Stenhoj MOLNAR BRADBURY SB40 Specification sheet

Please read this manual before you get started.

You must read and understand the precautions for safety purposes and any damages that may occur to your property.

Installation/Operation & Maintenance Manual

SB40: 2POSTHOIST

SB40

Updated 19/05/21

NOTE TO THE USER

Please read this instruction carefully for safety and proper use of the car

hoist, and retain it for future reference.

ANY PART OF THIS PRINT MUST NOT BE REPRODUCED IN ANY FORM WITHOUT

PERMISSION.

THIS PRINT IS SUBJECT TO CHANGE WITHOUT NOTICE.

This manual was prepared in December of 2018. The Specifications/images are subject to

change without prior notice, images and sketches are for illustration purposes only.

This Manual is for model: SB40

Design Registration V1803235

Vehicle Hoist - Model No. SB40

As for the assurance of safety in design and construction of car hoist, read this Manual first.

Please make sure that this Manual is delivered to end users for their implementation of safety.

Don’t use the car hoist in a potentially explosive atmosphere.

Introduction

Features and Characteristics

Part Descriptions

Description

Specification

4

4

6

7

7

Installation Procedures

Checklist Before Installing

Place of Installation-Layout

10

10

11

Safety

Danger/Warning/Caution

8

8

Operation

Check Points Before Operation

Operation

Operation Procedures of Each Part

16

16

17

28

Maintenance

Maintenance

Troubleshooting

Check List and Periodic Maintenance

Part List

20

20

23

24

IntroductionSafetyInstallation

Operation

Mainternance

Part List

TABLE OF CONTENTS

4

Features and Characteristics

Upper limit protection bar

Industrial direct

drive cylinder

Arm lock gear

Introduction

Door protection rubber

■ Upper limit protection bar

▶A limit bar prevents the vehicle from

being lifted too high.

This feature effectively protects

taller vehicles from being damaged.

5

■ Cable adjustment

▶Correct adjustment ensures

synchronization of both carriages.

Cable adjustment

■Operation of ram type cylinder

and longevity.

■ Powerful arm lock gear

▶At the bottom position the gears are

unlocked to allow arm adjustment. When

the hoist is raised the gears are

automatically locked ensuring

complete safety.

Unlocked Locked

Introduction

■ Door protection rubber

■ Safety locker

▶Vehicle door protect during working.

▶Safety locker system.

Two individual cylinders ensure reliability

6

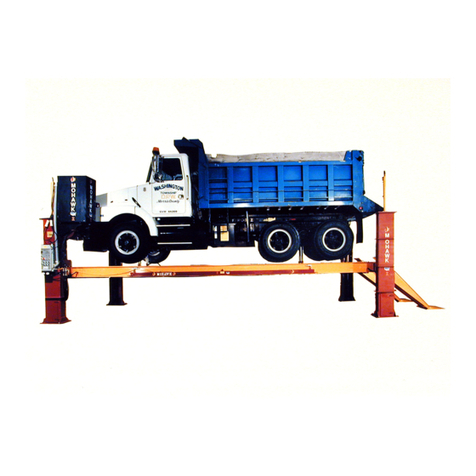

Cross beam

Post extension

Slave post

Cylinder

Locker cover & Locker(inside)

Short arm

1

2

3

4

5

6

7

8

9

10

11

12

13

Drive post

Power Pack

Carriage

Door protection rubber pad

Long arm

Pick-up pad

1

2

3

4

5

6

7

12

8

9

10

11

Part Descriptions

Introduction

13

Top limit touch bar

7

MODEL

CAPACITY

MAX. PRESSURE

MAX.HEIGHT

MIN. HEIGHT

STROKE

LIFTING TIME

LOWERING TIME

POWER & MOTOR

NET WEIGHT

SB40

4,000 Kg

14 Mpa

1,895~1,940 mm

95~140 mm

1,800 mm

Approx. 45 ~ 60 sec

Approx . 35 ~ 50 sec.

3Ph, 2.2Kw, 2Poles, 415V, 50Hz

700 kg

Specification

Introduction

1Ph, 2.2Kw, 2Poles, 240V, 50Hz

8

Warning before using the equipment

Danger/Warning/Caution

Make sure you follow the instructions.

otherwise critical injuries can occur.

Make sure you follow the instructions,

otherwise critical injury or damage can

occur.

Make sure you follow the instructions

otherwise injury or damage can occur.

The terms are described to enhance

the understanding of the equipment.

Information to use the equipment

efficiently.

Precautions or check points for the

use of the equipment.

Please refer to the page

Rules for illustrations

in the manual

Do not come under

the vehicle during

operation.

▶ It may cause

severe injuries.

Evacuate to a safe

place instantly in the

event that the vehicle

tips.

▶ It may cause

severe injuries.

Do not overload the

rated capacity.

▶ It may cause

severe injuries.

※Fail to follow the

instructions can lead

to a critical accident

involving your life.

Make sure you follow

the instructions.

Only trained

personnel may

operate the

equipment.

Inexperience can

cause accidents.

Position the vehicle

to make sure that it is

balanced front and rear,

right and left (otherwise

the vehicle may fall off).

Do not operate damaged

equipment (a critical accident

could occur - contact your

supplier

After that a vehicle is

placed on the hoist

make sure that the

hand brake is applied.

Passenger transport

is forbidden.

Safety

These are the rules

for the illustrations

in the manual.

Make sure that you

read and

understand them.

9

Make sure you follow the instructions.

otherwise critical injuries can occur.

Make sure you follow the instructions

otherwise injury or damage can occur.

Warning before using the equipment

Warning when operating

Warning when operating

Warning when operating

Allow no unauthorized

persons in the work

area.

Before lowering the

hoist, check that there

are no obstructions

under the vehicle or the

hoist arms.

When the vehicle is

lifted, do not rock it as

this may dislodge it.

Do not raise a vehicle

using one pair of arms

only.

To avoid injury, keep

your feet clear of the

arms and carriages.

Before going under

the hoist, make sure

that the safety pawls

are engaged.

To avoid being

electrocuted,

disconnect the

main power before

opening the control

panel.

Do not modify the

control panel or the

safety functions as

this may impair their

function.

Do not rock the

vehicle when lifted.

Do not use a high

pressure cleaner as

the vehicle lower part.

Read and fully

understand the

manual before using

the hoist.

Check the safety

devices to see that

they are clean and

operable.

If the hoist is idle for a

long time, disconnect

the main power

supply. In the event

of thunder storm.

disconnect the main

power supply.

Safety

10

Installation site

Check List Before Installing

The site must be

flat and horizontal.

The floor must have

minimum 160mm

depth of reinforced

concrete.

Surface load under

the posts must be

minimum 25N/㎟

Ambient temperature

10℃ to 50℃. Do not

operate under

freezing conditions.

Installation site

Vehicle access to

the hoist must be

safe and easy.

There must be a safe

working distance of

minimum 1m between

the hoist and the wall or

any fixed object.

To ensure that the

anchor is secure, the

hole for an anchor

bolt must be more

than 2/3 of the bolt

length.

Installation site

To maintain the warranty, the hoist is intended for

indoor installation only. In the event that it is installed

outside it should be protected from snow and rain.

Outdoor installation makes the warranty invalid.

Only competent

technicians shall install

the hoist, otherwise a

failure may occur.

Installation

The hoist must be installed by competent technicians. Failure to observe this

makes the hoist warranty invalid. If the hoist is to be moved to another site at a

later date, it must be reinstalled by competent technicians.

11

45

2516

3440

R1075

R600

R920

R1400

1895

1940

95

140

Place of Installation-Layout

Check points before selecting the place of installation.

① Distance from wall or any fixed object

② Drive-on direction

③ Positions of power post and slave post

④ Ceiling height and height of cross member

Installation

3750

3560

2856

12

12

■Setting up a post

Anchor bolt installation

① Drill a hole

② Clean the inside of the hole

③ Put an anchor bolt into the hole and hammer

it until it reaches the bottom of the hole

④ Tighten the bolt with a spanner (ⓐ:35~45mm)

(Tighten more 80N.m~100N.m)

▶Before securing with anchor bolts, ensure

that the post is vertical in both directions.

Vertical balance

Check that the post is vertical in both

directions and adjust by means of the shim

plates provided.

Fix by anchor bolts.

Adjusting verticality

Fixing the post

1

2

■Connection of the hydraulic hose

▶Before setting up the post, connect the

hydraulic hose and tighten it with a 19/17mm

spanner. Check for oil leakage.

Installation

13

■Cable synchronization

▶The cables ensure synchronization

between the carriage on the power post and

the carriage on the slave post.

① Top roller for cable.

② Synchronization cable from the

opposite carriage.

③ Synchronization cable mounting

bracket.

④ Bottom roller for cable.

Check which carriage first touches the

base plate of the post when the hoist descends

and then tighten. This cable until both carriages

lest on lie base plates simultaneously.

Adjusting the cables

How to check the tuning

adjustment.

① Check with "naked eyes" that the bottom

post reached simultaneously see above.

② Check with ears

Check the sound of the parking pawls

engaging in each slat during ascent.

The "clicks" should be simultaneously

if not tighten the cable on the later pawl.

(The wire of the locker that sounds later

shall be tightened more tensely.)

Installation

14 14

Installation

■Hydraulic Diagram

LOWERING VALVE

9/16-18 UNF

15

Installation

■Electrical Diagram

16

Check Points Before Operation

■ Test Operation

Before loading the hoist check

the following points.

▶Operate the hoist up and down 2-3 times to

check the full travel of the carriages.

■ Switch Operation

▶Check that the ascent and descent lever

operate correctly.

■ Hydraulic Check

▶Check that there are no hydraulic leaks

from either cylinders, pipes, or hose joints.

■ Mechanical Check

▶Check the tightness of all nuts, bolts, etc.

■ Exterior Check

▶Check the exterior of the hoist to ensure

that there is no obvious damage.

■ Cleanliness

▶Check every day that the hoist and the

work area are clean and free from debris or

obstructions.

Operation

17

Operation

Check that the carriages and arms are at

lowest position by operating the lock

release lever and descend lever.

Prior to use

1

At the bottom position the arm locks

are released. Swing the arms to the

straightahead position as shown.

Prior to vehicle entry

2

Position the vehicle centrally between

posts with the vehicle's center of gravity in

line with the 2 posts.

Vehicle entry

3

Raise the hoist approx. 50mm and

check visually and mechanically to

ensure that each arm lock is firmly

engaged.

Check the arm locks

5

Swing in the 4 arms under the vehicle and adjust

the length of each arm so that the pick-up pad is

directly underneath the pick-point recommended

by the vehicle manufacturer. Each pad is fitted with

telescopic thread allowing a 2-stage adjustment.

Adjust the height of each pad to engage the pick-up

point.

Arm and pad adjustment

4

Operation

18

After checking that the 4 pads are correctly adjusted

under the pick-up points recommended by the

vehicle manufacturer and that the arm locks are

engaged as previously described, press the

ascent push button and raise the hoist to the

required working height.

Ascent

6

Before going under the hoist, check again visually

the pick-up pads and arm locks. After repair of the

vehicle, check the floor and work area to ensure that

there are no obstructions. Press the descent push

button to lower the hoist. When the hoist is at the

bottom position, the arm locks are released

automatically. Release the pick-up pads from the

pick-up points by screwing down the telescopic

threads. Swing the arms from under the vehicle to

the straight-ahead position and remove the vehicle.

Vehicle repairs

7

Operation Procedures of Each Part

■ Arm Lock Operation

When the carriages go up the arm locks

are engaged automatically. Ensure that the

gears controlling the locks are in mesh,

i.e. fully engaged. If not, the arm must be

marginally adjusted until the spring loading

operates and locks successfully.

Ascent

1

■ Arm Operation

the arms are telescopic with either 2

sections or 3 sections as shown to allow

the required adjustment.

Adjustment of arm length

1

At the bottom position the locks are

automatically disengaged.

Descent

2

2 section 3 section

Operation

19

ⓐ 55 mm

ⓑ 75 mm

ⓒ 100 mm

ⓓ Dia.120mm

▶ 26K Arm

2-section telescopic arm

ⓐ 920 mm

ⓑ 1400 mm

3-section telescopic arm

ⓐ 600 mm

ⓑ 850 mm

ⓒ 1075 mm

The height of the pad can be adjusted 3

stages as shown below.

3-stage telescopic pad adjustment

2

Operation

20

Maintenance

■ Lubrication

■ Cleanliness

▶At 2-or 3-month intervals, depending on

service usage.

▶Apply molybdenum disulphide grease liberally to

the carriage guides and the guide runners inside

the posts.

Molybdenum disulphide grease

1

▶Check every day that the hoist is clean and

that the work area is clean and free from

debris or obstructions.

▶Clean safety devices at 2-or-3-month intervals,

depending on service usage.

- Clean the arm lock gears and surroundings,

lubricate the gear teeth and the release

mechanisms. Clean the safety lock pawls, and

lubricate the axles.

■ Synchronization Cable Adjustment

▶Check that both carriages are fully parked on the

base of the hoist at the bottom position. Raise the

hoist without load and listen to the audible clicks of the 2

lock pawls. The synchronization of the

2 carriages is correct when both lock pawls click

simultaneously. Adjust the length of the 2 cables as

shown to fulfill this.

▶Lubricate with oil the upper and lower cable

rollers and axles.

Lubricating oil

2

Maintenance

Table of contents

Other Stenhoj Lifting System manuals