SSDK12M - SSDK16M - SSDK20M 12

This is corrosive and irritant by all forms of exposure. If skin contact is made wash with clean water.

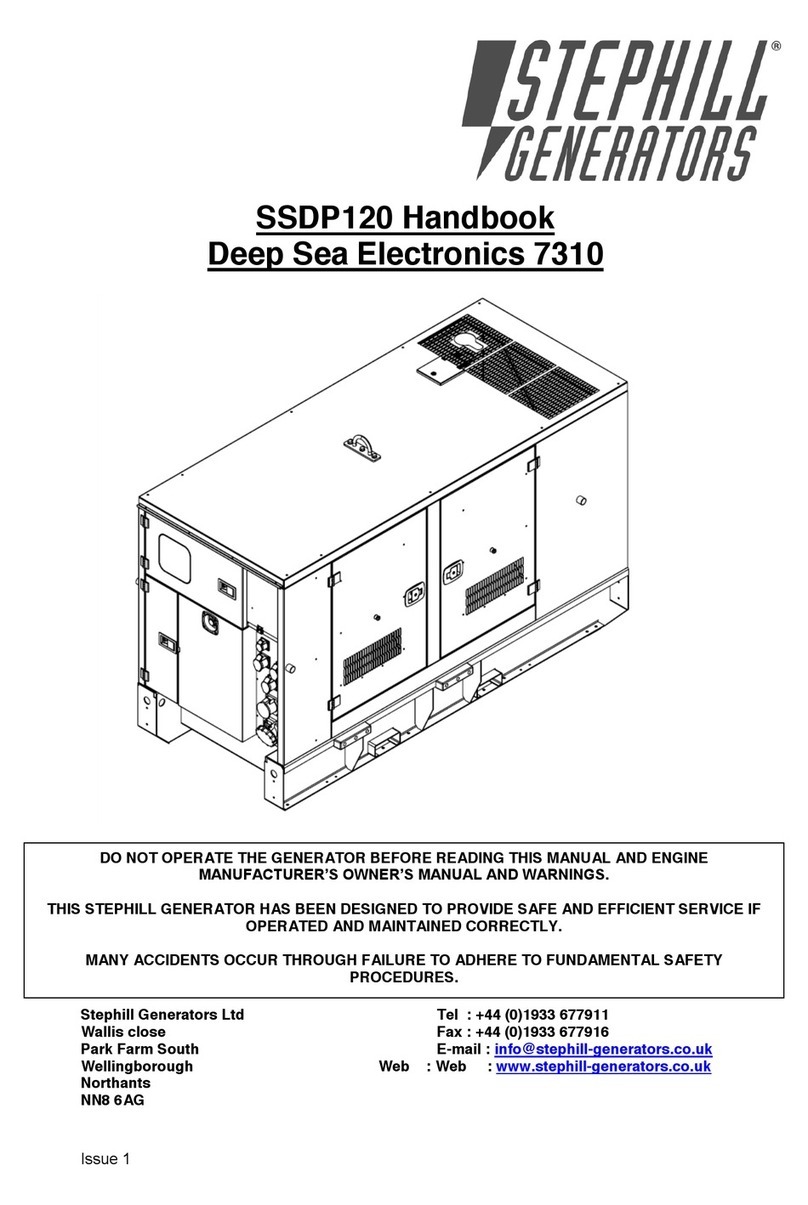

Where mechanical assistance is used in lifting machines, ensure the lifting eye is used, and that all

components used to lift the machine are within their Safe Working Load (SWL).

The integral lifting beam and associated lifting eye on the generator should be regularly checked for signs of

damage or gross corrosion.

All nuts and bolts associated with the lifting beam and eye should be regularly checked for tightness and

corrosion.

The SSDK-Range generators are fitted with a secondary fuel containment system, a bunded fuel tank. This will

require inspecting on a regular basis and drain accordingly. Any liquid drained from the bund/tank must be

treated as waste contaminated fuel/oil and disposed of correctly.

Warning Stephill Generators Ltd stress that he ultimate responsibility for ensuring the generator meets with

local/national regulations rests with the user.

DO NOT ATTEMPT TO LIFT THE GENERATOR WITHOUT PRIOR CHECKS TO THE LIFTING

SYSTEM AS INDICATED ABOVE

Lifting equipment should never be attached directly to the engine and/or alternator to fully lift the generator

except only if lifting engine and/or alternator.

All Stephill products are fitted with an earth stud on the control panel this must be connected to an earthing

system or spike. Any earth spike required is dependant on the local conditions of use. The size is determined

by reference to current IEE regulations or to a competent electrician.

Make sure that the Generator is at least 2 metres away from any building during operation. Operate in a well

ventilated unconfined area, so that fumes can be properly dispersed. Silencer outlet should be facing an open

area to prevent fumes being recirculated. There is the danger of asphyxiation due to exhaust gases.

Inhalation of poisonous exhaust fumes can lead to serious injury or death. The generator must not be used in

a poorly ventilated or enclosed area.

Ear protection may be required depending on the combined noise level of the Generator, auxiliary load and

the operator’s distance from it and the length of exposure. (Noise at Work Regulations 1989)

Ensure that suitable fire extinguishers (AFFF or CO2) are kept within close proximity of the generator. Do not

cover, enclose, or obstruct the airflow to the generator during or shortly after use, due to fire hazard or

damage to the generator from overheating. Allow the generator to cool after use before storing away. Keep

all inflammable objects clear of the generator.