Stephill SSD10000S User manual

Issue 4

SSD10000S –SSD10000S/3PH

+44 (0) 1933 677911 www.stephill-generators.co.uk

Handbook

&

Operation Manual

10.0kVA 3000rpm Generators

SSD10000S - SSD10000S/3PH

3 Introduction

12 Operating Instructions

12 Pre-starts Checks

3 Warranty Statement 12 Check Battery Isolator Key & Location

13 Check Oil Level - How to

3 Amendments 13 Adding Engine Oil

14 Check Coolant Level

4 Identification 14 Check Fuel Level

14 Control Panel Checks

5 Specification

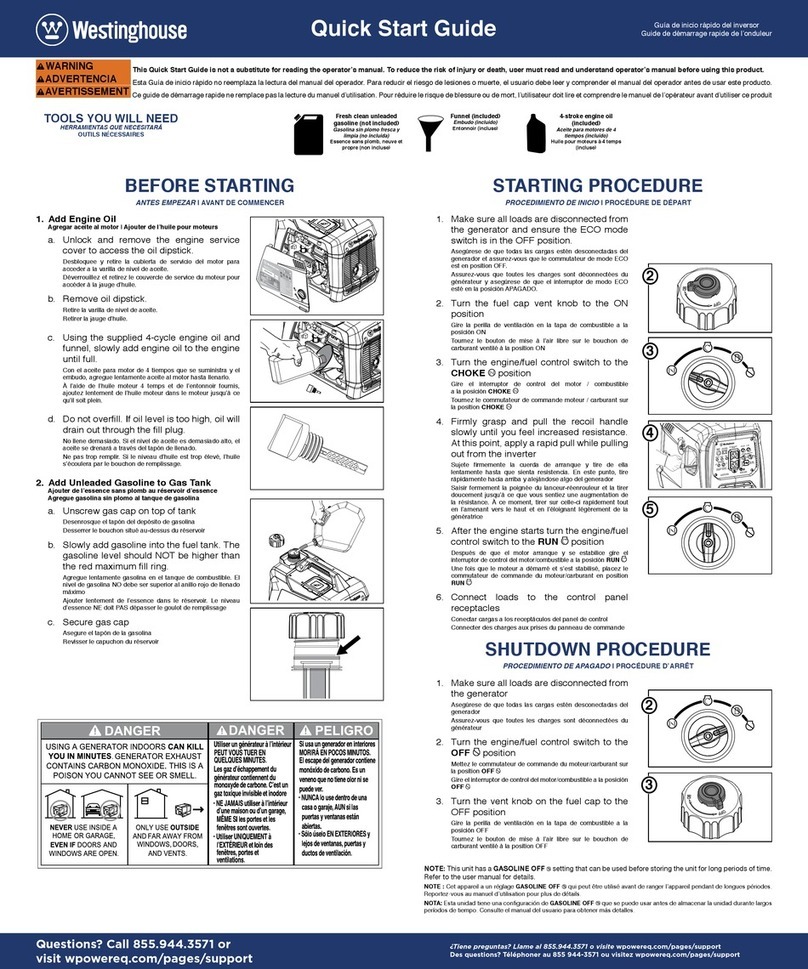

5 AC Output Protection - SSD10000S 15 Starting the Generator - Quick Start

5 AC Output Protection - SSD10000S/3Ph

5 AC Output Earthing Method 15 Manual Start

5 Running Hours 15 Applying Load

6 Engine

6 AC Alternator

6 Dimensions & Weights 15 Emergency Stop

15 Remote Start/Stop - 2-wire

7 Control Panel Identification

7 SSD10000S

7 SSD10000S/3Ph

16 DSE 3110 Control Module - Overview

8 Generator Safety 16 DSE 3110 Operation

8 Warning Signage 17 Starting Sequence

9 Personal Safety 17 Timer Icon

9 Auxiliary Power 17 Engine Running

9 Operating Environment 17 Viewing the Instruments

9 Temperature Range 17 AUTO MODE - Start/Stop Operation

10 Reference Relative Humidity 18 Waiting in AUTO MODE

10 Reference Barometric Pressure

10 Flammable Environment

18 Fault Finding

10 Saline Environment 18 Monitoring Systems

18 Before Fault Finding

10 Safety Considerations 18 Fault Finding - DSE 3110

10 General 22 Fault Finding - General

10 Fuel 23 Battery Charge Fault Finding Guide

10 Lubricating Oil

10 Safe Lifting

11 Earth Connections

11 Fumes

11 Noise

11 Battery Acid

11 Fire

11 Hot Parts

16 2-wire remote and ATS Auto

Start/Stop Connection Location

Contents

15 Stopping the Generator - Manual

Stop

Guide

SSD10000S - SSD10000S/3PH

25 Service and Maintenance

25 Pre-service

25 Engine Service

25 Alternator Service

26 Trolley Kit

26 Wheels

26 Maintenace

26 Road Tow Trailer

26 Trailer Information

27 Safety Precautions

27 Wheels

27 Number Plate

27 Hitch Type

27 Pre-towing/Hitch Up

27 Hitching Method

28 Spares

28 Kubota Consumable Service Spares

28 Control Panel - AC Components - SSD10000S

29 Control Panel - AC Components - SSD10000S/3Ph

29 Control Panel - DC Components

29 General Spares

29 Engine Accessories Spares

30 Exhaust System Spares

30 Trolley Kit Spares

31 Exploded View

Canopy Parts

Wiring Diagrams

SSD10000S - SSD10000S/3PH 3

© Stephill Generators Ltd.

All rights reserved.

Operation with incorrect fuel, lubricating oil or coolant.

Improper repair or use of parts not supplied or approved by Stephill Generators Ltd.

Lack of, or incorrect maintenance.

Issue Date By

Introduction

Warranty Statement

Amendments

This document has been produced for the owner/user of a Stephill generator. Inside this manual you will find

important safety, operating, maintenance and fault finding information.

The information contained within this manual is based upon the current data available before print. Due to

constant improvements on our products some information contained within this manual may change without

warning. Therefore Stephill Generators Ltd reserve the right to alter specifications as and when situations

demand without warning or obligation.

No part of this material may be reproduced in any form by any means without the written permission of

Stephill Generators Ltd.

All equipment supplied by Stephill Generators Ltd carries a warranty of 12 months from date of despatch.

During the warranty period, should the plant fail due to faulty design, materials or workmanship by Stephill

Generators Ltd or it’s sub-contractors, we undertake to rectify the fault. Stephill Generators Ltd will accept no

responsibility whatsoever for equipment that has failed due to;

Fair wear and tear, misuse, negligence, accidental damage, improper storage and incorrect starting / warm-

up / run-in or shutdown.

No warranty claim will be considered by Stephill Generators Ltd unless any defective parts are available for

inspection by us, or our nominees, to determine the reason or cause of failure, and Stephill Generators Ltd is

given the option of repair or replacement.

Stephill Generators Ltd are not responsible for incidental or consequential damages, downtime, or other

costs due to warrantable failure, and unauthorised alterations made to any product supplied by Stephill

Generators Ltd.

Amendment

SSD10000S - SSD10000S/3PH 4

Fig.1

1Generator model type

2Rated power, kVA & kW

3Unique serial number

5AC voltage output(s)

6Relevant maximum Amp ratings

7Rated output frequency

8Number of phases

9Power factor

10 Total fuel tank capacity

11 Generator performance class

12 MGW - Mass Gross Weight(s)

Each Stephill generator will have a Serial/Data plate fitted to the set. In most cases this can be found on the

canopy roof of a SSD10000S. Below is an example of the Serial/Data plate.

Identification

Item No.

Description

4

CE mark indicates the generator meets the directives listed on the Declaration of

Conformity

7

9

1

5

2

3

4

6

8

10

11

12

SSD10000S - SSD10000S/3PH 5

Main alternator 115/230V AC outputs protected by double pole MCB.

115V - Floating Earth - Thermal reset button overload protection for each socket.

Main outputs 400V/230V protected by an RCBO.

Note

MCB = Miniature Circuit Breaker (overcurrent)

RCD = Residual Current Device

RCBO = Residual Current Device with Overcurrent Protection

All are suitably rated for the generator model type.

400V 3Ph - Neutral (star point) bonded to earth.

230V 1Ph - Neutral bonded to earth.

115V 1Ph - Floating earth.

50% Load

75% Load

100% Load

10.0

10.0

AC Output & Protection - SSD10000S/3PH

(COP) Continuous Power: Applicable for supplying power to electrical load for unlimited hours in accordance

with ISO 8528-1 under the agreed operating conditions with the maintenance intervals and procedures being

carried out as prescribed by the manufacturers.

Specification

kVA (COP)

Fuel Tank Capacity

Model Type

SSD10000S

SSD10000S/3PH

kW (COP)

Frequency

AC Output Earthing Method

Running Hours

13 hours @ 2.8 L/h

10 hours @ 3.7 L/h

25% Load

Voltage

Phase

LWA

dBA @ 7M

67

1 Ph

3 Ph

92

67

92

115 / 230V AC

400V AC

8.0

50.0 Hz

8.0

50.0 Hz

37 Litres

41 hours @ 0.9 L/h

20 hours @ 1.8 L/h

AC Output & Protection - SSD10000S

230V - Neutral bonded to Earth - RCD protection & thermal reset button overload protection for

each socket.

SSD10000S - SSD10000S/3PH 6

Type

Emissions Certification

Cylinders

Cooling

Displacement

Rpm

Type

Skid Mounted

Weight - Dry

Weight - Wet

Trolley Mounted

Weight - Dry

Weight - Wet

Road Trailer Mounted

Weight - Dry

Weight - Wet

Length 2360mm Width 1300mm Height 1220mm

399 KG

330 KG

301 KG

388 KG

386 KG

AC Alternator

Length 1750mm Width 900mm Height 1080mm

357 KG

355 KG

Water Cooled

Engine

Net Engine Power

Kubota D722-E4B

SSD10000S/3PH

3

EU Stage V

Net Intermittent

719cc

3000

SSD10000S

SSD10000S/3PH

299 KG

Dimensions & Weights

430 KG

428 KG

397 KG

Continuous 10.3kWm

Length 1285mm Width 655mm Height 900mm

NSM Z100 LB

SSD10000S

NSM C112 SB

332 KG

SSD10000S - SSD10000S/3PH 7

Fig.2

1AC Voltage Switch

2Emergency Stop

3Fuel Gauge

4Main MCB & 230V RCD

5115V Socket Outlets (Yellow)

6Socket Outlet Reset Button(s)

7230v Socket Outlets (Blue)

8Earth Stud

9Fuel Pump Prime Button

10 DSE 3110 Reset Buttons

11 DSE 3110 Control Module

1400V Socket Outlet (Red)

2230V Socket Outlet (Blue)

3Emergency Stop

4Fuel Pump Prime Button

5Main RCBO

6Earth Stud

7Fuel Gauge

8DSE 3110 Reset Buttons

9DSE 3110 Control Module

Fig.3

Control Panel Identification

SSD10000S/3PH

Item No.

Description

SSD10000S

Item No.

Description

5

3

4

2

6

11

8

7

1

9

10

5

1

2

6

7

9

4

8

3

SSD10000S - SSD10000S/3PH 8

Warning Signage

b) Located on both main canopy doors.

a) Located behind the control panel cover near the DSE

3110 control module.

c) Located on the engine end of the canopy

near the exhaust outlet.

d) Located on top of the canopy near the

coolant filler flap for the radiator access.

e) Located on the canopy roof near the

control panel.

Generator Safety

Before using this equipment and to avoid personal injury, all warnings shown on the machine should be

observed. The warning signage should be checked for legibility and any that have become damaged should be

replaced.

Carefully read and understand the instructions provided. If there is anything you do not understand DO NOT

attempt to use this generator. Contact your supplier for advice.

WARNING

BEFORE STARTING

●READ HANDBOOK AND SAFETY ADVICE

●CHECK OIL LEVEL

●DO NOT ADJUST ENGINE SPEED

WITHOUT SUITABLE TEST EQUIPMENT

a)

b)

c)

d)

e)

f)

SSD10000S - SSD10000S/3PH 9

f) Located on the control panel door/cover.

• Do not climb on the generator - dents may cause overheating of the acoustic lining.

• Keep well clear of any moving parts on the generator at all times.

• Keep children and pets away from the generator and operating area.

• Test safety features often, emergency stop button and RCD (residual current device).

• Keep the generator canopy doors shut while running and locked if possible.

Do not remove covers and attempt to work on the generator while the engine is running.

Check the rating and electrical safety of the load before connecting the generator.

Equipment should never be connected that in total exceeds the specified rating of the generator.

• Do not cover the generator as this can obstruct air inlet and outlets on the canopy which can cause the

generator to overheat and cause permanent damage..

The electricity produced by an engine driven generator is very similar to mains AC electricity and should be

treated accordingly.

g) Located on the canopy roof near the

control panel.

Installation of the generator as a standby or secondary power source should only be undertaken by a fully

qualified electrician using the appropriate means of isolation from the mains supply. Installation must comply

with all applicable laws, electrical codes and wiring regulations.

The generator should always be operated on level ground and be able to bear its weight. Ensure the

generator canopy is not obstructed to allow cool air to enter the set and hot expelled air to escape.

Temperature Range

Auxiliary Power

Operating Environment

Personal Safety

A temperature range between -15⁰C and +45⁰C are the normal limits of operation. Operating outside the

range will require additional modifications.

f)

g)

SSD10000S - SSD10000S/3PH 10

Stephill generators must not be used in a flammable environment.

Operation of the machine in a saline environment will require additional corrosion protection.

All Stephill generators comply with current EEC directives including:

2016/1628/EU Non-Road Mobile Machinery (NRMM).

2014/30/EU The Electromagnetic Compatibility Directive.

2006/42/EC The Machinery Directive.

2000/14/EC Noise emission in the environment by equipment for use outdoors.

2011/65/EU The Restriction of Hazardous Substances Directive.

EC 1907/2006 REACH.

Reference Relative Humidity

General

Safety Considerations

Fuel

Reference Barometric Pressure

Saline Environment

The standard reference condition for relative humidity is 30%. Above this value the rated power must be

reduced.

New oil presents no hazard following short term exposure. Lubricants in particular used engine oil,

are potentially carcinogenic. Direct contact should always be avoided by wearing suitable rubber

gloves when handling them. Used oil should not be allowed to contact the skin. If this does occur,

wash off quickly with a proprietary hand cleanser.

Lubricating Oil

Safe Lifting

The standard reference condition for total barometric pressure is 1 bar. This corresponds to an altitude of

approximately 100m. Above 100m the rated power must be reduced.

Where mechanical assistance is used in lifting machines, ensure the lifting eye is used, and that all

components used to lift the machine are within their Safe Working Load (SWL).

The integral lifting beam and associated lifting eye on the generator should be regularly checked for signs of

damage or gross corrosion.

All nuts and bolts associated with the lifting beam and eye should be regularly checked for tightness and

corrosion.

Fuels and lubricants are a potential source of fire. Be careful not to spill fuel, clean up any spillages.

Inhalation or swallowing of diesel should be avoided. If in doubt seek medical advice. All other forms of

contact are an irritant and therefore should also be avoided. If skin contact is made wash with soap and

water.

Flammable Environment

SSD10000S - SSD10000S/3PH 11

This is corrosive and irritant by all forms of exposure. If skin contact is made wash with clean water.

Battery Acid

Earth Connection

DO NOT ATTEMPT TO LIFT THE GENERATOR WITHOUT PRIOR CHECKS TO THE LIFTING

SYSTEM AS INDICATED ABOVE

Lifting equipment should never be attached directly to the engine and/or alternator to fully lift the generator

except only if lifting engine and/or alternator.

Make sure that the Generator is at least 2 metres away from any building during operation. Operate in a well

ventilated unconfined area, so that fumes can be properly dispersed. Silencer outlet should be facing an open

area to prevent fumes being recirculated. There is the danger of asphyxiation due to exhaust gases.

Inhalation of poisonous exhaust fumes can lead to serious injury or death. The generator must not be used in

a poorly ventilated or enclosed area.

Ear protection may be required depending on the combined noise level of the Generator, auxiliary load and

the operator’s distance from it and the length of exposure. (Noise at Work Regulations 1989)

Ensure that suitable fire extinguishers (AFFF or CO2) are kept within close proximity of the generator. Do not

cover, enclose, or obstruct the airflow to the generator during or shortly after use, due to fire hazard or

damage to the generator from overheating. Allow the generator to cool after use before storing away. Keep

all inflammable objects clear of the generator.

There is the danger of burns as parts of the generator will become very hot during use. No part of the engine,

alternator or exhaust must be touched during or shortly after operation. Do not operate the generator unless

all guards are in place. There is a risk of burns or serious mechanical injury.

All Stephill products are fitted with an earth stud on the control panel this must be connected to an earthing

system or spike. Any earth spike required is dependant on the local conditions of use. The size is determined

by reference to current IEE regulations or to a competent electrician.

Fire

Hot Parts

Fumes

Noise

SSD10000S - SSD10000S/3PH 12

Before any attempt to start the generator please follow these important guidelines.

Isolator key location

(This is currently shown in the "OFF" position) Fig.4

To switch OFF the 12V battery supply, push down and turn the red key counter-clockwise to release .

Check Battery Isolator Key - Location

STEPHILL GENERATORS LTD STRESS THAT THE ULTIMATE RESPONSIBILTY FOR THE

SAFE USE OF THE GENERATOR RESTS WITH THE USER.

Open the main canopy door on the right when facing the control panel. The RED isolator key can be found

next to the in-line fuel filter - Fig.4

To switch ON the 12V battery supply, insert the red key and turn to lock into position.

Operating Instructions

Pre-start Checks

The 12V battery supply has been fitted with a red "Battery Isolator Key". This is to isolate the 12V battery

from the engines 12V DC system when not in use, transportation and when working on repairs/servicing

safely.

Engine

In-line Fuel Filter

Battery Isolator Key

Oil Drain Hose

SSD10000S - SSD10000S/3PH 13

It is recommended to check the oil level BEFORE EVERY START OPERATION - Ref. Fig.5

Ensure the generator (engine) is on level ground to ensure the correct oil quantity is measured.

● Check the engine oil level before starting or more than 5 minutes after stopping the engine.

● Remove the oil level gauge, wipe it clean and reinstall it.

● Take the oil level gauge out again, and check the oil level.

(1) Oil filler plug

(2) Oil level gauge (A) Ensure the engine oil level within this range

Fig.5

Adding Engine Oil

Refer to engine owners handbook supplied with each generator for oil specification, viscosity and typical

capacity. Alternatively navigate to the Service section at

Check Oil Level - How To

Fig.5 shows the oil fill and oil dipstick locations for the Kubota D722 engine used on the Stephill SSD10000S

generators.

Add oil If the level is low. Do fill past the high mark on the dipstick (2). WARNING - Never overfill the engine

with oil. Engine damage can occur.

www.stephill-generators.co.uk

SSD10000S - SSD10000S/3PH 14

Refer to engine owners handbook supplied with each generator for further information.

(A) "FULL"

(B) "LOW"

While holding down the fuel pump prime button you should be able to see the gauge needle rise and rest to

indicate a level, also you should hear the fuel pump operating.

The radiator is provided with a recovery tank (expansion vessel) , check the water/coolant is between the

"FULL" and "LOW" marks - Ref. Fig.6.

While the generator is at standstill you will notice the fuel gauge on the control panel will be showing empty

"no fuel".

Fig.6

Check Coolant Level

(1) Recovery tank

(expansion vessel)

Ensure the main MCB or RCBO is in the "OFF" position (switch down) - Ref Fig.2 & 3. WARNING - Never try to

start the generator with load connected.

It is recommended to check the water/coolant level of the radiator BEFORE EVERY START OPERATION - Ref.

Fig.6.

Check Fuel Level

Control Panel Checks

To check the fuel level in the generator fuel tank you can energise the fuel gauge by pressing and holding the

fuel pump prime button on the control panel - see Fig.2 & 3.

SSD10000S - SSD10000S/3PH 15

Once all the pre-checks have been made you can then start the generator. Follow the procedure below:

Press the button until the is displayed on the LCD screen.

A red LED flashes above the button.

Now the generator is ready to receive load. Select the desired AC voltage with the AC voltage switch.

Plug the load into the relevant AC voltage socket on the control panel.

Switch the main MCB to "ON" (switch up) position on the control panel.

You can then safely stop the generator.

Press the button and the generator will immediately stop.

Starting the Generator - Quick Start Guide

The DSE 3110 control module has a 2-wire Remote Start/Stop function. This is a volt free connection, closing

two contacts will start and allow the generator to run. Open the contacts and the generator will stop and the

DSE 3110 module will wait for the next start request.

Stopping the Generator - Manual Stop

Remote Start/Stop - 2-wire

The Emergency Stop button is located on the control panel. It must ONLY be used for emergencies

only.

Emergency Stop

Warning Using the Emergency Stop button regularly for a standard stop request can cause the 12V battery to

drain. This may effect the starting of the generator.

Manual Start

This is a quick start guide , refer to the DSE 3110 Control Module - Overview within this handbook for an in-

depth view/use of the DSE 3110 control module.

The icon will be displayed on the DSE 3110 module when an Emergency Stop request is

made.

Press the button once more, the icon rotating will be displayed on

the LCD screen. This will continue to rotate for approximately 10 seconds.

The generator will then crank and start.

Before stopping the generator it is recommended to switch off the load from the generator by switching the

main MCB on the control panel to the "OFF" position (switch down).

Applying Load

SSD10000S - SSD10000S/3PH 16

Fig.8

Fig.9 Fig.10

Once the correct connections have been made to the remote start terminals the DSE 3110 control module

will require activating to an AUTO MODE - See DSE 3110 Control Module - Overview . It will then be ready to

accept a remote start request.

2-Wire Remote and ATS Auto Start/Stop Connection Location

Behind the control panel there is a small push-on connector block for the remote and auto start/stop

connections. Refer to the DC wiring diagram at the back of this handbook or corresponding ATS handbook for

the relative terminal positions. - Fig.7 & 8.

DSE 3110 Operation

The DSE 3110 control module is used to start/stop and monitor key elements of the engine and main AC

alternator. Fig.9 show the layout and control buttons.

DSE 3110 Control Module - Overview

Engine Speed

Generator Volts (AC)

Generator Frequency

Engine Run Time

Battery Volts (DC)

Page Order

SSD10000S - SSD10000S/3PH 17

Once a start request is made the DSE 3110 will energise the pre-heat relay over a period of 10 seconds.

Once the engine is running and all starting timers have expired, the animated icon is displayed.

Fig.10 shows the page order when pressing the navigation button.

A red LED light will be illuminated above the button.

The generator is now ready to receive start/stop requests from the remote connections.

When scrolling manually, the display will automatically return to the Status page if no buttons are pressed for

the duration of the LCD Page Timer.

If the engine fails to fire during this cranking attempt then the starter motor is disengaged for the crank rest

duration after which the next start attempt is made.

Starting Sequence

Then the DSE 3110 will then attempt to crank the engine by operating the starter motor relay and also the

fuel pump relay.

Should this sequence continue beyond 3 attempts, the start sequence will be terminated and the Failed to

Start icon is displayed on the LCD screen.

(See Fault Finding - DSE 3110)

Timer Icon

Timer Icon

When the engine fires, the starter motor is disengaged. (The DSE 3110 de-energises the starter motor relay

once it detects an output frequency (Hz) from the main alternator).

It is possible to scroll to display the different pages of information by repeatedly operating the navigation

button.

Engine Running

AUTO MODE - Start/Stop Operation

Engine Running

Viewing the Instruments

Activate auto mode by pressing the button. The icon will be displayed on the LCD screen to

indicate the DSE 3110 module is in AUTO MODE if no alarms are present.

When the module is controlling the engine (starting and stopping) an animated (rotating) timer icon will be

displayed in the icon area to indicate that a timer is active, for example cranking time, crank rest, stopping

Once selected the page will remain on the LCD display until the user selects a different page or after an

extended period of inactivity, the module will revert to the status display.

Failed to Start

SSD10000S - SSD10000S/3PH 18

cont.

● Check No.1 wires on the control panel and engine DC

loom(s) have a sound connection to battery negative.

Negative / Ground Connections

● Check the operation of the switches on the back of the

emergency stop button.

● Check the operation and wiring of the starter motor relay -

Replace if necessary.

Emergency Stop Button

Possible Cause

Be aware of the service/maintenance schedule of the engine, ensuring the fuel filters are replaced regularly

along with the oil topped up and oil filter etc. - See Service and Maintenance

Before carrying out any checks ensure all Load is unplugged from the generator and be aware of any

potential exposed Live terminals while the generator is running! All checks and tests should only be carried

out by a competent engineer - Ref. DC wiring diagram

Starter Motor Relay

Check

Most common faults/issues can be Identified by the fault icon displayed on the DSE 3110 LCD screen. The

table below shows a fault icon and/or the relevant possible causes and checks.

It is advised to have a mains 12V battery charger fitted to the generator battery in most cases of occasional

use fixed positioned generators or ensure the generator is started and allowed to continuously run for a

minimum of 1 hour once a week.

Fail to Start

Is activated after

three attempts to

start

Battery

● Check the battery voltage, should be around 12.5V DC -

Charge or Replace.

● Check the condition of the battery leads.

STEPHILL GENERATORS LTD STRESS THAT THE ULTIMATE RESPONSIBILTY FOR THE

SAFE USE OF THE GENERATOR RESTS WITH THE USER.

All standard Stephill SSD10000S generators use a DSE 3110 control module to operate/monitor the engine

and generator.

While the DSE 3110 module is in AUTO MODE the LCD screen will be permanently illuminated and it will not

go into any power saving or sleep modes.

If the module is left in AUTO MODE for extended long periods of time without running the generator it could

flatten the generator battery.

Engine Not Starting/Running - Starter motor not engaging

Waiting in AUTO MODE

Fault Finding - DSE 3110

Fault Icon

Before Fault Finding

Fault Finding

Monitoring Systems

We strongly advise before attempting any fault finding is to check the health of the generator battery. It

should measure around 12.4 to 12.6 Volts DC while the generator is at standstill.

SSD10000S - SSD10000S/3PH 19

● Check and/or replace the main fuel filter.

● Check the connections on the capacitor.

● Test and/or replace the AC alternator capacitor.

The no-load frequency/rpm should measure approximately 52.5Hz/3150rpm.

● Check in-line fuel filter and replace if necessary.

● Check water separator filter if necessary.

● Check the condition of the air filter - Replace if necessary.

cont.

● Check the green plug with a brown & blue wire is not

loose.

● Start and run the generator and measure the AC voltage

across the brown & blue wires - this should measure

approximately 115V, 230V or 400V AC.

DSE 3110 Control Module

Low AC Voltage

● Check the switches function and wiring on the back of the

emergency stop.

Emergency Stop

Fuel Filter(s)

Air Filter

● Check main alternator output - AC alternator tests would

be advisable.

● Check in-line fuel filter and replace if necessary.

● Check the 40A fuse on the engine loom - Ref. wiring

diagram.

Fuel Filter(s)

● Check the plugs on the back of DSE 3110.

Starter Motor

Capacitor

DSE 3110 Control Module

● Check for battery + output at No.4 (starter motor relay

feed) after the pre-heat time - Ref. wiring diagram.

● Check the operation and wiring of the starter motor -

Replace if necessary.

Engine Not Starting/Running - Starter motor engaging but engine not starting

● Check for continuity and wiring on the AC 2A reset button

(brown wire from DSE 3110) - Replace if necessary.

2A Reset Button

Low AC Voltage and Low Hz/Frequency could indicate the engine is running too slow.

Warning - It is not recommended to adjust the engine speed unless absolutely

necessary.

Main AC Alternator

● Check the fuel pump is receiving 12V DC and is operating -

Replace if necessary.

● Check the condition of the air filter - Replace if necessary.

● If possible run the generator from a separate fuel source

from the fuel tank.

Engine Starting/Running Then Stopping - 3 Attempts

Fuse

Fault Icon

Possible Cause

Low Hz/Frequency

Shutdown

Check

Contaminated Fuel

Fuel Lift Pump (12V DC)

Fuel Lift Pump (12V DC)

● Check that all the green plugs are fitted correctly and the

wiring.

DSE 3110 Control Module

● If possible run the generator from a separate fuel source

from the fuel tank.

● Check the fuel pump is receiving 12V DC and is operating -

Replace if necessary.

Fail to Start

Is activated after

three attempts to

start

Shutdown

Consult an engine specialist if the above fails to rectify the issue.

Consult an engine specialist if the above fails to rectify the issue.

Emergency Stop Button

Air Filter

Contaminated Fuel

DSE 3110 not showing Volts or Hz when running?

● Check if the emergency stop button has been activated.

This manual suits for next models

1

Table of contents

Other Stephill Portable Generator manuals

Popular Portable Generator manuals by other brands

Advance Power

Advance Power AP3000 Operating and maintenance instructions

RVMP

RVMP Flex Power 5000i owner's manual

North Star

North Star 15000 PPG owner's manual

Matsusada Precision

Matsusada Precision PKTS Series instruction manual

Yamaha

Yamaha EF2400iS - Inverter Generator owner's manual

CAC / BDP

CAC / BDP FOR BYPASS AND FAN POWERED HUMIDIFIERS Diagnostic repair manual