Steinlen LA 63 User manual

Edition

5/2022

LA/LE/LES Motors

BA 2330

LA/LE/LES motors for mounting on

MOTOX gearbox

BA 2330

Operating Instructions

Translation of the original instructions

03/2021

A5E37460917A /RS

-AF-ST

General information and

safety notes

1

Technical description

2

Incoming goods, transport,

and storage

3

Installation

4

Commissioning

5

Operation

6

Faults, causes and

remedies

7

Service and maintenance

8

Disposal

9

Technical data

10

Spare parts

11

Explanations

12

Steinlen Elektromaschinenbau GmbH

Ehlbeek 21

30938 BURGWEDEL

GERMANY

A5E37460917A/RS

-

AFST

03/2021 Subject to change

Copyright ©

03/2021

Steinlen Elektromaschinenbau GmbH

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Proper use of Steinlen products

Note the following:

WARNING

Steinlenproducts may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Steinlen. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Steinlen Elektromaschinenbau GmbH. The remaining

trademarks in this publication may be trademarks whose use by third parties for their own purposes

could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Ⓟ

All rights reserved

BA 2330

Operating Instructions, 03/2021, A5E37460917A/RSAFST 3

Table of contents

1 General information and safety notes ...............................................................................................7

1.1 General information.........................................................................................................7

1.2 Copyright ........................................................................................................................9

1.3 Use as prescribed.............................................................................................................9

1.4 Installation notes ...........................................................................................................10

1.5 Geared motor with encoder for safety-relevant applications ..............................................11

1.6 Obligations of the user...................................................................................................12

1.7 The five safety rules .......................................................................................................13

1.8 Particular types of hazards ..............................................................................................13

2 Technical description ......................................................................................................................15

2.1 General technical description ..........................................................................................15

2.2 Cooling .........................................................................................................................16

2.3 Backstop at the motor ....................................................................................................16

2.4 Terminal box and application box....................................................................................17

2.5 SINAMICS G110M frequency inverters .............................................................................17

2.6 Rating plate ...................................................................................................................18

2.7 Surface treatment..........................................................................................................18

2.7.1 General information on surface treatment .......................................................................18

2.7.2 Painted version ..............................................................................................................19

2.7.3 Primed version...............................................................................................................21

3 Incoming goods, transport, and storage..........................................................................................23

3.1 Incoming goods .............................................................................................................23

3.2 Transport ......................................................................................................................24

3.2.1 General information on transport....................................................................................24

3.2.2 Fastening for suspended transport ..................................................................................25

3.3 Storage .........................................................................................................................26

4 Installation......................................................................................................................................27

4.1 Unpacking.....................................................................................................................27

4.2 General information on installation .................................................................................27

4.3 Thread sizes and tightening torques for fastening bolts.....................................................28

4.4 Installation conditions for the motor................................................................................29

4.5 Condensation drain hole (optional) .................................................................................29

4.6 Connecting the motor in the terminal box .......................................................................30

Table of c ontents

4

4.6.1 General information on motor connection .......................................................................30

4.6.2 Terminal box .................................................................................................................31

4.6.3 Terminal marking ..........................................................................................................32

4.6.4 Direction of rotation ......................................................................................................33

4.6.5 Connecting the cables in the terminal box ....................................................................... 34

4.6.6 External grounding ........................................................................................................34

4.6.7 Installation and routing.................................................................................................. 35

4.6.8 External fan (optional) ...................................................................................................37

4.7 Operation on the converter ............................................................................................40

5 Commissioning...............................................................................................................................41

5.1 Checking the insulation resistance.................................................................................. 41

5.2 Commissioning the motor .............................................................................................. 43

6 Operation .......................................................................................................................................45

7 Faults, causes and rem edies ...........................................................................................................47

8 Servic e and m ainten ance................................................................................................................ 49

8.1 General notes about maintenance ..................................................................................49

8.2 Locking the manual release of the brake (optional) ..........................................................49

8.3 Lubrication....................................................................................................................50

8.4 Cleaning the motor........................................................................................................52

8.5 Checking the tightness of fastening bolts ........................................................................52

8.6 Inspection of the motor .................................................................................................. 53

8.7 Servicing the brake ........................................................................................................53

8.7.1 Wear of the spring-operated brake ..................................................................................53

8.7.2 Maintenance intervals for the brake ................................................................................55

8.7.3 Adjusting the air gap...................................................................................................... 56

8.7.4 Replacin g the friction lin ing ............................................................................................ 58

9 Disposal..........................................................................................................................................61

10 Technical data ................................................................................................................................ 63

10.1 Type designation ...........................................................................................................63

10.2 Rating plate data ........................................................................................................... 64

10.2.1 General technical data ...................................................................................................64

10.2.2 Rating plate MOTOX geared motors ....................................................................... 64

10.3 Weight ..........................................................................................................................66

10.4 Circuit diagrams ............................................................................................................ 66

11 Spare parts .....................................................................................................................................

69

11.1 Stocking of spare parts...................................................................................................69

11.2Lists of spare parts......................................................................................................... 70

BA 2330

Operating Instructions, 03/2021, A5E37460917A/RSAFST

11.2.1 Motor sizes 63 - 250.......................................................................................................70

11.2.2 Brake ............................................................................................................................75

11.2.3 Backstop .......................................................................................................................78

11.2.4 Encoder on fan cover .....................................................................................................79

Table of contents

5

11.2.5 Encoder in the motor with external fan............................................................................80

11.2.6 SINAMICS G110M frequency inverters .............................................................................

81

12 Explanations ......................................................................................................................................83

BA 2330

Operating Instructions, 03/2021, A5E37460917A/RSAFST

12.1 EU-Declaration of Conformity.................................................................................................83

12.2EU-Declaration of Conformity DIN EN 80079-36 ...................................................................85

12.3UK Declaration of Conformity BS EN 80079-36 .................................................................... 86

Table of c ontents

6

BA 2330

Operating Instructions, 03/2021, A5E37460917A/RSAFST

7

General information and safety notes

1

1.1 General information

Note

Steinlen Elektromaschinenbau GmbH does not accept any liability for damage and failures

that result from the nonobservance of these operating instructions.

Note

European RoHS directive

MOTOX geared motors comply with the stipulations laid down in Directive 2011/65/EU

regarding restrictions in theuse of certain hazardous substances.

These operating instructions are part of the motor delivery. Store the operating instructions

near the motor. Please read theoperating instructions prior to handling the motor and

observe the information they contain. This is the best way of ensuringsafe and disturbance-

free operation.

These operating instructions apply to the standardversion of the motors for mounting on the

MOTOX gearbox series:

•LA motor, sizes 63 to 71

•LE motor, sizes 63 to 160

•LES motor, sizes 180 to 250

For a description of the precise designation, see Type designation (Page 63).

Table 1- 1 Article number code

Motor

Article number position

1

2

3

4

11

12

LA motor with standard efficiency

S

T

3

3

1

1

LE motor with standard efficiency

2

1

LE motor with high efficiency

2

2

LE motor with premium efficiency

2

3

LES motor with standard efficiency

3

1

LES motor with high efficiency

3

2

LES motor with premium efficiency

3

3

BA 2330

Operating Instructions, 03/2021, A5E37460917A/RSAFST

General information and safety notes

1.1 General information

8

The latest versions of the operating instructions, the declaration of incorporation and the

declarations of conformity are available in electronic form in the Industry Online Support

(https://www.steinlen.eu).

Valid operating instructions for MOTOX

●BA 2010 - operating instructions for MOTOX gearboxes

●BA 2011 - operating instructions for MOTOX worm gearbox SC

●BA 2012 - operating instructions for MOTOX worm gearbox S

●BA 2019 - operating instructions for MOTOX input units

●BA 2310 - operating instructions for three-phase and single-phase AC motors and motors

equipped with brake with accessories

●BA 2320 - operating instructions for LA/LG and LAI/LGI motors

●BA 2330 - operating instructions for LA/LE/LES motors

●BA 2510 - operating instructions for MOTOX optional add-on units

●BA 2515 - operating instructions for MOTOX gearboxes for overhead conveyors

BA 2330

Operating Instructions, 03/2021, A5E37460917A/RSAFST

General information and safety notes

1.2 Copyright

9

1.2 Copyright

The copyright to these operating instructions is held by Steinlen Elektromaschinenbau GmbH.

These operating instructions must not be wholly or partly reproduced for competitive

purposes, used in an y unau thorized way or made available to third parties without

agreement of Steinlen Elektromaschinenbau GmbH .

1.3 Use as prescribed

The motors described in these operating instructions have been designed for stationary use in

general engineering applications.

They comply with the harmonized standards of the series EN 60034 ( VDE 0530) . They are not

approved for operation in hazardous zones and areas.

Unless otherwise agreed, the motors have been designed for use in plant s and equipm en t i n

industrial environm ent s.

The motors have been built using stateoftheart technology and are shipped in an

operation ally reliable condit io n . C h an ges made by u sers cou ld affect t h is operat ion al

reliability an d are forbidden .

Note

The data on th e rating plate assumesan installation altitu de of up to 1000 m above sea level.

The permissible ambient temperature is stamped on the rating plate.

In the case of other ambient temperatures and installation altitudes, contact Technical

Support.

BA 2330

Operating Instructions, 03/2021, A5E37460917A/RSAFST

General information and safety notes

1.4 Installation notes

10

The motors have been designed for theapplication described in Section Technical data

(Page 63). Do not operate the motor outside thespecified power limit. Other operating

conditions must be contractually agreed.

Never use degrees of protection ≤IP54 outdoors. Air-cooled versions are designed for

ambient temperatures of -20 °C to +40 °C as standard and for an installation altitude of up to

1 000 m above sea level. Please note any deviations to the data on the rating plate.

Conditions at the location of use must comply with all specifications on the rating plate.

Do not climb on the motor. Do not place any objects on the motor.

1.4 Installation notes

Prerequisites for smooth, vibration-free running

•Stable foundation design

•Precise alignment of the machine

•Correct balancing of theparts to be mounted on theshaft extension

•Compliance with vibration severity values according to ISO 20816-1

Vibration severity

Due to the influencing variables listed below, the vibration response of thesystem atthe

location of usecan lead to increased vibration severity on the drive unit:

•Transmission elements

•Installation conditions

•Alignment and installation

•Effects of external and internal oscillation

The vibration severity values specified in accordance with ISO 20816-1 must not be exceeded

at any point on the surface of the drive. This ensures problem-free operation and a long

service life.

Maximum permissible vibration severity

Observe the values for the maximum permissible radial and axial oscillation vibration severity

in the following table. Radial/axial refers to the motor axes.

Vibration frequency

Vibration value

< 6.3 Hz

Vibration displacements≤0.16 mm

6.3 Hz to 250 Hz

Vibration velocity vrms ≤4.5 mm/s

> 250 Hz

Vibration acceleration apeak ≤10 m/s

2

BA 2330

Operating Instructions, 03/2021, A5E37460917A/RSAFST

General information and safety notes

1.5 Geared motor with encoder for safety-relevant applications

11

Maximum permissible axial vibration severity

Vibration velocity

Vibration acceleration

Vibration velocity vrms ≤4.5 mm/s

Vibration acceleration apeak ≤10 m/s

2

Resonant frequencies

Resonance can occur in the speed range of the geared motor depending on the machine to

be driven.

Operation in resonancecauses increased noise and vibration levels.

Adherence to the maximum permissible vibration severity is always required.

Operation in the resonant frequency leads to a reduced service life of the geared motor,

irrespective of adherence to the maximum vibration severity.

Continuous operation in the resonant frequency must be avoided.

1.5 Geared motor with encoder for safety-relevant applications

For a MOTOX geared motor with encoder for safety-relevant applications, it is crucial that

you observe the operating instructions BA 2730.These operating instructions arevalid for the

functionally safe encoders that are mounted ontoMOTOX geared motors. The functionally

safe encoders are in compliance with the relevant standards for safety-relevant applications

listed in the declaration of conformity of BA 2730.

The SMOTOX geared motor with functionally safe encoder has a signal yellow marking on

the fan cover. Marking SI04 for thefunctionally safe encoder is stamped on the rating plate.

The safety level is marked on the functionally safe encoder.

Figure 1-1 Marking for functional safety

BA 2330

Operating Instructions, 03/2021, A5E37460917A/RSAFST

General information and safety notes

1.6 Obligations of the user

12

1.6 Obligations of the user

The company operating the unit must ensure thatall persons assigned to work on the geared

motor have read and understood these operating instructions and that they comply with

them in all points in order to:

•Eliminate the risk to life and limb of users and others

•Ensurethe operational safety of the geared motor.

•Avoid disruptions and environmental damage through incorrect use.

Comply with the following safety instructions:

Shut down the geared motors and disconnect the power before you carry out any work on

them.

Make sure that the drive unit cannot be turned on accidentally, e.g. lock the key-operated

switch. Place a warning notice at the drive connection point which clearly indicates that work

is in progress on the geared motor.

Carry out all work with great care and with due regard to "safety".

For all work, carefully comply with the relevant regulations for work safety and

environmental protection.

Comply with the instructions on the rating plates attached to the geared motor. The rating

plates must be kept free from paint and dirt at all times. Replace any missing rating plates.

In the event of changes during operation, switch off the drive unit immediately.

Take appropriate protective measures to prevent accidental contact with rotating drive parts,

such as couplings, gear wheels or belt drives.

Take appropriate protective measures to prevent accidental contact with parts and

equipment that heat up to over +70 °C during operation.

When removing protective equipment, keep fasteners in a safe place. Re-attach removed

protective equipment before commissioning.

Collect and dispose of used oil in accordance with regulations. Immediately remove any spilt

oil with an oil-binding agent.

Do not carry out any welding work on the geared motor. Do not usethe geared motor as a

grounding point for welding operations.

Carry out equipotential bonding in accordance with applicable regulations and directives by

electrotechnology specialists.

Do not use high-pressure cleaning equipment or sharp-edged tools to clean the geared

motor.

Comply with the permissible tightening torque of the fastening bolts.

BA 2330

Operating Instructions, 03/2021, A5E37460917A/RSAFST

General information and safety notes

1.7 The five safety rules

13

Replace damaged bolts with new bolts of thesame type and strength class.

Steinlen Elektromaschinenbau GmbH accepts the warrant y only for original spare parts.

The manufacturerwho installs the geared motors in a plant must include the regulations

contained in the operating instructions in its own operating instructions.

Make surethat you observe themaximum permissible vibration levels specified in

ISO 20816-1 (zone limit A) during operation.

1.7 The five safety rules

For your own personal safety and to prevent material damage when carrying out any work,

always observe the safety-relevant instructions and the following five safety rules according

to EN 50110-1 Working in a voltage-free state. Apply the five safety rules in the sequence

statedbefore startingwork.

Five safety rules

1. Disconnect.

Also disconnect the auxiliary circuits, for example the anti-condensation heating.

2. Secureagainst reconnection.

3. Verify absence of operating voltage.

4. Ground andshort circuit.

5. Cover or safeguardneighboring live parts.

After the work has been completed, undo the measures taken in the reverse order.

1.8 Particulartypes of hazards

WARNING

Extreme surface temperatures

Hot surfaces over +55 °C pose a burn risk.

Cold surfaces below 0 °C pose a risk of damage due to freezing.

Do not touch the gearbox without protection.

BA 2330

Operating Instructions, 03/2021, A5E37460917A/RSAFST

General information and safety notes

1.8 Particular types of hazards

14

WARNING

Hot, escaping oil

Before starting any work wait until the oil has cooled down to below +30 °C.

WARNING

Poisonous vapors when working with solvents

Avoid breathing in vapors when working with solvents.

Ensure adequate ventilation.

WARNING

Risk of explosion when working with solvents

Ensure adequate ventilation.

Do not smoke!

WARNING

Risk of eye injury

Rotating parts can throw off small foreign particles such as sand or dust.

Wear protective eyewear!

In addition to theprescribed personal protection gear, also wear suitable protective gloves

and safety glasses.

BA 2330

Operating Instructions, 03/2021, A5E37460917A/RSAFST

15

Technical description

2

2.1 General technical description

The motor complies with the following regulations:

Table 2- 1 Overview of the standards

Topic

Standard

Dimensions and operation characteristics

EN 60034-1

Degree of protection

EN 60034-5

Cooling

EN 60034-6

Mounting position according to modular system

EN 60034-7

Terminal marking and direction of rotation

EN 60034-8

Noise emission

EN 60034-9

Thermal protection

EN 60034-11

Starting characteristics for rotating electrical motors

EN 60034-12

Vibration severity levels

EN 60034-14

IEC standard voltages

IEC 60038

Safety of machinery

EN 60204-1

The motor is equipped with grease-lubricated roller bearings. The bearings are permanently

lubricated.

The stator winding is designed for temperature class 155 (F).The stator winding can be

optionally implemented with temperature class 180 (H).

In thestandard version, therotor corresponds to vibration severity level A.

The technical data for the optional monitoring equipment can be viewed in thecircuit

diagrams, on the rating plate or in the special order documents.

The stator housing and bearing shields are made of die-cast aluminum or cast iron.

The surface of the stator housing is equipped with cooling fins and a mounted terminal box

or motor connector.

BA 2330

Operating Instructions, 03/2021, A5E37460917A/RSAFST

Technical description

2.2 Cooling

16

2.2 Cooling

NOTICE

Dust deposits prevent heat radiation

Dust deposits prevent heat radiation and cause a high housing temperature.

Keep the motor free from dirt, dust etc.

The motor is designed to be cooled by means of fins. An external fan draws in the cooling air

through the aperture in the fan cover and blows the air over the surfaceof thestator

housing.

2.3 Backstop at the motor

NOTICE

Service life limited

Drive speeds below 1 000 rpm or frequent startingand stopping operations

(≥20 starts / stops per hour) will limit service life.

Ensurethat the backstop is replaced in time when frequent startingand stopping operations

are performed.

NOTICE

Damage or destruction due to incorrect direction of rotation

Do not runthe motor against the backstop.

Note the directional arrow on the motor.

Note

The backstop is not suitable for ambient temperaturesunder -25 °C.

The motor can be fitted with a mechanical backstop. The backstop permits only the correct

direction of rotation during operation. The motor is marked by an arrow pointing in the

corresponding direction.

The backstop is fitted with centrifugally operated sprags. When the motor is running in the

specified direction, the inner ring and the cage with the sprags also rotate while the outer

ring remains stationary.

BA 2330

Operating Instructions, 03/2021, A5E37460917A/RSAFST

Technical description

2.4 Terminal box and application box

17

If the drive speed exceeds the speed listed in the table, the sprag rises. The backstop is wear-

free. The backstop does not require any maintenance.

Table 2- 2 Minimum drive speed when using backstops

Motor size Backstop

Speed

rpm

71

FXM31-17DX

> 890

80

FXM31-17DX

> 890

90, 100, 112

FXM38-17DX

> 860

132

FXM61-19DX

> 750

160

FXM66-25DX

> 730

180, 200

FXM76-25DX

> 670

225, 250

FXM86-25DX

> 630

2.4 Terminal box and application box

The following are contained in the motor terminal box:

•Terminals for the motor (terminal board)

•Terminals for checking equipment

•Terminals for anti-condensation heating

•Connector for the brake

The number of available terminals is shown in the circuit diagrams. The circuit diagrams are

located in the terminal box.

2.5 SINAMICS G110M frequency inverters

Note

SINAMICS G110M inverters are not suitable for ambient temperatures below -10 °C.

The user documentation for the inverters integrated in the motor will be supplied separately.

BA 2330

Operating Instructions, 03/2021, A5E37460917A/RSAFST

Technical description

2.6 Rating plate

18

Resetting the parameters to their factory settings

Resetting the parameters to their factory settings means that the motor parameter values

deviate from the required values. Restore the relevant motor parameter values.

Procedure

1. Set the value of parameter p0010 to 30.

2. Set the value of parameter p0970 to 10.

Detailed information can be found in the G110M List Manual.

2.6 Rating plate

The rating plate on the gearbox or geared motor is of coated aluminum foil. The rating plate

is glued using a special masking film. The film ensures permanent resistance to UV radiation

and media of all kinds, such asoils, greases, salt water and cleaning agents.

The adhesive and the material ensurefirm adhesion and long-term legibility within the

operating temperature range from -40 °C to +155 °C.

The edges of the rating plate are paint-finished to match the color of the gearbox or motor to

which it is affixed.

2.7 Surface treatment

2.7.1 General information on surface treatment

All paint finishes are sprayed on.

NOTICE

Failure of the external protection

If the paint finish is damaged, the geared motor may corrode.

Do not damage the paint finish.

Note

Information about the ability to be repainted does not guarantee the quality of the paint

product supplied by your supplier.

Only the paint manufacturer is liable for the quality and compatibility.

BA 2330

Operating Instructions, 03/2021, A5E37460917A/RSAFST

This manual suits for next models

13

Table of contents

Popular Engine manuals by other brands

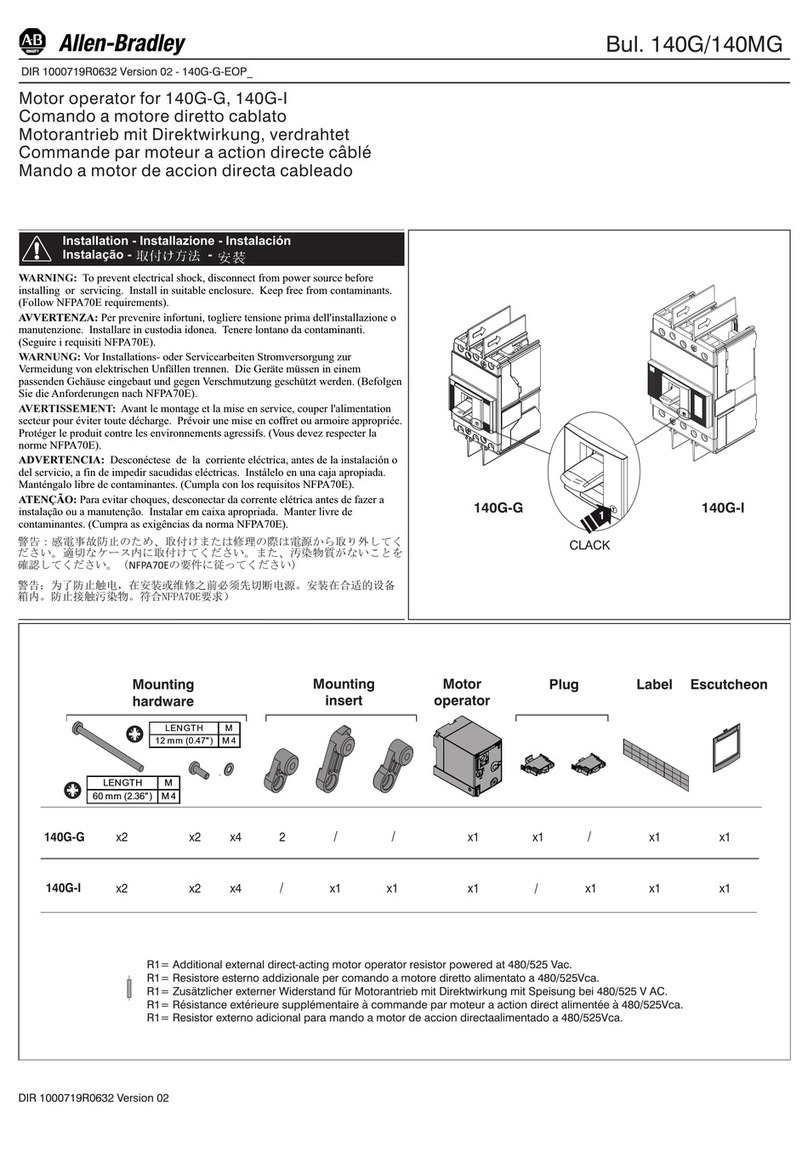

Allen-Bradley

Allen-Bradley 140G Series Installation

Rockwell Automation

Rockwell Automation Allen-Bradley TLP-SSN-F046 installation instructions

Seidel

Seidel UMS ST 7-70 instruction manual

Siemens

Siemens 1PH818 Operating instructions & installation instructions

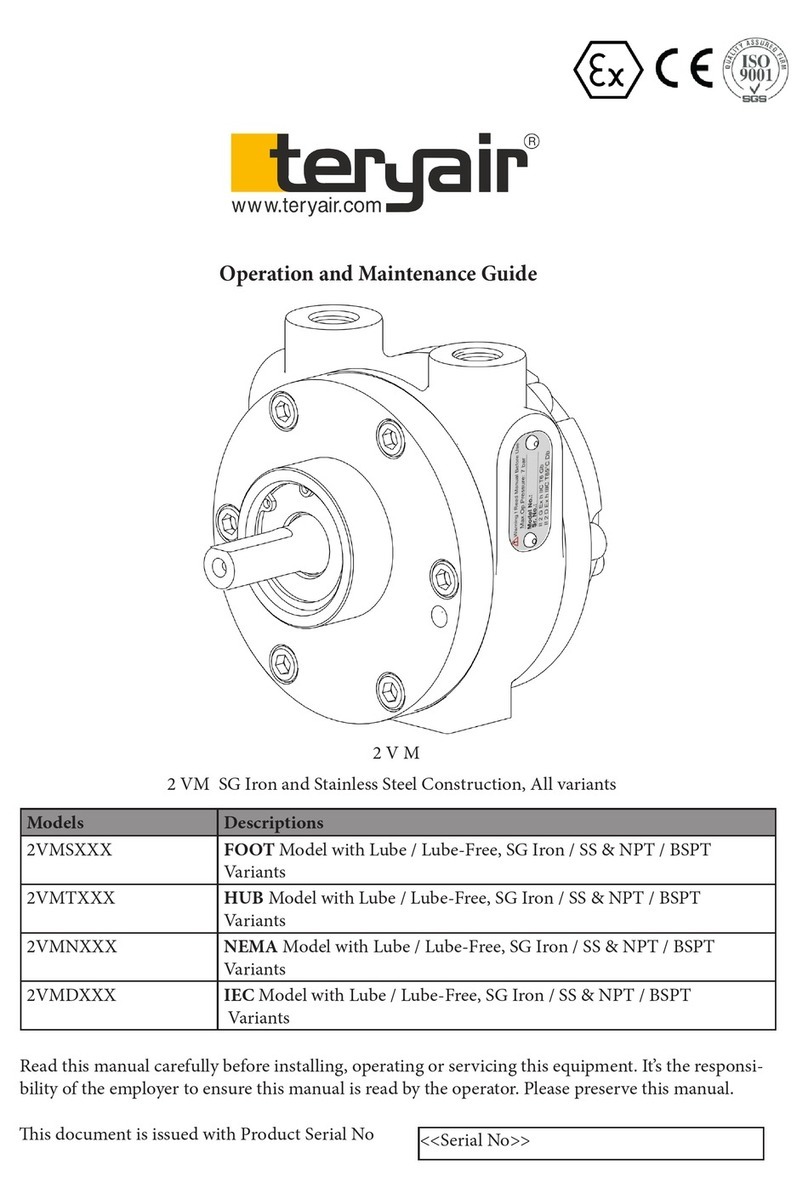

Teryair

Teryair 2VMS Series Operation and maintenance guide

Black Bruin

Black Bruin BB series General Instructions for Use