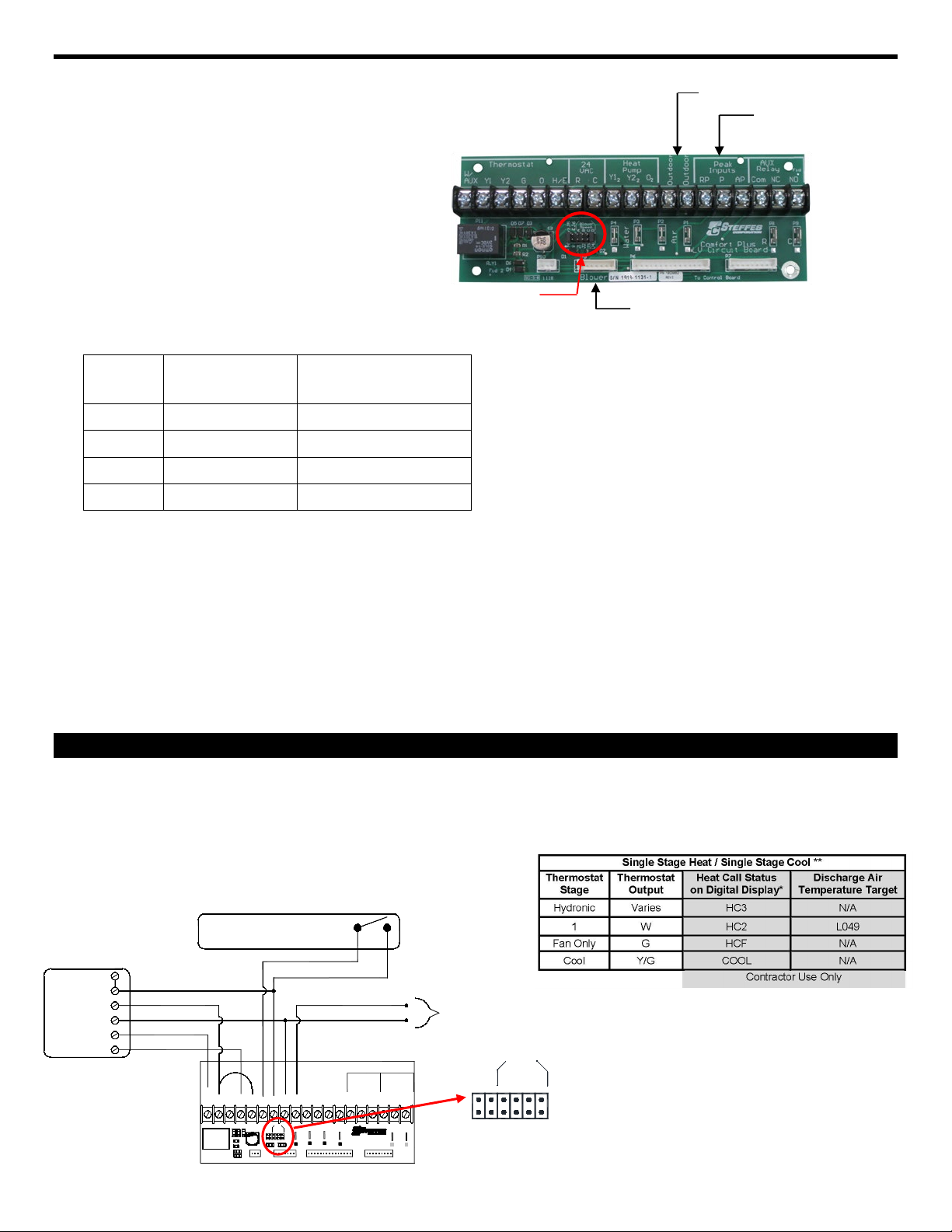

Variable Speed Air Handler Instructions(continued). . .

Page 5 of 5 Document #1200365 Rev 10

09/04/2020

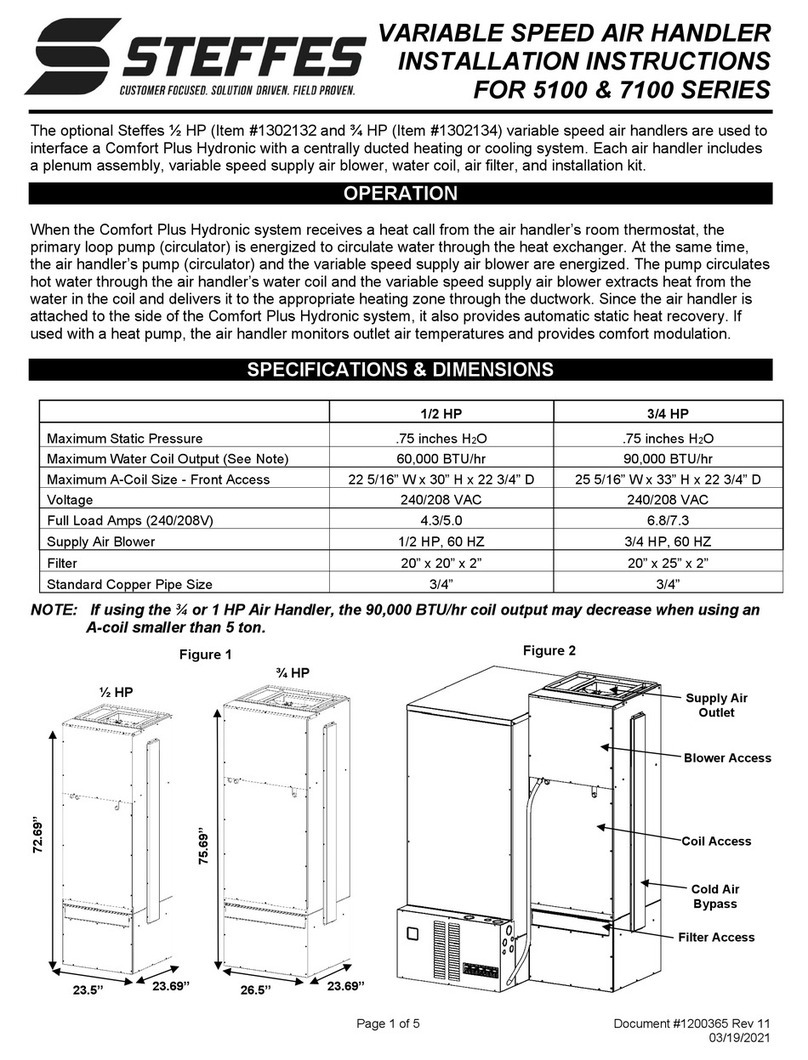

PLUMBING

Installation of the water coil plumbing should be

completed in a manner similar to the design shown

in Typical System Plumbing Diagram (Figure 14).

Standard copper pipe size 3/4".

Dedicated pump (circulator) to feed the water

coil and provide comfort modulation. Steffes

recommends a Taco 007 single speed 115

VAC pump (Order Item #1100002) or equal.

Maximum recommended water temperature

(as set in C011) is 180ºF/82ºC and the

minimum recommended water temperature (as

set in C012) is 150ºF/65ºC.

Pump serving the air handler is powered with

the black and white wires found in the junction

box on the lower left side of the Comfort Plus

Hydronic system. Refer to the Plumbing

Section of the Comfort Plus Hydronic Owner’s

and Installer’s Manual for more information.

Area in front of the air handler must remain

open for accessing the blower, filter, and coils.

NOTE: It is the responsibility of the installer to prevent involuntary flow of the water to the air

handler. Not doing so may cause limit tripping or decreased heat pump efficiency. Use of a

check valve, zone valve, etc. may help in this situation.

PLUMBING

The Air Handler filter should be replaced on a regular basis and general cleaning of the cabinet should be

conducted at the user’s discretion. No additional routine maintenance is required. Replacement filters can be

ordered from the factory (Order Item #1159017 for ½ HP and #1159063 for ¾ or 1 HP).

If utilizing a heat pump or air conditioner with the air handler, follow the manufacturer’s cleaning

recommendations for those devices.

WARNING

Risk of personal injury or property damage. Water

temperatures used for the Air Handler may not be

acceptable for other heating zones in the installation.

It is the responsibility of the installer to ensure that

proper tempering devices are in place.

FREEZE PROTECTION: Risk of frozen pipes. Can

cause property damage. Hydronic heating system

freeze-ups WILL cause extensive damage to the

entire heating system and/or property. Damage to the

air handler piping system can occur in low ambient

temperatures conditions or can be caused by a

system malfunction during air conditioning mode. It

is the responsibility of the installer to protect against

freezing of all plumbing and water coils.

PIPING SUPPORT: Risk of exchanger damage. Can

cause property damage or personal injury. DO NOT

use the exchanger as support for piping. Support

brackets should be in place to ensure proper

operation of the system and to keep pressure off the

inlet and outlet piping.

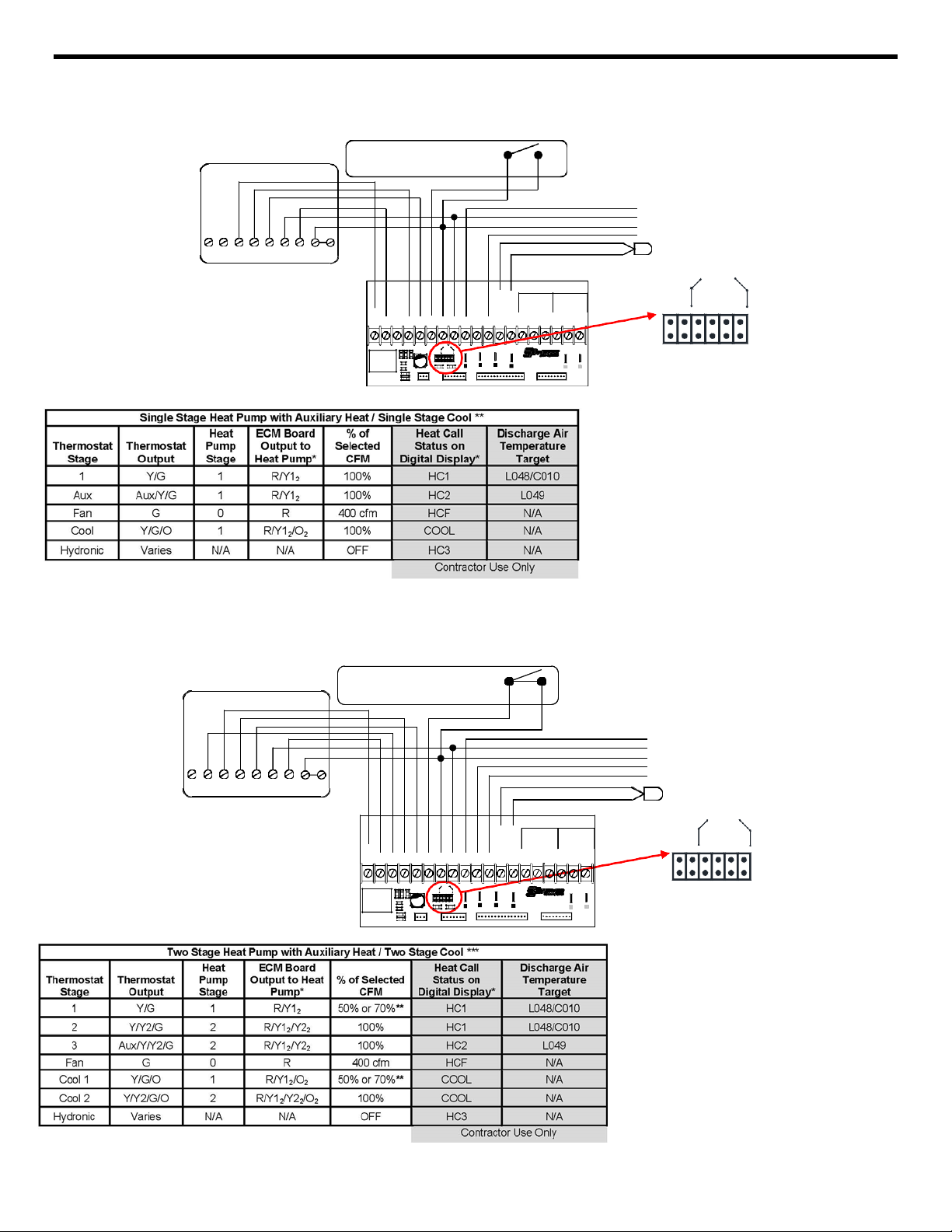

5100 Air

Secondary Loop

Low Temp Radiant Zones

White

This Valve Must

Be Open During

Normal Operation

Hydronic

Exchanger