3

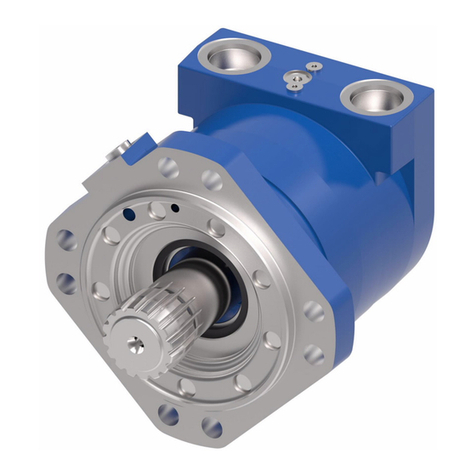

EATON Char-Lynn Delta Motors Parts and Repair Manual C-MOLO-TS003-E September 2007

Parts List

113 6.9 14384-026 88.1 3.47 4999844-001 18.5 0.73 5986952-001 88.9 3.50

146 8.9 14384-026 88.1 3.47 4999844-002 24.1 0.95 5986952-002 94.2 3.71

198 12.1 14384-025 100.8 3.97 4999844-003 32.5 1.28 5986952-003 102.9 4.05

234 14.3 14384-025 100.8 3.97 4999844-004 38.6 1.52 5986952-004 109.0 4.29

252 15.4 14384-001 108.2 4.26 4999844-012 41.4 1.63 5986952-012 112.0 4.41

300 18.3 14384-025 100.8 3.97 4999844-005 38.6 1.52 5986952-005 108.7 4.28

347 21.2 14384-002 113.0 4.45 4999844-006 44.7 1.76 5986952-006 114.8 4.52

395 24.1 14384-002 113.0 4.45 4999844-007 50.8 2.00 5986952-007 121.2 4.77

470 28.7 14384-004 127.3 5.01 4999844-008 60.7 2.39 5986952-008 131.1 5.16

542 33.1 14384-007 138.4 5.45 4999844-009 69.9 2.75 5986952-009 140.5 5.53

649 39.6 14384-009 151.1 5.95 4999844-010 83.6 3.29 5986952-010 154.2 6.07

754 46.0 14384-012 164.6 6.48 4999844-011 99.6 3.92 5986952-011 167.9 6.61

DISPLACEMENT HE HEAD LENGTH WIDTH LENGTH

cm3/rin3/rSCREW mm inch GEROLER mm inch DRIVE mm inch

1 5987016-001 1 Grease Seal

2 5986832-001 1 Bearing Shell

3 4999949-001 1 Housing

4 5986912-001 3 -ring

5 6943-000 1 Back-up Washer

6 9057-012 1 Shaft Seal

7 4999849-001 2 Bearing Race

8 5986825-001 1 Thrust Bearing

9 4999967-002 1 utput Shaft

10 —1Drive

11 5990003-001 2 Back-up Ring

12 112530-037 1 -ring

13 5987176-001 1 Valve Spring

14 14416-001 4 Dowel Pin

15 4999900-001 1 Balancing Ring

16 4999904-001 1 Valve

17 5990407-001 1 Bearing

18 4998396-001 1 Thrust Bearing

20 4999898-001 1 Valve Plate

21 — 1 Gerolor Assembly

22 5986586-001 1 End Cap

23 —7Hex Head Screw

14163-001 1 Nut, Slotted (Not Shown)

14392-006 1 Key (Not Shown)

14628-012 Slinger Seal

9900436-000 Seal Kit-Contains Parts Indicated

by ‘+’

9900437-000 Seal Kit with Seal Guard-Contains

Parts Indicated by ‘=’

=, +

=, +

=, +

=, +

=, +

=, +

=, +

=

REF PART NO. QTY. DESCRIPTION Tools Required

1. Screw driver

2. 9/16 Socket Wrench

3. Torque Wrench

4. Shell Bearing Tool no. 606253

5. Grease Seal Tool no. 606254

6. Main Seal Tool no. 600421-2

7. Press

8. Shaft Bullet no. 606256

9. Loctite 277

10. Inside Bearing Tool

no. 606252

11. Hammer

12. Modified Key

13. Modified Cotter Pin Puller

DeltaPartManual_v7.qxd:Hydraulic Tech.qxd 9/19/07 11:40 AM Page 3