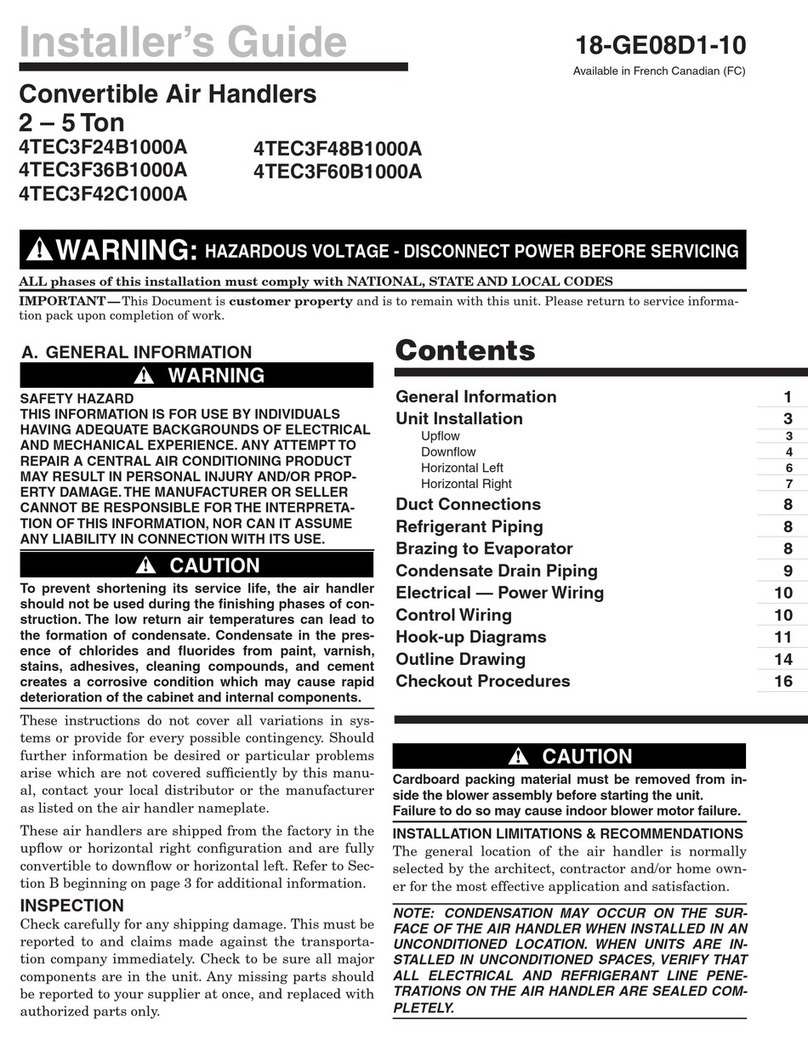

Installer's Guide

2. The trap must be located within 4 feet of the Air

Handler drain outlet connection.

3. It is recommended that a clean-out tee or cross be

installed in the primary drain line for future main-

tenance (See Figure 16 & 17).

4. Do not use reducing fittings in the condensate drain

lines.

blower. Openings where field wiring enters the

cabinet must be completely sealed. Location of

power entry is shown on the outline drawing. Use 2.5"

clear stickers to seal all unused electrical knockouts.

NOTE: If Air Handler is used with or without a heater,

the electrical entry hole as well as any other cabinet

penetrations must be sealed air tighL

5. Slope the drain lines downward a minimum of 1/4" I.

per foot. 1.

6. Insulate the primary drain to prevent sweating

where pipe temperature could meet or fall below

dewpoint temperatures.

7. Provide means for drainage to prevent winter

freeze-up of condensate line.

8. Do not connect the drain line to a closed drain sys-

tem.

9. Use Teflon _'_tape on the Air Handler drain line con-

neetions! Do Not Use pipe joint compound or PVC/

CPVC cement!

It is always recommended that an auxiliary drain pan

be installed under a horizontally installed Air Handler.

Connect the auxiliary drain line to a separate drain line

(no trap is needed in this line) and terminate according

to local codes.

NOTE: Do NOT use a torch or flame near the plastic

drain pan coupling.

NOTE: Do NOT tighten the drain pipe excessively. Sup-

port the condensate piping and traps outside the unit

to prevent strain on the drain coupling.

H. ELECTRICAL- POWER WIRING

1. These Air Handlers are shipped from the factory

wired for 230 Volts. The units may be wired for 208

Volts. Follow instructions on unit wiring diagram

located on inside blower panel housing and in the

Service Facts document included with the unit.

2. The selection of wire and fuse sizes should be made

according to the Minimum Branch Circuit Ampacity

and the Maximum Overcurrent Device listed on the

unit nameplate.

3. Field wiring diagrams for electric heaters and unit

accessories are shipped with the accessory.

4. Wiring must conform to National and Local codes.

Ground unit per Local codes following recognized

safety procedures.

If an electric heater is not installed, the Knockout Plate pro-

vided in the Accessory Kit MUST be installed on the air han-

dler and the conduit terminated to it. The electrical connec-

tions are made using the two power leads and ground wire

connections which are located near the discharge of the

.

.

CONTROL WIRING

Connect wiring between indoor unit, outdoor unit

and Comfort Control. The use of color-coded low-

voltage wires is recommended.

A low voltage terminal board is provided for control

wiring, and is located on the left side of the cross

brace in the center of the unit.

Field wiring diagrams are provided which show the

low voltage wiring hookup for a single speed cooling

only system (with supplementary heaters) and a

Heat Pump system (with supplementary heaters).

Plug in type electrical connectors are provided for

use with supplementary heaters.

IMPORTANT:

When supplementary heaters are installed, inspect to

insure that all packaging material has been removed.

J. AIRFLOW ADJUSTMENT

Blower speed changes are made using the User Inter-

face mounted on the communicating Comfort Control

box. The Air Handler control board controls the variable

speed motor.

Table 1 -- Control Wiring

ComfortLink TM II Control Wiring

WIRE SIZE MAX. WIRE LENGTH*

18 AWG 250 FT

NEC Class II Wiring - 24 VOLTS

WIRE SIZE MAX. WIRE LENGTH**

18 AWG 150 FT

16 AWG 225 FT.

14 AWG 300 FT.

* The maximum total cable length for the entire Comfort

Control communicating system is 500 ft. 18 AWG.

* * Maximum total length of low voltage wiring fi'om outdoor

unit, to indoor unit, and to Comfort Control.

NOTE: Direct drive motors have bearings which are

permanently lubricated and under normal use lubri-

cation is not recommended.

10 18-GELID1-4