Stellcase Lift and Lock Jules Platform with Standard Palm... User manual

Page 1 of 37

939504740 Rev E

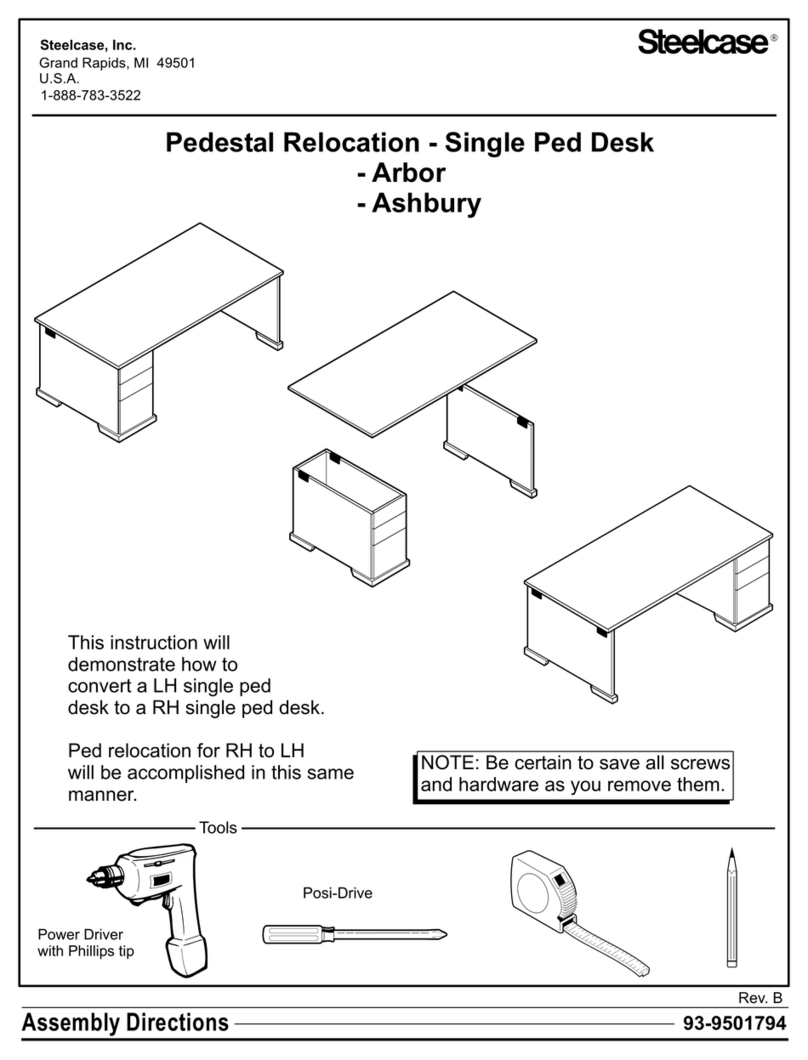

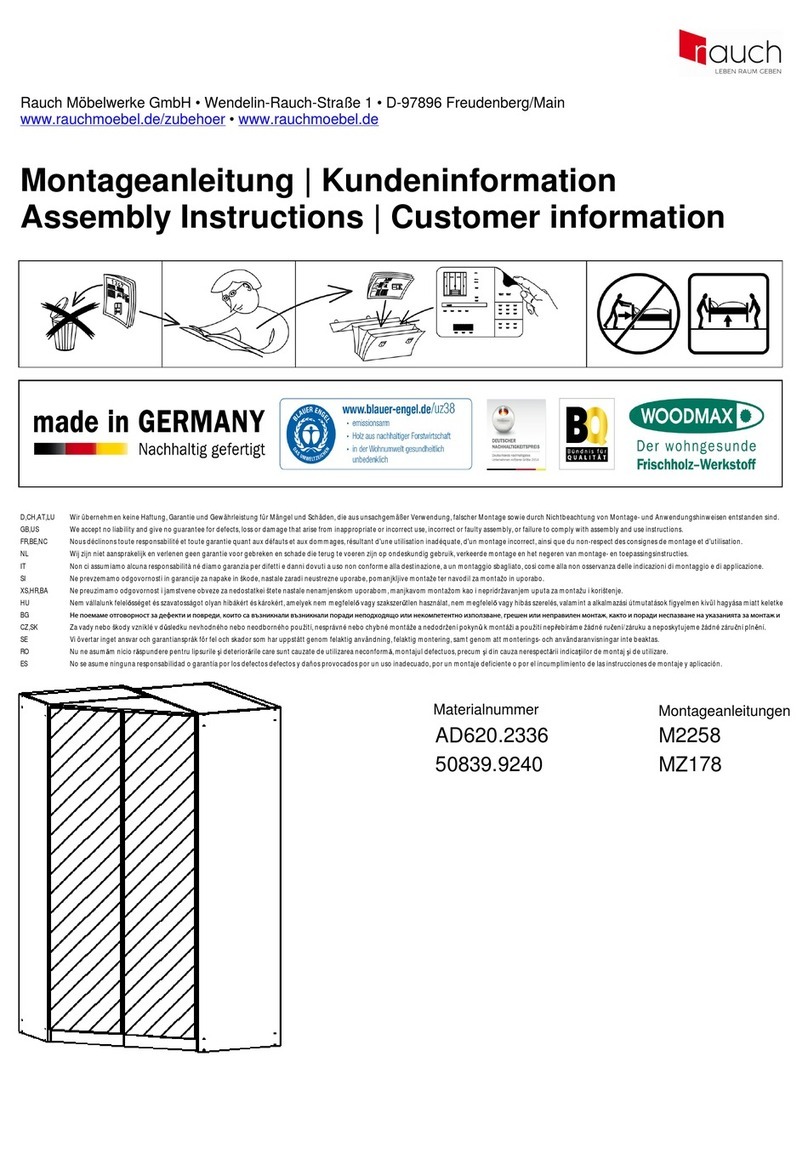

Crank Adjustable Units

Please identify the unit before selecting what section to follow

for assembly of product.

®

If you have a problem, question, or request, call

your local dealer, or Steelcase Line 1 at

888.STEELCASE (888.783.3522)

for immediate action by people who want to help you.

(Outside the U.S.A., Canada, Mexico, Puerto Rico,

and the U.S. Virgin Islands, call: 1.616.247.2500)

Or visit our website: www.steelcase.com

©2002 Steelcase Inc.

Grand Rapids, MI 49501

U.S.A.

Printed in U.S.A.

Extended or Hyperextended on Standard Corner Units

Straight or Corner Bilevel Unit

Straight, Corner, Corner Dual, or Straight Dual Unit

Right

Extension

Hyper

Extended

Left

Extension

Extended or Hyperextended on Bilevel Corner Units

Section A

(begins on page 2)

Section B

(begins on page 8)

Section C

(begins on page 13)

Section D

(begins on page 26)

Right

Extension

Hyper

Extended

Left

Extension

Page 2 of 37

939504740 Rev E

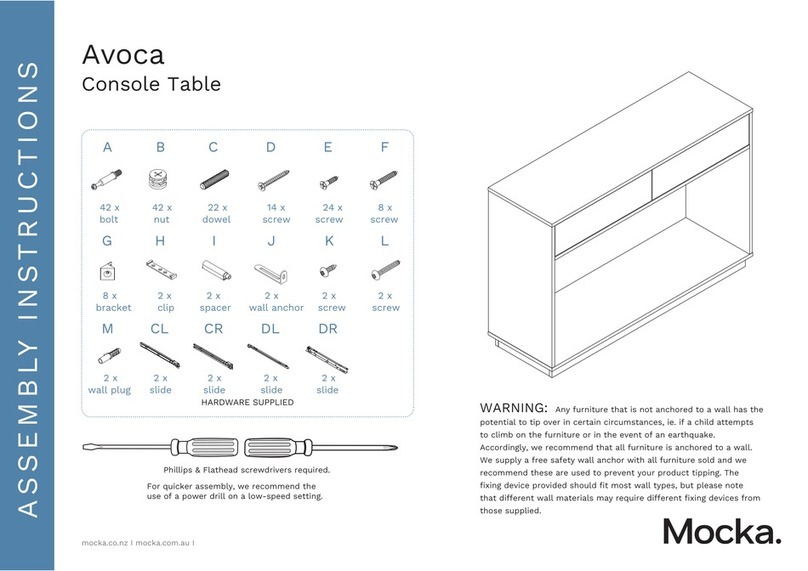

Worksurface

Screw

(Qty. 6)

Foot

Bolt

(Qty. 4)

5mm

Short

Mounting

Screw

(Qty. 8)

5mm

Crank

Handle

(Qty. 1)

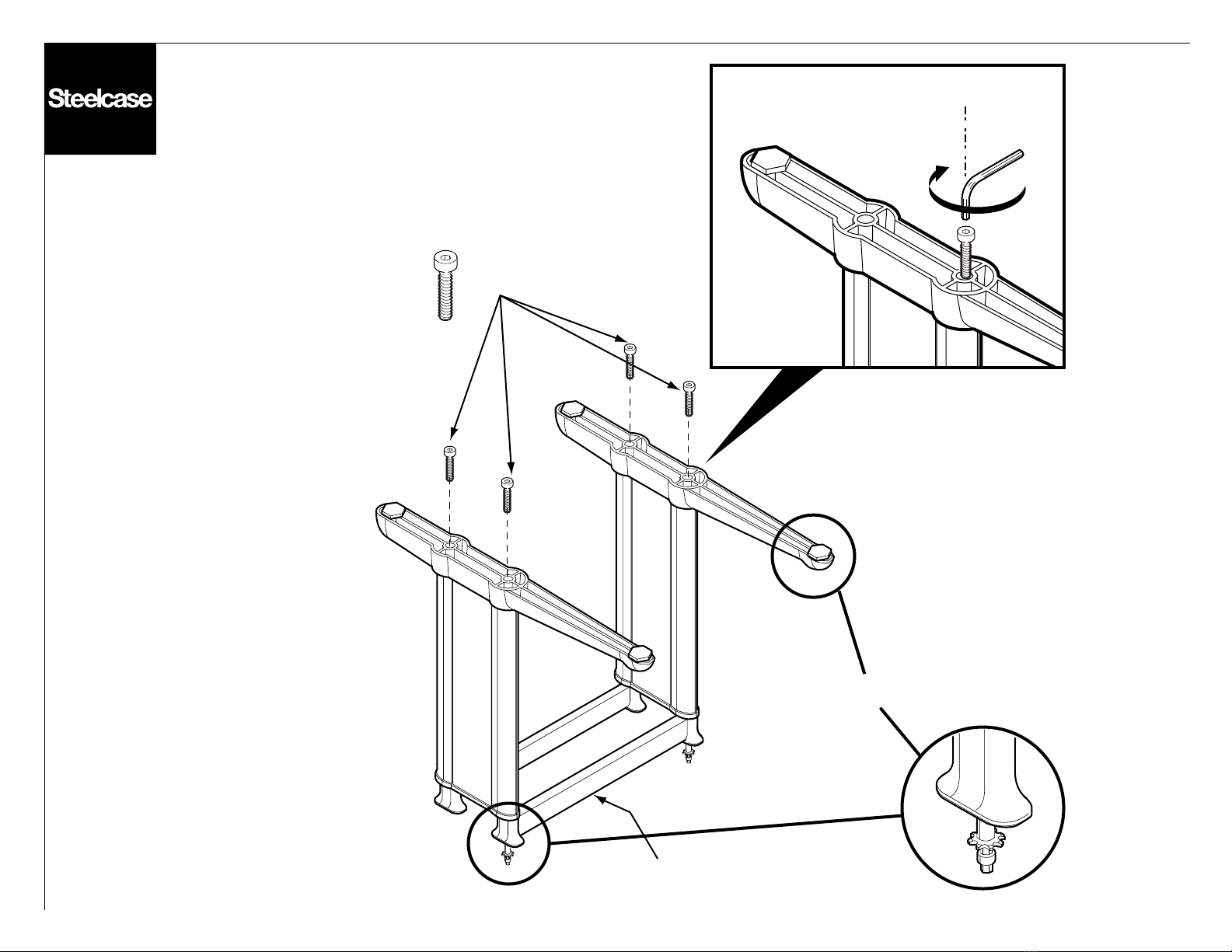

Section A

Assembly instructions to

assemble the following units:

Page 3 of 37

939504740 Rev E

Foot Bolts

Front

1. Flip the base upside down and without

cutting the tie wraps, put the feet on.

Page 4 of 37

939504740 Rev E

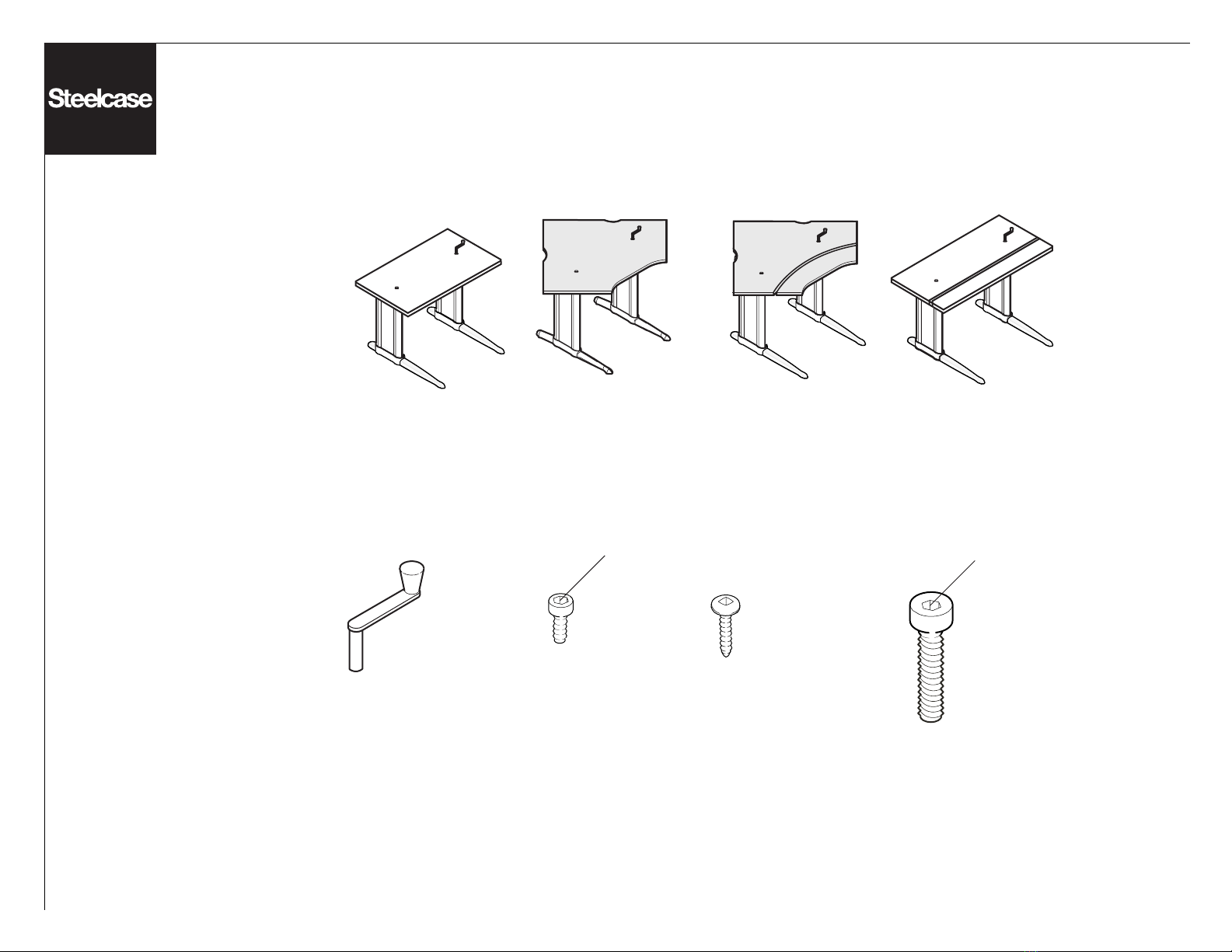

2.

3.

Straight Standard

Corner Standard

Corner Dual

Straight Dual

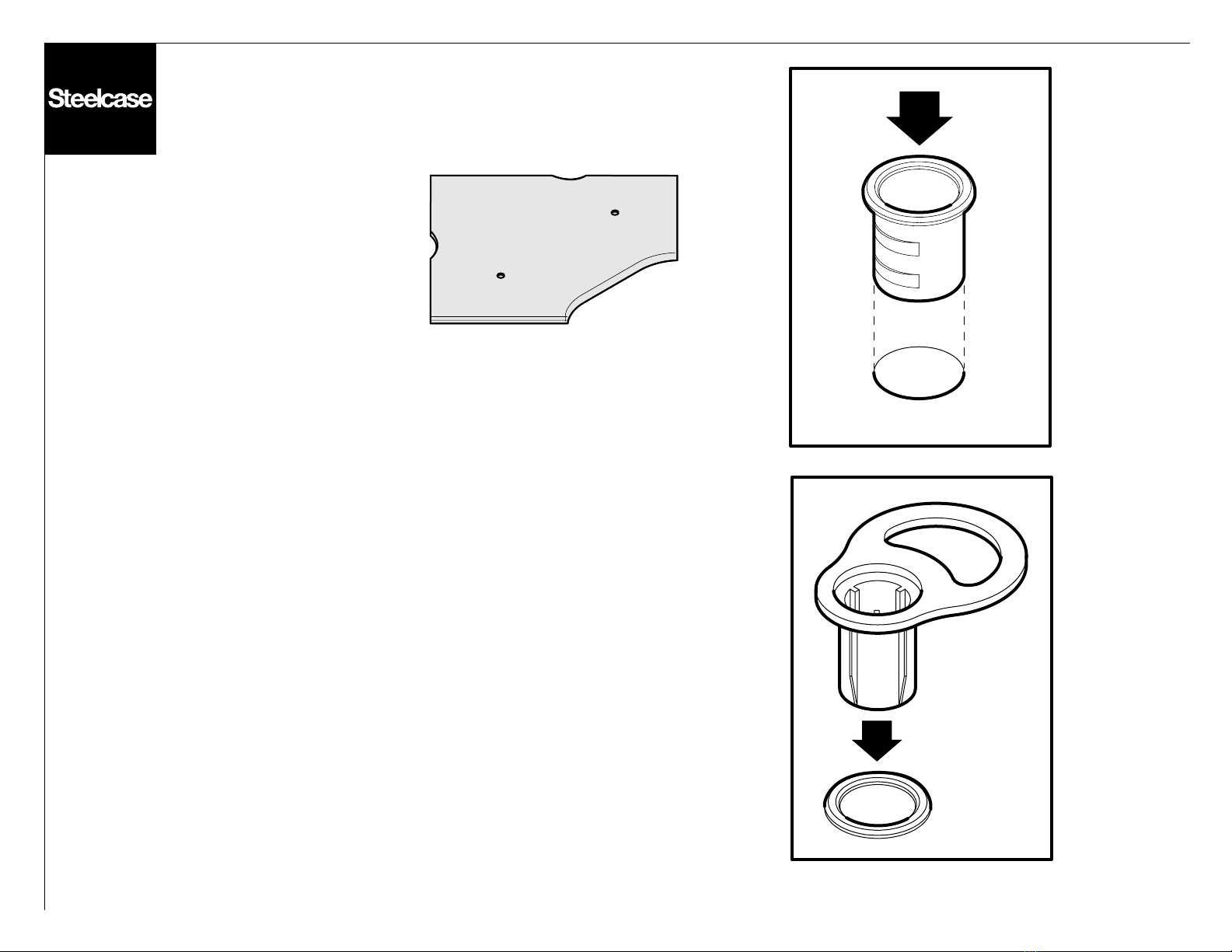

2. Install grommet (black) into laminated

side of worksurface.

3. Install guide (white) into grommet.

Page 5 of 37

939504740 Rev E

5.

(optional)

Gas Cylinder

Washer

Disk

Nut

4. Cut the tie wraps.

5. (Optional for STANDARD and

DUAL units only) Install the "nut",

"washer" and "disk" to the gas cylinder

(if not already installed). Place gas

cylinder as shown.

NOTE: DO NOT attempt to screw or

compress the gas cylinder into place.

CAUTION: Cylinder under compression!

To avoid possible injury when servicing

cylinder, raise worksurface to uppermost

position and remove worksurface prior to

removing mounting plate. This will minimize

compression in the cylinder and facilitate

its removal.

Page 6 of 37

939504740 Rev E

Worksurface Screws

Standard Corner

Straight Dual

Standard Straight

Rear

Rear

Front

Rear

Front

Front

6. Place the worksurface on a protected

surface. Attach mounting plates on

worksurface, at the screw locations shown,

after aligning the pilot holes.

Page 7 of 37

939504740 Rev E

Corner Standard

7. 8.

10.

Short Mounting Screws

Straight Standard

11.

NOTE: If unit is placed with a gas cylinder, adjust

the unit to full height of travel using crank handle.

7. Flip base upside down on a protected surface.

NOTE: If base has gas cylinder, be careful when

inverting the base.

8. Mount top to base with short mounting screws.

9. Flip unit to upright.

10. Remove Guides, retain for future assembly.

11. Test: Using the crank handle, adjust the unit

to different heights to ensure unit works properly.

Page 8 of 37

939504740 Rev E

Worksurface

Screw

(Qty. 16)

Foot

Bolt

(Qty. 4)

5mm

Short

Mounting

Screw

(Qty. 8)

5mm

Crank

Handle

(Qty. 1)

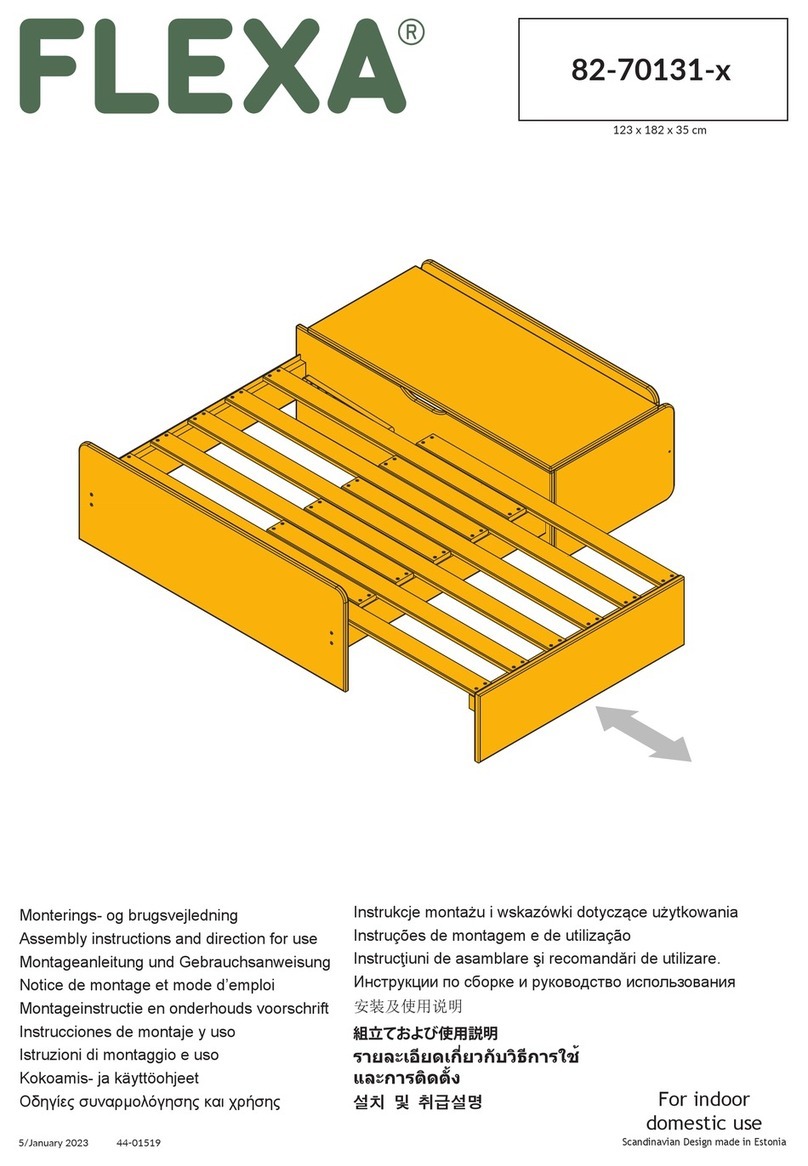

Section B

Assembly instructions to

assemble the following units:

Page 9 of 37

939504740 Rev E

Foot Bolts

Front

1. Flip the base upside down and without

cutting the tie wraps, put the feet on.

Page 10 of 37

939504740 Rev E

2.

3.

Straight Bilevel

Corner Bilevel

2. Install grommet (black) into laminated

side of worksurface.

3. Install guide (white) into grommet.

Page 11 of 37

939504740 Rev E

Worksurface

Screws

Bilevel Corner

Bilevel Straight

Rear

Front

Rear

Front

4. Place worksurface on a protected surface.

Attach mounting plates on worksurface.

Page 12 of 37

939504740 Rev E

Corner Bilevel

7.

6.

9.

Short Mounting Screws

Straight Bilevel

10.

5. Cut tie wraps.

6. Flip base upside down on a protected surface.

7. Mount top to base with short mounting screws.

8. Flip unit to upright.

9. Remove Guides, retain for future assembly.

10. Test: Using the crank handle, adjust both the

front and the rear surfaces of the unit to different

heights to ensure unit works properly.

Page 13 of 37

939504740 Rev E

Short

Mounting

Screw

(Qty. 12 max)

Worksurface

Screw

(Qty. 12 max)

Foot

Bolt

(Qty. 8 max)

5mm

5mm

Crank

Handle

(Qty. 1)

Strap

Screw

(Qty. 8 max)

Spacer

(Qty. 1)

Long

Mounting

Screw

(Qty. 4)

5mm

Tie Strap

(Qty. 2 max)

Connector Plate

(Qty. 2 max)

Connector

Plate

Screw

(Qty. 16 max)

Section C

Assembly instructions to

assemble the following units:

Page 14 of 37

939504740 Rev E

Foot Bolts

Front

1. Flip the base upside down and without

cutting the tie wraps, put the feet on.

NOTE: The large crossbar MUST

be in front for Standard Unit.

Page 15 of 37

939504740 Rev E

2.

3.

Corner Standard

2. Install grommet (black) into laminated

side of worksurface.

3. Install guide (white) into grommet.

Page 16 of 37

939504740 Rev E

5.

(optional)

Gas Cylinder

Washer

Disk

Nut

4. Cut the tie wraps.

5. (Optional for STANDARD and

DUAL units only) Install the "nut",

"washer" and "disk" to the gas cylinder

(if not already installed). Place gas

cylinder as shown.

NOTE: DO NOT attempt to screw or

compress the gas cylinder into place.

CAUTION: Cylinder under compression!

To avoid possible injury when servicing

cylinder, raise worksurface to uppermost

position and remove worksurface prior to

removing mounting plate. This will minimize

compression in the cylinder and facilitate

its removal.

Page 17 of 37

939504740 Rev E

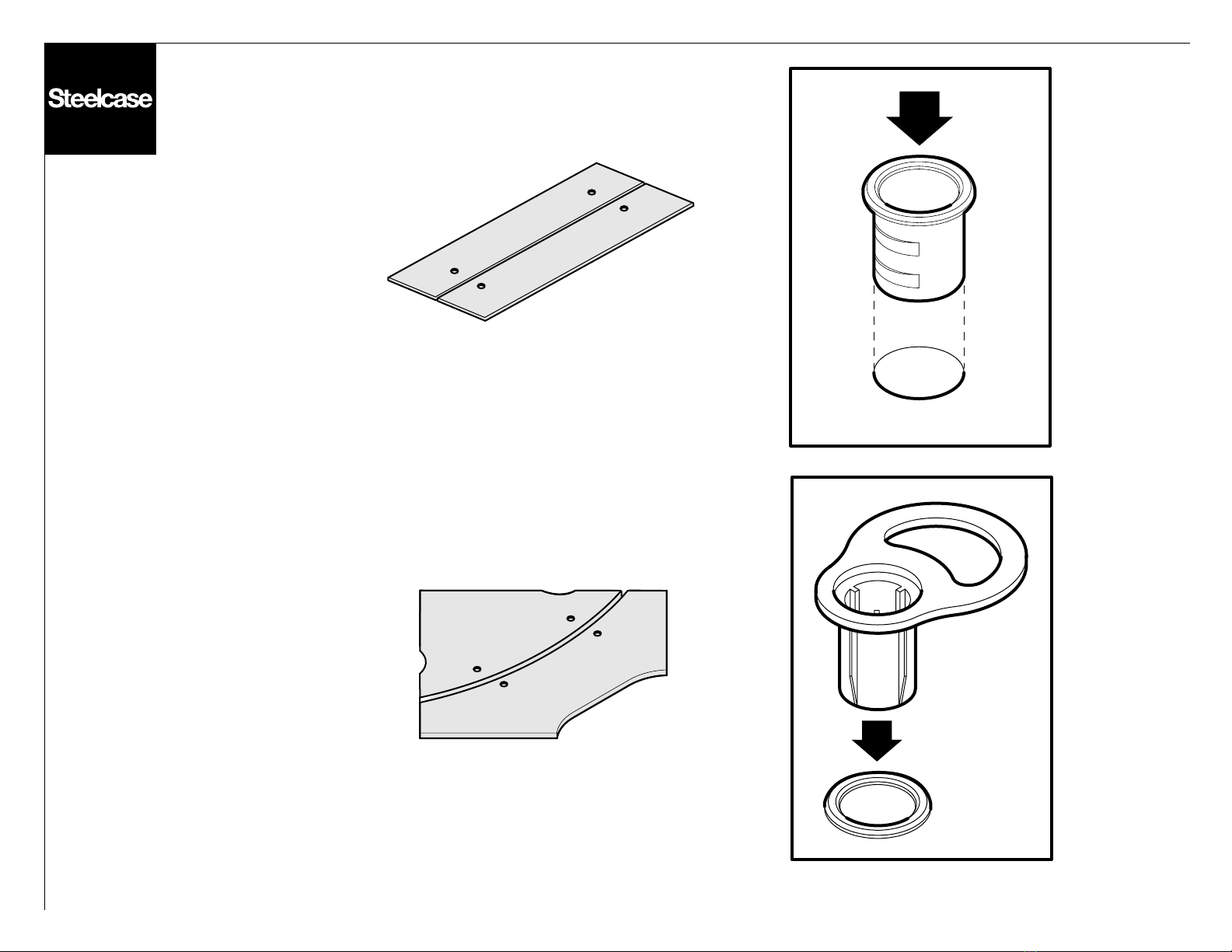

Connector Plate

Connector Screw

Make sure the recessed holes are

facing away from the worksurface

at the holes that align with the

worksurface pilot holes.

6. Flip worksurface over on a protected surface.

Attach connector plates to corner worksurface.

Page 18 of 37

939504740 Rev E

8.

8.

7.

7. Loop chain over sprocket making sure that

the extensions must have the crossbars to the front.

NOTE: Do not pull the chain in any direction as

this could affect the height of the base.

8. Cut tie wraps.

NOTE: The front of the feet must be pointed

towards the inside of workstation.

9. FOR HYPER EXTENDED UNITS ONLY:

Repeat the above 2 steps to attach the other

extended link.

Page 19 of 37

939504740 Rev E

10.

Align

10. Adjust the extension links so as to align

the slots.

Page 20 of 37

939504740 Rev E

optional

necessary

optional

necessary

necessary

Gas

Cylinder

Washer

Disk

Nut

11. Install gas cylinder into open column of

extension bases.

NOTE: DO NOT attempt to screw in or compress

the gas cylinders into place.

OPTIONAL: If standard hyperextension unit has an

extra pair of gas cylinders (ordered separately),

place them now.

CAUTION: Cylinder under compression! To avoid

possible injury when servicing cylinder, raise

worksurface to uppermost position and remove

worksurface prior to removing mounting plate. This

will minimize compression in the cylinder and

facilitate its removal.

Other Stellcase Indoor Furnishing manuals

Popular Indoor Furnishing manuals by other brands

MAISONS DU MONDE

MAISONS DU MONDE GUAM 198367 manual

Kohler

Kohler MING K-77127T installation instructions

RTA

RTA TVM-060 Assembly instructions

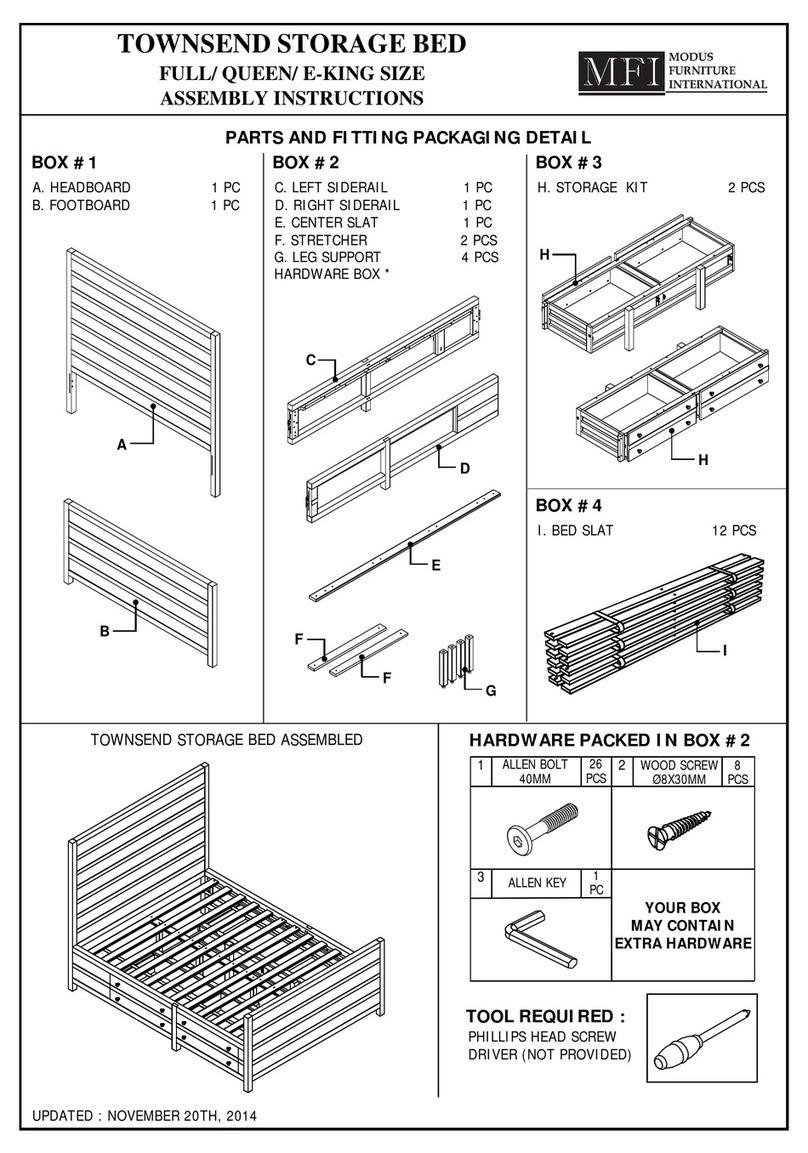

Modus Furniture International

Modus Furniture International TOWNSEND STORAGE BED Assembly instructions

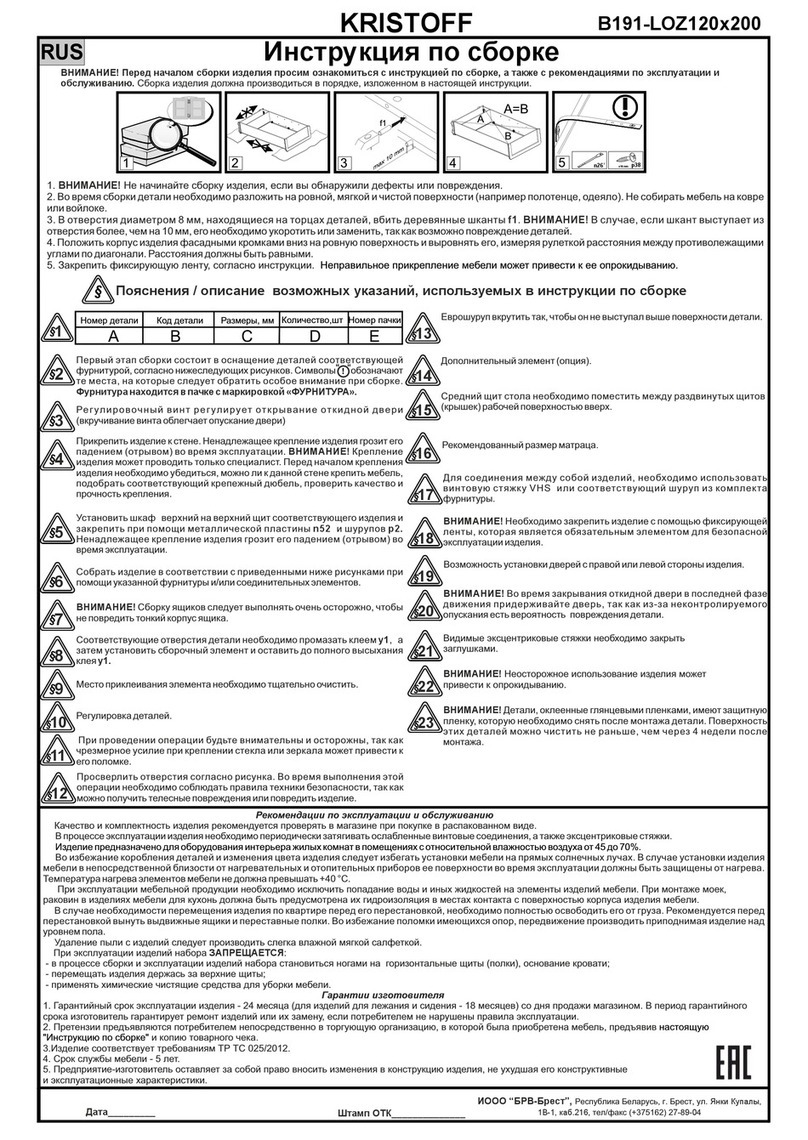

BLACK RED WHITE

BLACK RED WHITE KRISTOFF B191-LOZ120x200 Assembly

INOSIGN

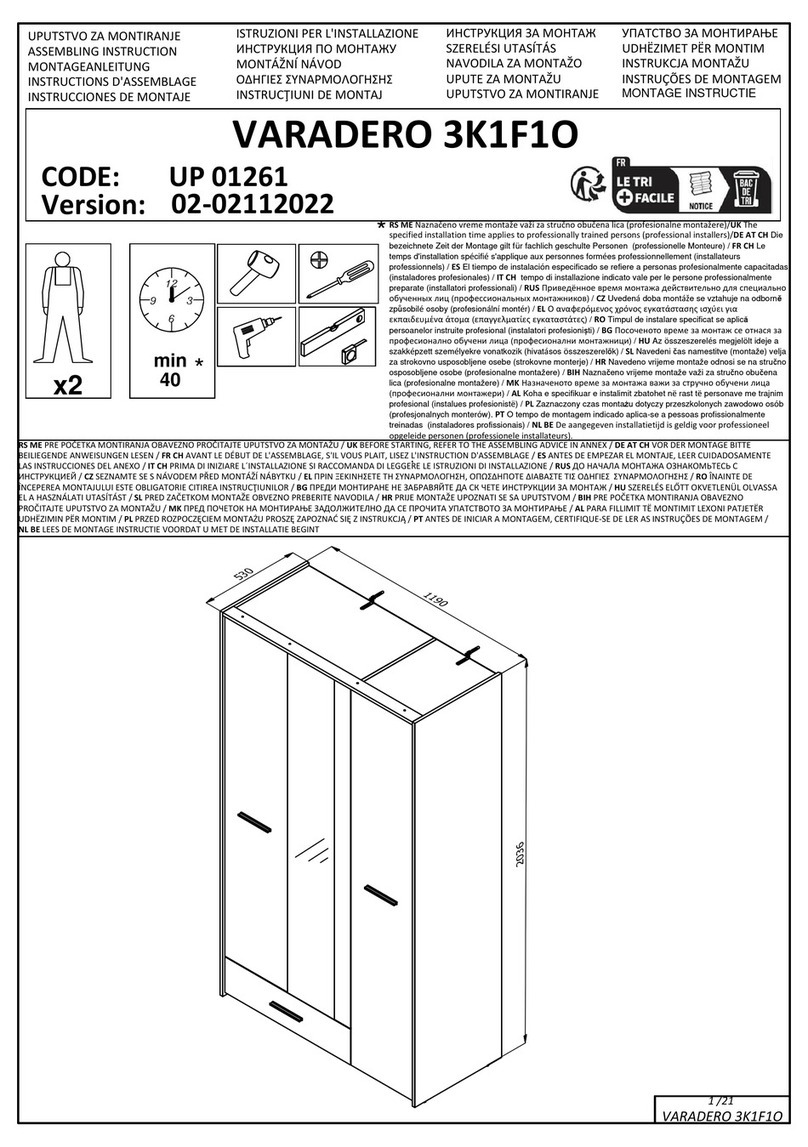

INOSIGN VARADERO 3K1F1O UP 01261 Assembling Instruction