Steris AMSCO 7000 Series User manual

10432589

Revision G

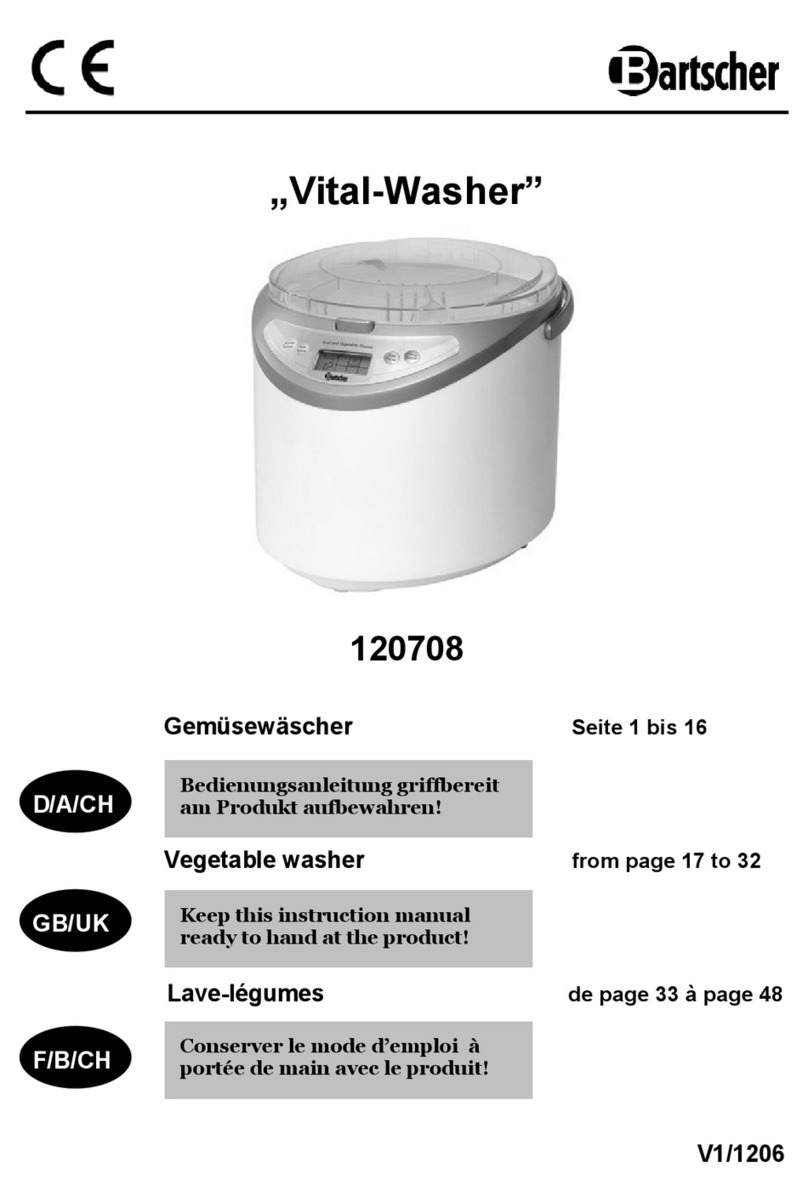

AMSCO®7000 Series

Washer/Disinfector Models # 7052HP and # 7053HP

Operator Manual

— A Word from STERIS

2

10432589_G AMSCO®7000 Series Operator Manual

A Word from STERIS

A Word From STERIS — Introduction

This manual contains important information on the proper use and routine maintenance of the AMSCO® 7052HP

Single-Chamber Washer/Disinfector and the AMSCO® 7053HP Single-Chamber Washer/Disinfector. All personnel

involved in the use and maintenance of this equipment must carefully review and comply with the Safety

Precautions and instructions contained in this manual. These instructions are important to protect the health and

safety of personnel operating these washers/disinfectors and should be retained in a conveniently accessible area for

quick reference. This equipment is specifically designed only for the uses outlined in this manual.

Complete instructions for uncrating and connecting utilities, as well as the equipment drawing, have been provided. If

they are missing, contact STERIS for replacement copies, providing the serial number and model of the

washer/disinfector.

STERIS provides a line of accessories for use with these washers/disinfectors. A STERIS representative will gladly

review these with you.

Please familiarize all users with this manual and store in an accessible location.

Also, refer to GENERAL NOTES – APPLICABLE TO STERILIZER AND WASHER EQUIPMENT DRAWINGS (P062941-091)

for more information about utilities requirements.

Advisory

IMPORTANT: A listing of the Safety Precautions to be observed when operating and servicing these washers/disinfectors can

be found in Section 1.1, Safety Precautions — Introduction of this manual. Do not operate the equipment until you have

become familiar with this information.

STERIS does not intend, recommend or represent in any way that the AMSCO 7052HP Single-Chamber

Washer/Disinfector and the AMSCO 7053HP Single-Chamber Washer/Disinfector be used for the terminal disinfection

or sterilization of any regulated medical device. The AMSCO 7052HP Single-Chamber Washer/ Disinfector and the

AMSCO 7053HP Single-Chamber Washer/Disinfector are intended only to perform an initial step in the processing of

soiled, reusable medical devices. If medical devices will be contacting blood or compromised tissues, such devices must

be terminally processed in accordance with device manufacturer's instructions and/or Good Hospital Practices before

each use in human patients.

Any alteration of this equipment not authorized or performed by STERIS will void the warranty. Alteration of this

equipment which could adversely affect its operation and efficacy may violate national, state and local laws or

regulations.

The protection provided by the equipment may be impaired if the equipment is used in a manner not specified by

STERIS.

To help ensure operators are adequately trained in the safe use of the equipment, STERIS recommends:

• all personnel who operate or maintain the equipment are trained in its operation and in its safe use;

• personnel working with toxic chemicals and vapors (if applicable) have comprehensive instructions in the

washer/disinfector process, relevant health hazards and methods to detect the escape of toxic materials;

• there is regular training of all personnel concerned with the operation and maintenance of the equipment;

attendance records are maintained; and that evidence of understanding is demonstrated;

• current Safety Data Sheets (SDS) should be available to all users in the department. For current SDS, contact

STERIS.

Serious incidents that have occurred in relation to this medical device should be reported to the manufacturer and

competent authority in the country where the incident occurred.

— A Word from STERIS

3

Operator Manual AMSCO®7000 Series 10432589_G

Waste Products Disposal

The following are waste materials associated with the washers/disinfectors. When disposing of waste materials,

ensure disposal is in compliance with federal, state and local regulations.

• Printer paper - Recyclable.

• Printer ribbon - Not recyclable.

• Optional bar code reader battery - Lithium-Ion battery. Refer to local Regulatory and other laws and regulations

about the proper disposal.

• HEPA Filter - Place HEPA filter in a large, sealable bag. Discard the bagged HEPA filter in an outdoor waste

container.

• Chemicals - Dispose in a safe manner in accordance with local/national regulations and current Safety Data Sheets

(SDS).

• Chemical containers - Dispose of empty containers in a safe manner in accordance with local/national regulations.

• Entire washer/disinfector (end-of-life) - Contact STERIS Corporation for disposal or recycling recommendations.

Indications For Use

The AMSCO 7052HP Single-Chamber Washer/Disinfector and the AMSCO 7053HP Single-Chamber Washer/Disinfector

are intended for use in the cleaning and intermediate-level disinfection of soiled reusable simple hard-surfaced rigid

surgical instruments (such as forceps and clamps), utensils (such as bedpans, urinals, trays, bowl, basin and kidney

dishes), rubber and plastic goods, theatre shoes and other similar and related articles found in healthcare facilities.

Service Information

A thorough preventive maintenance program is essential to help ensure safe and proper equipment operation. This

manual contains maintenance schedules and procedures which should be followed for satisfactory equipment

performance. Customers are encouraged to contact STERIS concerning our comprehensive annual maintenance

program. Under the terms of the program, preventive maintenance, adjustments and replacement of worn parts are

performed on a scheduled basis to help ensure equipment performance at peak capability and to help avoid untimely

and costly interruptions.

STERIS maintains a global staff of well-equipped, qualified service technicians to provide this service, as well as

professional repair services. Please contact STERIS for details.

Addresses

The base language of this document

is ENGLISH. Any translation must be

made from the base language

document.

Manufactured by:

STERIS Canada ULC

490 boulevard Armand-Paris

Québec (Québec)

CANADA G1C 8A3

Sales and Service –America, Oceania and Asia:

STERIS Corporation

5960 Heisley Road

Mentor, Ohio 44060

800-548-4873

Sales and Service – Europe, Middle-East and Africa:

STERIS

116 Avenue de Magudas, 33185

Le Haillan

FRANCE

Support Service, by email:

— A Word from STERIS

4

10432589_G AMSCO®7000 Series Operator Manual

All other requests, by phone:

+33 5 56 93 94 94

European Community Representative:

STERIS Ireland Limited

IDA Business and Technology Park

Tullamore

County Offaly

R35 X865

Ireland

Website: www.steris.com

© 2022, STERIS Corporation. All rights reserved. Printed in Canada.

Permissible Environmental Conditions

The AMSCO 7052HP Single-Chamber Washer/Disinfector and the AMSCO 7053HP Single-Chamber Washer/

Disinfector are designed to operate under the following conditions:

• Indoor use only;

• Altitude of operation up to 2000 m (6560 ft);

• Temperature of 5 to 40°C (41 to 104°F);

• Relative humidity of 30% to 80% non-condensing;

• Pollution Degree 2.

Pollution degree 2: Equipment must be installed in an environment where normally only non-conductive pollution

occurs but where occasional, temporary conductivity caused by condensation can be expected (as determined according

to International Standard EN/IEC 61010-1, Third Edition).

Seismic Anchorage System (Accessory)

A seismic anchorage system (based on California requirements) is available for high-risk seismic zones (refer to CBC

2013 report # 10392574 and CBC 2019 report # 1186350).

Noise Level

Equivalent Sound Pressure: 60.6 dB (A). (Results determined according to ISO-3746: 2010 Third Edition Standard:

Acoustics – Determination of sound power levels and sound energy levels of noise sources using sound pressure – Survey

method using an enveloping measurement surface over a reflecting plane.)

Certification

These AMSCO 7052HP Single-Chamber Washer/Disinfector and AMSCO 7053HP Single-Chamber Washer/Disinfector

meet the applicable requirements of the following:

• Safety Standards - General Requirements:

European Union

◻IEC 61010-1: 2010 Safety requirements for electrical equipment for measurement, control, and laboratory use

- Part 1: General requirements; AMD1:2016 Consolidated version, 3rd Edition (publication date 2017-01-10).

United States of America

— A Word from STERIS

5

Operator Manual AMSCO®7000 Series 10432589_G

◻UL 61010-1 Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use -

Part 1: General Requirements, 3rd Edition (2012-05-11).

Canada

◻CAN/CSA C22.2 No. 61010-1-12 Safety Requirements for Electrical Equipment for Measurement, Control, and

Laboratory Use - Part 1: General Requirements, 3rd Edition (R2017).

• Safety Standards - Particular Requirements:

European Union

◻IEC 61010-2-040: 2015 Safety requirements for electrical equipment for measurement, control, and laboratory

use - Part 2-040: Particular requirements for sterilizers and washer-disinfectors used to treat medical

materials 2nd Edition. Dated: 07/07/15

United States of America

◻UL 61010-2-040 Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use

- Part 2-040: Particular Requirements for Sterilizers and Washer-Disinfectors Used to Treat Medical

Materials, 2nd Edition. Dated: 01/15/2016

Canada

◻CAN/CSA-C22.2 No. 61010-2-040:16 Safety Requirements for Electrical Equipment for Measurement, Control,

and Laboratory Use - Part 2-040: Particular Requirements for Sterilizers and Washer-Disinfectors Used to

Treat Medical Materials, 2nd Edition. Dated: 07/01/2016

• Electromagnetic Compatibility (EMC) Standards:

European Union

◻IEC 61326-1:2012 Electrical equipment for measurement, control and laboratory use - EMC Requirements -

Part 1: General Requirements. Dated: 07/2012

– Immunity test reference:

◻IEC 61000-4-2: 2008 Electrostatic discharge immunity test.

◻IEC 61000-4-3: 2006 Radiated radio-frequency, electromagnetic field immunity test (+ A1: 2007 + A2:

2010).

◻IEC 61000-4-4: 2004 Electrical fast transient/burst immunity test.

◻IEC 61000-4-5: 2005 Surge immunity test.

◻IEC 61000-4-6: 2008 Immunity to conducted disturbances, induced by radio-frequency fields.

◻IEC 61000-4-8: 2009 Power Frequency Magnetic Field immunity test.

◻IEC 61000-4-11: 2004-03 Voltage dips, short interruptions and voltage variations immunity tests.

– Emissions test reference:

◻CISPR 11:2015+AMD1:2016 CSV Industrial, scientific and medical equipment - Radio-frequency

disturbance characteristics - Limits and methods of measurement. Edition 6.1. Dated: 06/2016 Class A -

Industrial, Scientific and Medical Equipment.

United States of America / Conducted and Radiated Emission testing

• Federal Communications Commission (FCC) CFR 47, Part 15, Subpart B, Class A Unintentional Radiators for use in

Commercial and Industrial Areas.

INFORMATION TO USER:

— A Word from STERIS

6

10432589_G AMSCO®7000 Series Operator Manual

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provided reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates, uses, and

can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may

cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be required to correct the interference at his own expense.

WARNING: Changes or modifications not expressly approved by STERIS could void the user's authority to operate the

equipment.

Canada / Conducted and Radiated Emission testing

• Industry Canada ICES-001, Issue 4, Class A, Group 1 - Industrial, Scientific and Medical (ISM) Radio Frequency

Generators. Dated: June 2006

LABELING REQUIREMENTS:

Self-Declaration of Compliance (SDoC) to Industry Canada ICES-001.

CE marking

European Union

• Governing Directive for the affixing of the CE mark:

◻Medical Device (Directive 93/42/EEC as amended by 2007/47/EC)

• Conformity to other applicable directives:

◻Machinery (Directive 2006/42/EC)

◻Electromagnetic compatibility (Directive 2014/30/EU)

◻RoHS (Directive 2011/65/EU)

(Medical devices are not covered by the Low Voltage (Directive 2014/35/EU), as the Medical Devices Directive

contains its own electrical safety requirements)

• European Standards applied to demonstrate conformity to the directives:

◻CENELEC EN 61010-1: 2010 Safety requirements for electrical equipment for measurement, control, and

laboratory use - Part 1: General requirements, 3rd Edition.

◻CENELEC EN 61326-1:2013 Electrical equipment for measurement, control and laboratory use - EMC

requirements - Part 1: General requirements. Dated: 01/2013

◻CENELEC EN 55011:2009/A1:2010 Industrial, scientific and medical equipment - Radio-frequency disturbance

characteristics - Limits and methods of measurement

Guidelines and other regulations followed:

• Performance requirements:

European Union

◻EN ISO 15883-1:2009/A1:2014 - Washer-disinfectors - Part 1: General Requirements, Terms and Definitions

and Tests

◻EN ISO 15883-2:2009 - Washer-disinfectors - Part 2: Requirements and tests for washer-disinfectors

employing thermal disinfection for surgical instruments, anesthetic equipment, bowls, dishes, receivers,

utensils, glassware, etc.

United States of America

◻ANSI/AAMI ST15883-1:2009 (R2014) - Washer-Disinfectors - Part 1: General Requirements, Terms and

Definitions and Tests

— A Word from STERIS

7

Operator Manual AMSCO®7000 Series 10432589_G

◻ANSI/AAMI ST15883-2:2013 (R2015) - Washer-Disinfectors - Part 2: Requirements and Tests for Washer-

Disinfectors employing Thermal Disinfection for Surgical Instruments, Anesthetic Equipment, Bowls, Dishes,

Receivers, Utensils, Glassware, Etc.

Canada

◻CAN/CSA-Z15883-1-09 (R2019) - Washer-disinfectors - Part 1: General requirements, terms and definitions

and tests

◻CAN/CSA-Z15883-2-09 (R2019) - Washer-disinfectors - Part 2: Requirements and tests for

washerdisinfectors employing thermal disinfection for surgical instruments, anesthetic equipment, bowls,

dishes, receivers, utensils, glassware, etc.

Building Construction Code:

• United States of America

◻California Building Standards Code (California Code of Regulations, Title 24) for Seismic Anchoring

Requirements

8

10432589_G AMSCO®7000 Series Operator Manual

TABLE OF CONTENTS

Section Number Description Page

1 Safety Precautions ........................................................................................................................................ 1

1.1 Safety Precautions — Introduction .......................................................................................... 1

1.2 Safety Precautions ..................................................................................................................... 1

2 Symbols and Labels....................................................................................................................................... 5

2.1 Equipment Symbols.................................................................................................................... 5

2.2 Nameplate Symbols ................................................................................................................... 5

2.3 Transportation and Storage....................................................................................................... 6

3 Component Identification ............................................................................................................................. 8

3.1 Washer/Disinfector — General................................................................................................. 8

3.2 Control System ......................................................................................................................... 13

3.3 Emergency Safety Features..................................................................................................... 19

3.4 SCS Conveyor System (Option)................................................................................................ 20

3.5 ATLAS Workflow Automation Vehicle System ....................................................................... 21

3.6 Accessories — AMSCO 7052HP WD ...................................................................................... 22

3.7 Accessories — AMSCO 7053HP W/D .................................................................................... 32

3.8 Flexible Hoses for Cannulated Instruments (Accessory) ....................................................... 44

3.9 Chemicals and Cycles ............................................................................................................... 50

4 Operating Instructions ................................................................................................................................ 56

4.1 Operating Instructions — Introduction................................................................................... 56

4.2 Before Operating Equipment ................................................................................................... 57

4.3 Loading Washer/Disinfector Manually.................................................................................... 58

4.4 Loading Washer/Disinfector With a Washer Automation System........................................ 60

4.5 Typical Cycle Operation ............................................................................................................ 64

4.6 Unloading Washer/Disinfector ................................................................................................ 68

4.7 Visual Inspection....................................................................................................................... 69

4.8 Responding to an Alarm........................................................................................................... 69

4.9 Aborting Cycle Operation ......................................................................................................... 71

4.10 Shutdown .................................................................................................................................. 72

4.11 Standby ..................................................................................................................................... 72

4.12 Power Door Operation ............................................................................................................. 75

5 Cycle and Control Value Programming ..................................................................................................... 77

5.1 Cycle and Control Value Programming — General ................................................................ 77

5.2 Supervisor Mode Menus .......................................................................................................... 97

5.3 Cycles Menu .............................................................................................................................. 99

5.4 Transfer Cycle Reports Menu ................................................................................................103

5.5 Miscellaneous Menu...............................................................................................................104

5.6 Password Menu......................................................................................................................107

5.7 Chemical Pumps Name Menu................................................................................................108

5.8 Prime Chemical Pumps Menu................................................................................................110

5.9 Units Menu..............................................................................................................................111

5.10 Print Menu (Accessory) ..........................................................................................................112

5.11 Date and Time Menus ............................................................................................................113

5.12 Language Menu ......................................................................................................................114

5.13 Software Version Menu .........................................................................................................114

9

Operator Manual AMSCO®7000 Series 10432589_G

5.14 Test Menu ...............................................................................................................................115

5.15 Cycle History Menu.................................................................................................................116

5.16 Formatting USB Key ...............................................................................................................124

6 Routine Maintenance ................................................................................................................................131

6.1 Preventive Maintenance ........................................................................................................131

6.2 Routine Maintenance .............................................................................................................132

6.3 Cleaning Debris Screen...........................................................................................................134

6.4 Cleaning Water Outlet Connection ........................................................................................136

6.5 Cleaning Door Gasket .............................................................................................................136

6.6 Cleaning Washer/Disinfector Exterior...................................................................................137

6.7 Processing DECONTAMINATION Cycle .................................................................................138

6.8 Replacing Chemical Container ...............................................................................................140

6.9 Changing Printer Paper Roll and Printer Ink Cartridge (Accessory) ....................................142

6.10 Changing Thermal Printer Paper Roll (Accessory)................................................................145

6.11 Inspecting and Cleaning Rotary Spray Arm Assemblies AMSCO 7052HP W/D ...............147

6.12 Inspecting and Cleaning Rotary Spray Arm Assemblies - AMSCO 7053HP W/D .............151

6.13 Door Safety Test.....................................................................................................................156

6.14 Sump Safety Level Test..........................................................................................................157

6.15 Water Inlet Pressure Test ......................................................................................................158

6.16 Verifying Emergency Stop Pushbuttons ..............................................................................161

7 Troubleshooting.........................................................................................................................................164

7.1 Troubleshooting — Introduction...........................................................................................164

7.2 Troubleshooting — General ..................................................................................................164

7.3 ABNORMAL CONDUCTIVITY READINGS FOR THERMAL RINSE DRAINING .......................165

7.4 ABNORMAL NOISE GENERATED BY WASHER/DISINFECTOR ............................................166

7.5 AIR PRESSURE TOO LOW ......................................................................................................166

7.6 AUTO-DOCKING TRANSFER CART DOES NOT REMAIN DOCKED TO TRANSFER CART

ADAPTOR ................................................................................................................................167

7.7 CHAMBER DOES NOT DRAIN PROPERLY.............................................................................167

7.8 CHAMBER ROTARY SPRAY ARM ASSEMBLY DOES NOT ROTATE DURING

CYCLE.......................................................................................................................................167

7.9 CLEAN SUMP FILTER..............................................................................................................168

7.10 CYCLE HISTORY DOWNLOAD DUE ........................................................................................168

7.11 CYCLE HISTORY IS FULL.........................................................................................................168

7.12 DECONTAMINATION CYCLE DUE...........................................................................................169

7.13 DELETE ALL HISTORY FILES DOES NOT RESET REMINDER DISPLAY

CONDITION..............................................................................................................................169

7.14 DISPLAY BLANK; NO ACKNOWLEDGMENT WHEN TOUCH PADS PRESSED .....................169

7.15 DOOR SAFETY TEST DUE.......................................................................................................170

7.16 EXCESSIVE FOAMING DURING PRE-WASH, PHASE REPEATED ........................................170

7.17 EXCESSIVE FOAM IN CHAMBER............................................................................................171

7.18 HAND-HELD BAR CODE READER (EMEA OPTION) DOES NOT SCAN ................................171

7.19 BAR CODE READER DOES NOT OPERATE PROPERLY ........................................................171

7.20 TRANSFER DOES NOT OCCUR BETWEEN CONVEYORS AND CHAMBER ..........................172

7.21 GENERATED PRINTOUT IS LIGHT OR BLANK, OR PARTS OF CHARACTERS ARE

MISSING ..................................................................................................................................172

7.22 PAPER IS NOT TAKEN UP INTO POWER TAKE-UP ..............................................................172

7.23 PRINTER DOES NOT WORK ...................................................................................................173

7.24 PRINTER PRINTOUT IS ERRATIC ...........................................................................................173

10

10432589_G AMSCO®7000 Series Operator Manual

7.25 INVALID DIRECTORY NAME ...................................................................................................173

7.26 LOAD COMES OUT DIRTY AT THE END OF CYCLE ...............................................................174

7.27 LOAD COMES OUT WET AT THE END OF A CYCLE ..............................................................175

7.28 PREVENTIVE MAINTENANCE DUE ........................................................................................175

7.29 NO AUDIBLE ALARM SIGNAL WHEN ALARM OCCURS, WHEN CYCLE IS COMPLETED,

ETC...........................................................................................................................................176

7.30 NO CODE DETECTED OR CYCLE LOCKED OR INVALID CODE ..............................................176

7.31 PHASE STOPS FOR NO APPARENT REASON.......................................................................176

7.32 PLEASE CLOSE DOOR.............................................................................................................177

7.33 PRINTER NOT CONNECTED ...................................................................................................177

7.34 PUMP STARTS BEFORE APPROPRIATE CHAMBER WATER LEVEL IS REACHED .............177

7.35 RETRIEVAL FAILED, NETWORK CONNECTION ERROR........................................................178

7.36 RETRIEVAL FAILED, NO LOAD NUMBER READY..................................................................178

7.37 RINSE RESERVOIR LEAKING..................................................................................................178

7.38 RINSE RESERVOIR NOT HEATING.........................................................................................179

7.39 SAVE COMPLETE SOME CORRUPT FILES WERE DISCARDED ............................................179

7.40 STATUS LIGHT DOES NOT TURN ON ....................................................................................179

7.41 SUMP SAFETY LEVEL TEST DUE ...........................................................................................180

7.42 TEST FAILED: CALL STERIS ....................................................................................................180

7.43 TOUCH SCREEN DOES NOT WORK PROPERLY....................................................................180

7.44 UNLOAD CONVEYOR NOT READY.........................................................................................181

7.45 UNLOAD DOOR DOES NOT OPEN .........................................................................................181

7.46 °F DIFFERENT ON PRINTOUT AND CAT; OR THERMAL DISINF. PASSED AS SHOWN

IN PROCONNECT ....................................................................................................................181

7.47 ENTIRE PARAMETERS OF LONG CYCLE NOT PRINTED OR REBOOT AFTER

DOUBLE/LONG PRINT JOBS ..................................................................................................182

7.48 WASHER NOT CALIBRATED...................................................................................................182

7.49 WASHER STUCK IN PHASE: PREPARING FOR STANDBY, DRAINING

RESERVOIR..............................................................................................................................182

7.50 WATER LEAKS FROM WASHER/DISINFECTOR....................................................................183

7.51 ALARM# 1 LOAD DOOR OPEN (CRITICAL) ............................................................................183

7.52 ALARM# 2 UNLOAD DOOR OPEN (CRITICAL).......................................................................183

7.53 SYSTEM ERROR# 3 CYCLES RETURNED TO DEFAULT VALUES (CRITICAL).......................184

7.54 ALARM# 4 SUMP TOO LONG TO FILL (CRITICAL).................................................................184

7.55 ALARM# 5 SUMP NOT DRAINED (NON-CRITICAL) ..............................................................185

7.56 ALARM# 6 WATER REMAINED IN CHAMBER (CRITICAL) ....................................................185

7.57 ALARM# 7 SUMP TOO LONG TO HEAT (NON-CRITICAL) ....................................................186

7.58 ALARM# 8 SUMP SAFETY WATER LEVEL REACHED (CRITICAL) ........................................187

7.59 ALARM# 9 RECIRCULATION TEMPERATURE PROBE #1 DEFECTIVE (CRITICAL) ..............187

7.60 ALARM# 10 SUMP TEMPERATURE TOO HIGH (CRITICAL)..................................................187

7.61 ALARM# 11 DRYING TEMPERATURE TOO HIGH (CRITICAL)...............................................188

7.62 ALARM# 12 SUMP OVER TEMPERATURE SWITCH TRIPPED (CRITICAL) ..........................188

7.63 ALARM# 13 PUMP DID NOT START (CRITICAL) ...................................................................189

7.64 ALARM# 14 DRYING OVER TEMPERATURE SWITCH TRIPPED (CRITICAL)........................189

7.65 ALARM# 15 RECIRCULATION TEMPERATURE PROBE #2 DEFECTIVE (CRITICAL)............190

7.66 ALARM# 16 CHEMICAL INJECTED VOLUME TOO LOW (CRITICAL) .....................................190

7.67 ALARM# 17 RECIRCULATION TEMP. PROBES VARIANCE EXCEEDS RANGE

(CRITICAL) ................................................................................................................................191

7.68 ALARM# 18 MOTOR OVERLOAD DETECTED (CRITICAL) .....................................................191

11

Operator Manual AMSCO®7000 Series 10432589_G

7.69 ALARM# 19 POWER FAILURE DURING CYCLE (ABORT PROGRESS...) ...............................191

7.70 SYSTEM ERROR# 20 I/O BOARDS OR CLOCK FAILURE (CRITICAL) ....................................192

7.71 SYSTEM ERROR# 21 CYCLE AND UNIT CONFIG. RESET TO DEFAULT (CRITICAL) ............192

7.72 ALARM# 22 EMERGENCY STOP PRESSED (CRITICAL) ........................................................193

7.73 ALARM# 23 PRESSURE TRANSMITTER DEFECTIVE (CRITICAL) .........................................193

7.74 ALARM# 24 LOAD DOOR DID NOT OPEN (NON-CRITICAL).................................................194

7.75 ALARM# 25 LOAD DOOR DID NOT CLOSE (NON-CRITICAL) ...............................................194

7.76 ALARM# 26 LOAD DOOR OBSTRUCTED (NON-CRITICAL)...................................................195

7.77 ALARM# 27 UNLOAD DOOR NOT OPEN (NON-CRITICAL) ..................................................195

7.78 ALARM# 28 UNLOAD DOOR DID NOT CLOSE (NON-CRITICAL) ..........................................196

7.79 ALARM# 29 UNLOAD DOOR OBSTRUCTED (NON-CRITICAL) .............................................196

7.80 ALARM# 30 WATER LEVEL DEFECTIVE (CRITICAL)..............................................................197

7.81 ALARM# 31 LOW PRESSURE DETECTED (NON-CRITICAL) .................................................198

7.82 ALARM# 32 DRYING SYSTEM NOT HEATING (CRITICAL) ....................................................199

7.83 ALARM# 34 CONDUCTIVITY TRANSMITTER DEFECTIVE (CRITICAL) ..................................200

7.84 ALARM# 35 DRYING TEMPERATURE PROBES VARIANCE EXCEEDS RANGE

(CRITICAL) ................................................................................................................................200

7.85 ALARM# 36 DRYING TEMPERATURE PROBE #2 DEFECTIVE (CRITICAL) ..........................200

7.86 ALARM# 37 DRYING TEMPERATURE PROBE #1 DEFECTIVE (CRITICAL) ..........................201

7.87 ALARM# 38 READ/WRITE ERROR ........................................................................................201

7.88 ALARM# 40 SOFTWARE APPLICATION ERROR ...................................................................202

7.89 ALARM# 41 CHEMICAL CONTAINER [X] EMPTY..................................................................202

7.90 ALARM# 42 CHEMICAL CONTAINER [X] EMPTY..................................................................203

7.91 ALARM# 43 CHEMICAL CONTAINER [X] EMPTY..................................................................203

7.92 ALARM# 44 CHEMICAL CONTAINER [X] EMPTY..................................................................204

7.93 ALARM# 45 CHEMICAL CONTAINER [X] EMPTY..................................................................204

7.94 ALARM# 46 RINSE RESERVOIR TOO LONG TO FILL (CRITICAL)..........................................205

7.95 ALARM# 47 RINSE RESERVOIR WATER LEVEL SWITCH DEFECTIVE (CRITICAL) ..............205

7.96 ALARM# 48 RINSE RESERVOIR SAFETY WATER LEVEL SWITCH REACHED

(CRITICAL) ................................................................................................................................206

7.97 ALARM# 49 RINSE RESERVOIR TRANSFER MALFUNCTION (CRITICAL) ............................206

7.98 ALARM# 50 RINSE RESERVOIR TEMPERATURE TOO HIGH (CRITICAL).............................206

7.99 ALARM# 51 RINSE RESERVOIR OVERTEMPERATURE SWITCH TRIPPED

(CRITICAL) ................................................................................................................................207

7.100 ALARM# 52 COMMUNICATION WITH DRAIN COOLDOWN CONTROLLER LOST

(CRITICAL) ................................................................................................................................207

7.101 ALARM# 53 RINSE RESERVOIR TEMPERATURE PROBE DEFECTIVE (CRITICAL)..............208

8 Replacement Parts and Consumables.....................................................................................................209

9 Software Code Copyright..........................................................................................................................210

1 — Safety Precautions

1

10432589_G AMSCO®7000 Series Operator Manual

Safety Precautions

1.1 Safety Precautions — Introduction

The following Safety Precautions must be observed when uncrating/installing, operating or servicing this equipment.

WARNING indicates the potential for personal injury and CAUTION indicates the potential for damage to equipment. It

is important to review ALL Safety Precautions before operating or servicing the equipment.

Strictly following these Safety Precautions enhances the Customer’s ability to safely and effectively utilize the unit and

helps avoid improper maintenance methods which may damage the unit or render it unsafe. It is important to

understand that these Safety Precautions are not exhaustive; Customers are encouraged to develop their own safety

policies and procedures to enhance and complement these Safety Precautions.

1.2 Safety Precautions

WARNING

PERSONAL INJURY AND/OR EQUIPMENT DAMAGE HAZARD

Always load empty baskets on appropriate loading cart or surface.

Always use a hold-down screen to secure small or light items. While loading instrument

racks, do not place miscellaneous articles on the sides of instrument trays. Incorrect

rack loading/overloading could lead to injury and/or damage to the equipment or

instruments.

Always wear Personal Protective Equipment (PPE) appropriate for the task to be

performed.

Do not place empty baskets on the conveyor modules to load soiled articles. If you do,

the proximity sensor will detect the baskets and indexing will automatically start.

If an obstruction is present in the wash chamber door, the door safety bar will detect an

obstruction and the door will automatically stop from closing. Wait until door is fully

open before removing obstruction.

Regularly scheduled routine maintenance, as well as preventive maintenance, are

required for safe and reliable operation of this equipment. Routine maintenance

procedures are explained in this manual. For preventive maintenance, contact STERIS to

schedule preventive maintenance or obtain the necessary Maintenance Manual if

preventive maintenance is done by the Customer.

1 — Safety Precautions

2

Operator Manual AMSCO®7000 Series 10432589_G

Maximum operating weight, including weight of basket and load, is 61 kg (135 lb) for

the AMSCO 7052HP Single-Chamber Washer/Disinfector and 73 kg (160 lb) for the

AMSCO 7053HP Single-Chamber Washer/Disinfector.

Repairs and adjustments to this equipment must be made only by STERIS or STERIS-

trained service personnel. Repairs and adjustments performed by unqualified personnel

or installation of unauthorized parts could cause personal injury, result in improper

equipment performance, void the warranty or result in costly damage. Contact STERIS

regarding service options.

Never use long racks or long accessories in the AMSCO 7052HP Single-Chamber

Washer/Disinfector as they are only meant to be used in the AMSCO 7053HP Single-

Chamber Washer/Disinfector.

WARNING

PERSONAL INJURY HAZARD

Risk of pinch point between door and threshold when the door opens. Keep fingers

away from threshold.

Risk of pinch point between door and upper panel. Do not push on top portion of doors;

do not push on door when door is rising; do not push on door when door is jammed.

When baskets are present on the conveyor modules, keep fingers and hands away from

wash chamber doors and moving baskets.

If it ever occurs that the sensor does not detect a door obstruction, never use your hand

to push on the obstruction trying to dislodge it. Call STERIS for this abnormal situation.

1 — Safety Precautions

3

10432589_G AMSCO®7000 Series Operator Manual

WARNING

ELECTRIC SHOCK AND/OR BURN HAZARD

Fasteners and star washers are used to ensure protective bonding continuity. Always

reinstall any star washer which may have been removed during installation or servicing.

Pressing bottom portion of POWER (ON/OFF) toggle switch to turn off

washer/disinfector DOES NOT cut off electrical power. Lockout/Tagout building

electrical disconnect switch to turn off power to washer/disinfector for maintenance or

repairs.

Repairs and adjustments to this equipment must be made only by STERIS or STERIS-

trained service personnel. Service personnel must disconnect all utilities to unit before

servicing. No one should service unit unless all utilities have been properly locked out.

Always follow local electrical codes and safety-related work practices.

WARNING

CHEMICAL BURN AND/OR EYE INJURY HAZARD

Chemicals are caustic and can cause adverse effects to exposed tissues. Do not get in

eyes, on skin or attempt to swallow. Read and follow the precautions and instructions

on the chemical label and in the Safety Data Sheet (SDS) prior to handling the chemical,

refilling the chemical container or servicing the chemical injection pump. Wear

appropriate Personal Protective Equipment (PPE) whenever handling the chemical or

servicing the chemical injection pump and lines.

Wear gloves and eye protection when using a chemical. Avoid contact with the eyes or

skin. If a chemical spills or splashes on you, flush the affected area with water for 15

minutes. If swallowed, DO NOT induce vomiting. Seek medical attention immediately.

WARNING

BURN HAZARD

In case of an emergency, always stop cycle by pressing Emergency Stop pushbutton

and wait for water flow to stop prior to trying to open door. Wear appropriate Personal

Protective Equipment (PPE) whenever reaching into the chamber.

Inner surfaces of washer/disinfector are very hot after cycle is completed. Allow

washer/disinfector to cool down before touching chamber. Always wear appropriate

Personal Protective Equipment (PPE), including gloves as well as a face shield, and avoid

all contact with inner walls when reaching into chamber.

1 — Safety Precautions

4

Operator Manual AMSCO®7000 Series 10432589_G

Rack and items are extremely hot when cycle is completed. Allow rack and items to cool

to room temperature and always wear appropriate Personal Protective Equipment (PPE)

before reaching into chamber.

WARNING

SLIPPING HAZARD

To prevent slips, keep floors dry. Promptly clean up any spills or drippage. For spills or

drippage of detergents or other chemicals, follow safety precautions and handling

procedures set forth on detergent or chemical label and/or Safety Data Sheet (SDS).

CAUTION

POSSIBLE EQUIPMENT DAMAGE

Always position manifold rack over the manifold connector before operating

washer/disinfector. If manifold rack and/or bottom rotary spray arm assembly are not

positioned correctly, damage may result and washer/disinfector will be unable to

effectively wash load.

Always select a cycle appropriate for the items being processed. Failure to do so may

result in product damage.

Suction tips (as well as other items) must be fully enclosed within the accessory (curved

suction tips facing inward) to prevent obstruction in conveyor system.

Use nonabrasive cleaners when cleaning unit. Follow directions on containers and rub in

a back-and-forth motion (in same direction as surface grain). Abrasive cleaners will

damage stainless steel. Cleaners rubbed in a circular motion or applied with a wire

brush or steel wool on door and chamber assemblies can be harmful to stainless steel.

Do not use these cleaners on painted surfaces.

When choosing a detergent, select one with a low-chloride content. Detergents with a

high-chloride content must not be used, as such detergents may harm stainless steel.

Wipe all plastic surfaces or painted surfaces with 70% isopropyl alcohol cleaner (such as

glass or countertop cleaners).

2 — Symbols and Labels

5

10432589_G AMSCO®7000 Series Operator Manual

Symbols and Labels

2.1 Equipment Symbols

The table below contains symbols which may be on your washer/disinfector components:

Symbol Definition

Attention. Refer to Manual For Further Instructions.

Transfer of Heat. Hot Surface.

Protective Earth (Ground).

Warning! Risk of Electrical Shock.

ON (For Part of Equipment).

OFF (For Part of Equipment).

Risk of Crushing Fingers or Hands.

2.2 Nameplate Symbols

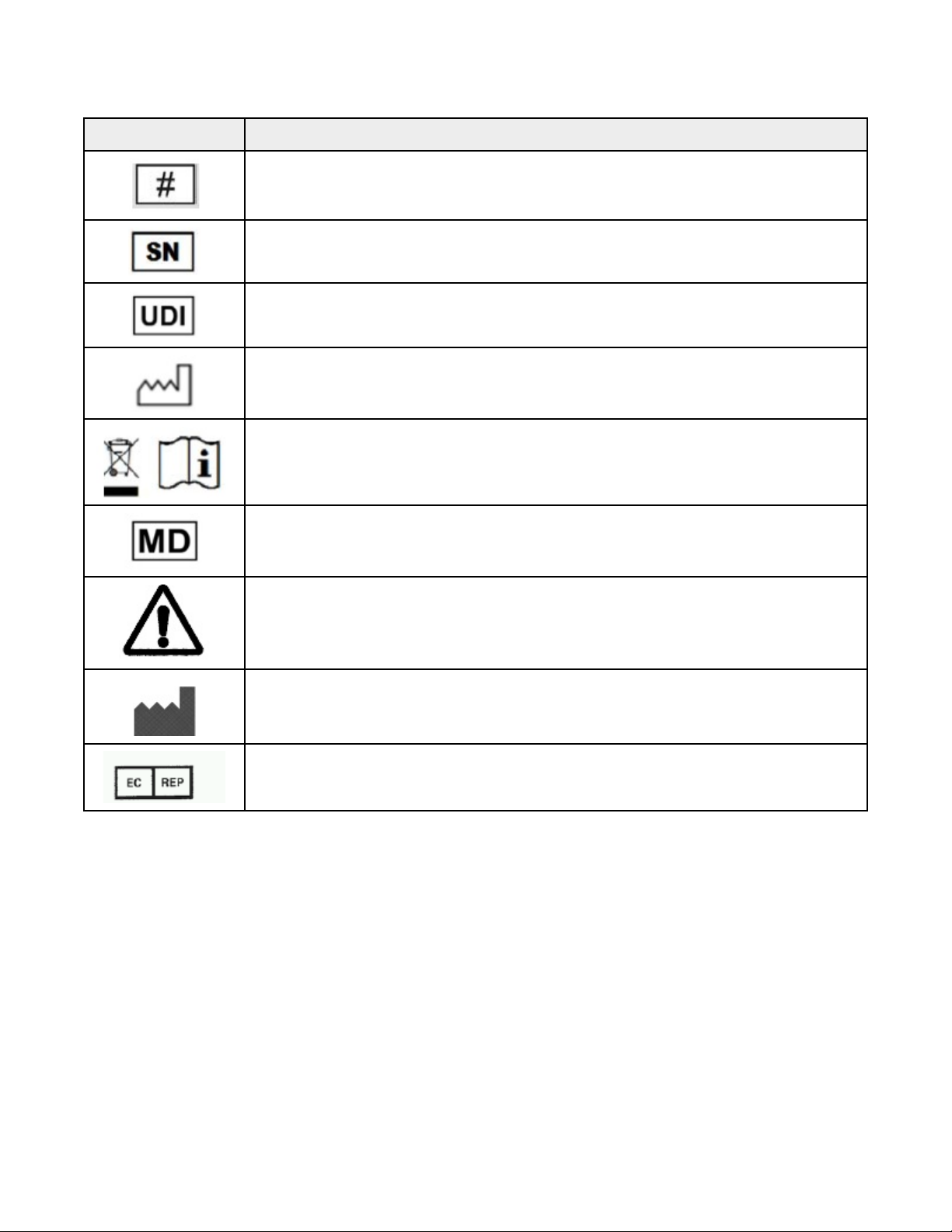

The table below contains symbols which may be on the identification nameplate of your equipment:

2 — Symbols and Labels

6

Operator Manual AMSCO®7000 Series 10432589_G

Table 2-1. Definition of Symbols

Symbol Definition

Model of Equipment.

Serial Number of Equipment.

Unique Device Identification.

Year of Manufacture of the Equipment.

Safe Disposal of the Device — Refer to Instruction for Use.

Medical Device.

Power Rating of Processor: Voltage, Frequency (Hertz), Type of Supply.

Address of Manufacturing Facility.

Address of European Community Representative.

2.3 Transportation and Storage

Symbols on the shipping crates stipulate equipment transport and storage environmental conditions for temperature

and relative humidity as well as storage conditions and handling information.

2 — Symbols and Labels

7

10432589_G AMSCO®7000 Series Operator Manual

Table 2-2. Definition of Symbols on Crates

Symbol Definition

Maximum Shipping and Storing Temperature.

Maximum Humidity Level.

This Way Up.

Do not Stack.

Fragile.

Keep Dry.

3 — Component Identification

8

Operator Manual AMSCO®7000 Series 10432589_G

Component Identification

3.1 Washer/Disinfector — General

Before operating the AMSCO® 7052HP Single-Chamber Washer/Disinfector and/or the AMSCO® 7053HP Single-

Chamber Washer/Disinfector, it is important to become familiar with the location and function of all major components

and controls (see Figure 3-1 to Figure 3-10).

NOTE: Installation configuration may vary. See Figure 3-1 for a typical washer/disinfector configuration.

This manual suits for next models

2

Table of contents

Other Steris Washer manuals

Steris

Steris RELIANCE 400 User manual

Steris

Steris BASIL 9500 User manual

Steris

Steris AMSCO 5000 Series User manual

Steris

Steris Reliance 1227 User manual

Steris

Steris ML 200 User manual

Steris

Steris RELIANCE 200 User manual

Steris

Steris ML 222 User manual

Steris

Steris Basil 4600 User manual

Steris

Steris AMSCO RELIANCE 430 User manual

Steris

Steris RELIANCE 400 User manual