set at the factory to

deliver a medium flow rate, but it can be adjusted in the field. A temporary increase in oil flow is oen desireable when cung things like

hardwood or wood with a lot of pitch.

ADJUST THE PUMP AS FOLLOWS:

1ΉStop the engine and make sure the stop switch is in the

STOP posion.

2ΉPlace the unit on it’s side with the oil Reservoir up

3ΉWith a screw driver, push in on the oil flow rate adjusng

screw and turn in the desired direcon (there are

three incremental sengs):

CLOCKWISEͳDECREASE LUBRICATION

COUNTERCLOCKWISEͳINCREASE LUBRICATION

NEVER FILL THE OIL RESERVOIR NOR ADJUST THE OILER WITH THE ENGINE RUNNING.

N

11

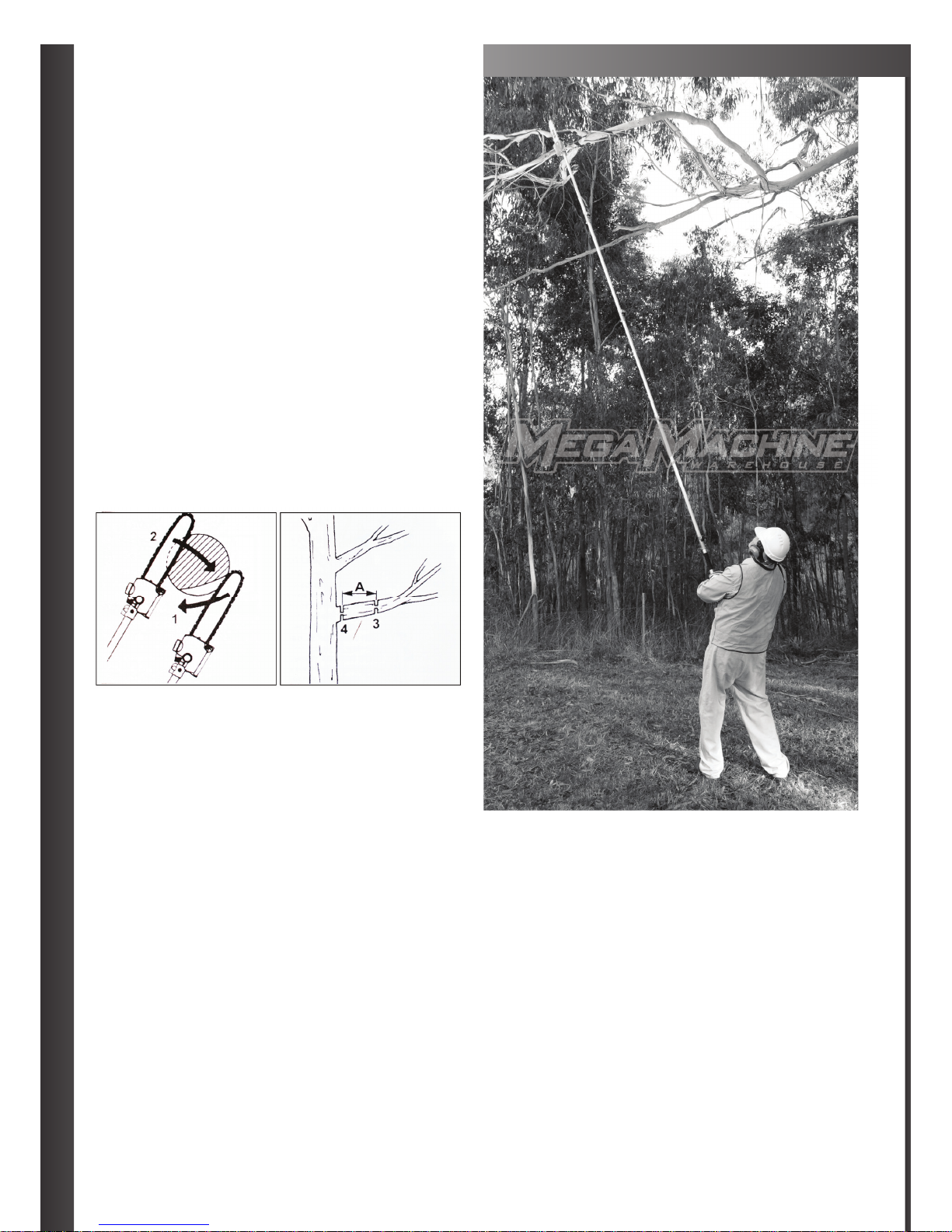

TYPICAL APPLICATIONS

STANDARD CUT:

The most convenient working posion is a tool angle of 60O, but any

other angle may be used to suit the situaon concerned.

CUTTING ABOVE OBSTACLE:

Thanks to the unit’s long reach it is possible to prune branches that

are overhanging obstacles, such as rivers or lakes. The tool angle in

this case depends on the posion of the branch.

WORKING TECHNIQUES ΈPLEASE READΉ

RELIEVING CUT:

To avoid tearing the bark, kickback or pinching the bar when pruning

thick branches, always start by performing a relieving cut e.g if the

branch you are cung is around 5 cms thick cut from the lower part

of the branch upwards, then stop and turn the pole pruner on the

other side of the branch downwards cung the branch offthe tree.

FLUSHͳCUTTING THICK BRANCHES:

If branch diameter is more than 10cm (4”), first perform undercut

(3) and cross-cut at a distance (A) of about 25cm (10”) from the final

cut. Than carry out the flush-cut (4), starng with a relieving cut and

finishing with a cross-cut.

12

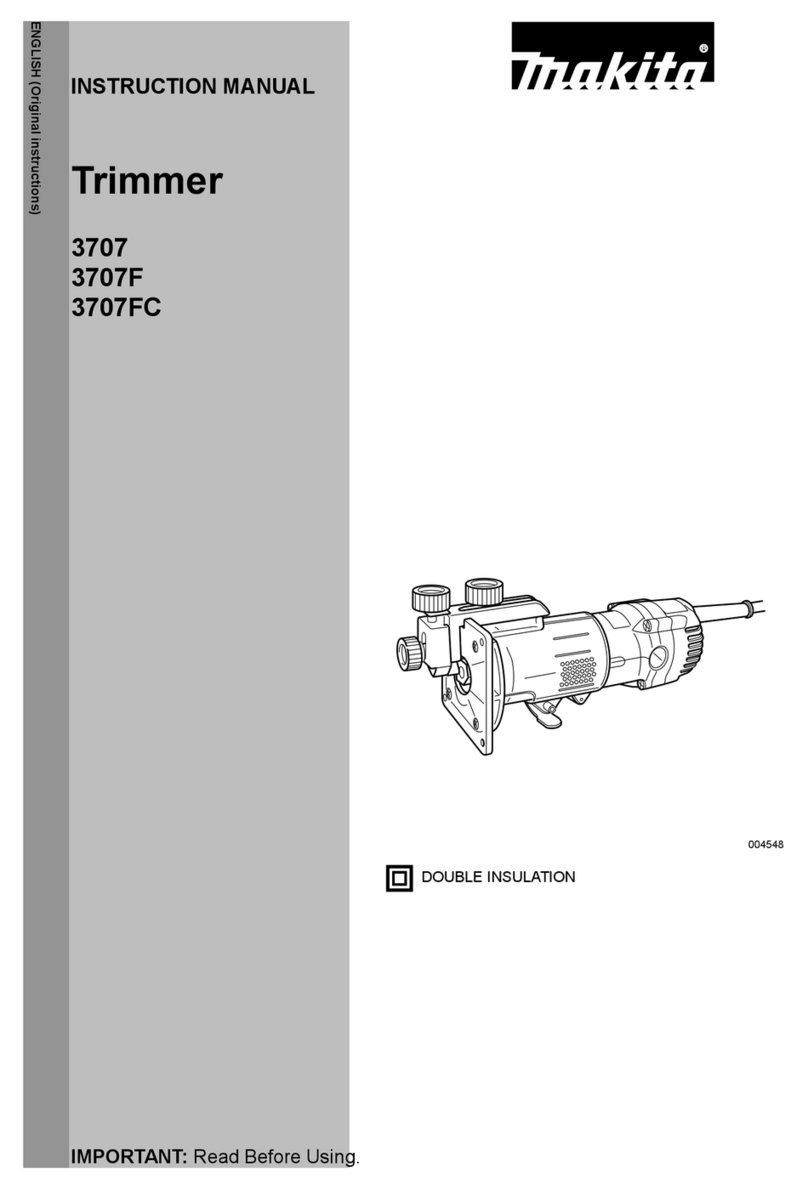

STEPS FOR STARTING YOUR MACHINE

STEP 1

Mix the 2 stroke fuel to the correct

rao (25:1)-(30:1) and fill the tank.

!SEE BELOW FOR FUEL INFORMATION

STEP 4

Slide the take on switch to the

down posion.

STEP 7

Pull the recoil 2–4 mes. By the fourth

pull, it should sound like the engine is

going to start. Move to Step 8.

STEP 2

Press the fuel bubble 5–7 mes (no

more than 7). Fuel should now fill the tube

next to pump.

STEP 5

Squeeze the top and boom levers

in and hold in firmly (as pictured in 5.2).

STEP 8

Slide the choke down to the boom

posion for the final starng and running

operaon of the machine.

STEP 3

Slide the choke to the up posion.

STEP 6

While holding top lever and boom

lever squeezed in, slide down or push in

the locking switch.

STEP 9

Pull the recoil once again, or unl

the engine starts.

CHOKE SETTINGS

ON POSITION: IS FOR INITIAL STARTING

OFF POSITION: IS FOR THE RUNNING OPERATION OF THE MACHINE

13

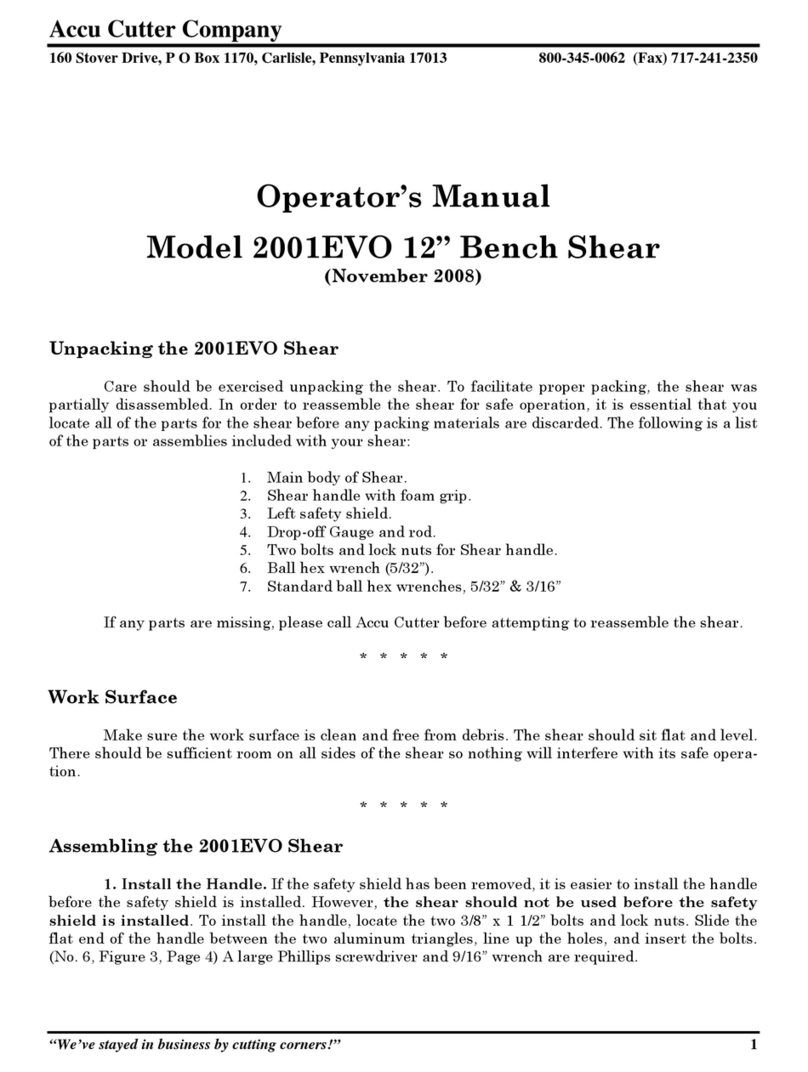

HOW TO MIX YOUR FUEL

Common mixtures are 25:1/30:1. If you find your machine is too

smoky please use the higher rao which is 30:1 as seen in diagram C.

WHAT IS 25:1/30:1?

The first part of the formula refers to how many parts of fuel as seen

in diagram A. The second part of the formula refers to how many

parts of oil (diagram B or C). For example, 25 parts of unleaded fuel or

low octane to 1 part of two stroke oil or 30 parts of unleaded or low

octane fuel to 1 part of two stroke oil.

REMEMBER TO MIX WELL (SHAKE BOTTLE)

ONLY USE THIS RECOMMENDED 2 STROKE FUEL MIX WITH A GOOD QUALITY 2 STROKE OIL FROM YOUR LOCAL SUPPLIER, USING A MIX

RATIO OF 25:1/30:1 IN THE MACHINE. UNLEADED OR LOW OCTANE FUEL ANY OTHER FUEL MUST BE USED IN A TWO STROKE MIX. MIX WELL

AS RECOMMENDED. INCORRECT MIX COULD DAMAGE YOUR ENGINE VOIDING YOUR WARRANTY, USE THIS FUEL MIX EVERY TIME YOUR

MACHINE IS IN OPERATION FOR THE BEST DINGO TOOLS PERFORMANCE YOU CAN EXPECT OUT OF YOUR DINGO TOOLS MACHINE.

1

:

25

OIL

600

576.92

500

400

300

200

100

GASOLINE

FULL

1

:

25

OIL

600

576.92

30:1

C

1

:

25

OIL

600

576.92

25:1

BA

1

:

:

:

:

:

:

:

25

25

25

25

2

5

5

25

5

OI

O

O

O

O

O

O

O

L

L

L

L

600

576 92

57

57

7

7

7

57

7

7

6.

6.

.

6.

.

.

92

92

92

9

9

500

25

AT ALL TIMES PLEASE KEEP THE FUEL TANK FULL WHEN IN OPERATION,

“AVOID HAVING THE YOUR ENGINE FINISHING OPERATION FROM FUEL

STARVATION. FUEL TANKS BEING KEPT FULL AT ALL TIMES WILL IMPROVE

YOUR MACHINE PERFORMANCE.

FUEL RUNNING OUT WHILE IN OPERATION MAY DAMAGE YOUR ENGINE,

PLEASE BE SURE TO REFILL THE TANK, KEEPING THE FUEL WELL FILLED

DURING OPERATION IN ASSISTING AND AVOIDING BREAK DOWNS OR

OPERATION INTERRUPTIONS. FUEL TANKS BEING EMPTIED DURING

OPERATION, MAY RISK DEBRIS ALL FOREIGN OBJECTS ENTERING INTO

THE FUEL INTAKE CONFIGURATION SYSTEM CAUSING BLOCKAGES, OVER

HEATING AND EVEN PISTON FAILURE. TO AVOID THESE CIRCUMSTANCES

PLEASE KEEP YOUR FUEL TANK WELL FILLED AT ALL TIMES, AVOIDING

ENGINE BREAKS INCURRED, FROM THE RESULT OF FUEL STARVATION.

14

ADJUSTING IDLE SCREW

ON YOUR MACHINE

If your Idling of your brushcuer needs adjusng e.g it is idling too fast or slow or is cung out please follow the steps below on how to adjust

this on your machine.

When looking down in a birds eye view at the carby or Choke area, at the the top of the Carby where the throle control cable aaches to the

side of the mechanism, you will see a silver screw on the right hand side at the top.

Where the Sliver Screw enters in and the p of the Silver Screw comes out the outer side, you should be able to view when looking at least 3 –

4mm of screw p, turning this screw to the lewill speed up the idle, while turning the silver screw to the right will slow the idle down.

We suggest that you adjust the screw so you may be able to view 3 or 4mm of screw p, if you see more screw p, please back adjust the

screw to this suggested seng and if you are viewing less of the screw p, please adjust the screw so you are able to view more of the p at

least 3 or 4mm of screw p and no more or less.

FUEL MIXTURE SCREW ADJUSTMENT

If your machine is not revving or not running correctly please

adjust the Fuel Mixture Screw with the steps

to the right.

When facing the Carby side of the machine and looking at the

carby on the right hand side of the Carby down near the top of

the fuel tank and infront of the black fuel line in take tube, you

will see a brass screw, this is the fuel mix screw, this adjusts how

much fuel may enter the machine.

To set this screw in the correct posion we need to start the screw at zero first, please turn the brass screw all the way to the right or clock wise

unl it will not turn any further, please try not to over turn it when screwing it all the way in, as when you have reached the end of it’s thread

and if you keep turning it with force, you may snap the screw off.

When you have turned the screw all the way in to the right or clock wise so it can not turn any further this is what we call or state as being

at zero. Now please turn the screw 1 and 1 quarter turns to the leor anclock wise to set it in the correct posion for the fuel intake and

smooth operaon.

*** NOTE ***

If 1 and 1 quarter turns isnt enough as the adjustment has not being successful please start the brass screw back at zero and try

a 1 and half full turns anti clock wise or to the left to set the carby with a little bit more fuel into the machine.

15

MAINTENANCE OF YOUR POLE PRUNER

EVERY 50 HOURS OF OPERATION (more frequently in dusty or dirty condions)

1) Remove and clean the cylinder cover and clean dirt and debris from the cylinder cooling fins.

2) Remove the sprocket cover and inspect the sprocket for

excessive dirt, debris, or wear. Remove the guide

bar and clean out the guide bar groove. If the sprocket

is excessively worn, replace it with a new one.

3) Lubricate the gearcase. To perform this operaon, first

remove the gearcase from the upper outer tube

as follows.

4) Follow “Disassembling the pole secons” secon to remove the upper tube from the gearcase.

5) Using a lever-type grease gun, pump lithium-base grease (about 10 grams) into the grease fing unl you see old grease being

purged from the gearcase, which can be seen in the outer tube cavity. Clean up excess grease, then reassemble the gearcase

onto the outer tube.

16

ATTACHING BLADES

ATTACHING NYLON CUTTER AND BRACKET ONTO GUARD

STEP 1

Remove top nut, top plate and

resng plate.

STEP 2

Posion center of blade over raised circular

lip (fing into blade.)

STEP 3

Posion 3 (boom plate) onto assembly.

STEP 4

Posion 2 (top plate) onto assembly.

STEP 5

Apply 1 (locking nut) and

turn an-clockwise to lock into posion

(whilst holding the screw driver through

outer and inner index hole on head.)

1

1

1

1

1

2

2

2

2

2

3

3

3

STEP 1

Aach screw into nylon cuer and then screw onto splaer cover

which is the lower outer black part of the guard.

STEP 2

Apply hex screws into bracket and fit bracket and hex screws around

pole into guard. Tighten unl firm.

B

A

1

1

1

1

1

1

1

1

1

2

2

3

2

1

1

1

1

1

1

2

2

2

2

2

2

2

2

2

3

17

HOW TO OPEN WHIPPER SNIPPER HEAD

HOW TO CLOSE WHIPPER SNIPPER HEAD

STEP 1

To aach lid correctly please line up

markers on base and lid.

STEP 4

Line up markers in the appropriate posion

for aachment.

STEP 7

Push down on tab from step 2 while

applying pressure to top and boom.

STEP 2

Push down on tab and Rotate base

clockwise.

STEP 5

Please be sure that the male and famale

connectors are aligned.

STEP 8

Following through from step 7, when tab

has been pushed into lid rotate to lock

into place.

STEP 3

Connue rotaon and seperate lid

from base.

STEP 6

Following through from step 5.

Please see videos on Mega Machine on Changing Whipper Snipper Line or Assembling Whipper Snipper Head.

18

CUTTING OPERATION

Always Cut by Guiding the head from your right to le.

Adjust the idle speed (see page X) for different types of grass you cut e.g cut tough shrubs or weeds at a high idle, and young

grass at a middle speed.

A metal blade cut best up to the point 1/3 from the edge. Use that area for cung shrubs, tough and thick weeds. For cung

young grass, you can use up to 2/3 from the p of the blade.

MAINTENANCE OF MACHINE

GEAR CASE

Please Supply Mul-purpose grease at every 25 hours of use. Remove the cuer holders to arrange for old grease to exsist.

MAITENANCE BEFORE STORAGE

Brushing offdirt from the machine, check damage or slack of each part. If you find out abnormalies,

repair them for the next use.

Extract fuel from the tank, and loose the drain screw of the float cabin to extract fuel, turn on the engine, and leave it running

unl it stops naturally.

Remove the spark plug and put in 1-2cc of 2 cycle oil in the engine. Draw the starter 2-3 mes, set the plug back and stop it at

the contacon posion.

Apply an-rust oil to the metal parts such as the throle wire, put the cover on the blade, and keep it indoor avoiding dampness.

PLEASE BE AWARE THAT THE CUTTING ATTACHMENTS CAN CONTINUE ROTATING AFTER THE ENGINE IS

SWITCHED OFF! SO PLEASE WATCH OUT FOR THIS. WE RECOMMEND USING 20:1 UNLEADED FUEL TO OIL

MIXTURE FOR THIS BRUSHCUTTER.

19

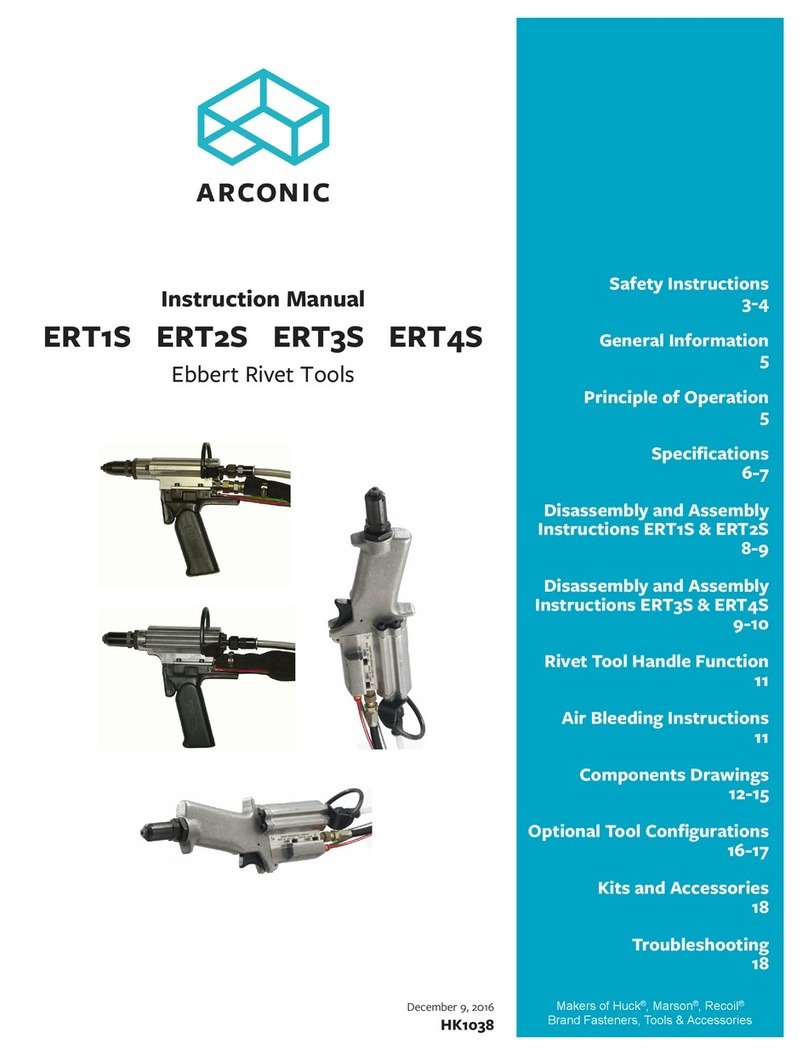

HEDGETRIMMER ATTACHMENT

CAUTION

Always maintain the arculated hedge trimmer according to the owner’s manual and follow the recommended

scheduled maintenance.

Never modify or disable any of the hedgetrimmer’s safety devices.

Always use genuine parts and accessories when repairing or maintaining this machine.

When transporng the hedgetrimme in a vehicle, e it down securely to prevent fuel spillage or damage to the machine.

Always clear your work area of trash or hidden debris to help ensure good foong.

Keep the cuers sharp and properly adjusted.

Keep the arculated hedgetrimmer as clean as possible. Keep it free of loose vegetaon, mud, debris, etc.

PRIOR TO ASSEMBLY

Using image 3 as a guide, familiarize yourself with the aachment of long reach hedgetrimmer and it’s various components. Understanding

your machine helps ensure top performance, longer service life, and safer operaon. Before Assembling, make sure you have all the

components required for the complete unit:

CUTTER ASSEMBLY

CUTTER BLADE COVER

TOOL KIT FOR ROUTINE MAINTENANCE

Image 3

20

INSTALLING THE HEDGETRIMMER

CUTTER ASSEMBLY

IMPORTANT! ALWAYS WEAR GLOVES WHEN WORKING WITH OR NEAR THE CUTTER ASSEMBLY.

Insert the end of the outer tube into the hedgetrimmer cuer gearcase clamp assembly and push unl it

booms. The outer tube should go into the gearcase about 38mm. If the outer tube stops before booming, rotate it unl you

feel the inner mainsha(drivesha) splines engage the gearcase. Then push the outer tube all the way in.

Rotate the gearcase/cuer assembly so that index screw aligns with the hole in the outer tube. With the

powerhead in the upright posion, the cuer assembly will appear to be upside down (while in the storage/transport posion).

Use a 4mm Allen wrench to ghten the hedge trimmer gearcase index screw first, then the gearcase clamp screw.

ADJUSTING THE ARTICULATED HEDGETRIMMER CUTTING ASSEMBLY

Posion the hedgetrimmer on a flat, level surface with the engine resng on the fuel tank guard. Make sure the hedgetrimmer

blade cover is in place.

THE CUTTER BLADES ARE VERY SHARP. DO NOT HANDLE THE

CUTTER ASSEMBLY UNLESS THE PROTECTIVE BLADE

COVER IS IN PLACE.

THE CUTTER BLADES ARE VERY SHARP. DO NOT GRASP THE BLADES WITH YOUR HANDS. DO NOT BRUSH THE

BLADES AGAINST YOUR BODY. NEVER RUN THE ENGINE OR OPERATE THE ARTICULATING HEDGETRIMMER

WHEN THE CUTTER ASSEMBLY IS IN THE STORAGE/TRANSPORT POSITION.

STEP 1

With your right hand, grasp the handle.

With your lehand, grip the adjustment

lever on the cuer assembly.

STEP 4

Release the latch lock and the latch

release. Make sure the latch lock and the

latch release return securely to a locking

posion.

STEP 2

With the index finger of your lehand,

press the latch release. With your le

thumb, press the latch lock.

STEP 5

Remove the cover from the cuer blade,

The engine may be Started.

STEP 3

While holding the latch lock down, pivot

the cuer assembly using the adjustment

lever unl it is straight with the outer tube

(pivot 180 degrees).

Other manuals for 52CC

1

Table of contents

Other STEELTEC Power Tools manuals