10

FORM NO. L-20365-B-0714

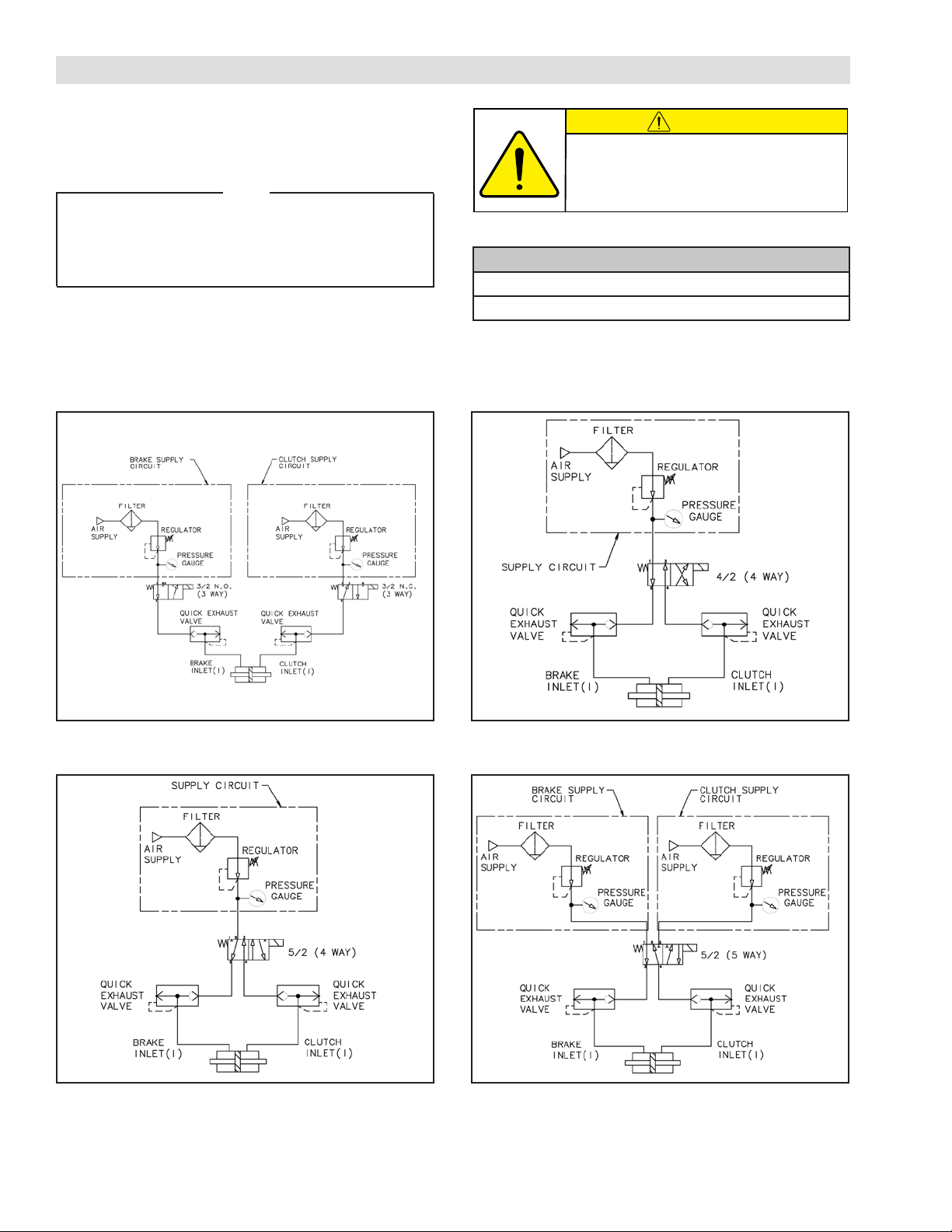

Refer to Figures 6, 7, 8, 9 and 10.

1. Remove the four Socket Head Cap Screws (Item 13)

and slide the Housing (Item 1) Bearing (Item 2), and

the Drive Disc (Item 4) out of the FMCBE.

2. Remove the Retaining Ring (Item 6).

3. Press the Drive Disc (Item 4) out of the Bearing (Item

2) and the Housing (Item 1).

4. Remove the Retaining Ring (Item 3) from the Housing

(Item 1).

5. Support the Housing (Item 1) and press the old Bearing

(Item 2) out of the Housing.

NOTE: Removing the bearing damages it. Do not reuse

the bearing.

6. Clean the bearing bore of the Housing (Item 1) with

fresh safety solvent. Make sure that all of the old

Loctite® residue is removed.

7. Apply an adequate amount of Loctite® 680 to evenly

coat the outer race of the new Bearing (Item 2).

8. Carefully align the outer race of the new Bearing (Item

2) with the bore of the Housing (Item 1).

9. Support the Housing (Item 1), press on the outer race

of the new Bearing and press the new Bearing (Item

2) into the Housing.

10. Reinstall the Retaining Ring (Item 3).

11. Support the inner race of the new Bearing (Item 2) and

press the Drive Disc (Item 4) into the new Bearing and

Housing (Item 1).

12. Reinstall the Retaining Ring (Item 6).

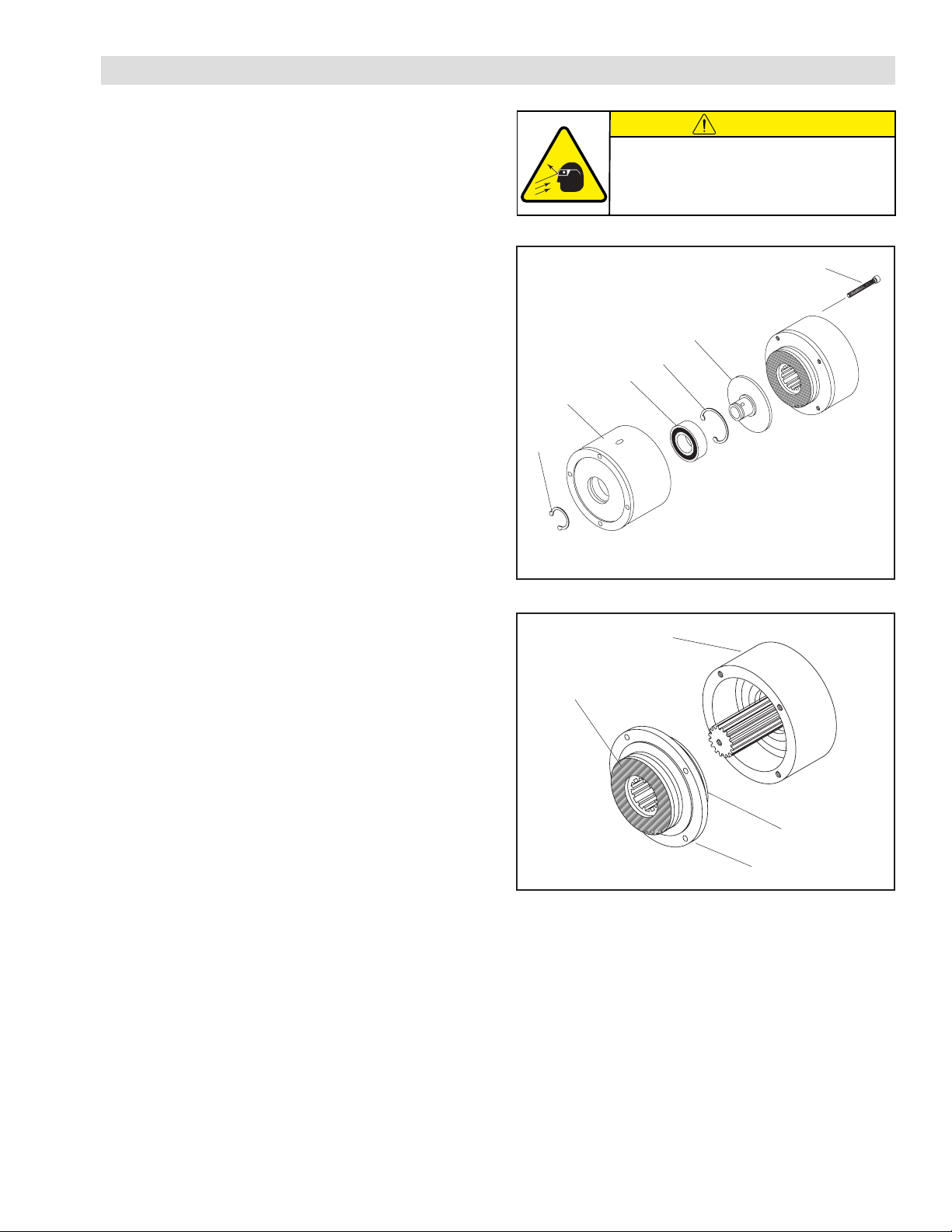

13. Slide the Friction Facing Splined Disc Assembly (Item

10), the Cylinder (Item 12), and the Piston (Item 16)

out of the Air Chamber (Item 20).

14. Remove the Retaining Ring (Item 6) and press the

Friction Facing/Splined Disc Assembly (Item 10) out

of the Cylinder (Item 12) and the Piston (Item 16).

15. Slide the Piston (Item 16) out of the Cylinder (Item 12),

then remove the old O-Ring Seals (Items 14 and 15)

from the Piston and the Cylinder.

16. Remove the Retaining Ring (Item 3) from the Piston

(Item 16), then press the old Bearing (Item 2) out of

the Piston.

17. Clean the bearing bore of the Piston (Item 16) with fresh

safety solvent. Make sure that all of the old Loctite®

residue is removed.

FIGURE 6

6

1

2

3

4

13

FIGURE 7

10

20

12

16

(Continued...)

CAUTION

Working with spring loaded or tension

loaded fasteners and devices can cause

injury. Wear safety glasses and take the

appropriate safety precautions.

18. Apply an adequate amount of Loctite® 680 to evenly

coat the outer race of the new Bearing (Item 2).

19. Support the Piston (Item 16), press on the outer race

of the new Bearing (Item 2), press the new Bearing

(Item 2) into the Piston.

20. Reinstall the Retaining Ring (Item 3).

21. Clean the O-Ring grooves and contact surfaces of the

Piston (Item 16) and Cylinder (Item 12) with fresh safety

solvent. Lubricate the O-Ring grooves and contact

surfaces with fresh O-Ring lubricant.

FMCBE ASSEMBLY