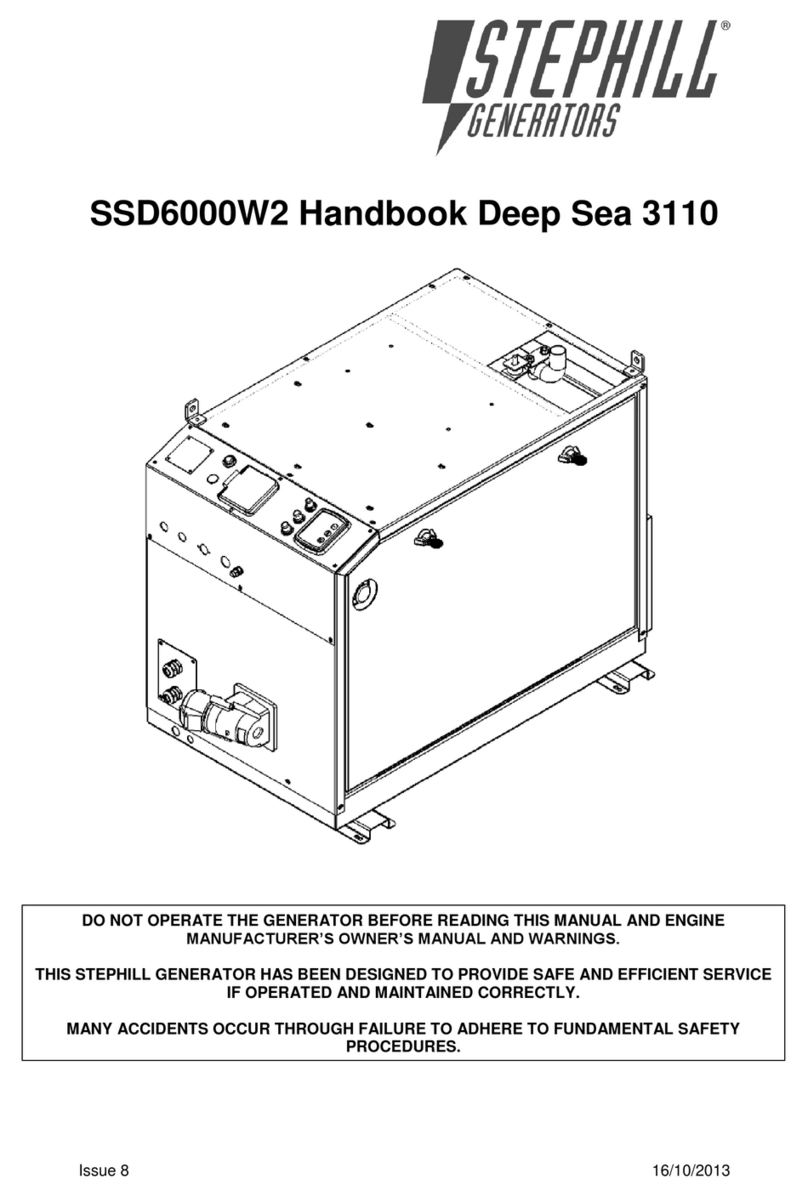

Stephill SE6000D4 User manual

Issue 6 15/06/2015

SE6000D4 - SSD6000 - SSD6000S NSM

Handbook

Stephill Generators Ltd

Wallis close

Park Farm South

Wellingborough

Northants

NN8 6AG

Tel : +44 (0)1933 677911

Fax : +44 (0)1933 677916

Web : www.stephill-generators.co.uk

DO NOT OPERATE THE GENERATOR BEFORE READING THIS MANUAL AND ENGINE

MANUFACTURER’S OWNER’S MANUAL AND WARNINGS.

THIS STEPHILL GENERATOR HAS BEEN DESIGNED TO PROVIDE SAFE AND EFFICIENT SERVICE

IF OPERATED AND MAINTAINED CORRECTLY.

MANY ACCIDENTS OCCUR THROUGH FAILURE TO ADHERE TO FUNDAMENTAL SAFETY

PROCEDURES.

Issue 6 15/06/2015

Contents

Page

1

SPECIFICATION

1

2

GENERAL SAFETY

1

2.1

Warning signs

1

2.2

Safety hazards

1

3

POTENTIAL HAZARDS

1

3.1

Auxiliary power

1-2

3.2

Operating environment

2

3.3

Temperature range

2

3.4

Reference relative humidity

2

3.5

Reference barometric pressure

2

3.6

Flammable environment

2

3.7

Saline environment

2

4

SAFETY CONSIDERATIONS

2

4.1

General

2

4.2

Fuel

2

4.3

Lubricating oil

2

4.4

Safe lifting

2

4.5

Earth connection

3

4.6

Fumes

3

4.7

Noise

3

4.8

Battery acid

3

4.9

Fire

3

4.10

Hot parts

3

5

OPERATING INSTRUCTIONS

3

5.1

Pre-Start checks

3

5.2

Warning

3

5.3

Fuel system bleeding procedure SE6000D4

3-4

5.4

Fuel system bleeding procedure SSD6000/S

4

5.5

Control panel

4

5.6

Long term storage

4

6.0

KEY START OPERATING INSTRUCTIONS

5

6.1

Fault finding key start

5

7.0

DEEP SEA 3110 OPERATING INSTRUCTIONS

6

7.1

Description of controls

6

7.2

Starting the engine

6

7.3

Starting sequence

6

7.4

Engine running

6

7.5

Stopping the engine

6

7.6

Automatic operation

6

7.7

Waiting in auto mode

6

7.8

Viewing the instruments

7

7.9

Fault icons

7-8

7.10

Fault finding 3110

8-9

8

SERVICE AND MAINTENANCE

10

8.1

Engine service

10

8.2

Alternator service

10

9

Alternator spares

10

10

Yanmar consumable spares

10

11

General spares

10-11

12

SE6000D4 Spares

11

13

SSD6000 Spares

12

14

SSD6000S Spares

12

15

WARRANTY

12

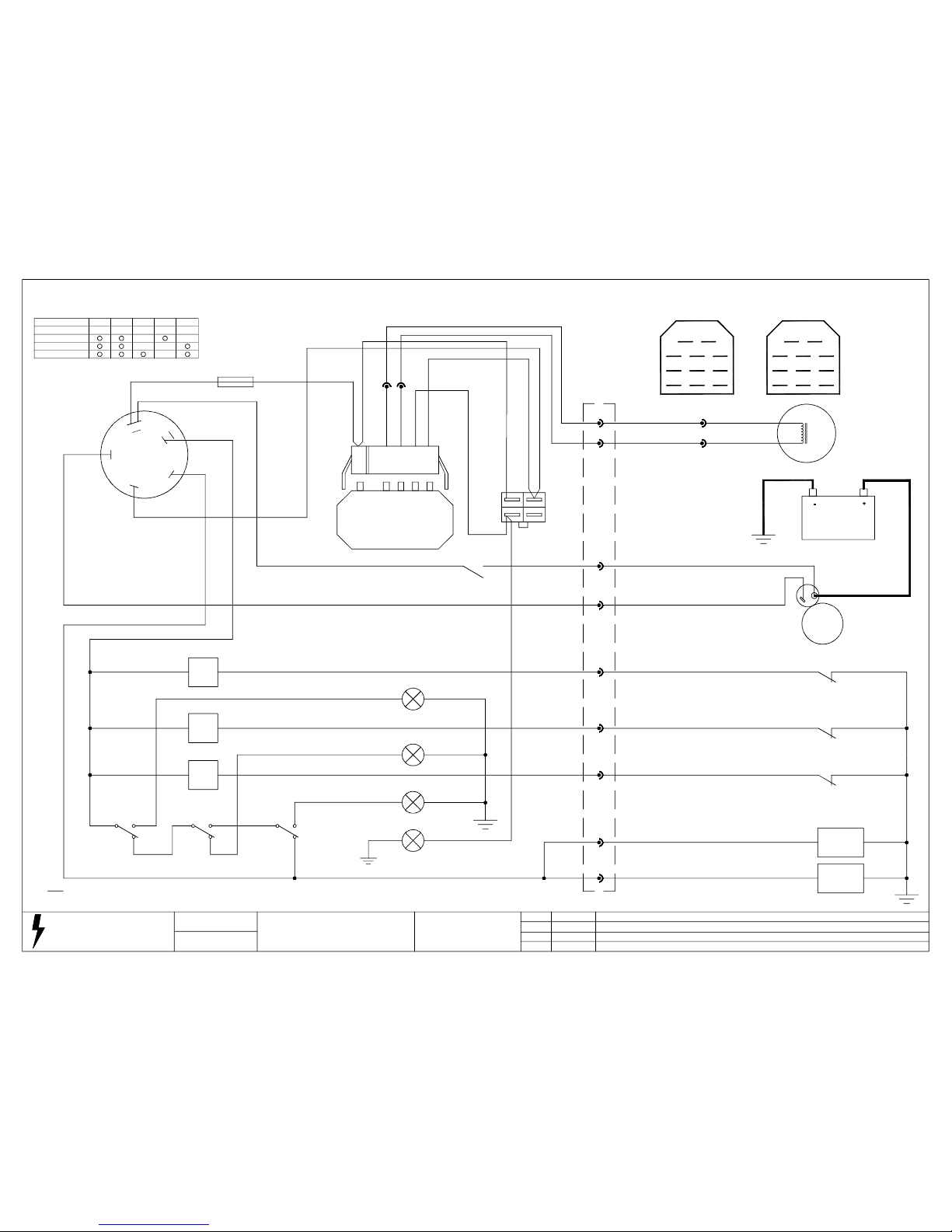

L100 Key switch wiring diagram

13

L100 Deep sea 3110 wiring diagram

14

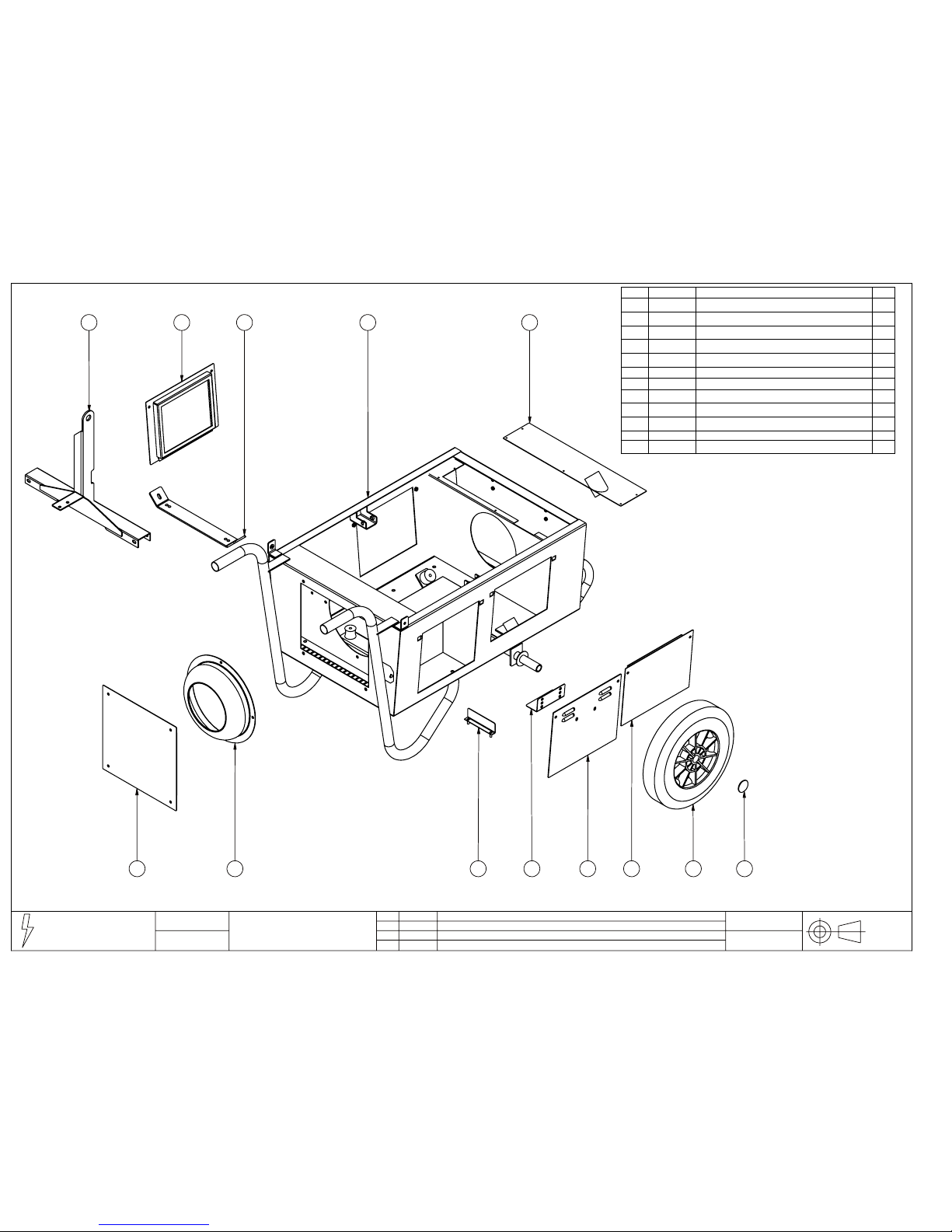

Dual voltage AC wiring diagram

15

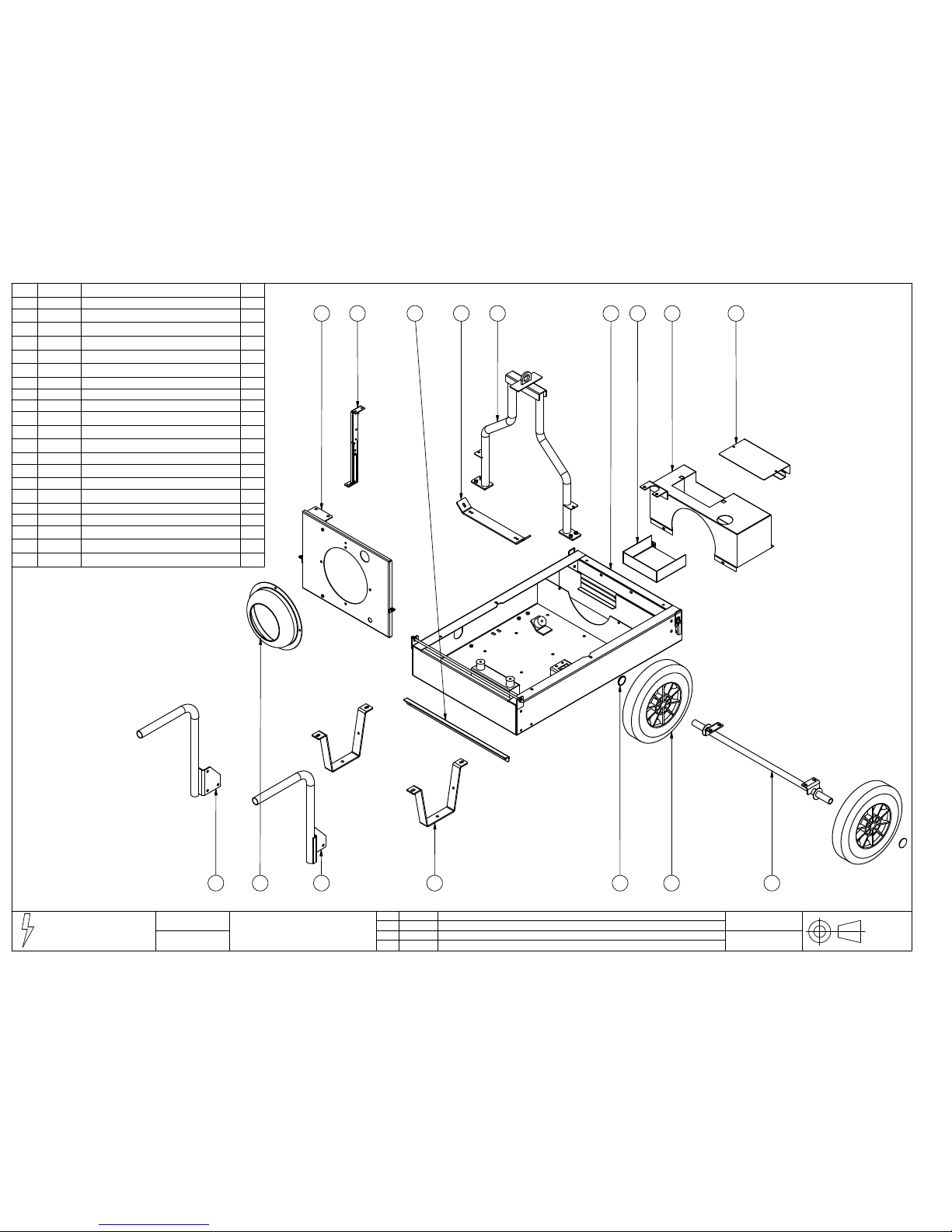

SE6000D4 Base exploded view

16

SE6000D4 Roof exploded view

17

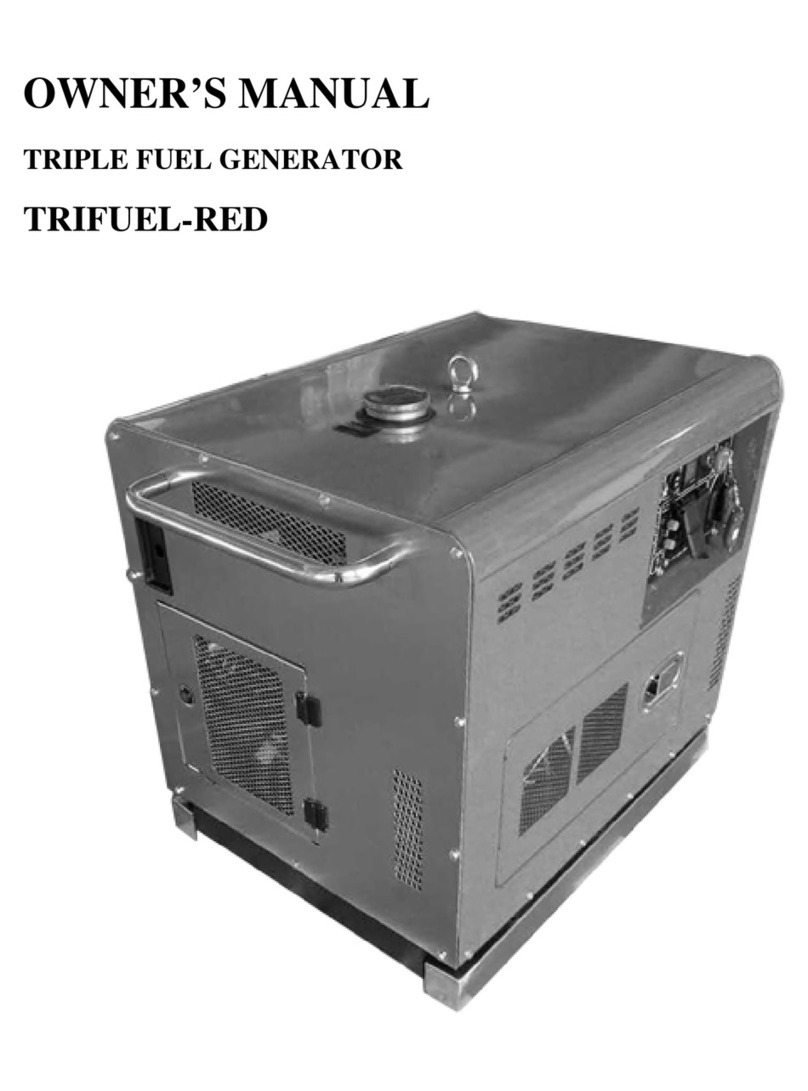

SSD6000/S Base exploded view

18

SSD6000/S Roof exploded view 19

Issue 6 1 15/06/2015

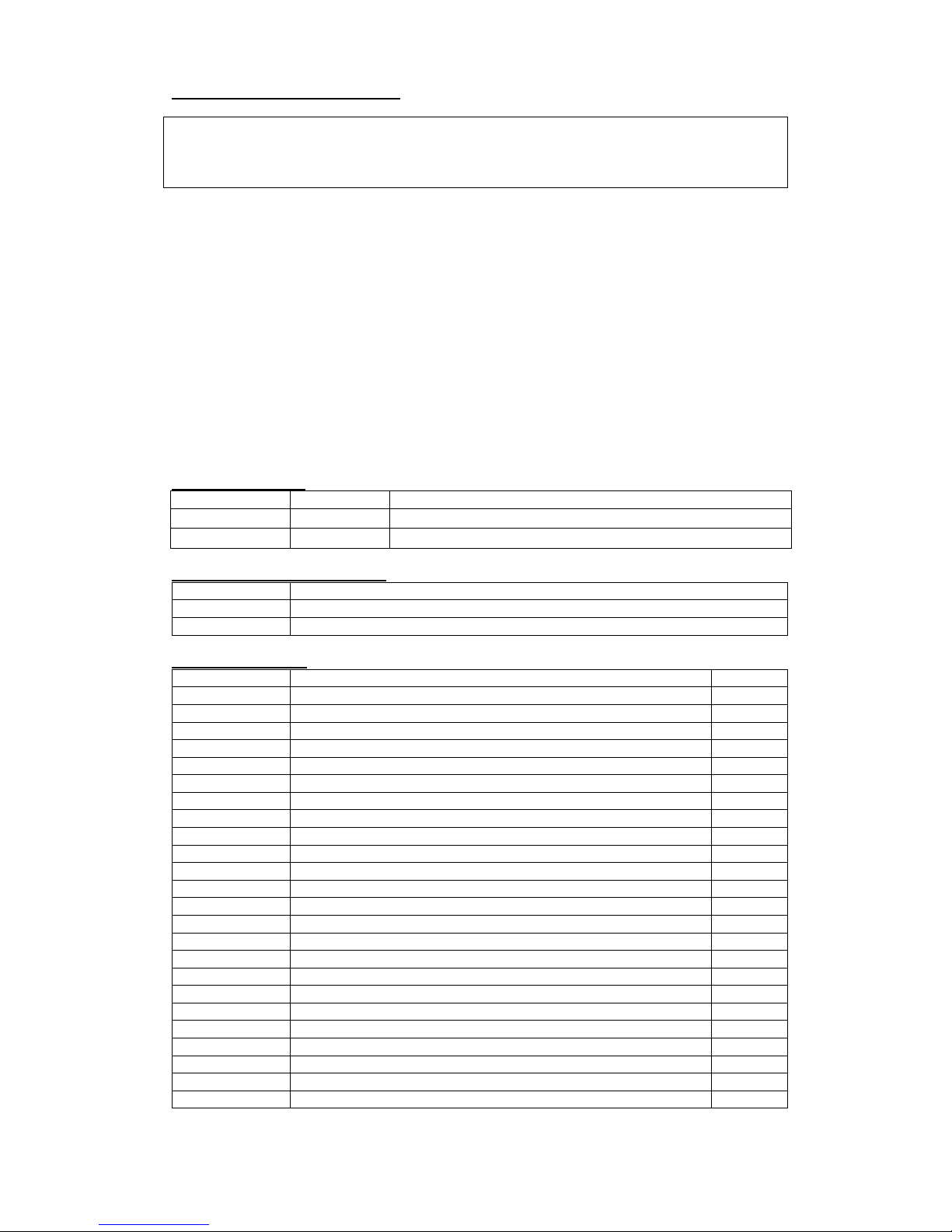

1 Specification

SE6000D4

SSD6000

SSD6000S

kVA

6.0

6.0

6.0

kW

4.8

4.8

4.8

LWA

96

91

84

dBA@7M

71

66

59

Engine

Yanmar L100

Yanmar L100

Yanmar L100

Alternator

NSM M100 SG

NSM M100 SG

NSM M100 SG

Voltage

230v &115v CTE

230v &115v CTE

230v &115v CTE

Weight

174Kg

196Kg

230Kg

Length

1220mm

1290mm

1290mm

Width

710mm

785mm

785mm

Height

910mm

890mm

970mm

Fuel

24L

24L

24L

Hours run 100% load

13

13

13

Hours run 75% load

17

17

17

2 General Safety

2.1 Warning signs

Warnings shown on the machine should be observed at all times. The warning signs

should be checked for legibility and any that have become damaged should be replaced.

The following are shown on the generator:

2.2 Safety hazards

Do not climb on the generator, as dents may cause overheating of the acoustic lining. It is

important to keep the generator clean and well serviced, in particular keep all air vents /

louvers clear of debris to prevent poor performance or possible overheating and

permanent damage to the generator.

Keep well clear of moving parts on the generator at all times.

Children and pets must be kept clear of the operating area.

3 Potential Hazards

3.1 Auxiliary power

The electricity produced by an engine driven Generator is very similar to mains electricity

and should be treated accordingly.

Do not remove covers and attempt to work on the Generator while the engine is running.

Check the rating and electrical safety of the load before connecting the Generator.

CAUTION

HOT EXHAUST

RISK OF ELECTRIC SHOCK

ALWAYS TURN OFF GENERATOR

BEFORE OPENING. KEEP

CLOSED AT ALL OTHER TIMES

BEFORE STARTING.

READ HANDBOOK AND SAFETY ADVICE

CHECK OIL LEVEL

DO NOT ADJUST ENGINE SPEED

WITHOUT SUITABLE TEST EQUIPMENT

WARNING

Issue 6 2 15/06/2015

Equipment should never be connected that in total exceeds the specified rating of the

Generator.

Installation of the generator as a standby or secondary power source should only be

undertaken by a fully qualified electrician using the appropriate means of isolation from

the mains supply. Installation must comply with all applicable laws and electrical codes.

3.2 Operating Environment

The Generator should always be operated on level ground.

3.3 Temperature Range

A temperature range between -10˚C and +40˚C are the normal limits of operation.

Operating outside the range will require additional modifications.

3.4 Reference Relative Humidity

The standard reference condition for relative humidity is 30%. Above this value the rated

power must be reduced.

3.5 Reference Barometric Pressure

The standard reference condition for total barometric pressure is 1 bar.

This corresponds to an altitude of approximately 100m. Above 100m the rated power

must be reduced.

3.6 Flammable Environment

Stephill Generators must not be used in a flammable environment.

3.7 Saline Environment

Operation of the machine in a saline environment will require additional corrosion

protection.

4 Safety Considerations

4.1 General

All Stephill Generators comply with all the current EEC directives including:

2006/42/EC Machinery Directive

2000/14/EC Noise Emission in the Environment by Equipment for use Outdoors

2004/108/EC EMC Directive

2006/95/EC Low Voltage Directive

4.2 Fuel

Fuels and lubricants are a potential source of fire. Lubricants in particular used engine oil,

are potentially carcinogenic. Direct contact should always be avoided by wearing suitable

rubber gloves when handling them. Be careful not to spill fuel, clean up any spillages.

Inhalation or swallowing of Diesel should be avoided. If in doubt seek medical advice. All

other forms of contact are irritant and therefore should also be avoided. If skin contact is

made wash with soap and water.

4.3 Lubricating Oil

New oil presents no hazard following short term exposure.

Used oil should not be allowed to contact the skin. If this does occur, wash off quickly

with a proprietary hand cleanser.

4.4 Safe Lifting

Where mechanical assistance is used in lifting machines, ensure the lifting eye is used,

and that all components used to lift the machine are within their Safe Working Load

(SWL).

The integral lifting beam and associated lifting eye on the generator should be regularly

checked for signs of damage or gross corrosion.

All Nuts and Bolts associated with the lifting beam should be regularly checked for

tightness and corrosion.

Lifting equipment should not be attached directly to the Engine/Alternator except for lifting

of Engine/Alternator only.

Issue 6 3 15/06/2015

4.5 Earth connection

All Stephill products are fitted with an earth stud on the control panel this must be

connected to an earthing system or spike. Any earth spike required is dependant on the

local conditions of use. The size is determined by reference to current IEE regulations or

to a competent electrician.

4.6 Fumes

Make sure that the Generator is at least 2 metres away from any building during

operation. Operate in a well ventilated unconfined area, so that fumes can be properly

dispersed.

Silencer outlet should be facing an open area to prevent fumes being recirculated. There

is the danger of asphyxiation due to exhaust gases. Inhalation of poisonous exhaust

fumes can lead to serious injury or death. The generator must not be used in a poorly

ventilated or enclosed area.

4.7 Noise

Ear protection may be required depending on the combined noise level of the Generator,

auxiliary load and the operator’s distance from it and the length of exposure. (Noise at

Work Regulations 1989)

4.8 Battery Acid

This is corrosive and irritant by all forms of exposure. Direct contact should always be

avoided by wearing suitable rubber gloves, some form of eye protection should also be

used. If skin contact is made wash with clean water.

4.9 Fire

Ensure that suitable fire extinguishers (AFFF or CO2)are kept within proximity to the

generator. Do not cover, enclose, or obstruct the airflow to the generator during or shortly

after use, due to fire hazard or damage to the generator from overheating. Allow the

generator to cool after use before storing away. Keep all inflammable objects clear of the

Generator.

4.10 Hot parts

There is the danger of burns as parts of the generator will become very hot during use.

No part of the engine, alternator or exhaust must be touched during or shortly after

operation. Do not operate the generator unless all guards are in place. There is a risk of

burns or serious personal injury.

5 Operating instructions

5.1 Pre-start checks

Before starting the generator please read the Yanmar engine owners manual.

Check Fuel & Oil level before attempting to start.

The generator is equipped with a low fuel level switch which will shutdown the engine and

prevent it from starting, if the fuel level is low.

The engine is equipped with an oil and temperature switch and will shutdown for low oil

pressure and high engine temperature.

5.2 Warning

Do not operate the changeover switch with load connected.

Always switch load off before disconnecting plugs.

To switch power off at the Generator always use the circuit breaker.

5.3 Fuel system bleeding procedure SE6000D4

Before attempting to bleed the fuel system on the SE6000D4, ensure the key switch is in

the off position, the tank has a minimum of 10 litres of fuel and the lid is open.

1. Loosen the Brass injector pipe fitting (17mm nut) on the fuel pump, move to one side,

leaving the delivery valve holder (black male fitting) on the fuel pump exposed.

2. Loosen the Delivery valve holder (17mm nut) but only by 2 complete turns.

3. Turn the starter key to the on position, (do not start the generator). The battery and

low oil pressure warning lamps should be illuminated.

4. Then slowly turn the starter key to the spring position until the battery warning lamp

goes out. You should also hear the fuel solenoid click to indicate it is open. Hold the

Issue 6 4 15/06/2015

key in this position until all the air has escaped from the delivery valve holder fitting on

the fuel pump and diesel starts to trickle out, then turn the starter key back to the off

position.

5. Then tighten the Delivery valve holder and the Brass injector pipe.

Now the fuel system has been bled and the generator should start.

6. If the engine still will not start repeat steps 1-5 but turn key to start position and diesel

should squirt out of delivery valve holder. Once this has been achieved go to step 6.

Injector pipe fitting Delivery valve holder

5.4 Fuel system bleeding procedure SSD6000/S

A self-bleeding system is fitted to these generators; the engine should not need

bleeding unless maintenance has been carried out.

Before attempting to bleed the fuel system on the SSD6000/S ensure the tank has at

least 10 litres of fuel.

1. Turn the starter key to the first position, do not start the generator. The battery and

low oil pressure warning lamps should be illuminated.

2. Then slowly turn the starter key to the spring position until the battery warning lamp

goes out. You should also hear the fuel solenoid click to indicate it is open; the fuel lift

pump will also be operational. Hold the key in this position for around 1 minute, turn

the starter key back to the off position.

Now the fuel system has been bled and the generator should start.

Note: If a Deepsea 3110 control module is fitted to the generator you have a fuel

pump prime button to bleed the system with.

5.5 Control panel

Before connecting plugs into generator ensure the load is turned off. If this is not possible

turn the circuit breaker to the off position.

The 230v Supply is Neutral bonded to earth.

The 115v Supply is CTE. (Centre Tapped to Earth)

Turn the voltage selector switch to the required voltage.

Connect the plug/plugs into the generator.

Switch on the load / Circuit breaker.

Always turn load off before stopping generator.

5.6 Long term storage

For storage or long periods of inactivity, Stephill Generators recommend the following:

Generators should be stored with oil filled to the correct capacity; Storage periods of 18

months and over may require special lubricants and treatments. If so please seek further

advice from the engine manufacturer.

Before the generator is used after long term storage, all fuels and oils should be replaced.

Generator mounts, pipes and hoses should be checked to ensure that they are un-

perished following extended periods of storage.

The generator should be stored in a clean dry area, ideally having a reasonable constant

ambient temperature, and ideally not below freezing.

Issue 6 5 15/06/2015

6 KEY START OPERATING INSTRUCTIONS

Before attempting to start the generator ensure the engine has the appropriate amount of

lubricating oil and the fuel tank has at least 10 litres of diesel.

Turn the key to the first position, the oil and battery lamps should be illuminated.

Turn the key to crank position until engine fires, oil and battery lamps should now have

been extinguished.

Return key to run position and the generator should now be running.

To stop, turn the key to stop position.

6.1 Fault finding key start

Before diagnosing a possible fault ensure all the bulbs in the fault lamps are working.

The easiest way to check is to swap the lamp heads containing the bulb into a holder

you know works eg. the battery or oil lamp. A blown bulb will not show you a possible

fault!

Fault

Possible cause

Check

Starter motor not

engaging & not

starting

Battery

Reset button

Faulty wiring

Faulty starter motor

Check battery voltage, should be about 12.5V.

Check electrolyte level in battery.

Check DC reset button on control panel.

Check for loose wires on starter motor.

Check continuity from key switch to reset

button.

Check continuity from key switch to starter

motor.

Check / Change starter motor.

Starter motor

engaging & not

starting

Faulty lamps/lamp holder

Run-Stop lever in wrong

position

Fuel lamp illuminated

Full of fuel still won't run

Temperature lamp lit

Fuel Solenoid

Check bulbs and lamp holders.

Move to Run position.

See fuel lamp fault.

Check machine has not run out of fuel and

introduced air into system (bleed).

See temperature lamp fault.

Check 12v supply to solenoid.

Check solenoid is operating.

Check connections on key switch.

Battery charge

lamp illuminated

when running

Fuse blown

Wiring

Regulator

Fuse holder situated next to regulator

Check regulator and harness connections.

Check continuity (earth connection) from

regulator to body of engine.

Check AC voltage on green/white wires from

engine voltage should be 38V.

Check key switch connections.

Replace regulator.

Oil lamp stays

illuminated

during start

procedure

Low oil

Oil pressure switch

Oil pressure relay

Check oil level is at max on dip stick.

Check for signs of oil leak.

Check oil pressure switch normally closed

when engine is at rest and open when engine

running.

Replace Oil pressure switch.

Check relay for loose wires.

Check operation of relay.

Temperature

lamp stays

illuminated during

start procedure

Temperature switch

Temperature switch relay

Check operation of temperature switch

normally closed opens with fault.

Check relay for loose wires.

Check operation of relay.

Fuel lamp stays

illuminated during

start procedure

Low fuel

Faulty level switch

Fuel level relay

Check fuel level is at 1/3 a tank minimum.

Check level switch operation normally closed

with low fuel, opens when fuel level ok.

Check connections on level switch.

Check relay for loose wires.

Check operation of relay.

Issue 6 6 15/06/2015

7 DEEP SEA 3110 OPERATING INSTRUCTIONS

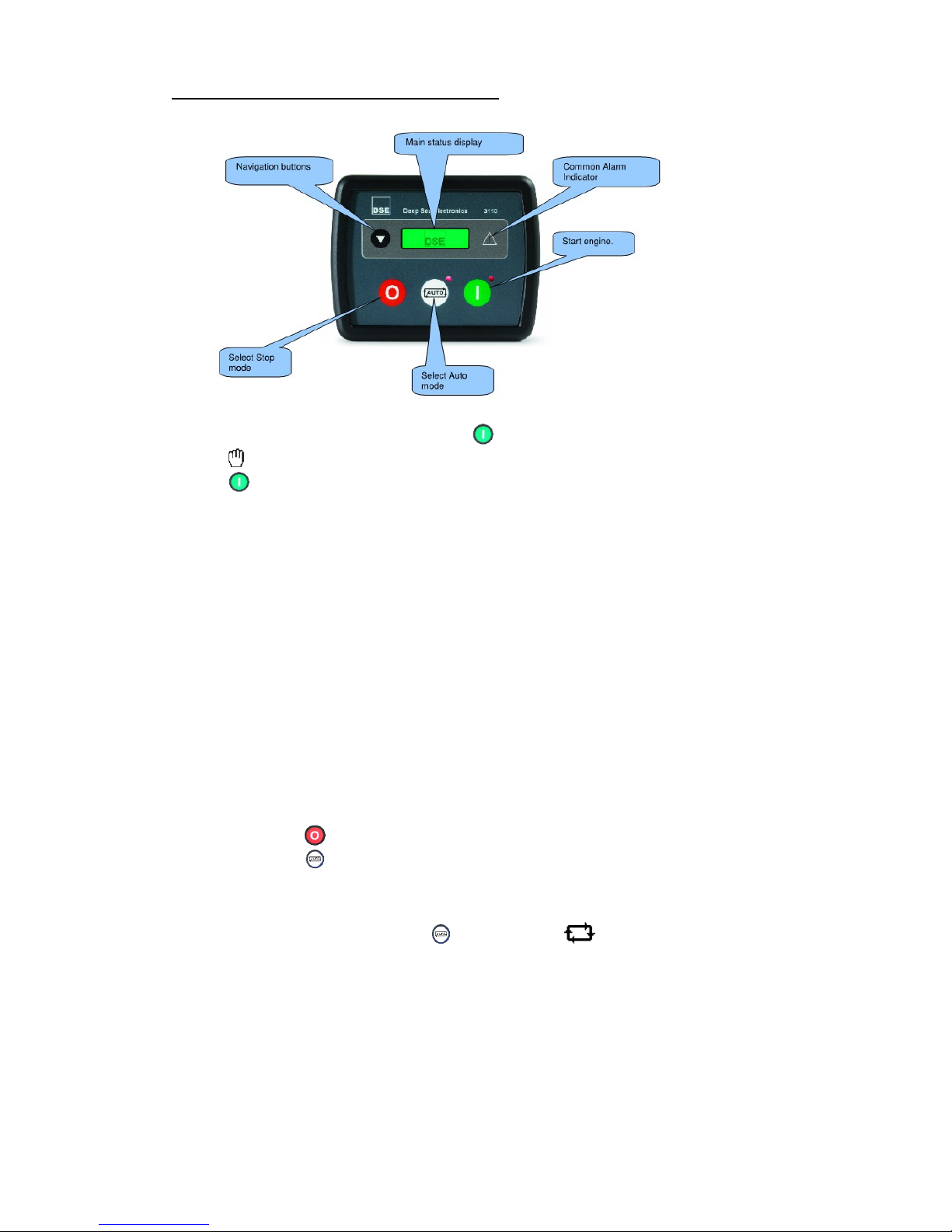

7.1 Description of controls

7.2 Starting the engine

To begin the starting sequence, press the button.

The icon is displayed to indicate Manual mode and the manual LED flashes.

The button must be pressed once more to begin the start sequence.

7.3 Starting sequence

If a start request is present, the fuel relay is energised and the engine will be cranked. If

the engine fails to fire during this cranking attempt then the starter motor is disengaged

for the crank rest duration after which the next start attempt is made. Should this

sequence continue beyond 3 attempts, the start sequence will be terminated and the

display shows Fail to Start.

When the engine fires, the starter motor is disengaged. Speed detection is factory

configured to be derived from the main alternator output frequency.

After the starter motor has disengaged, the Safety On timer activates (10 Sec), allowing

Oil Pressure, High Engine Temperature, Under-speed, Charge Fail and any delayed

Auxiliary fault inputs to stabilise without triggering the fault.

7.4 Engine running

Once the engine is running and all starting timers have expired, the animated icon is

displayed.

If all start requests are removed, the stopping sequence will begin.

7.5 Stopping the engine

In manual mode the set will continue to run until either:

The stop button is pressed –The set will immediately stop

The auto button is pressed. The set will observe all auto mode start requests and

stopping timers before beginning the Auto mode stopping sequence.

7.6 Automatic operation

Activate auto mode by pressing the pushbutton. The icon is displayed to

indicate Auto Mode operation if no alarms are present.

Auto mode will allow the generator to operate fully automatically, starting and stopping as

required with no user intervention.

7.7 Waiting in auto mode

If a starting request is made, the starting sequence will begin.

Starting requests can be from the following sources:

Activation of an auxiliary input that has been configured to remote start.

Issue 6 7 15/06/2015

7.8 Viewing the instruments

It is possible to scroll to display the different pages of information by repeatedly operating

the scroll button

Once selected the page will remain on the LCD display until the user selects a different

page or after an extended period of inactivity, the module will revert to the status display.

When scrolling manually, the display will automatically return to the Status page if no

buttons are pressed for the duration of the configurable LCD Page Timer.

If an alarm becomes active while viewing the status page, the display shows the Alarms

page to draw the operator’s attention to the alarm condition.

Page order:-

Engine speed

Generator volts

Generator frequency

Engine run time

Battery volts

7.9 Fault icons

AUXILIARY INPUTS

Auxiliary inputs can be user configured and will display the message

as written by the user.

FAIL TO START

The engine has not fired after the pre-set number of start attempts.

FAIL TO STOP

The module has detected a condition that indicates that the engine is

running when it has been instructed to stop.

LOW OIL PRESSURE

The module detects that the engine oil pressure has fallen below the

low oil pressure pre-alarm setting level after the Safety On timer has

expired.

ENGINE HIGH

TEMPERATURE

The module detects that the engine temperature has exceeded the

high engine temperature pre-alarm setting level after the Safety On

timer has expired.

UNDERSPEED

The engine speed has fallen below the underspeed pre alarm

setting.

OVERSPEED

The engine speed has risen above the overspeed pre alarm setting.

CHARGE FAILURE

The auxiliary charge alternator voltage is low as measured from the

W/L terminal.

LOW FUEL LEVEL

The level detected by the fuel level sensor is below the low fuel level

setting. (Optional)

BATTERY UNDER

VOLTAGE /

BATTERY

OVER VOLTAGE

The DC supply has fallen below or risen above the low/high volts

setting level.

GENERATOR UNDER

VOLTAGE

The generator output voltage has fallen below the pre-set pre-alarm

setting after the Safety On timer has expired.

GENERATOR OVER

VOLTAGE

The generator output voltage has risen above the pre-set pre-alarm

setting.

GENERATOR UNDER

FREQUENCY

The generator output frequency has fallen below the pre-set pre-

alarm setting after the Safety On timer has expired.

GENERATOR OVER

FREQUENCY

The generator output frequency has risen above the pre-set pre-

alarm setting.

EMERGENCY STOP

The emergency stop button has been depressed. This is a failsafe

(normally closed to battery positive) input and will immediately stop

the set should the signal be removed. Removal of the battery positive

supply from the emergency stop input will also remove DC supply

Issue 6 8 15/06/2015

from the Fuel and Start outputs of the controller.

INTERNAL MEMORY

ERROR

The configuration file is corrupted. Contact your supplier for

assistance.

7.10 Fault finding 3110

Unit is inoperative

Read/Write

configuration does not

operate

Check the DC supply.

Check reset button not tripped and reset if required.

Check 12V DC supply to module. If supply present but not operational try new

unit.

Check for loose wires on the DC connector plug and socket.

Check continuity on +VE and -VE wires to battery.

Unit shuts down

Check DC supply voltage is not above 16 Volts or below 9 Volts

Check the operating temperature is not above 70°C.

Check the DC fuse.

Unit locks out on

Emergency Stop

Check emergency stop switch is functioning correctly.

Check wiring is not open circuit.

Low oil Pressure fault

operates

after engine has fired

Check engine oil pressure.

Check oil pressure switch and wiring, switch is normally closed and opens

with pressure.

Check Oil level and fill to correct level if necessary

Check for loose wires on the Oil switch & DC loom connector block.

Check the continuity of the earth wire. (Refer to wiring diagram)

Check operation of Oil switch.

High engine

temperature fault

operates after engine

has fired.

Check engine temperature.

Check switch/sensor and wiring.

Check switch polarity is correct Normally closed.

Check for loose wires on the temperature switch & DC loom connector block.

Check the continuity of the earth wire. (Refer to wiring diagram)

Check operation of the temperature switch.

Check that the generator air inlets and outlets are not obstructed.

Shutdown fault

operates

Check relevant switch and wiring of fault indicated on LCD display.

Check configuration of input.

HZ / Frequency

shutdown &

Voltage

shutdown

Check reset button not tripped and reset if required.

Check AC Input at module. 115V or 230V (Dependant on type of generator)

Check engine speed is set to 52.5Hz at no load. Adjust if required (Speed

should be set when engine is cold)

Check AC supply from alternator. (If no output refer to alternator handbook)

Check fuse on AVR. (If fitted)

Check engine has been regularly serviced.

Warning fault

operates

Check relevant switch and wiring of fault indicated on LCD display.

Check configuration of input.

Fail to Start is

activated after pre-set

number of attempts to

start

Check wiring of fuel solenoid.

Check fuel lift pump operational & fuel supply to engine.

Check battery supply.

Check battery supply is present on the Fuel output of the module.

Check battery voltage is above 12.5V.

Check Oil level and fill to correct level if necessary.

Check fuel level.

Check operation of fuel lift pump.

Check fuel is reaching the injectors. When running correctly fuel should be

running freely from the injector return pipe. If no fuel running from return

check the fuel filters & check condition of fuel.

Check no air in system. Keep fuel pump running using prime button for 20-

30 seconds.

Starter Motor not

operating

Check Emergency stop.

Check the fuses.

Check battery voltage is above 12.5V.

Check for loose wires on the solenoid, relays, fuses, module terminals, plug

Issue 6 9 15/06/2015

and socket.

Check +VE supply from battery to starter motor.

Check -VE supply.

Check start terminal on Starter motor & trace back to battery via relay.

Check start terminal on Starter motor & trace back to module via relay, plug &

socket.

Ensure oil pressure switch or sensor is indicating the “low oil pressure” state

to the 3110 controller.

Fuel solenoid not

operating

Does the Fuel solenoid energise when the starter motor turns over.

Check Emergency stop.

Check the re-sets.

Check battery voltage is above 12.5V.

Check for loose wires on the solenoid, relays, fuses, module terminals, plug

and socket.

Check -VE supply.

Check +VE on Fuel solenoid & trace back to battery via relay.

Check +VE on Fuel solenoid & trace back to module via relay, plug & socket.

Continuous starting of

generator when in

AUTO

Check that there is no signal present on the “Remote Start” input.

Check configured polarity is correct.

Generator fails to start

on receipt of Remote

Start signal.

Check Start Delay timer has timed out. (Not configured on standard builds)

Check signal is on “Remote Start” input.

Confirm correct configuration of input is configured to be used as “Remote

Start”.

Check that the oil pressure switch or sensor is indicating low oil pressure to

the controller. The set will not start if oil pressure is not low.

Battery not

charging

Check for loose wires on charge alternator.

Check for loose wires on the DC connector plug and socket.

Check fuse. Fuse holder situated next to regulator in control panel.

Check continuity of all wires from charge regulator. (Refer to wiring diagram)

Check voltage at the battery while generator is running, voltage should be

13.4V - 14.4V.

Check AC voltage on green/white wires from engine voltage should be 38V.

Replace regulator.

Low fuel level

Check fuel level is at 1/3 a tank minimum.

Check level switch operation normally closed with low fuel, opens when fuel

level ok.

Check connections on level switch.

Engine runs but

generator will not take

load

Check MCB is switched on.

Check change over switch if fitted is switched to correct voltage.

Fail to stop alarm

when engine is at rest

Check low oil pressure switch is operating correctly.

Check engine is operating correctly.

Module appears to

‘revert’ to an

earlier configuration

When editing a configuration using the PC software it is vital that the

configuration is first ‘read’ from the controller before editing it. This edited

configuration must then be “written” back to the controller for the changes to

take effect.

When editing a configuration using the Front Panel Editor, be sure to press

the Save button to save the change before moving to another item or

exiting the Front Panel Editor.

Inaccurate generator

measurements on

controller display

The 3110 controller is true RMS measuring so gives more accurate display

when compared with an ‘average’ meter such as an analogue panel meter or

some lower specified digital multimeters. Accuracy of the controller is better

than 1% of full scale. Ie Gen volts full scale is 333V ph-n so accuracy is

±3.33V (1% of 333V).

NOTE:- The above fault finding is provided as a guide check-list only. For

further information http://www.deepseaplc.com/

Issue 6 10 15/06/2015

8 SERVICE AND MAINTAINENCE

IMPORTANT WARNING:

After any service on the generator, ensure that all piping and electrical cables are correctly

routed and secured away from hot parts. Failure to observe this warning may result in

damage to the piping and cables which could result in a fire.

Do not service or work on generator whilst the engine is running. Always disconnect

battery prior to working on engine or alternator.

8.1 Engine service

Service the engine strictly in accordance with the instructions given in the relevant

operator manual / handbook. An approved specialist must carry out any maintenance.

Any spare parts required should be of genuine manufacturer’s origin. Note: failure to

adhere to manufacturer’s recommended service schedules may invalidate the warranty.

Please consult engine operator’s manual for full service intervals.

8.2 Alternator service

Brushless alternators employed on Stephill Generators are maintenance free. Service

must be carried out by competent qualified personnel strictly in accordance with the

instructions given in the handbook. Any spare parts required should be of genuine

manufacturer’s origin.

9 Alternator spares

Part No

Alternator

Description

028-0026

NSM

Diode

037-0019

NSM

Capacitor - 35µf

10 Yanmar consumable spares

Part No

Description

029-0007

Air filter

029-0032

Oil filter

11 Spares (general)

Part No

Description

Qty

028-0036

Alternator NSM

1

029-0022

Engine L100

1

039-0015

Engine wiring loom

1

027-0013

Engine mount

2

027-0014

Alternator mount

2

027-0022

Wheel

2

027-0023

Wheel cap

2

022-1012

Filler cap

1

022-1003

50mm Fuel tank gasket

1

022-1004

Temperature switch

1

020-0128

Temperature switch plate

1

022-1015

Low fuel switch

1

022-1001

Neoprene door seal

3M

022-1017

Toggle latch strike

2

022-1018

Toggle latch

2

022-1002

Coverstay

1

022-1007

Wing head stud

6

022-1008

Retainer washer (wing head stud)

6

022-1009

Snap in housing (wing head stud)

6

022-1010

Wear washer (wing head stud)

6

018-0054

50mm Grommet

2

022-1021

50mm Air hose

0.5M

055-0006

Hours run meter

1

036-0039

MCB Cover

1

Issue 6 11 15/06/2015

Part No

Description

Qty

036-0009

Circuit breaker 20Amp 2pole

1

036-0049

Re-set button 16Amp

3

036-0052

Re-set button 30Amp

2

036-0056

Re-set button Dust cover

6

036-0050

Re-set button 20Amp

1

044-0001

Socket 115V 16Amp

2

044-0002

Socket 230V 16Amp

1

044-0003

Socket 115V 32Amp

1

044-0004

Socket 230V 32Amp

1

043-0021

Voltage selector switch

1

045-0012

Battery warning lamp

1

045-0013

Low fuel warning lamp

1

045-0016

Low oil warning lamp

1

045-0014

High engine temperature warning lamp

1

045-0001

Key switch

1

045-0017

Bulb

4

054-0009

Battery 12N24-3

1

056-0001

Relay-5pin 12V DC

3

022-0596

Fan adaptor

1

022-0614

Fan cowl

1

022-1035

Fan

1

022-1036

Fan locking ring

1

12 SE6000D4

Part No

Description

Qty

022-0536

SE6000D Silencer bracket

1

022-0563

SE6000D4 Silencer

1

022-0501

SE6000D4 Tail pipe

1

014-1004

Flush pull (Roof hand hold)

1

022-2002

SE6000D4 Control panel (wired)

1

022-0552

SE6000D4 Control panel (blank)

1

022-0562

SE6000D4 Fuel tank

1

048-0013

SE6000D4 Fuel filter

1

13 SSD6000

Part No

Description

Qty

022-0565

SSD6000 Manifold pipe

1

022-0566

SSD6000 Silencer

1

022-0569

SSD6000 Down pipe

1

022-0567

SSD6000 Tail pipe

1

022-0579

SSD6000 Fuel tank

1

022-1011

6mm Tee piece

2

022-2010

SSD6000 Control panel (wired)

1

022-0606

SSD6000 Control panel (blank)

1

022-1037

Facet fuel lift pump

1

045-0061

Deep Sea 3110 Module

1

045-0062

Deep Sea 3110 Gasket

1

048-0004

Fuel filter inline

1

022-1033

Flush pull (Roof hand hold)

1

14 SSD6000S

Part No

Description

Qty

022-0565

SSD6000S Manifold pipe

1

022-0566

SSD6000S Silencer

1

022-0580

SSD6000S Secondary Silencer

1

022-0569

SSD6000 Down pipe

1

022-0579

SSD6000 Fuel tank

1

022-1011

6mm Tee piece

2

Issue 6 12 15/06/2015

Part No

Description

Qty

022-2010

SSD6000 Control panel (wired)

1

022-0606

SSD6000 Control panel (blank)

1

022-1037

Facet fuel lift pump

1

045-0061

Deep Sea 3110 Module

1

045-0062

Deep Sea 3110 Gasket

1

048-0004

Fuel filter inline

1

022-1033

Flush pull (Roof hand hold)

1

15 WARRANTY

This generator supplied by STEPHILL GENERATORS LTD carries a warranty of 12

months from date of despatch or 2000 Hours.

During the warranty period, should the plant fail due to faulty design, materials or

workmanship by STEPHILL GENERATORS LTD or its sub-contractors, we undertake to

rectify the fault.

STEPHILL GENERATORS LTD will accept no responsibility whatsoever for equipment

that has failed due to;

- Operation with incorrect fuel, lubricating oil.

- Improper repair or use of parts not supplied by STEPHILL GENERATORS LTD.

- Lack of, or incorrect maintenance.

- Fair wear and tear, misuse, negligence, accidental damage, improper

storage, incorrect starting / warm-up / run-in or shutdown.

No warranty claim will be considered by STEPHILL GENERATORS LTD unless any

defective parts are available for inspection by us, or our nominees, to determine the

reason or cause of failure, and STEPHILL GENERATORS LTD is given the option of

repair or replacement.

STEPHILL GENERATORS LTD are not responsible for incidental or consequential

damages, downtime, or other costs due to warrantable failure, and unauthorised

alterations made to any product supplied by STEPHILL GENERATORS LTD.

Wiring updated to show plug and socket & dynamo.

Revision

STEPHI GENERATORS

Drawn

R GO DING

Drawing Number

SW11016

Phone 01933 677911

Fax 01933 677916

Description

100 WIRING E ECTRIC START

OP/HET/CHARGE FAI 15A F YWHEE

CHARGER

D

Issue

21/11/11

Dateast Number Used

20

DYNAMO

OI PRESSURE SWITCH

R3

FUE

SO ENOID

17 16

2.5mm

2.5mm

2.5mm

WHITE

OI PRESSURE

BATTERY CHARGE

STARTER MOTOR

R2

HIGH TEMPERATURE SWITCH (RS Part No 228-2260)

HIGH TEMPERATURE

R1

HIGH TEMPERATURE AMP

OI PRESSURE AMP

R2

16mm16mm

14

2

3

4

1

22

2 2

2

3 3

5 5

66

7

8

8

8

8

8

9

10

12

4

8

REGU ATOR

18

WHITE

14 20A

19

GREEN

YE OW

YE OW

WHITE

12

PUMP

3 8

FUE IFT

(OPTIONA )

1

2

5

4

3

14

20A RE-SET

1

FUE EVE

22 R1 15

FUE EVE SWITCH

15 8

R3

3

9

FUE EVE AMP

17 8

7

Note

All cable to be 1.5mm unless stated.

All cable except battery cable to be white.

3

16

10

2.5mm

Wire numbers added to regulator.

20/01/06

B

ucas key switch

POSITION

OFF

RUN

PRE HEAT

CRANK

21 3 4 5

Wiring changed numbers 11 & 14.24/09/08C

11

12 PIN P UG - SOCKET

11

2.5mm2.5mm

18 18

1919

GREEN / WHITE

GREEN / WHITE

18

19

4 4

15 15

5 5

6 6

3 3

11 Pin plug

viewed from rear

1 3

65 8

1918 15

4

3

11 Pin socket

viewed from rear

4 3

68 5

1915 18

1

3

11

WHITE / GREEN

WHITE / GREEN

GREEN

REAR

P UG

3

3 3

New drawing.

Revision

STEPHILL GENERATORS

Drawn

R Golding

Drawing Number

SW 12072

Phone 01933 677911

Fax 01933 677916

Description

SE6000D NSM Dual voltage wiring

diagram 115V CTE / 230V Neutral bonded

& Single pole Re-Sets.

A

Issue

28/01/13

Date

Last Number Used

N/A

2.5mm Blue

2.5mm Brown

L

1.5mm Brown

1.5mm Black

115V 16A SOCKET

HRM

E

20A MCB

115V 16A SOCKET

LE

L

2.5mm Blue

NN

115V 32A SOCKET

E

N2.5mm Brown

2.5mm Blue

C/0 SWITCH

115 0 230

2B 1

6B

4B

5

3

8B 7

2A

6A

4A

8A

230V 16A SOCKET

E

NL

4.0mm Brown

Viewed from cable inlet

2.5mm Black

2.5mm Blue

2.5mm Brown

2.5mm Red

4mm Blue

E

NL

230V 32A SOCKET

BLUE

BROWN

RED

BLACK

Viewed from cable inlet

4.0mm Blue

2.5mm green/yellow

2.5mm Black

30A Re-Set

16A Re-Set

30A Re-Set 4mm Brown

2.5 Brown

16A Re-Set 2.5 Brown

16A Re-Set 2.5 Brown

4mm Brown

2.5mm Brown

2.5mm Blue

2.5mm Brown

NSM

Note

Links 4B - 6B & 4A - 8A are internal

GREEN

THIS IS NOT AN EARTH WIRE - 110V CENTRE TAP

Socket connector

Plug connector

2.5mm Blue

2.5mm Brown

2.5mm Red

2.5mm Black

2.5mm Red

2.5mm Black

2.5mm Brown

2.5mm Blue

21 3 4 5

6 7 8 10 11 1229

Item

Part Number

Description

Qty

1

022-0687

SE6000D4 NSM Lifting beam

1

2

022-0585

SE6000D4 Engine door

2

3

022-0538

SE6000D4 Engine mounting bracket

1

4

022-0681

SE6000D4 NSM Trolley base

1

5

022-0537

SE6000D4 L100 Air inlet tube plate

1

6

022-0682

SE6000D4 NSM door

1

7

022-0614

SE6000D4 Fan cowl

1

8

022-0572

SE6000D4 Battery clamp bottom

1

9

022-0571

SE6000D4 Battery clamp top

1

10

022-0546

SE6000D4 Battery door 1

11

027-0022

Wheel

2

12

027-0023

Wheel cap 2

R Golding

A

04/02/13

New drawing

Date

Revision

Issue

THIRD

ANGLE

PROJECTION

Colour

Material

Description

Fax :

Phone :

Drawing Number

Drawn

SE6000D4 NSM Exploded view

22-696

Mild steel

N/A

STEPHILL GENERATORS

+44 (0)1933 677911

+44 (0)1933 677916

B

Descriptions changed.

17/06/15

3 672 541

New part numbers added.26/05/06

C Descriptions changed.

Golding

A 08/11/04 New drawing

B

STEPHILL GENE ATO S

Date evision

Issue

P OJECTION

Description

Fax 01933 677916

Phone 01933 677911

Drawing Number

Drawn

SE6000D4 oof exploded view22-590 THI D

ANGLE

17/06/15

Item Issue Description

1 022-0590 SE6000D4 Dual voltage control panel

2 022-0583 SE6000D4 oof

3 022-0544 SE6000D4 Fuel tank support bracket large

4 022-0562 SE6000D4 Fuel tank

5 022-0544 SE6000D4 Fuel tank mounting bracket small

6 022-1012 Kelch cap

7 022-0119 SE6000D4 Fuel tank sealing gasket

Part No Description Qty

1 022-0627 SSD6000 Base 1

1 022-0675 SSD6000S Base 1

2 022-0607 SSD6000 Battery tray 1

2 022-0673 SSD6000S Battery tray 1

3 022-0576 SSD6000 Engine air inlet duct 1

4 022-0575 SSD6000 Battery door 1

5 022-0598 SSD6000 A le 1

6 027-0022 Wheel 2

7 027-0023 Wheel cap 2

8 022-0599 SSD6000 Trolley foot 2

9 022-0643 SSD6000 Handle right 1

9 022-0655 SSD6000 Light tower handle right 1

10 022-0642 SSD6000 Handle left 1

10 022-0654 SSD6000 Light tower handle left 1

11 022-0614 SSD6000 Fan cowl 1

12 022-0538 SSD6000 Engine mounting bracket 1

13 022-0697 SSD6000 NSM Alternator air inlet duct 1

14 022-0609 SSD6000 Lift beam 1

14 022-0677 SSD6000S Lift beam 1

15 022-1002 Stay 1

16 022-0666

SSD6000 Mark 5 Trolley foot brace

1

16/06/15

R Golding

A 04/02/13 New drawing

Date RevisionIssue

Descriptions updated.

+44 (0)1933 677916 PROJECTION

Colour

Material

Description

Fa :

Phone :

Drawing Number

Drawn

ANGLE

view

22-697

Mild steel

N/A

STEPHILL GENERATORS

+44 (0)1933 677911

THIRD

SSD6000 & SSD6000S Base e ploded

B

3

16 41 2

5

15 12

8

910

13 14

6711

This manual suits for next models

2

Table of contents

Other Stephill Inverter manuals

Popular Inverter manuals by other brands

Dynamic Power

Dynamic Power TriFuel owner's manual

Generac Power Systems

Generac Power Systems Centurion 005223-0 owner's manual

SolaX Power

SolaX Power X3 Hybrid Series installation guide

Onan

Onan 16004 Series installation guide

Wagan

Wagan Smart AC Inverter 100 USB user manual

Underwriters Laboratories

Underwriters Laboratories S600 Series user manual