Steris AMSCO RELIANCE 430 User manual

UNCRATING/INSTALLATION INSTRUCTIONS

AMSCO®RELIANCE® 430

Single-Chamber Washer/Disinfector

(09/15/00) P-122990-172

Rev. 5

LIMITATIONS OF LIABILITY AND INDEMNITY

IN NO CASE, WHETHER AS A RESULT OF A BREACH OF CONTRACT, BREACH OF WAR-

RANTY OR TORT (INCLUDING STERIS'S OR CUSTOMER'S WILLFUL ACTS OR NEGLIGENCE

OR STRICT LIABILITY) SHALL STERIS OR CUSTOMER BE LIABLE TO THE OTHER FOR ANY

CONSEQUENTIAL OR INCIDENTAL DAMAGES INCURRED BY THE OTHER, INCLUDING, BUT

NOT LIMITED TO, LOSS OF REVENUE, PROFITS OR GOODWILL. HOWEVER, NOTHING

CONTAINED IN THIS AGREEMENT IS INTENDED TO RELIEVE EITHER STERIS OR CUS-

TOMER FROM CLAIMS, LIABILITY, DAMAGES OR EXPENSES RESULTING FROM BODILY

INJURY, INCLUDING DEATH, OR FROM PROPERTY DAMAGE INCURRED DUE TO THE

WILLFUL ACTS, THE NEGLIGENCE OF OR THE STRICT LIABILITY OF THAT PARTY.

STERIS AGREES TO DEFEND, INDEMNIFY AND HOLD CUSTOMER HARMLESS FROM ANY

AND ALL CLAIMS, LIABILITY, DAMAGES OR EXPENSES DUE TO PERSONAL INJURIES,

INCLUDING DEATH, TO EMPLOYEES OF STERIS AND CUSTOMER AND TO THIRD PARTIES

AND FOR PROPERTY DAMAGE TO THE EXTENT OF THE WILLFUL ACTS OF THE NEGLI-

GENCE OF STERIS OR THE STRICT LIABILITY OF STERIS CAUSED BY THE ACTS OR

OMISSIONS OF STERIS. CUSTOMER AGREES TO DEFEND, INDEMNIFY AND HOLD STERIS

HARMLESS FROM ANY AND ALL CLAIMS, LIABILITY, DAMAGES OR EXPENSES DUE TO

PERSONAL INJURIES, INCLUDING DEATH, TO EMPLOYEES OF CUSTOMER AND STERIS

ANDTOTHIRDPARTIESANDFROMPROPERTYDAMAGETOTHEEXTENTOFTHEWILLFUL

ACTS OR THE NEGLIGENCE OF CUSTOMER OR THE STRICT LIABILITY OF CUSTOMER

CAUSED BY THE ACTS OR OMISSIONS OF CUSTOMER.

WARNING - COPYING PROHIBITED

This manual is protected by Federal Copyright Law, which

provides for damages of up to $20,000, as well as

criminal fines and imprisonment, for unauthorized copying.

i

Table of Contents Uncrating/InstallationInstructions 122990-172

Follow each step of the uncrating/installation instructions in the

order presented.Openthe carton carefullyto avoid damageto

the equipment inside. If you find any indication of damage to the

equipment (no matter how slight), show it to your supervisor.

To properly install this unit, you will need the Equipment Drawings

(previouslyfurnished),showingallutilityserviceandspacerequire-

ments.Ifdrawingscannotbelocated,replacement copiesmaybe

obtainedbywriting, faxing,ortelephoningSTERIS,givingtheserial

and model numbers of your equipment.

Onceinstalled,equipmentoperationshouldbetestedbyaqualified

service technician prior to your usage of the equipment.

If STERIS supervision is desired for installing and starting up this

equipment, contact your local STERIS representative.

TheAmsco®Reliance®430Single-Chamber Washer/Disinfector is

indicatedforuseinthecleaningandlow-leveldisinfectionofsoiled

reusable utensils, trays, glassware, bedpans and urinals, rubber

andplasticgoods,simplehard-surfacedrigidsurgicalinstruments,

suchasforceps,andclamps,andothersimilarandrelatedarticles

found in health care facilities.

STERISdoesnotintend,recommendnorrepresentinanywaythat

this Amsco Reliance 430 Single-Chamber Washer/Disinfector be

used for the terminal disinfection or sterilization of any regulated

medical device. Amsco Reliance 430 Single-Chamber Washer/

Disinfectors are intended only to perform an initial step in the

reprocessing of soiled, reusable medical devices. If medical de-

vices will be contacting blood or compromised tissues, such

devices must be terminally processed in accordance with good

Hospital Practices before each use in human patients.

A thorough preventive maintenance program is essential to safe

and proper equipment operation. You are encouraged to contact

your STERIS reprsentative concerning extended service mainte-

nanceagreementstogiveyourwasher/disinfectorplannedmainte-

nance, assuring equipment performance according to factory

specifications.STERISmaintainsanationwidestaffofwell-equipped,

factory-trainedtechnicianstoprovidethisservice,aswellasexpert

repairservices.PleasecontactyourlocalSTERISrepresentativefor

service details.

STERIS carries a complete line of accessories for use in this

equipment. A STERIS representative will gladly review these

with you.

©2000- STERIS Corporation. All rights reserved. Printed in Canada

A WORD FROM STERIS

Indications For Use

12345678901234567890123456789012123456789012345678901234567

1

234567890123456789012345678901212345678901234567890123456

7

12345678901234567890123456789012123456789012345678901234567

12345678901234567890123456789012123456789012345678901234567

1

234567890123456789012345678901212345678901234567890123456

7

12345678901234567890123456789012123456789012345678901234567

Service Information

12345678901234567890123456789012123456789012345678901234567

1

234567890123456789012345678901212345678901234567890123456

7

12345678901234567890123456789012123456789012345678901234567

12345678901234567890123456789012123456789012345678901234567

1

234567890123456789012345678901212345678901234567890123456

7

12345678901234567890123456789012123456789012345678901234567

Advisory

12345678901234567890123456789012123456789012345678901234567

1

234567890123456789012345678901212345678901234567890123456

7

12345678901234567890123456789012123456789012345678901234567

12345678901234567890123456789012123456789012345678901234567

1

234567890123456789012345678901212345678901234567890123456

7

12345678901234567890123456789012123456789012345678901234567

ii

122990-172 Uncrating/InstallationInstructions Table of Contents

SalesSales

SalesSales

Sales Direct Technical AssistanceDirect Technical Assistance

Direct Technical AssistanceDirect Technical Assistance

Direct Technical Assistance

STERIS Corporation STERIS Field Engineering

5960, Heisley Road 2424, West 23rd Street,

Mentor, Ohio 44060-1834 Erie, PA 16506

Tel.: 440 354 2600 Tel.: 814 452 3100

Fax: 440 639 8199 Fax: 814 870 8400

ManufacturingPlantManufacturingPlant

ManufacturingPlantManufacturingPlant

ManufacturingPlant

STERIS Canada Corporation

415, rue des Alleghanys

Beauport (Quebec)

Canada G1C 4N4

Tel.: 418 664 1549

Fax: 418 664 0188

Web Site:Web Site:

Web Site:Web Site:

Web Site:www.steris.com

iii

Table of Contents Uncrating/InstallationInstructions 122990-172

1 LISTING OF WARNINGS, CAUTIONS AND

SYMBOLS....................................................... 1-1

2 UNCRATING INSTRUCTIONS ........................2-1

Open the Crate ........................................................ 2-1

Remove Crate and Packing ..................................... 2-1

Remove Base and Move Washer/Disinfector ........... 2-1

Prepare Washer/Disinfector for Installation .............. 2-2

3 INSTALLATION INSTRUCTIONS....................3-1

Before Installing Equipment ..................................... 3-1

Connect Utilities ....................................................... 3-1

Initial Set-up ............................................................. 3-2

Initial Set-up Test ..................................................... 3-3

4 OPERATIONAL TESTS ...................................4-1

First Operational Test............................................... 4-1

Second Operational Test ......................................... 4-2

TABLE OF CONTENTS

SECTIONSECTION

SECTIONSECTION

SECTION TITLETITLE

TITLETITLE

TITLE PAGEPAGE

PAGEPAGE

PAGE

1-1

122990-172Summary of Warnings and Cautions Uncrating/Installation Instructions

Thefollowingisalistingofsafetyprecautionswhichmustbeobservedwhenuncrating,installing,andcheckingthis

equipment. WARNINGS indicate the potential for danger to personnel and CAUTIONS indicate the potential for

damage to equipment. These precautions are repeated (in whole or in part), where applicable, throughout the

instructions.

WARNING - LACERATION/EYE INJURY HAZARD:

WHENREMOVINGBANDS,weareyeprotectionandalwaysuseatoolspecificallydesignedtocutthebands.

The bands used to secure this container can cause personal injury when cut and tension is released.

WARNING - PERSONAL INJURY AND/OR EQUIPMENT DAMAGE HAZARD:

WHEN MOVING WASHER/DISINFECTOR, use a forklift. Do not use the doors or door handles for lifting.

TO TILT THE WASHER/DISINFECTOR, more than one person is required. Washer/disinfector weighs

approximately 1000 lbs (454 kg).

WARNING - LACERATION HAZARD:

WHEN REMOVING BOLTS, wear gloves to protect your hands.

WARNING - BURN HAZARD:

WHENCHECKING AUTOMATICSTOP FEATURE, openchamberdoor slowly andweargloves and

face protection. Hot water/steam may be sprayed through door opening if door is opened while

washer is operating.

EXCEPTFORANEMERGENCY,donotopendoorwhencycleisinprogress.Inanemergency,firststopcycle

by pressing the STOP touch pad and wait for water flow to stop. Wear protective gloves and face shield

whenever reaching into the chamber.

WARNING - FALL HAZARD:

TO PREVENT FALLS, keep floor dry. Promptly clean up any spills or drippage.

WARNING - CHEMICAL BURN HAZARD:

WASHER/DISINFECTOR DETERGENTS ARE CAUSTIC and can cause adverse effects to exposed tissues.

Do not get in eyes, on skin or attempt to ingest by mouth.

•Read and follow the precautions and instructions on the detergent label and in the Material Safety Data

Sheet (MSDS) prior to handling the detergent, refilling the detergent container or servicing the detergent

injection pump and lines.

•Wear protective gloves, face shield and clothing whenever handling the detergent or servicing the

detergent injection pump and lines.

WARNING - ELECTRICAL SHOCK HAZARD:

FASTENERS AND STAR WASHERS ARE USED to ensure protective bonding continuity. Always re-

install any star washers which may have been removed during installation or servicing.

CAUTION - POSSIBLE EQUIPMENT DAMAGE:

Leave door closed to prevent counterweight from dropping to bottom of guiding box.

!

!

!

!

!

!

!

!

!

LISTING OF WARNINGS, CAUTIONS AND

SYMBOLS 1

!

1-2

122990-172 Summary of Warnings and CautionsUncrating/Installation Instructions

CAUTION (Cont'd)

Oncethree-phasepowerisconnected,checkpumpforcorrectrotation,indicatedbyarrowonpumpmotor.

Incorrect pump rotation may result in pump damage and improper washing action.

If unit must be tilted, tilt onto left or right side. Handles and control panels could be damaged if unit is tilted

onto front (soiled) or back (clean) side.

Avoid product damage. Always select a cycle appropriate for the items being processed.

Whenchoosingdetergent,selectonewithalowchloridecontent.Detergentswithahighchloridecontentmust

not be used, as chlorides will harm and deteriorate stainless steel.

IMPORTANT::

::

: Be sure to check the Occupational Health and Safety Act, as well as local electric and plumbing

codes, for any special requirements that may pertain to installation of this washer/disinfector.

!

!

!

!

Symbols Symbol Definition

Protective Earth (Ground)

Warning! Risk of Electrical Shock

Electrostatic Sensitive Device

This Way Up

Do Not Stack

Fragile

Keep Dry

A Amperage Rating of the Unit

VVoltage Rating of the Unit

~AlternatingCurrent

kW Power Rating of the Unit

Hz Frequency of the Unit

φφ

φφ

φPhase of the Unit

2-1

122990-172UncratingInstructions Installation/Uncrating Instructions

NOTE:

The equipment in this container weighs approximately

1100 lbs (500 kg). Use a forklift to move washer.

NOTE: Uncrate on level floor as close to the installation site as

possible.

1. Place crate in position to be opened from the top. Provide a

clear work area on all sides (see Figure 2-1).

2. Carefully cut and remove bands from container.

3. Discard bands before continuing.

1. Lift off top wooden panels.

2. Remove wooden side panels. Discard top and side panels.

3. Remove foam sheets.

4. Check tip indicator (located inside bottom service compart-

ment, see Figure 2-2). If unit has been tipped, notify the

STERIS Regional Office nearest you.

1. Openbottomservice compartment and removethefourlag

bolts holding washer to shipping base (see Figure 2-2).

2. Using a forklift, lift the washer from base. If washer is too high

to be lifted by forklift, proceed to step 6.

Figure 2-2. Remove Lag BoltsFigure 2-1. Position Crate

Top

Bands

Container

Nails

Lag

Bolts Tip Indicator

Wood Base

Lag Bolts

Remove Base and Move

Washer/Disinfector

12345678901234567890123456789012123456789012345678901234567

1

234567890123456789012345678901212345678901234567890123456

7

12345678901234567890123456789012123456789012345678901234567

12345678901234567890123456789012123456789012345678901234567

1

234567890123456789012345678901212345678901234567890123456

7

12345678901234567890123456789012123456789012345678901234567

Remove Crate

and Packing

12345678901234567890123456789012123456789012345678901234567

1

234567890123456789012345678901212345678901234567890123456

7

12345678901234567890123456789012123456789012345678901234567

12345678901234567890123456789012123456789012345678901234567

1

234567890123456789012345678901212345678901234567890123456

7

12345678901234567890123456789012123456789012345678901234567

WARNING - LACERATION HAZ-

ARD: When removing bolts, wear

gloves to protect your hands.

Open the Crate

12345678901234567890123456789012123456789012345678901234567

1

234567890123456789012345678901212345678901234567890123456

7

12345678901234567890123456789012123456789012345678901234567

12345678901234567890123456789012123456789012345678901234567

1

234567890123456789012345678901212345678901234567890123456

7

12345678901234567890123456789012123456789012345678901234567

WARNING - PERSONAL INJURY

AND/OR EQUIPMENT DAMAGE

HAZARD: When moving washer/

disinfector, use a forklift. Do not

use doors or door handles for

lifting.

WARNING - LACERATION/EYE

INJURY HAZARD: When remov-

ing bands, wear eye protection

and always use a tool specifically

designed to cut the bands. The

bands used to secure this con-

tainer can cause personal injury

when cut and tension is released.

UNCRATING INSTRUCTIONS 2

Installation/Uncrating Instructions

2-2

122990-172 UncratingInstructions

3. Pull out and discard the wooden base under the washer.

4. Move washer to installation site.

5. Lower the washer.

6. If washer is too high to be lifted by forklift, the washer may be

tilted (see Figure 2-3).

a. Place cardboard or removed foam sheets on skid to

protect cabinet.

b. Slowly tip washer sideways and lower onto skid, being

careful to prevent damage.

c. Move unit by forklift to its permanent site.

d. Carefully tip unit back to a standing position.

1. Remove all tape from washer/disinfector.

2. With door closed to prevent counterweight from dropping,

remove the door counterweight blocking pin as follows (see

Figure 2-4):

a. Removeboltsholdingleft(whenfacingfront[soiled]sideof

unit) side panel to washer.

b. Remove left side panel.

c. Remove screw from blocking pin. Keep screw.

d. Slide blocking pin out of counterweight box.

e. Once counterweight moves freely, fasten blocking pin

ontooutsideedgeofcounterweightbox,attachingscrew

previously removed through hole provided for pin stor-

age (see Figure 2-4). Pin may be needed for future door

maintenance work.

Figure 2-3. Tilt WasherFigure 2-3. Tilt Washer

Figure 2-3. Tilt WasherFigure 2-3. Tilt Washer

Figure 2-3. Tilt Washer Figure 2-4. Remove Blocking PinFigure 2-4. Remove Blocking Pin

Figure 2-4. Remove Blocking PinFigure 2-4. Remove Blocking Pin

Figure 2-4. Remove Blocking Pin

1

2

4

Blocking Pin For Blocking Pin

Storage

Screw

Prepare Washer/

Disinfector for

Installation

12345678901234567890123456789012123456789012345678901234567

1

234567890123456789012345678901212345678901234567890123456

7

12345678901234567890123456789012123456789012345678901234567

12345678901234567890123456789012123456789012345678901234567

1

234567890123456789012345678901212345678901234567890123456

7

12345678901234567890123456789012123456789012345678901234567

CAUTION: Leave door closed to

preventcounterweightfromdrop-

ping to bottom of guiding box.

WARNING - PERSONAL INJURY

AND/OR EQUIPMENT DAMAGE

HAZARD: To tilt the washer/

disinfector, more than one per-

son is required. Washer/

disinfectorweighsapproximately

1000 lbs (454 kg).

CAUTION: If unit must be tilted,

tilt unit onto left or right side.

Handlesandcontrolpanelscould

be damaged if unit is tilted onto

front(soiled)orback(clean)side.

2-3

122990-172UncratingInstructions Installation/Uncrating Instructions

f. Check that cables are seated in the pulley grooves (see

Figure 2-5).

g. Replace left side panel.

h. Repeat steps a. through g. for back (clean) side door.

3. Open chamber door. Remove nylon straps holding spray

headers to frame.

4. Remove nylon straps holding chamber spray arms.

5. Remove tape holding chamber filter.

6. Remove nylon straps and foam holding steam coils in the tub.

7. Remove tape and foam from pure water tank.

8. Remove all packing and tape from control panel.

9. Remove envelope containing Operator Manual and other

printed material. Give to appropriate personnel.

Figure 2-5. Door Cables and

Pulleys

Pulley

Cable

Counterweight

3-1

122990-172Installation Instructions Installation/Uncrating Instructions

1. Review permissible environmental conditions. This washer/

disinfectorisdesignedtogiveoptimalresultsinanenvironment

where maximum relative humidity is 80% for temperatures up

to 88°F (31°C) decreasing linearly to 50% relative humidity at

104°F (40°C).

a. Clearance-ClearancespaceshownonEquipmentDrawing

is necessary for easy installation and proper operation and

maintenance of washer/disinfector.

b. Utility service lines:

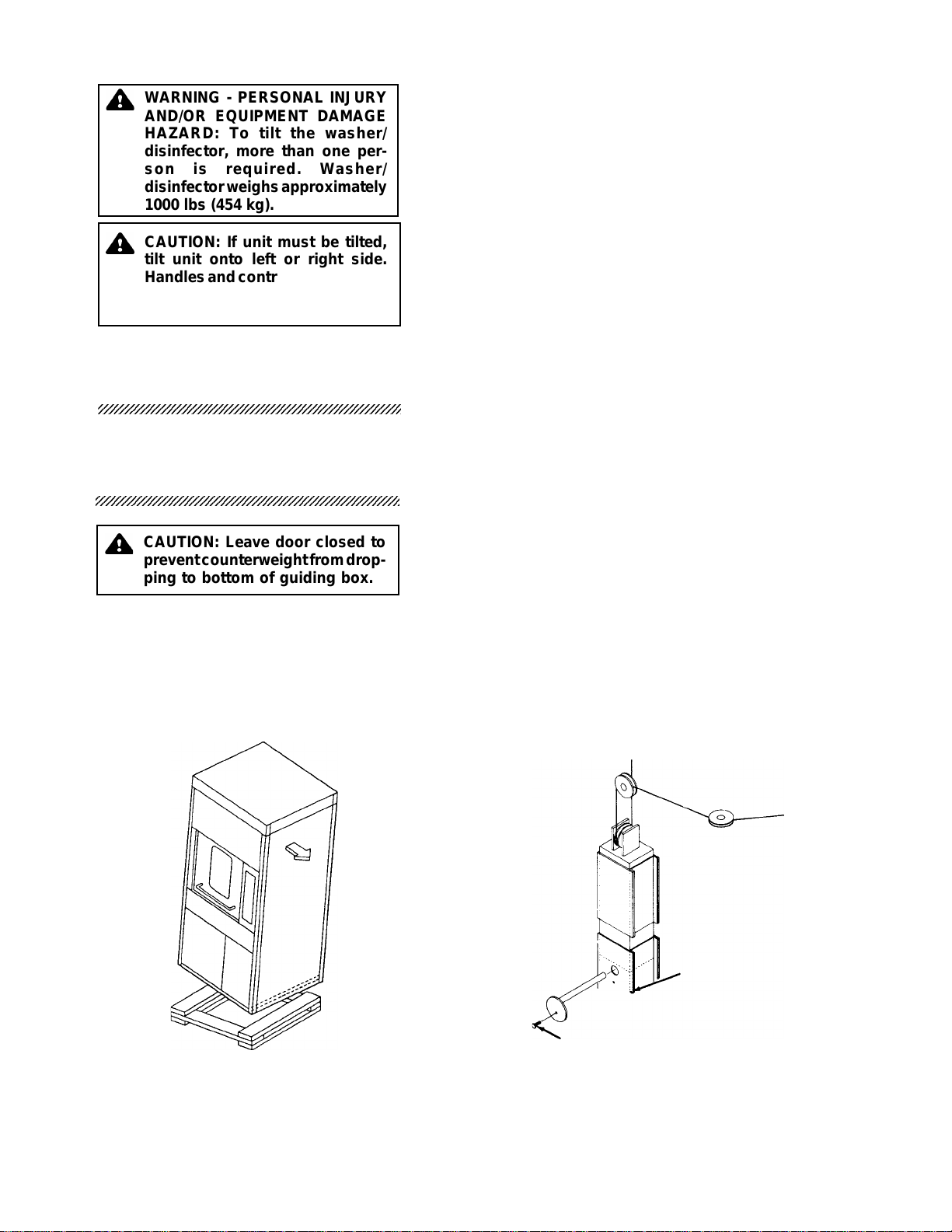

•Shutoff valves (not by STERIS) should be installed on

steam and water lines to washer/disinfector (see Figure

3-1). Shutoff valves allow washer/disinfector to be ser-

vicedwithoutshuttingoffbuildingsupply.Shutoffvalves

mustbecapableofbeinglockedinOFFposition.Vacuum

breakers are also recommended on water lines.

•Disconnectswitches(notbySTERIS)shouldbeinstalled

inelectric supplylines near washer/disinfector(see Fig-

ure 3-1). Disconnect switches should be capable of

being locked in OFF position only.

•If this machine is installed next to other equipment,

shutoff valves and disconnect switches should be lo-

cated so that service can be shut off to one piece of

equipment at a time.

•Utility service requirements are shown on Equipment

Drawing.Thismachinerequireseither208volts,3phase,

60 Hz (steam heated) or 480 volts, 3 phase, 60 Hz

(electric heated) power. Check Equipment Drawings or

name plate for proper voltage.

2. Place washer/disinfector, as shown on Equipment Drawing, in

correctrelation tobuilding supplylines. Ifunit is not at installa-

tion site, refer to Uncrating Instructions (Section 2) for proper

moving instructions.

NOTE:Floorunderwasher/disinfectorshouldbelevel.Ifnecessary,

adjustlevelinglegstolevelwasher/disinfector.Ifwasher/disinfector

is not level, water level control may not work properly.

3. Locate access door keys (inside chamber) and open rear

access doors.

1. COLDWATER-Blowoutthebuildingcold-watersupplylineto

remove chips, scale, etc. Connect line to washer/disinfector.

2. HOT WATER - Blow out the building hot-water supply line to

remove chips, scale, etc. Connect line to washer/disinfector.

3. STEAM - Blow out the building steam supply line to remove

chips, scale, etc. Connect line to washer/disinfector.

4. PURIFIEDWATER-Connectsupplylinetowasher/disinfector.

Figure 3-1. Utility Service

Connections

INSTALLATION INSTRUCTIONS 3

Before Installing

Equipment

12345678901234567890123456789012123456789012345678901234567

1

234567890123456789012345678901212345678901234567890123456

7

12345678901234567890123456789012123456789012345678901234567

12345678901234567890123456789012123456789012345678901234567

1

234567890123456789012345678901212345678901234567890123456

7

12345678901234567890123456789012123456789012345678901234567

Connect Utilities

12345678901234567890123456789012123456789012345678901234567

1

234567890123456789012345678901212345678901234567890123456

7

12345678901234567890123456789012123456789012345678901234567

12345678901234567890123456789012123456789012345678901234567

1

234567890123456789012345678901212345678901234567890123456

7

12345678901234567890123456789012123456789012345678901234567

WARNING - FALL HAZARD: To

prevent falls, keep floor dry.

Promptly clean up any spills or

drippage.

3-2

122990-172 Installation InstructionsInstallation/Uncrating Instructions

5. WASTE - Connect washer/disinfector drain line to building

waste line.

6. VENTILATION-Connectwasher/disinfectorventilationtobuild-

ing ventilation, as required.

7. Open building supply valves and check for leaks: correct if

necessary.

8. ELECTRIC - Connect building electrical supply to washer/

disinfector. Verify tight electrical connections.

Figure 3-2. Front (Soiled) Side

Control Panel Figure 3-3. Back (Clean) Side Control Panel

3-3

122990-172Installation Instructions Installation/Uncrating Instructions

NOTE:

Beforeoperatingthewasher/disinfector,aninitialset-uptest

shouldbeconductedbyaSTERISEngineeringServicetechnician

or equivalent person familiar with the operational test procedures,

including leak testing.

1. Open chamber door. Check that filters are positioned in wash

chamber bottom.

2. Remove manifold or accessory from chamber.

3. Checkthatnothinghasbeenleftinchamber(tapeortiewraps).

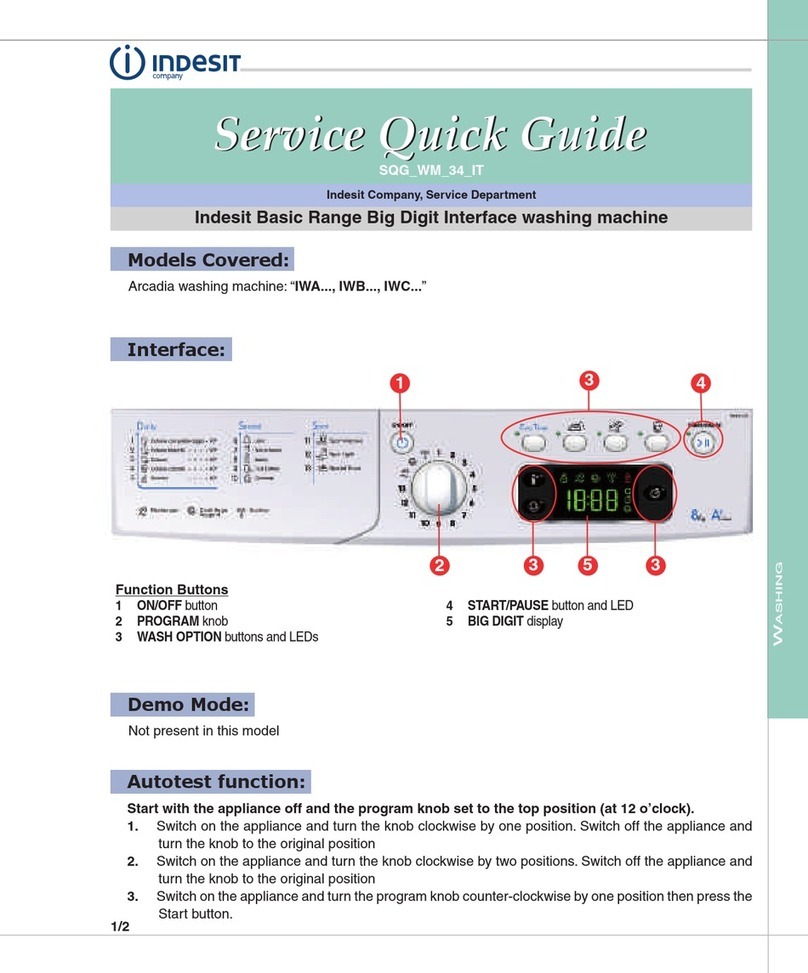

4. Close door and press POWER button. POWER light goes on

(see Figures 3-2 and 3-3).

5. Checkthatpurifiedwater storage tankbeginstofillas soon as

washer/disinfector is turned on. If not, contact a qualified

STERISEngineeringServicetechnician. Check that tankdoes

not overfill.

IMPORTANT: Do not use any detergent or lubricant for this test.

1. Select desired cycle by pressing the corresponding button

(INSTRUMENT, UTENSILS, RUBBER GOODS, PLASTIC

GOODS, or GLASSWARE).

NOTE: Washer/Disinfector operation can be halted at any time by

pressing STOP, waiting for water flow to stop, and then opening

door. Close door and press START to resume cycle. Pump opera-

tion will be delayed for 2 minutes after door is closed to avoid

chamber pressurization.

2. PressSTART.Letcycleruntoclearpipingsystemofanyforeign

matter.

NOTE:Lowdetergentandlubricantlevellightswillglow.Donotadd

any detergent or lubricant.

NOTE:Phasestatuslightsflashtoindicatewhichphaseisrunning,

showingcycleprogression(seeFigures3-2and3-3,andTable1).

3. Inspect piping for leaks. If necessary, tighten connections.

4. Check that CYCLE COMPLETE light turns on at end of cycle.

When cycle is complete, open door.

5. Remove and clean wash chamber filters. Replace filters in

chamber.

THIS COMPLETES THE INSTALLATION.Beforeoperating

the equipment, an operational test should be conducted by a

servicetechnician. ContactyourlocalSTERISsalesrepresentative

for availability and information on this service. Refer to the Mainte-

nance Manual (P-764327-734) for further details on these proce-

dures.

Initial Set-up Test

12345678901234567890123456789012123456789012345678901234567

12345678901234567890123456789012123456789012345678901234567

12345678901234567890123456789012123456789012345678901234567

1

234567890123456789012345678901212345678901234567890123456

7

12345678901234567890123456789012123456789012345678901234567

CAUTION: Avoid product dam-

age. Always select cycle appro-

priate for the items being pro-

cessed.

WARNING - BURN HAZARD: Ex-

cept for an emergency, do not

open door when cycle is in

progress. In an emergency, first

stopcyclebypressingtheSTOP

touchpadandwaitforwaterflow

to stop. Wear protective gloves

and face shield whenever reach-

ing into the chamber.

Initial Set-up

12345678901234567890123456789012123456789012345678901234567

1

234567890123456789012345678901212345678901234567890123456

7

12345678901234567890123456789012123456789012345678901234567

12345678901234567890123456789012123456789012345678901234567

1

234567890123456789012345678901212345678901234567890123456

7

12345678901234567890123456789012123456789012345678901234567

3-4

122990-172 Installation InstructionsInstallation/Uncrating Instructions

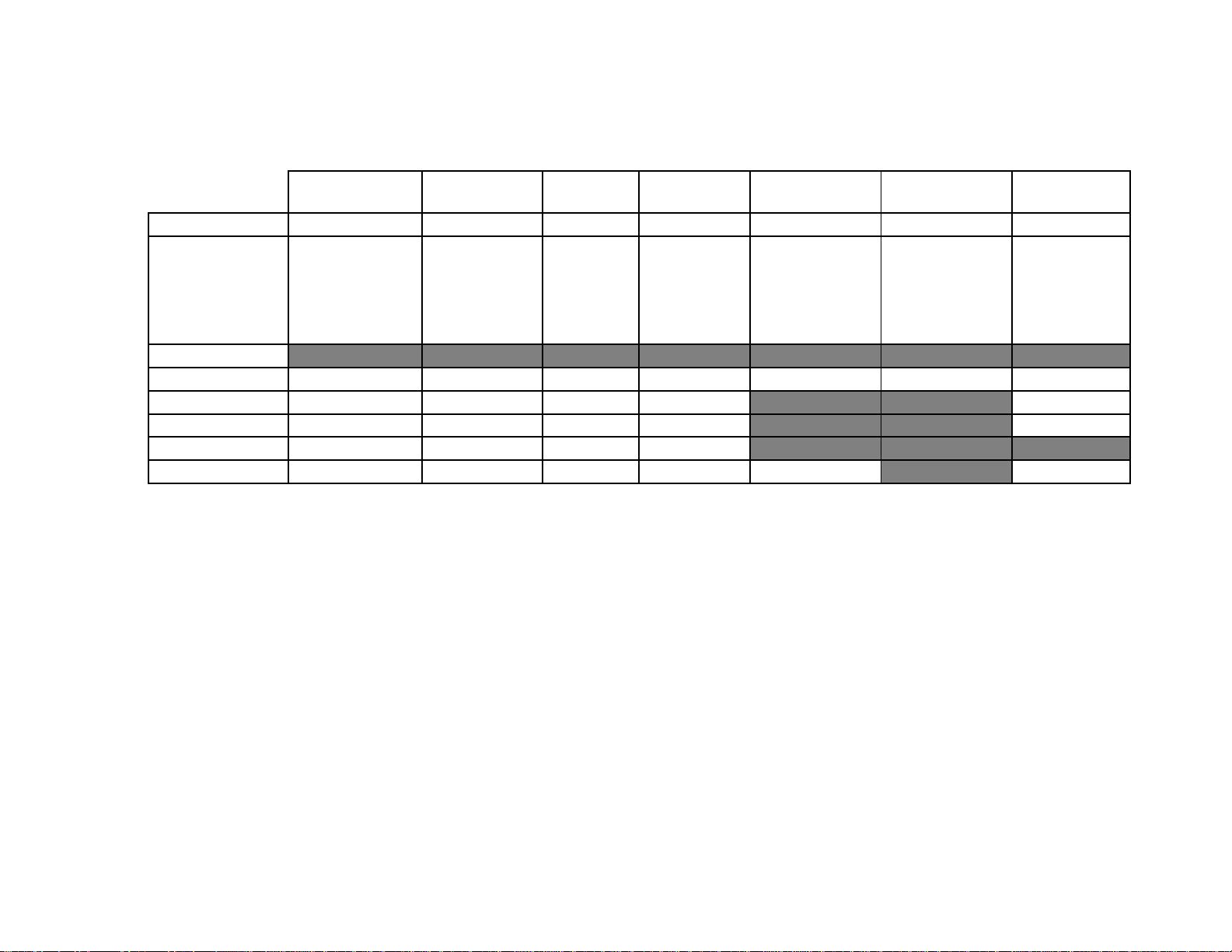

Table 3-1. AmscoTable 3-1. Amsco

Table 3-1. AmscoTable 3-1. Amsco

Table 3-1. Amsco®®

®®

®RelianceReliance

RelianceReliance

Reliance®®

®®

®430 Single-Chamber Washer/Disinfector Cycle Description Chart430 Single-Chamber Washer/Disinfector Cycle Description Chart

430 Single-Chamber Washer/Disinfector Cycle Description Chart430 Single-Chamber Washer/Disinfector Cycle Description Chart

430 Single-Chamber Washer/Disinfector Cycle Description Chart

COLD WATER

PRE-WASH DETERGENT

WASH RINSE 1 RINSE 2 PURE WATER

RINSE LUBRICATION DRY

Fixed Time

2 min. 4-8 min. 30 sec 60 sec

Temperature

Cold Tap Water Hot Tap Water

Heated to 150°F

(66°C)

Hot Tap

Water

Hot Tap Water

Heated and

Maintained at

180°F (82°C) *

Cold Pure Water

or 180°F Pure

Water

Lubricant Milk is

Added to Pure

Water

Air Heated and

Maintained at

200°F (93°C)

CYCLES

Instruments

XXXX

Utensils

XXXX

Rubber Goods

XXXX

Plastic Goods

XXXX

Glassware

XXXX

X = Applicable

*Selection indicates temperature at which sump water will be maintained. Temperature on items will be approximately 4°F (2°C) lower.

Rev. 4 (2000-05-26)

122-991-634

4-1

122990-172Operational Tests Installation/Uncrating Instructions

IMPORTANT: Do not use any detergent or lubricant for this test.

1. Insertamanifoldoraccessoryinchamber.Be sure the acces-

sory is properly positioned over manifold connector.

2. Close chamber door and press POWER button. POWER light

goes on.

3. Select desired cycle by pressing corresponding cycle button

(see Figure 3-2).

NOTE: Washer/Disinfector operation can be halted at any time by

pressing STOP, waiting for water flow to stop, and then opening

door. Close door and press START to resume cycle. Pump opera-

tion will be delayed for 2 minutes after door is closed to avoid

chamber pressurization.

4. Press START button.

5. Observe (through window in door) operation of the spray

assemblies.Allrotaryspray assemblies shouldrotatefreely.If

they do not, press STOP, open the door, and clean out spray

armnozzleswithathinpieceofwire(seeFigure4-1).Closethe

door and press START.

6. Check all safety features.

a. Beingcarefulofhotwaterescaping,openfront(soiled)side

chamber door. Safety lock-out feature should shut all ser-

vice off. Close door and press START to resume cycle.

b. Open back (clean) side chamber door. Safety lock-out

feature should shut all service off. Close door and press

START to resume cycle.

7. Check pump rotation. Pump should rotate clockwise (while

facing it) as indicated by arrow on pump motor.

8. Check fan rotation. Arrow on fan indicates proper direction.

OPERATIONAL TESTS 4

First Operational Test

12345678901234567890123456789012123456789012345678901234567

1

234567890123456789012345678901212345678901234567890123456

7

12345678901234567890123456789012123456789012345678901234567

12345678901234567890123456789012123456789012345678901234567

1

234567890123456789012345678901212345678901234567890123456

7

12345678901234567890123456789012123456789012345678901234567

WARNING - FALL HAZARD: To

prevent falls, keep floor dry.

Promptly clean up any spills or

drippage.

CAUTION: Avoid product dam-

age. Always select a cycle ap-

propriate for the items being

processed.

WARNING-BURNHAZARD:Ex-

cept for an emergency, do not

open door when cycle is in

progress. In an emergency, first

stopcyclebypressingtheSTOP

touchpadandwaitforwaterflow

to stop. Wear protective gloves

andfaceshieldwheneverreach-

ing into the chamber.

WARNING - BURN HAZARD:

When checking automatic stop

feature, open chamber door

slowlyandweargloves andface

protection.Hotwater/steammay

be sprayed through door open-

ingifdoorisopenedwhilewasher

is operating.

CAUTION: Once three-phase

powerisconnected,checkpump

forcorrect rotation,indicatedby

arrow on pump motor. Incorrect

pumprotationmayresultinpump

damage and improper washing

action.

Figure 4-1. Rotary Spray ArmsFigure 4-1. Rotary Spray Arms

Figure 4-1. Rotary Spray ArmsFigure 4-1. Rotary Spray Arms

Figure 4-1. Rotary Spray Arms

Spray Arm

Nut

Manifold Connector

Sleeve

Bolt

4-2

122990-172 Operational Tests

Installation/Uncrating Instructions

9. When cycle is over, the CYCLE COMPLETE light comes on.

Open door and remove the accessory.

10. Clean chamber filters. Replace filters in chamber and close

chamber doors.

NOTE: Always use a non-foaming detergent for effective cleaning

and proper pump and water level control operation.

NOTE: Refer to Section 2 and follow detergent manufacturer's

recommendations to determine the temperature of the WASH

treatment.

NOTE: Follow detergent manufacturer's recommendations for the

amount of detergent used according to water hardness.

1. Open injection pump access door (lower right).

2. Slideinjectionpumpdraweroutfromunderwasher/disinfector.

3. Installone-gallondetergentandlubricantcontainers(see Fig-

ure 4-2).

4. Insert squeeze tube into each container.

5. Using the PRIME switch beside each injection pump, fill up

tubing between container and pump.

6. Select Instrument cycle by pressing INSTRUMENT button.

7. Press START button.

8. VerifydetergentisinjectedintochamberduringWashphaseas

soon as chamber begins to fill.

Check detergent concentration. Pump injection rate is

10 oz/min (284 ml/min). The detergent injection time is preset

at34seconds.Tomodifyconcentration,adjusttheappropriate

timer located in the injection pump drawer.

Figure 4-2. Detergent/Lubricant Container in place

Second Operational Test

12345678901234567890123456789012123456789012345678901234567

12345678901234567890123456789012123456789012345678901234567

12345678901234567890123456789012123456789012345678901234567

1

234567890123456789012345678901212345678901234567890123456

7

12345678901234567890123456789012123456789012345678901234567

CAUTION:Whenchoosingdeter-CAUTION:Whenchoosingdeter-

CAUTION:Whenchoosingdeter-CAUTION:Whenchoosingdeter-

CAUTION:Whenchoosingdeter-

gent, select one with a low chlo-gent, select one with a low chlo-

gent, select one with a low chlo-gent, select one with a low chlo-

gent, select one with a low chlo-

ride content. Detergents with aride content. Detergents with a

ride content. Detergents with aride content. Detergents with a

ride content. Detergents with a

high chloride content must nothigh chloride content must not

high chloride content must nothigh chloride content must not

high chloride content must not

be used, as chlorides will harmbe used, as chlorides will harm

be used, as chlorides will harmbe used, as chlorides will harm

be used, as chlorides will harm

and deteriorate stainless steel.and deteriorate stainless steel.

and deteriorate stainless steel.and deteriorate stainless steel.

and deteriorate stainless steel.

WARNING - CHEMICAL BURNWARNING - CHEMICAL BURN

WARNING - CHEMICAL BURNWARNING - CHEMICAL BURN

WARNING - CHEMICAL BURN

HAZARD:Washer/Disinfectorde-HAZARD:Washer/Disinfectorde-

HAZARD:Washer/Disinfectorde-HAZARD:Washer/Disinfectorde-

HAZARD:Washer/Disinfectorde-

tergents are caustic and cantergents are caustic and can

tergents are caustic and cantergents are caustic and can

tergents are caustic and can

causeadverseeffectstoexposedcauseadverseeffectstoexposed

causeadverseeffectstoexposedcauseadverseeffectstoexposed

causeadverseeffectstoexposed

tissues. Do not get in eyes, ontissues. Do not get in eyes, on

tissues. Do not get in eyes, ontissues. Do not get in eyes, on

tissues. Do not get in eyes, on

skin or attempt to ingest byskin or attempt to ingest by

skin or attempt to ingest byskin or attempt to ingest by

skin or attempt to ingest by

mouth. Read and follow the pre-mouth. Read and follow the pre-

mouth. Read and follow the pre-mouth. Read and follow the pre-

mouth. Read and follow the pre-

cautions and instructions on thecautions and instructions on the

cautions and instructions on thecautions and instructions on the

cautions and instructions on the

detergent label and in the MSDSdetergent label and in the MSDS

detergent label and in the MSDSdetergent label and in the MSDS

detergent label and in the MSDS

prior to handling the detergentprior to handling the detergent

prior to handling the detergentprior to handling the detergent

prior to handling the detergent

or refilling the detergent con-or refilling the detergent con-

or refilling the detergent con-or refilling the detergent con-

or refilling the detergent con-

tainer. Wear protective gloves,tainer. Wear protective gloves,

tainer. Wear protective gloves,tainer. Wear protective gloves,

tainer. Wear protective gloves,

face shield and clothing when-face shield and clothing when-

face shield and clothing when-face shield and clothing when-

face shield and clothing when-

ever handling the detergent.ever handling the detergent.

ever handling the detergent.ever handling the detergent.

ever handling the detergent.

Container

Timer

Pump

4-3

122990-172Operational Tests Installation/Uncrating Instructions

9. Verify lubricant is injected into chamber during Lubrication

phase as soon as Purified Water Rinse phase is complete.

Checklubricantconcentration.Pumpinjectionrateis10oz/min

(284 ml/min). The lubricant injection time is preset at 60 sec-

onds. To modify concentration, adjust the appropriate timer

located in the injection pump drawer.

10. When cycle is complete, slide injection pump drawer back in

place. Close access door.

11. Press the POWER button to turn off the unit. POWER light

goes off.

This unit is now ready for a thorough System Field Test,

Calibration and a first time Preventive Maintenance Checklist

Inspection by a qualified STERIS service representative. Con-

tactyourSterisSalesRepresentativeforavailabilityandinformation

on this service. Refer to Maintenance Manual (P-764327-734) for

further details on these procedures.

The best way to prevent costly downtime due to equipment malfunction is with

regularlyscheduledmaintenanceperformedbyqualifiedtechnicianstrainedinthe

latesttechnology. STERISoffers annualmaintenance agreementsto giveyour capital

equipmentplannedmaintenance that will helpcorrectlittleproblems before they

becomebigones.STERISEngineeringServicecombinestheprecisemaintenance

programand factory-trainedtechnicians to assureyou ofmaximum productivity.

Our STERIS service technicians thoroughly inspect, clean, adjust and provide all

necessarymaintenancetokeepyourequipmentperformingaccordingtofactoryspeci-

fications, all at an established economical rate that you can plan for.

Wehavemore than 5,000customerswhoare benefiting fromSTERISmaintenance

agreements.Why not jointhem? Obtain completedetails by calling1-800-333-8828, or

writing to:

Protect your STERIS equipment with

cost-effective extended service agreements

Table of contents

Other Steris Washer manuals

Steris

Steris RELIANCE 400 User manual

Steris

Steris ML 200 User manual

Steris

Steris Basil 4600 User manual

Steris

Steris BASIL 9500 User manual

Steris

Steris AMSCO 7000 Series User manual

Steris

Steris RELIANCE 400 User manual

Steris

Steris AMSCO 5000 Series User manual

Steris

Steris ML 222 User manual

Steris

Steris Reliance 1227 User manual

Steris

Steris RELIANCE 200 User manual