Steiner ZTM 1250 User manual

WARNING: If incorrectly used this machine can cause severe injury. Those who use

and maintain this machine should be trained in its proper use, warned of its dangers

and should read the entire manual before attempting to set up, operate, adjust or

service the machine.

SETUP, PARTS & MAINTENANCE

MANUAL ZTM 1250

Power Unit Model:

442105-Power Unit ZTM1250 25 Klr Collection

(Operation & Safety Manual: 4136742)

For Cutterdecks:

954204A-Cutterdeck 42” Collection

954804A-Cutterdeck 48” Collection

(Parts Manual: 4136039)

4136743 REV B

CALIFORNIA

Proposition 65 Warning

Diesel engine exhaust and some of

its constituents are known to the State

of California to cause cancer, birth

defects and other reproductive harm.

Californie Proposition 65

Avertissement

Les échappements des moteurs diesel

et certains de leurs composés sont

reconnus par l’Etat de Californie pour

être cancérigènes, provoquer des

défauts congénitaux et d’autres dangers

en matière de reproduction.

ADVERTENCIA

AVERTISSEMENT

WARNING

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects or other reproductive harm.

California Advertencia

de la Proposicion 65

El estado de California hace saber que

los gases de escape de los motores

diesel y algunos de sus componentes

producen cáncer, defectos de

nacimiento y otros daños en el

proceso de reproducción humana.

L’

é

mission du moteur de ce mat

é

riel

contient des produits chimiques que

l’Etat de Californie consid

è

re

ê

tre

canc

é

rig

è

nes, provoquer des d

é

fauts

cong

é

nitaux et d’autres dangers en

mati

è

re de reproduction.

El estado de California hace saber

que los gases de escape de este

producto contienen productos

quÍmicos que producen cáncer,

defectos de nacimiento y otros daños

en el proceso de reproducción

humana.

CALIFORNIA

Proposition 65 Warning

Battery posts, terminals, wiring

insulation, and related accessories

contain lead and lead compounds,

chemicals known to the State of

California to cause cancer and birth

defects or other reproductive harm.

WASH HANDS AFTER HANDLING.

1

ZTM 1250ZTM 1250

ZTM 1250ZTM 1250

ZTM 1250

12-2005

IMPORTANT MESSAGE

Thank you for purchasing this Steiner product. You have purchased a world class mowing product, one of the

best designed and built anywhere.

This machine comes with an Operation and Safety Manual and a separate Setup, Parts and Maintenance Manual.

The useful life and good service you receive from this machine depends to a large extent on how well you read and

understand these manuals. Treat your machine properly, lubricate and adjust it as instructed, and it will give you

many years of reliable service.

Your safe use of this Steiner product is one of our prime design objectives. Many safety features are built in, but

wealsorelyonyourgoodsenseandcaretoachieveaccident-freeoperation. Forbestprotection,studythemanuals

thoroughly. Learn the proper operation of all controls. Observe all safety precautions. Follow all instructions and

warnings completely. Do not remove or defeat any safety features. Make sure those who operate this machine

are as well informed and careful in its use as you are.

See a Steiner dealer for any service or parts needed. Steiner service ensures that you continue to receive the

best results possible from Steiner’s products. You can trust Steiner replacement parts because they are

manufactured with the same high precision and quality as the original parts.

Steiner designs and builds its equipment to serve many years in a safe and productive manner. For longest life,

use this machine only as directed in the manuals, keep it in good repair and follow safety warnings and instructions.

You'll always be glad you did.

Jacobsen, a Textron Company

One Bob Cat Lane

Johnson Creek, WI 53038-0469

TABLE OF CONTENTS FIGURES PAGE

SAFETY ......................................................................................................................................................... 2

ASSEMBLY AND SETUP ............................................................................................................................ 3-5

MAINTENANCE CHART................................................................................................................................ 6

MAINTENANCE RECORD ............................................................................................................................ 7

MAINTENANCE ........................................................................................................................................ 8-13

ADJUSTMENTS...................................................................................................................................... 14-16

BELT REPLACEMENT............................................................................................................................ 17-20

SPECIFICATIONS .................................................................................................................................. 21-23

ENGINE & FRAME ASSEMBLY ......................... FIGURE 1 ................................................................. 24, 25

WHEELS & BRAKES ......................................... FIGURE 2 ................................................................. 26, 27

FRONT PANEL & PUSH ARMS ......................... FIGURE 3 ................................................................. 28, 29

PUMPS & CONTROL PANEL ............................ FIGURE 4 ................................................................. 30, 31

BLOWER & FUEL TANK.................................... FIGURE 5 ................................................................. 32, 33

BELTS ................................................................ FIGURE 6 ................................................................. 34, 35

BUMPER & GRASSBOX FRAME ...................... FIGURE 7 ................................................................. 36, 37

HEAVY DUTY AIR CLEANER ............................ FIGURE 8 ................................................................. 38, 39

GRASSBOX ....................................................... FIGURE 9 ................................................................. 40, 41

ELECTRICAL ..................................................... FIGURE 10 ............................................................... 42, 43

HYDRAULICS .................................................... FIGURE 11 ................................................................ 44, 45

SEAT ASSEMBLY ............................................. FIGURE 12 ............................................................... 46, 47

DECALS ............................................................. FIGURE 13 ............................................................... 48, 49

OPTIONAL FILL INDICATOR : 970145.............. FIGURE 14 ............................................................... 50, 51

HYDROGEAR PUMP ......................................... FIGURE 15 ............................................................... 52, 53

BRAKE ASSEMBLY ........................................... FIGURE 16 ............................................................... 54, 55

2

ZTM 1250ZTM 1250

ZTM 1250ZTM 1250

ZTM 1250

SAFETY

NOTICE !!!

Unauthorized modifications may present extreme

safety hazards to operators and bystanders and

could also result in product damage.

Jacobsen, a Textron Company strongly warns

against, rejects and disclaims any modifications,

add-on accessories or product alterations that are

not designed, developed, tested and approved by

Jacobsen’sEngineeringDepartment. AnyJacobsen

product that is altered, modified or changed in any

manner not specifically authorized after original

manufacture–includingtheadditionof“after-market”

accessories or component parts not specifically

approved by Jacobsen–will result in the Jacobsen

Warranty being voided.

Anyandallliabilityforpersonalinjuryand/orproperty

damage caused by any unauthorized modifications,

add-on accessories or products not approved by

Jacobsen will be considered the responsibility of

the individual(s) or company designing and/or

making such changes. Jacobsen will vigorously

pursue full indemnification and costs from any party

responsibleforsuchunauthorizedpost-manufacture

modifications and/or accessories should personal

injury and/or property damage result.

This symbol means:

ATTENTION!

BECOME ALERT!

Your safety and the safety of others is involved.

Signal word definitions:

The signal words below are used to identify levels

of hazard seriousness. These words appear in this

manual and on the safety labels attached to

Jacobsen machines. For your safety and the safety

of others, read and follow the information given with

thesesignal wordsand/orthe symbolshownabove.

DANGER indicates an imminently hazardous

situation which, if not avoided, WILL result in death

or serious injury.

WARNINGindicatesapotentiallyhazardoussituation

which, if not avoided, COULD result in death or

serious injury.

CAUTION indicatesa potentiallyhazardoussituation

which,ifnotavoided,MAY resultinminorormoderate

injury. It may also be used to alert against unsafe

practices or property damage.

CAUTION used without the safety alert symbol

indicates a potentially hazardous situation which, if

not avoided, MAY result in property damage

MODEL NUMBER: This number appears on

sales literature, technical manuals and price lists.

SERIAL NUMBER: This number appears only

on your mower. It contains the model number

followed consecutively by the serial number. Use

this number when ordering parts or seeking

warranty information.

3

ZTM 1250ZTM 1250

ZTM 1250ZTM 1250

ZTM 1250

ASSEMBLY AND SETUP

TOOLS REQUIRED FOR ASSEMBLY

– Wrecking bar

– Claw hammer

– Ratchet: 3/8" drive

– Socket:10 mm

– Pliers

– Side Cutter or Jack knife

NOTE: All references below to the "right" or "left" are with respect to an operator at the controls.

1. Open crates and remove packing material.

2. Open hydrostat release (dump) valves Uon the

pumps on the power unit and roll it off the pallet.

3. Remove the height of cut hairpin cotters from the

height of cut posts and lift the cutterdeck carrier

frame CC off the cutterdeck C.

4. Cut the wire tie holding the PTO shaft to the

deck.

Bolt the discharge chute to the rear of the

cutterdeck with (2) M6x16 carriage bolts, (2) M6

nylon locknuts and (2) washers. The head of the

carriage bolt should be inside the chute.

Connect the small spring between the bracket on

the discharge chute and the bracket on the

cutterdeck.

4

ZTM 1250ZTM 1250

ZTM 1250ZTM 1250

ZTM 1250

7. Have a helper lift the cutterdeck carrier frame as

high as it will go. Connect a counterbalance

spring from the carrier frame to the pin on the

tractor.

ASSEMBLY AND SETUP

5. Roll the power unit up to the cutterdeck. Cut the

tie holding the PTO shaft together. Connect

the PTO shaft to the power unit gearbox with the

quick coupler. Line up the splines in the coupler

with those on the gearbox. Pull back on the

outside of the quick coupler to slide it on the

gearbox, then release. Pull back on the shaft to

seat the locking balls in the groove of the gearbox

shaft. When properly installed the PTO shaft

should not pull off the gearbox shaft. Push the

deck close to the power unit. Guide the

discharge chute into the blower inlet

opening.

6. Roll the deck carrier frame to the power unit.

Slide the receiver blocks over the power unit push

arm pins (3/4"-10x1/4"). Secure the carrier frame

with (2) (3/4 ID x1/4") thick washers and a

hairpin cotter, on each side.

5

ZTM 1250ZTM 1250

ZTM 1250ZTM 1250

ZTM 1250

ASSEMBLY AND SETUP

8. Locate the cutterdeck height of cut posts C under

the corresponding bushings of the cutterdeck

carrier frame. Use the handles on the cutterdeck

to lift the deck, guiding the height of cut posts into

their bushings. Secure each with a 3/4”(19mm)

I.D. washer and large hairpin cotter.

9. Set tire pressures down to 14 psi(.98kg/sq cm).

Tires are over inflated for shipping. Close

hydrostat release (dump) valves opened in step

2, finger tight. Do not overtighten.

10. FINAL PREPARATIONS

– Check the engine and hydraulic oil levels. Top up with the correct oil if necessary. Use 10W30 motor oil

for the engine. Use fresh, clean 15W40 or 20W50 motor oil or 15W50 synthetic motor oil for the hydrau-

lic system.

– Remove the battery from the machine.Fill the battery to the bottom of the vent wells with acid and trickle

charge for several hours.

Battery acid is caustic and fumes are explosive and can cause serious injury or death.

Use insulated tools, wear protective glasses or goggles and protective clothing when working with

batteries. Read and obey the battery manufacturer’s instructions.

Be certain the ignition switch is “OFF” and the key has been removed before servicing the battery.

a) Verify battery polarity before connecting or disconnecting the battery cables.

b) When installing the battery, always assemble the RED, positive ( + ) battery cable first

and the ground, BLACK, negative ( - ) cable last.

c) Tighten cables securely to battery terminals and apply a light coat of silicone dielectric

grease to terminals and cable ends to prevent corrosion. Keep terminal covers in place.

– Read Operation and Safety Manual before starting.

– Run engine at full RPM for 5 minutes before engaging blades to allow the engine to be fully lubricated

before load is applied.

– Check the hydrostat neutral adjustment. Neutral is set at the factory but may require readjustment if air

trapped during the initial oil fill has worked out of the system. See adjustments section later in this

manual.

– Do not use the machine without an approved grass collector, the grass discharge chute or mulching

plates correctly fitted.

6

ZTM 1250ZTM 1250

ZTM 1250ZTM 1250

ZTM 1250

MAINTENANCE CHART

ECNANETNIAM

NOITAREPO

neewtebsemitmumixameraslavretniesehT.bojgniognonasiecnanetniaM

.snoitidnocerevesrednunetfoerommrofreP.

snoitarepoecnanetniam

5TSRIF

SRUOH YLIAD

YREVE

52

SRUOH

YREVE

05

SRUOH

YREVE

001

SRUOH

YREVE

002

SRUOH

YREVE

005

SRUOH

ENIGNE

snoitcurtsnidnanoitamrofnilanoitiddaroflaunamenigneehttlusnoC

levelliokcehCX

skaeLrofkcehCX

ekatnIriAnaelC

neercS X

renaelCriAnaelC

renaelcerP X

renaelCriAnaelC

tnemelE X

sniFgnilooCnaelC X

dnaliOegnahC

retliF Xlaunams'rerutcafunamenigneeeS

pag&kcehC

sgulPkrapS X

SCILUARDYH

skaeLrofkcehCX

levelliokcelC X

dnaliOegnahC

retliF XX

ENIHCAM

kcolretnIkcehC

noitarepO X

eriTkcehC

serusserP X

pupoT/kcehC

yrettaB X

stnioPllAetacirbuLX

7

ZTM 1250ZTM 1250

ZTM 1250ZTM 1250

ZTM 1250

NOTES

_______________________________________________________________

____________________________________________________

________________________________________________________________________

_______________________________________________________________

____________________________________________________________

____________________________________________________

________________________________________________________________________

_______________________________________________________________

____________________________________________________________

_______________________________________________________________

____________________________________________________________

____________________________________________________________

MAINTENANCE RECORD

LARENEG ETAD SRH ETAD SRH ETAD SRH ETAD SRH ETAD SRH ETAD SRH

serusserperitkcehC

stniopllaetacirbuL

stlob&stunkcehC

ENIGNE

levelliokcehC

lioegnahC

naelC

tnemelerenaelcria

snifgniloocnaelC

ecalpeR

tnemelerenaelcria

pag&naelC

sgulpkraps

.sretlifhtobdnaliociluardyh,lioenigneecalpernoitarepofosruoh5tsrifretfA:ETON

8

ZTM 1250ZTM 1250

ZTM 1250ZTM 1250

ZTM 1250

MAINTENANCE

CHECK DAILY

Operator Presence Interlock System - Start Operation

For the engine to crank, the parking brake must be on, the PTO (blades) off and traction levers in the

neutral position. Sit in the seat and check, one by one, if the engine will crank with the parking brake off, the

blades on, and either traction lever out of neutral.

Operator Presence Interlock System - Run Operation

The operator must be in the seat for the engine to run with the parking brake off, the traction levers moved out

of the neutral position, or the blades on. To check:

1. Start the engine and run at 1/2 throttle with the operator on the machine but raised off the seat.

2. One by one: move the parking brake to the “OFF” position, traction levers out of the neutral position (check

each independently), and turn the blades on. Each check should kill the engine after 1/2 second. (A 1/2

second delay is built into the system to prevent engine cutout when in rough terrain.)

Repair machine before using if the Operator Presence Interlock System does not operate correctly in start or

run. Contact your authorized Steiner dealer.

Hardware

Tighten any nuts and bolts found loose. Replace any broken or missing cotter pins. Repair any other

problems before operating.

Tire pressure

Tires should be kept inflated at 14 lbs/in2(1.0 kg/cm2). Improper tire inflation can cause rapid tire wear and

poor traction. Uneven inflation can cause uneven cutting.

Gearboxes

Check for evidence of leaks daily. If leaks are detected, get them repaired immediately to avoid wrecking a

gearbox from lack of lubrication. The gearboxes only contain a few ounces of lubricant, which won’t last long if

there is a leak.

Battery

Battery acid is caustic and fumes

are explosive and can cause serious injury or death.

Use insulated tools, wear protective glasses or

goggles and protective clothing when working with

batteries. Read and obey the battery manufacturer’s

instructions.

Be certain the ignition switch is “OFF” and the key

has been removed before servicing the battery.

1. Verify battery polarity before connecting or

disconnecting the battery cables.

2. When installing the battery, always assemble the

RED, positive ( + ) battery cable first and the

ground, BLACK, negative ( - ) cable last.

3. When removing the battery, always remove the

ground, negative ( - ) cable first and the red,

positive ( + ) cable last.

4. Check the electrolyte level every 100 hours of

operation.

5. Clean the cable ends and battery posts with

steel wool. Use a solution of baking soda and

water to clean the battery. Do not allow the

solution to enter into the battery cells.

6. Tighten cables securely to battery terminals and

apply a light coat of silicone dielectric grease to

terminals and cable ends to prevent corrosion.

Keep terminal covers in place.

9

ZTM 1250ZTM 1250

ZTM 1250ZTM 1250

ZTM 1250

MAINTENANCE

LUBRICATION

Every 50 hours of operation, lubricate the following points with grease:

1. Caster wheel pivots (2 points)

2. Caster wheel bearings ( 2 points)

3. Deck pivot (2 points, every 100 hrs.)

4. Pusharm (2 points, every 100 hrs.)

5. Deck idler pivot (1 point)

6. Drive shaft slip sleeve (1point)

7. Drive shaft u-joints (2 points)

8. Rear caster pivot (1 point)

9. Rear caster bearing (1 point)

NOTE ON BLADE SPINDLES -The blade spindles and blower spindle

(if so equipped) on these machines use a superior sealed bearing that does

not require relubrication.

10

ZTM 1250ZTM 1250

ZTM 1250ZTM 1250

ZTM 1250

MAINTENANCE

HYDRAULIC SYSTEM

Check fluid level in the hydraulic system every 100

hours or when a leak has occurred. If the fluid is

low, check all components for leaks.

To check, remove reservoir cap M. The fluid level

should be at the bottom of the filler tube. If low, top up

(do not overfill). Use one of the oils listed below:

– SAE 15W40 motor oil

– SAE 20W50 motor oil

– 15W50 synthetic motor oil

AFTER FIRST FIVE (5) HOURS

1. Remove plug Nto drain hydraulic reservoir.

Dispose of used oil in accordance with local

requirements.

2. Clean and replace the plug.

3. Change hydraulic oil filter G.

4. Fill the reservoir with fresh oil to the bottom of the

reservoir filler tube, using an oil from the list

above. Do not overfill.

PERIODIC OIL CHANGES

Change the hydraulic fluid and hydraulic filter after

each 500 hours of operation using the same

procedure given above.

NOTES:

Before servicing the hydraulic system, stop the engine, disconnect spark plug wires and disengage the PTO.

– After any hydraulic line is opened, plug or cap it promptly to reduce the risk of contamination.

– Do not use teflon tape on hydraulic pipe fittings. Use a liquid sealant that will dissolve into the system.

– Make sure all hydraulic connections are tight and hydraulic hoses and lines are in good condition before

applying pressure to system.

The machine's hydraulic system operates under high pressure. When checking for leaks, do not use your

hands to attempt to find a leak. Instead, use cardboard or paper. Escaping hydraulic fluid can be under

sufficient pressure to penetrate skin and cause serious injury. If hydraulic fluid is injected into the skin, it

must be promptly removed by a doctor familiar with this form of injury or gangrene may result.

View from right side

11

ZTM 1250ZTM 1250

ZTM 1250ZTM 1250

ZTM 1250

SPARK PLUGS

Remove each plug and check condition.

– Good operating conditions are indicated if the plug has a light coating of grey or tan deposit.

– A white blistered coating indicates overheating. A black coating indicates an “over rich” fuel mixture.

Both may be caused by a clogged air cleaner or improper carburetor adjustment.

– Do not sandblast, wire brush or otherwise attempt to repair a plug in poor condition. Best results are

obtained with a new plug.

– Set plug gap as specified in engine manual..

MAINTENANCE

ENGINE OIL

Do not perform engine maintenance without the

engine off, spark plug wires disconnected and PTO

disengaged.

AFTER FIRST FIVE (5) HOURS

While the engine is warm:

1. Remove drain cap Dand drain the crankcase.

Dispose of used oil in accordance with local

requirements.

2. Clean and replace the cap.

3. Change oil filter.

4. Fill the crankcase with fresh oil to the full mark.

Do not overfill. See engine manual for oil

specifications.

DAILY

1. Check oil level with the dipstick.

2. If oil is needed, add fresh oil of proper viscosity

and grade. See engine manual for oil

specifications. Do not overfill.

3. Replace dipstick before starting engine.

PERIODIC OIL CHANGES

1. See engine manual for oil and filter change

intervals after the break-in period.

2. Follow instructions for first oil change, above.

FUEL FILTER

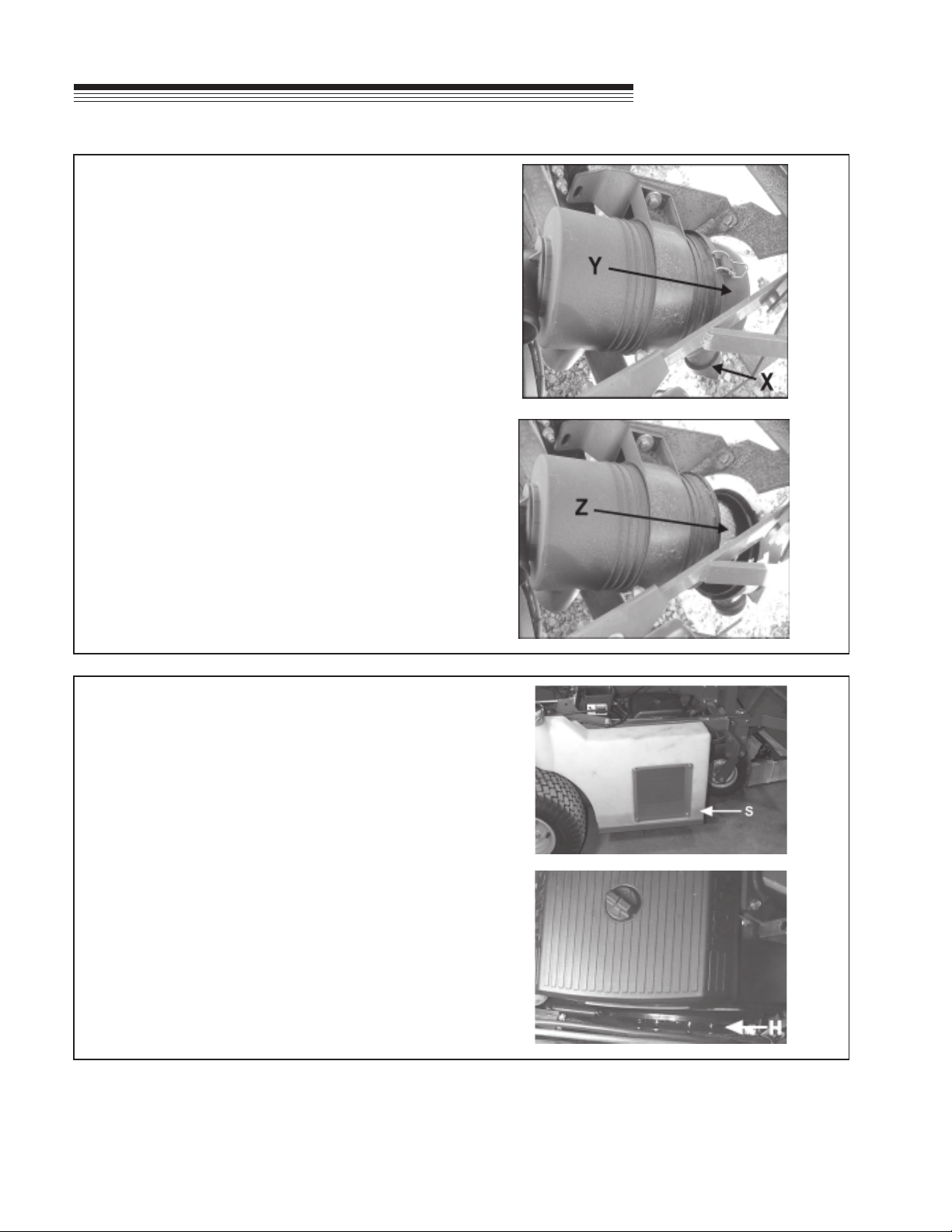

An inline fuel filter Sis located at the right side of the

engine. Inspect at every oil change to make sure it

is clean and unobstructed. Replace if dirty.

12

ZTM 1250ZTM 1250

ZTM 1250ZTM 1250

ZTM 1250

ENGINE COOLING

Continued operation with a clogged cooling system

will cause severe overheating and can result in

engine damage.

–Daily: Clean air intake screen S.

–Every 100 hours: Clean cooling fins beneath

blower housing Hwith reference to information in

the engine manufacturer's manual.

MAINTENANCE

AIR CLEANER

The air cleaner with this engine has a high density

paper air cleaner cartridge. It should be inspected

regularly and maintained. Uneven running, lack of

power or black exhaust fumes may indicate a dirty air

cleaner.

To clean or replace diesel engine air cleaner element:

1. Unclamp end cover Yand remove element Z.

2. Insert new element and replace end cover by

clamping in position as shown on the cover.

Every 100 hours (more often under very dusty or dirty

conditions), check the paper cartridge.

– Clean by tapping gently.

– Do not wash the cartridge or use compressed air

which can cause damage.

– Replace when cartridge is dirty, bent or damaged.

13

ZTM 1250ZTM 1250

ZTM 1250ZTM 1250

ZTM 1250

BLADE REMOVAL

Follow these instructions to prevent injury during

blade removal:

1. Loosen with a box wrench or a socket and long

breaker bar. To gain additional leverage, slip a

long pipe or thick-walled tube over breaker bar or

wrench.

2. Insert a block of wood A as shown to prevent

blade from turning when loosening.

3. Wear thickly padded gloves. Keep hands clear of

blade path. Blades may rotate when bolt

releases.

SHARPENING

Blades may be sharpened by filing or grinding.

–Inspect blades before sharpening.

–Replace bent or cracked blades.

–Replace blades when the lift portion has worn

thin.

–Maintain cut angle at 30o.

–Do not overheat blades when sharpening.

–Always use Steiner blades. Use of another

manufacturer’s blades may be dangerous.

BLADE BALANCE

Blade balance must be maintained at 5/8 oz-in (19.4

g-cm) or less. Failure to keep blades balanced

causes excess vibration, wear, and shortened life of

most components of the machine.

To balance a blade:

1. Sharpen blade first.

2. Balance the blade at the center.

3. Attach a 1/8 oz (3.9 g) weight at a distance 5"

(127 mm) from center on the light end. This

should make the light end the heavy end:

– If it does, the blade is balanced.

– If does not, file or grind the heavy end until

the addition of the weight makes the light end

the heavy end.

BLADE INSTALLATION

1. Wear thickly padded gloves to prevent cuts from

the sharp blade.

2. Insert the blade bolt, in order, through the conical

washer (cup side toward the blade, as shown),

the blade, and the blade spacer.

3. Install assembly on the blade spindle.

4. Torque the blade bolt to 70 ft-lbs.

MAINTENANCE

14

ZTM 1250ZTM 1250

ZTM 1250ZTM 1250

ZTM 1250

ADJUSTMENTS

HEIGHT OF CUT

The height of cut is set by raising or lowering the

cutterdeck on the carrier frame.

To change the height of cut:

1. Hold the deck up with the handle H provided.

2. Remove the hairpin cotters on one side.

3. Raise or lower the deck to the desired height of

cut P.

Secure the height of cut with the hairpin

cotters.

4. Repeat for the other side.

NOTES:

- Large changes in the height of cut may need to

be done in two steps-1/2 in the first step, 1/2 in the

second step.

- Height of cut may vary due to the amount of tread

on the tires, variances in tire diameter, and

inflation pressure.

BELTS

All V-belts are tensioned by spring loaded idlers. No adjustment is required. The blade drive timing belt

does not require adjustment once properly tensioned.

15

ZTM 1250ZTM 1250

ZTM 1250ZTM 1250

ZTM 1250

ADJUSTMENTS

PARKING BRAKE

Adjust the parking brake to provide 1/4” travel in each

cable before the slack is taken up.

To adjust:

1. Start with the brake in the 'OFF' position.

2. Remove the pin Pholding the brake links to the

brake cable ends.

3. Reinstall the pin but only through the end of one

cable.

4. Move the brake lever toward the 'ON' position

until the slack in the cable is taken up, and

resistance

from the brake spring begins to be felt.

5. Adjust the cable with jam nuts Jso there is

1/4”(6mm) of slack before the resistance of the

spring is felt.

6. Repeat for the other brake cable. When both

cables have been adjusted, reinstall the brake pin

through both cable ends and secure with the

hairpin cotter.

NOTE: If there isn’t enough adjustment at the brake

lever end of the cables, the drive wheels may be

removed and the cable adjusted at the mounting

bracket. Further adjustment may be obtained by

turning the bracket over.

Parking brake assembly - (brake in ON position).

Parking brake assembly - (brake in OFF position).

16

ZTM 1250ZTM 1250

ZTM 1250ZTM 1250

ZTM 1250

ADJUSTMENTS

HYDROSTAT ADJUSTMENTS

A turnbuckle-style hydrostat neutral adjustment is

provided.

Neutral:

1. Support the machine with the drive wheels off the

ground. Use jackstands or equivalent support.

Do not rely only on mechanical or hydraulic jacks.

2. Move the traction levers into the neutral position

and raise the seat and grass collection hopper or

utility box.

3. Disconnect the seat switch and temporarily connect

the two terminals with jumper wire Jas shown.

4. Loosen jam nuts T( (h) =hidden) at both ends of

the turnbuckle.

5. Start the engine and run at low speed.

6. Hold one of the traction control levers up against

the resistance of the reverse return spring. Rotate

the corresponding turnbuckle until the wheel it

controls turns in reverse, then rotate the turnbuckle

in the opposite direction until the wheel stops

turning. Lock the turnbuckle jam nuts. Run the

engine up to high idle and stroke the pump in

forward and reverse to check the adjustment.

Re-adjust if necessary.

7. Repeat steps 4 through 6 for the opposite side.

8. Remove the jumper wire and reconnect the seat

switch. Lower the grass collection hopper or utility

box

Reverse Return:

1. Move traction levers to neutral and raise the seat.

2. Locknuts Ushould be run on the bolt as far as they

will go.

3. Loosen jam nuts Y. Move the traction levers to

their forward stop. Adjust the clevis yoke by turning

the head of the bolt until the pin through the clevis

yoke is up against the back end of the slot in the

traction control shaft lever. Once the initial setting

is made for both sides, the levers may be evened

up by adjusting the how far the bolt is turned into

the clevis. Tighten jam nut Y.

NOTE: A slight creep in reverse is acceptable provided

the wheel does not turn and the hydrostat pump does

not whine when the parking brake is on. The reverse

return should be adjusted and set before neutral is set

on the hydrostatic transmissions.

17

ZTM 1250ZTM 1250

ZTM 1250ZTM 1250

ZTM 1250

NOTE: Always use Steiner replacement belts, not general purpose belts. Steiner belts are specially

designed for use on commercial mowers and will normally last longer.

BELT REPLACEMENT

ENGINE-CUTTERDECK (PTO) BELT

1. Raise the seat and grass collection hopper or

utility box.

2. Disconnect the electric clutch from the wire

harness at plug P.

3. Remove the carriage bolts securing torque

restraint Qto the clutch.

4. Insert the square drive end of a 3/8” ratchet or

breaker bar into the square hole in the idler arm

and use the ratchet handle to rotate the idler

assembly enough to remove the belt from the

idler and gearbox pulley.

5. Work the belt out of the space between the

gearbox pulley and the frame and remove it from

the electric clutch pulley.

6. Install the new belt by doing steps 1 through 4 in

reverse order.

18

ZTM 1250ZTM 1250

ZTM 1250ZTM 1250

ZTM 1250

GEARBOX-BLOWER BELT

1. Raise the grass collection hopper.

2. Insert a 3/8" rachet in the square hole on the

Gearbox-Blower idler arm. Use it to rotate the

arm enough to remove the belt from the

gearbox pulley. Remove the E-ring securing the

idler arm at the pivot and slide the idler arm out

far enough to remove the belt.

3. Install the new belt by performing steps 1 & 2 in

reverse order.

BELT REPLACEMENT

ENGINE-PUMP BELT

1. Remove the Engine-Gearbox belt. See

Engine Gearbox belt in the preceding section.

2. Use a 9/16" wrench on the bolt Bsecuring the

idler pulley to rotate the idler arm enough to

remove the belt from the idler and pump pulleys.

Finish removing the belt from the engine pulley.

3. Install the new belt by doing steps 1 and 2 in

reverse order.

PUMP-PUMP BELT

1. Raise the seat and grass collection hopper or

utility box.

2. Remove the Engine-Pump belt from the pump

only. The Engine-Gearbox belt does not need to

be removed. See Engine-Pump belt in the

preceeding section.

3. Rotate the Pump-Pump idler arm enough to

remove the belt from the idler and pump pulleys.

A 3/8" breaker bar may be useful to rotate the

idler arm.

4. Install the new belt by doing steps 1 and 2 in

reverse order.

This manual suits for next models

1

Table of contents