Steris Basil 4600 User manual

OPERATOR MANUAL

Basil 4600 Cage and Rack Washer

Basil 4602 Cage and Rack Washer

(2008-06-12) P122997-341

i

Introduction Operator Manual 122997-341

A WORD FROM STERIS CORPORATION

This manual contains important information on proper use and main-

tenance of this equipment. Refer to SECTION 6, ROUTINE MAINTE-

NANCE,for instructions in routine care of this washer. All personnel

involved in the use and maintenance of this equipment must

carefully review and comply with the warnings, cautions and

instructions contained in this manual. These instructions are

important to protect the health and safety of personnel operating a

Basil®4600 Cage and Rack Washer or a Basil®4602 Cage and

Rack Washer and should be retained in a conveniently accessible

area for quick reference.

This equipment is specifically designed only for the uses outlined in

this manual.

Complete instructions for uncrating and connecting utilities, as well

as equipment drawings, have been provided. If they are missing,

contact STERIS for replacement copies, providing the serial and

model numbers of the unit.

Advisory IMPORTANT: A listing of the Safety Precautions to be observed

when operating this washer can be found in SECTION 1. Do not oper-

ate the equipment until you have become familiar with this informa-

tion.

Any alteration of this equipment not authorized or performed by

STERIS could void the warranty, adversely affect its efficacy and vio-

late national, state and local regulations.

To help assure operators are adequately trained in the safe use of

the equipment, STERIS recommends that:

• all personnel who operate or maintain the equipment are trained

in its operation and in its safe use;

• personnel working with toxic chemicals and vapors (if

applicable) have comprehensive instructions in the unit, washing

process, relevant health hazards and methods to detect the

escape of toxic materials;

• there is regular training of all personnel concerned with the

operation and maintenance of the equipment; attendance

records are maintained; and the evidence of understanding is

demonstrated.

©2008, STERIS Corporation. All rights reserved. Printed in Canada.

ii

122997-341 Operator Manual Introduction

Indications For Use The Basil 4600 Cage and Rack Washer and Basil 4602 Cage and

Rack Washer are heavy duty, large capacity hydrospray washers

designed for thorough, efficient cleaning of cages, racks, debris

pans and miscellaneous items used in the care of laboratory ani-

mals.

These units are specifically designed to only process goods as out-

lined in this manual. If there is any doubt about a specific material or

product, contact the manufacturer of the product for the recom-

mended washing technique.

Service Information A thorough preventive maintenance program is essential to safe and

proper unit operation. This manual contains maintenance schedules

and procedures which should be followed for satisfactory equipment

performance.

Customers are encouraged to contact STERIS concerning extended

service maintenance agreements to give their equipment planned

maintenance assuring equipment performance according to factory

specifications.

A global network of skilled service specialists can provide periodic

inspections and adjustments to help ensure low-cost peak perfor-

mance. STERIS representatives can provide information regarding

annual maintenance agreements. STERIS carries a complete line of

accessories for use with this washer. Please contact STERIS for

details.

Basil 4600 Cage and Rack Washer and Basil 4602 Cage and Rack

Washer meet the application requirements of the following standard:

• 61010-1 Electrical Equipment for measurement; control and

laboratory use; Part 1 General requirements as certified by

Underwriters Laboratories (UL).

Manufacturer:

Corporation STERIS

Canada

Beauport, Qc, CANADA

ISO 13485

ISO 9001

Certified

Facility

The base language of this document is

ENGLISH. Any translations must be made

from the base language document.

Sales and Service:

STERIS Corporation

5960 Heisley Road

Mentor, Ohio 44060

440-354-2600 • 800-444-9009

www.steris.com

iii

122997-341 Operator Manual Table of Contents

TABLE OF CONTENTS

Section

Number Description Page

A WORD FROM STERIS CORPORATION................................................................. I

Advisory ........................................................................................................................................................... i

Indications For Use .........................................................................................................................................ii

Service Information .........................................................................................................................................ii

1 SAFETY PRECAUTIONS .....................................................................................1-1

2 INSTALLATION CHECKLIST ...............................................................................2-1

2.1 General .................................................................................................................................................. 2-1

2.1.1 Technical specifications ................................................................................................................. 2-1

2.1.2 Amperage and Power Consumption .............................................................................................. 2-1

2.1.3 Permissible Environmental Conditions ........................................................................................... 2-2

2.1.4 Noise Level ..................................................................................................................................... 2-2

2.1.5 Seismic Anchorage System ........................................................................................................... 2-2

2.2 Installation Checklist .............................................................................................................................. 2-2

2.3 Chemical Additives Specifications ........................................................................................................ 2-4

3 COMPONENT IDENTIFICATION ..........................................................................3-1

3.1 General .................................................................................................................................................. 3-1

3.2 POWER-OFF/STANDBY Switch ............................................................................................................. 3-2

3.3 Interior Light ........................................................................................................................................... 3-2

3.4 Control Panel ......................................................................................................................................... 3-3

3.4.1 Display Screen ............................................................................................................................... 3-3

3.4.2 Cycle Status Touch Pads ............................................................................................................... 3-3

3.4.3 Manual Control Touch Pads ........................................................................................................... 3-4

3.4.4 Program Touch Pads ..................................................................................................................... 3-4

3.5 Printer .................................................................................................................................................... 3-5

3.5.1 Printer Function Switch ................................................................................................................... 3-5

3.5.2 Sample Printout .............................................................................................................................. 3-6

3.6 Unload-Side Control Panel .................................................................................................................... 3-7

3.7 Oscillating Jet System ........................................................................................................................... 3-7

3.8 Safety System ........................................................................................................................................ 3-8

3.9 Heat Exchanger ..................................................................................................................................... 3-9

3.10 Automatic Detergent Injection System ................................................................................................ 3-9

3.11 Reusable-Throwaway Acid Detergent System ..................................................................................3-10

3.12 Non- Recirculated Final Rinse ........................................................................................................... 3-10

3.13 Feeder Bottle Washing System ......................................................................................................... 3-11

Continued...

iv

Table of Contents Operator Manual 122997-341

TABLE OF CONTENTS (Cont’d)

Section

Number Description Page

3 COMPONENT IDENTIFICATION (Cont’d)

3.14 Automatic Water Flush System for Two Racks .................................................................................. 3-11

3.15 Drain Discharge Cooldown with Side Tank and Temperature Guarantee ........................................ 3-12

3.16 Drain Discharge Cooldown System with Cold Water Injection Only ................................................. 3-13

3.17 Exhaust Fan ....................................................................................................................................... 3-13

4 WASHER OPERATION .........................................................................................4-1

4.1 Before Operating Washer ...................................................................................................................... 4-1

4.2 How to Load Washer ............................................................................................................................. 4-2

4.3 Cycle Operation ..................................................................................................................................... 4-4

4.4 Review and Print Specific Cycle Program ........................................................................................... 4-17

4.5 Stop Cycle Operation .......................................................................................................................... 4-19

4.6 Abort Cycle Operation ......................................................................................................................... 4-19

4.7 Extend Cycle Phase Time .................................................................................................................... 4-20

4.7.1 During a Cycle ............................................................................................................................. 4-20

4.7.2 Prior to Starting a Cycle ............................................................................................................... 4-20

4.8 Bypass Phase ...................................................................................................................................... 4-22

4.9 Shutdown Procedure ........................................................................................................................... 4-22

4.10 Manual Control Mode ........................................................................................................................ 4-23

4.10.1 Accessing Manual Control Mode ............................................................................................... 4-24

4.10.2 FILL Function .............................................................................................................................. 4-24

4.11 DRAIN Function ................................................................................................................................. 4-25

4.11.1 Draining Sump ........................................................................................................................... 4-25

4.11.2 Draining Alkaline Tank ............................................................................................................... 4-26

4.11.3 Draining Acid Tank ..................................................................................................................... 4-27

4.11.4 Draining Cooldown Tank ............................................................................................................ 4-27

4.12 PUMP/DRV Function .......................................................................................................................... 4-28

4.13 DRIVE Function .................................................................................................................................. 4-29

5 CYCLE PROGRAMMING ......................................................................................5-1

5.1 Program Touch Pads ............................................................................................................................. 5-1

5.2 Change Values Mode ............................................................................................................................ 5-1

5.3 Programming Cycle Values ................................................................................................................... 5-3

5.3.1 Pre-Wash ........................................................................................................................................ 5-4

5.3.2 Alkaline Wash ................................................................................................................................. 5-4

5.3.3 Acid Wash ...................................................................................................................................... 5-5

5.3.4 Rinse .............................................................................................................................................. 5-7

Continued...

v

122997-341 Operator Manual Table of Contents

TABLE OF CONTENTS

Section

Number Description Page

5 CYCLE PROGRAMMING (Cont’d)

5.4 Programming Operating Values .......................................................................................................... 5-10

5.5 Programming Values with Access Code Enabled ............................................................................... 5-11

6 ROUTINE MAINTENANCE ...................................................................................6-1

6.1 General .................................................................................................................................................. 6-1

6.2 Preventive Maintenance Schedule ........................................................................................................ 6-2

6.3 Daily Cleaning Procedures .................................................................................................................... 6-4

6.4 Weekly Cleaning Procedures ................................................................................................................ 6-5

6.4.1 Clean Washer Exterior..................................................................................................................... 6-5

6.4.2 Clean Washer Interior ..................................................................................................................... 6-5

6.4.3 Clean Spray Jets and Headers ...................................................................................................... 6-6

6.4.4 Inspect Self-Cleaning Screen ........................................................................................................ 6-7

6.5 Monthly Cleaning Procedures ............................................................................................................... 6-8

6.5.1 Remove Hard Water Deposits From Chamber and Accessories .................................................. 6-8

6.6 Routine Maintenance ............................................................................................................................. 6-9

6.6.1 Grease Exhaust Fan Bearings ....................................................................................................... 6-9

6.6.2 Clean Drain Discharge Side Tank ................................................................................................ 6-10

6.6.3 Clean Drain Discharge Temperature Control Probe .................................................................... 6-12

6.6.4 Replace Detergent Squeeze Tube ............................................................................................... 6-13

6.6.5 Replacing Detergent Container ................................................................................................... 6-14

6.7 Printer Paper ........................................................................................................................................ 6-15

6.7.1 Printer Paper Roll Replacement ................................................................................................... 6-15

6.7.2 Storing Thermal Paper ................................................................................................................. 6-17

7 TROUBLESHOOTING .......................................................................................... 7-1

5.1 Test Procedure – Allen-Bradley Control ................................................................................................ 5-1

5.2 Test Procedure – Siemens Control ........................................................................................................ 5-7

TABLE OF CONTENTS (Cont’d)

vi

Table of Contents Operator Manual 122997-341

TABLE OF CONTENTS (Cont’d)

Section

Number Description Page

2 INSTALLATION CHECKLIST

2-1 Shutoff Valves and Disconnect switch ................................................................................................. 2-1

3 COMPONENT IDENTIFICATION

3-1 Washer Components - Basil 4600 (Typical) ........................................................................................ 3-1

3-2 Control Column ................................................................................................................................... 3-2

3-3 Control Panel ....................................................................................................................................... 3-3

3-4 Printer .................................................................................................................................................. 3-5

3-5 Sample Printout ................................................................................................................................... 3-6

3-6 Sample Alarm Printout ......................................................................................................................... 3-6

3-7 Unload-Side Control Panel .................................................................................................................. 3-7

3-8 Oscillating Jet System ......................................................................................................................... 3-7

3-9 Safety Cables ...................................................................................................................................... 3-8

3-10 Heat Exchanger .................................................................................................................................. 3-9

3-11 Non-Recirculated Final Rinse Spray Header .................................................................................... 3-10

3-12 Drain Discharge Side Tank (Typical) ................................................................................................ 3-12

3-13 Exhaust Fan ....................................................................................................................................... 3-13

4 WASHER OPERATION

4-1 Manual Drain Valve ............................................................................................................................. 4-1

4-2 Accessories ......................................................................................................................................... 4-3

4-3 Manual Control Mode Flow Chart ...................................................................................................... 4-23

5 CYCLE PROGRAMMING

5-1. Program Touch Pads ............................................................................................................................ 5-1

6 ROUTINE MAINTENANCE

6-1. Spray Header Flush Plug ..................................................................................................................... 6-6

6-2. Self-Cleaning Screen ............................................................................................................................ 6-7

6-3. Exhaust Fan Grease Fittings ................................................................................................................ 6-9

6-4. Manual Drain Valve ............................................................................................................................ 6-10

6-5. Replace Squeeze Tube ...................................................................................................................... 6-13

6-6. Replacing Detergent Container........................................................................................................... 6-14

6-7. Printer Paper Roll Replacement ......................................................................................................... 6-16

Figure

LIST OF FIGURES

1-1

Safety Precautions Operator Manual 122997-341

1

The following Safety Precautions must be observed when operating or servicing this equipment. WARNING indi-

cates the potential for personal injury and CAUTION indicates the potential for damage to equipment. For empha-

sis, certain Safety Precautions are repeated throughout the manual. It is important to review ALL Safety

Precautions before operating or servicing the unit.

WARNING – PERSONAL INJURY AND/OR EQUIPMENT DAMAGE HAZARD:

WARNING – PERSONAL INJURY HAZARD:

WARNING – ELECTRIC SHOCK AND/OR BURN HAZARD:

Always wear appropriate Personal Protective Equipment (PPE) when cleaning or removing debris from

bottom of wash chamber and over suction plate.

Only STERIS or STERIS-trained service personnel should make repairs and adjustments to this equip-

ment. Maintenance done by inexperienced, unqualified personnel or installation of unauthorized parts

could cause personal injury, invalidate warranty, or result in costly damage. Contact STERIS regarding

Service options.

Regularly scheduled preventive maintenance, in addition to faithful performance of minor maintenance

described within this manual, is required for safe and reliable operation of this equipment. Contact

STERIS to schedule preventive maintenance.

To open doors from inside wash chamber, pull EMERGENCY STOP cables. Washer operation will

automatically stop. Then, push firmly on door panel using shoulder and upper arm, applying upper body

force.

Items in washing cart may move during processing and be filled with residual hot water or protrude from

cart at the end of the cycle. Always wear appropriate personal protective equipment (PPE) and carefully

remove items from cart.

Never perform cleaning of wash chamber until full cycle has been completed. If cycle has not been

completed, contaminated debris or water may remain in the bottom of the wash chamber.

Keep fingers away from door hinges to prevent pinching.

To prevent tipping, place biggest and heaviest items on the lower levels of accessory cart.

Disconnect all utilities to washer before servicing. Do not service washer unless all utilities have been

properly locked out. Always follow local occupational health and safety regulations, as well as electric

and plumbing codes.

SAFETY PRECAUTIONS

1-2

122997-341 Operator Manual Safety Precautions

WARNING – CHEMICAL BURN AND/OR EYE INJURY HAZARD:

WARNING – BURN HAZARD:

WARNING – SLIPPING HAZARD:

CAUTION – POSSIBLE EQUIPMENT DAMAGE:

Washer chemicals are caustic and can cause adverse effects to exposed tissues. Do not get in eyes, on

skin, or attempt to swallow. Read and follow precautions and instructions on chemical label and in

Material Safety Data Sheet (MSDS) prior to handling detergent containers, or servicing detergent injec-

tion pumps, tank, and lines. Wear appropriate Personal Protective Equipment (PPE) whenever handling

chemicals or servicing chemical injection pumps, tank, and lines.

Wear appropriate Personal Protective Equipment (PPE) when removing clamps and replacing squeeze

tubes. Residual chemicals might remain in used squeeze tubes. If chemical contacts skin or eyes,

immediately flush with running water for at least 10 minutes. If contact was with eyes, seek medical

attention.

Wear gloves and eye protection when using a descaling product. Avoid contact with eyes or skin. If

spilled or splashed, flush with plenty of water for 15 minutes. If swallowed, DO NOT induce vomiting.

Administer an alkali with plenty of water. Seek medical attention immediately.

Allow unit to cool down before performing any service on mechanical components and on piping. Com-

ponents and piping become very hot during operation.

Inner surfaces of washer are very hot after cycle completion. Operator should wear appropriate Per-

sonal Protective Equipment (PPE) and avoid all contact with inner walls when entering chamber to

unload washer.

Pipes may be extremely hot.

When cycle is complete, partially open chamber door and allow chamber and load to cool. Hot steam

may escape through door opening if door is fully opened after a cycle.

To avoid slippery floor conditions, keep floor dry. Promptly wipe up any spilled liquids or condensation. If

spilled liquids are detergents or other chemicals, follow safety precautions and handling procedures set

forth on detergent or chemical label and/or Material Safety Data Sheet (MSDS).

Always use non-foaming chemical for effective cleaning and proper pump and water level control opera-

tion. Follow manufacturer’s recommendations for amount of chemical to be used.

Always use a silicone lubricant to lubricate squeeze tubes. Petroleum-based lubricants, such as

Vaseline®1 or grease, will cause squeeze tubes to melt.

Avoid product damage. Always select a cycle appropriate for items being processed.

1Vaseline is a trademark of Chesebrough Pond's Incorporated.

1-3

Safety Precautions Operator Manual 122997-341

CAUTION – POSSIBLE EQUIPMENT DAMAGE (Cont’d):

Before operating unit, always position manifolded Bottle Washing Cart over central water inlet connec-

tor. If manifolded accessory is not positioned correctly, damage may result and unit will be unable to

effectively wash load.

Do not process load using Bottle Washing Cart when Automatic Floor Tilting option is activated. If Auto-

matic Floor Tilting is used, manifolded water inlet and washer will be damaged.

Remove all cellulose-type bedding from cages and pans before processing. Cellulose bedding can clog

filters and piping.

Use nonabrasive cleaners when cleaning unit. Follow directions on containers and rub in a back-and-

forth motion (in same direction as surface grain). Abrasive cleaners will damage stainless steel. Clean-

ers rubbed in a circular motion applied with a wire brush or steel wool will scratch and dull stainless

steel. Do not use these cleaners on painted surfaces.

When choosing a detergent, select one with a low chloride content. Detergents with a high chloride con-

tent can corrode stainless steel.

1-4

122997-341 Operator Manual Safety Precautions

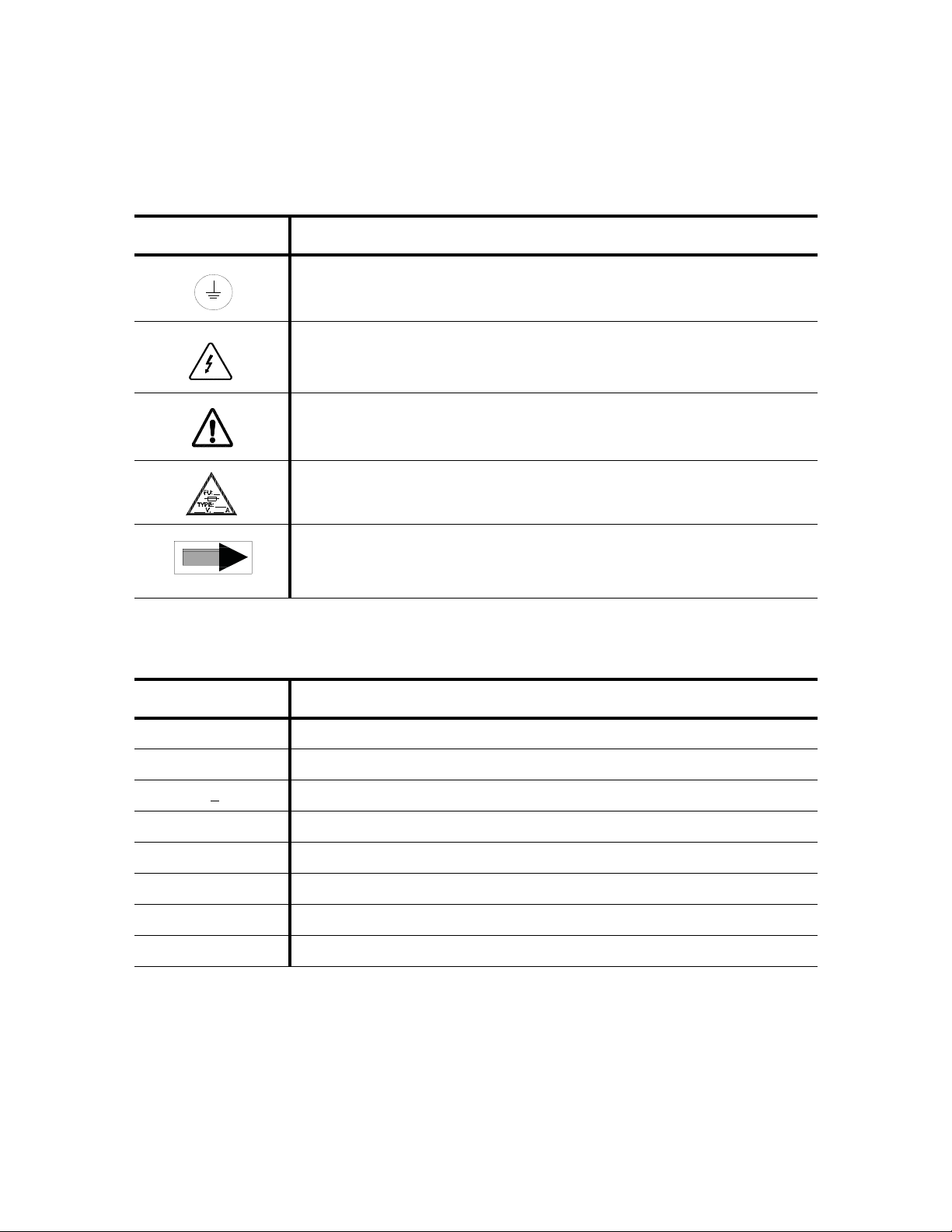

The tables below contain symbols which may be on your Basil 4600 Cage and Rack Washer or 4602 Cage and

Rack Washer components:

Table 1-1. Definition of Symbols on Unit

Symbol Definition

Protective Earth (Ground).

Warning! Risk of Electrical Shock.

Attention! Refer to Manual for Further Instructions.

Fuse Identification.

Pump Rotation

Table 1-2. Definition of Symbols on Identification Nameplate

Symbol Definition

MODEL Model Number of the Unit.

S/N Serial Number of the Unit.

V 3~Volt, Number of the Phase (Three) Alternating Current.

WIRE Number of Wires of the Unit, Ground not Included.

YEAR Year of Manufacture of the Unit.

kW Power Rating of the Unit

AAmperage.

Hz Hertz – Frequency of the Unit.

2

2-1

Installation Checklist Operator Manual 122997-341

2.1 General An equipment drawing, showing all utility and space requirements,

was supplied with the washer. Clearance space specified on equip-

ment drawing is necessary for ease of installation and to assure

proper operation and maintenance of equipment. If documents are

missing or misplaced, contact STERIS giving unit serial, equipment,

and model numbers. Replacement copies will be sent to you

promptly.

2.1.1 Technical

specifications

These specifications are intended to describe technical information

given on nameplate of your washer and to state other relevant infor-

mation. Check equipment drawing or identification nameplate,

located inside control door, above main electrical box, for proper

voltage and amperage.

2.1.2 Amperage and Power

Consumption

Basil®4600 Cage and Rack Washer and Basil®4602 Cage and

Rack Washer operate on:

• 208 V~, three-phase, 60 Hz

• 480 V~, three-phase, 60 Hz.

A protective ground conductor is required (Class 1 Equipment).

Installation Category is Overvoltage II.

Refer to equipment drawing (920-505-383 for Basil 4600; 920-505-

871 for Basil 4602 or custom equipment drawing) for proper connec-

tion.

IMPORTANT: Customer is responsible for compliance with

applicable codes and regulations.

Maximum currents and power consumptions, are indicated on

nameplate.

IMPORTANT: A listing of the Safety Precautions to be observed when operating and servicing this Cage

and Rack Washer can be found in SECTION 1. Do not install equipment until you have become familiar with

this information.

INSTALLATION CHECKLIST

2-2

122997-341 Operator Manual Installation Checklist

2.1.3 Permissible

Environmental Conditions

This unit is designed to give optimal results under the following con-

ditions:

- Indoor use only;

- Altitude of operation up to 6562 ft (2000 m);

- Temperature 41°F to 104°F (5°C to 40°C);

- Maximum relative humidity is 80% for temperatures up to 88°F

(31°C) decreasing linearly to 50% relative humidity at 104°F

(40°C);

- Installation Category II;

- Pollution Degree 2.

2.1.4 Noise Level Equivalent Sound Pressure Level: 84 dB (A). Results determined

according to ISO-3746: 1995 Standard: Acoustics Determination of

Sound Power Levels of Noise Sources Survey Method.

2.1.5 Seismic Anchorage

System

Washer can be built to seismic zone 3 and 4 requirements.

2.2 Installation

Checklist

After installing washer according to Uncrating/Installation Instruc-

tions (P910000-015), complete the following checklist to assure

complete and correct installation. Contact STERIS to schedule a

technician to test your installation and demonstrate proper equip-

ment operation.

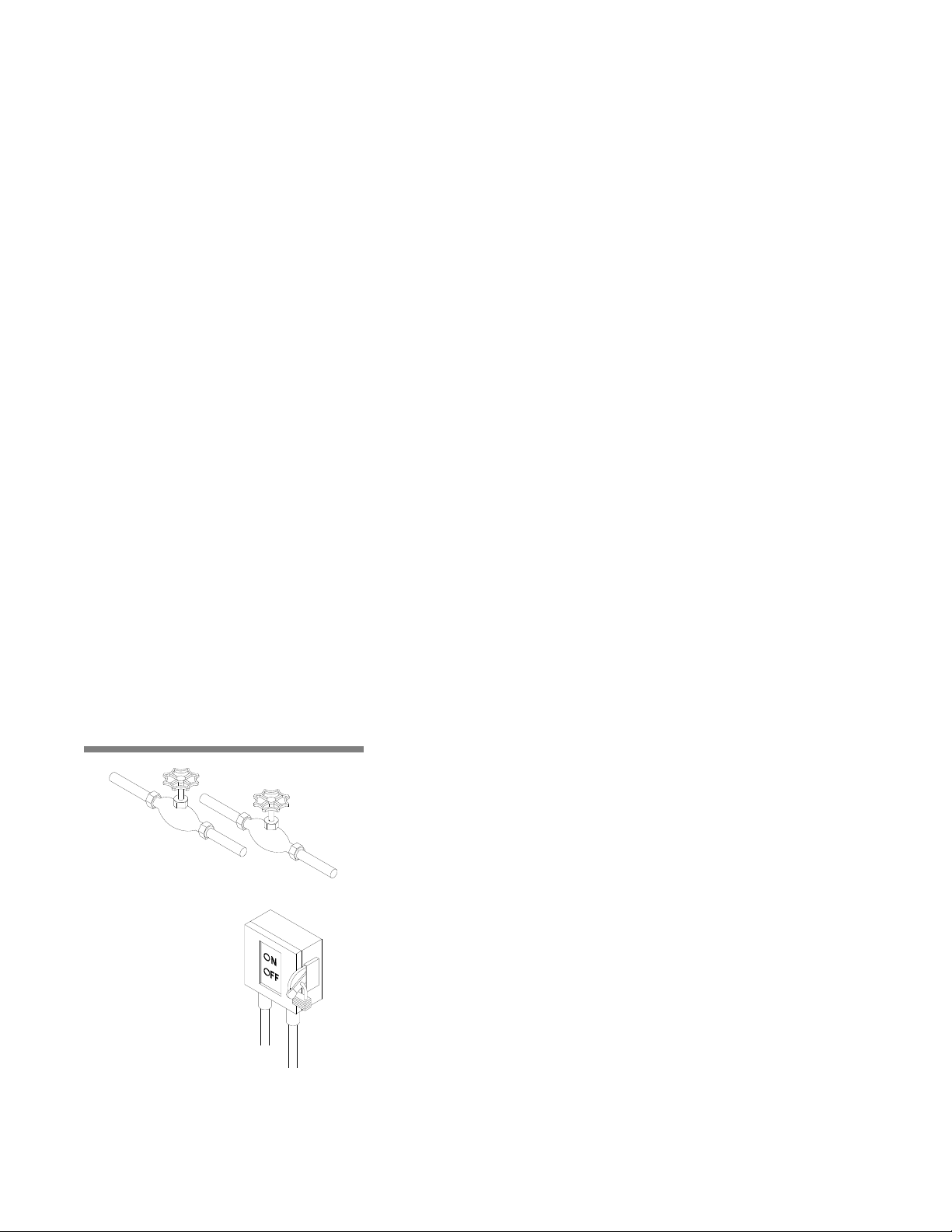

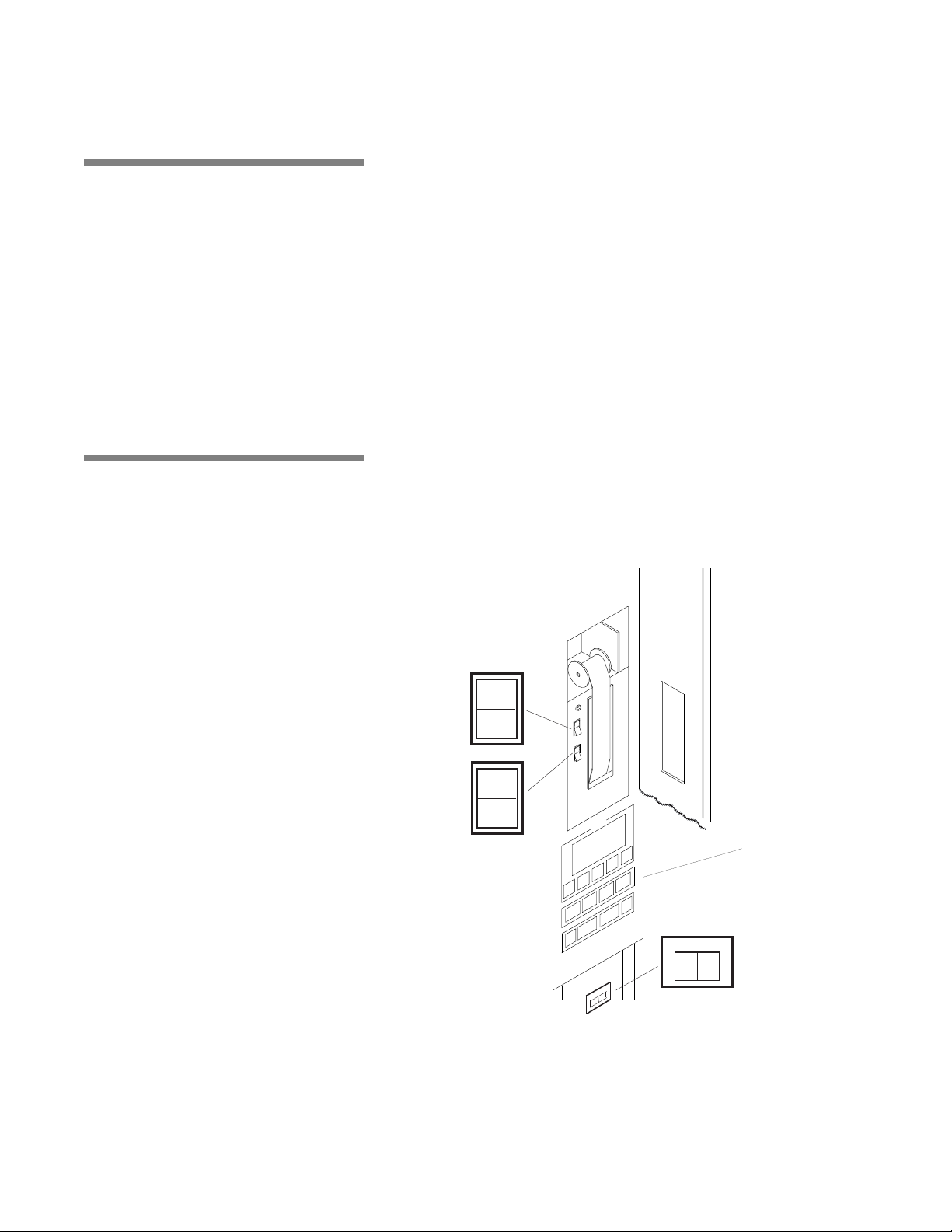

❑Shutoff valves (not provided by STERIS) should be installed on

steam and water supply lines to unit (see Figure 2-1). Shutoff

valves must be capable of being locked in OFF position only and

in compliance with occupational health and safety regulations,

as well as electric and plumbing codes for any special require-

ments that may pertain to installation of this unit.

❑Disconnect switches (not provided by STERIS) should be

installed in electric supply lines near unit (see Figure 2-1). Dis-

connect switches must be capable of being locked in OFF posi-

tion only. Disconnect switches must be installed in electric

supply line near unit (within 10' [3 m] of equipment) and in com-

pliance with occupational health and safety regulations, as well

as electric and plumbing codes for any special requirements

that may pertain to installation of this unit.

NOTE: If washer is installed next to other equipment, shutoff valves

and disconnect switch should be placed so that service can be shut

off to any one unit.

Figure 2-1. Shutoff Valves and

Disconnect Switch

Shutoff Valves

Disconnect Switch

2-3

Installation Checklist Operator Manual 122997-341

❑Washer is positioned, as shown on equipment drawing, with

required service clearance space and in relation to building sup-

ply lines.

❑Basil 4600 Cage and Rack Washer and Basil 4602 Cage and

Rack Washer must be installed between two walls, with a key-

locked service door, so washer service side is not accessible to

operator.

❑Building steam line provides maximum dynamic steam pressure

and flow rate to washer as specified on equipment drawing.

❑Drip leg with steam trap installed in steam supply line.

❑Building hot water line supplies water to washer at pressure and

temperature specified on equipment drawing.

❑Building cold water line supplies water to washer at pressure

specified on equipment drawing.

❑Electrical supply for washer is as specified on equipment draw-

ing.

❑Condensate returns are sized as specified on equipment draw-

ing.

❑Vent connections are sized as specified on equipment drawing.

❑Recirculation pump pressure is within 25 to 60 psig.

❑Recirculation pump motor rotating in direction shown by arrow.

❑Self-cleaning screen assembly functioning properly.

❑Carriage drive motor rotating in direction shown by arrow.

❑Carriage drive system functioning properly.

❑Carriage drive motor amperage within rating indicated on the

motor.

❑Optional exhaust fan rotating in direction shown by arrow.

❑All piping is leak-free.

❑Chamber sump steam coil functioning properly.

❑Door safety switch(es) functioning properly.

❑Cabinet joints are completely sealed, no leaks (for verification,

run machine for 1/2 hour).

❑Door(s) easily opens from inside of chamber.

❑Safety cables immediately stop washer operation when pulled.

❑Each gear box plastic cap removed and replaced with air vent

provided.

❑Floor surrounding unit has non-slip surface.

IMPORTANT: After a few weeks of operation, inspect unit for leaks.

Retighten all clamps and connections.

2-4

122997-341 Operator Manual Installation Checklist

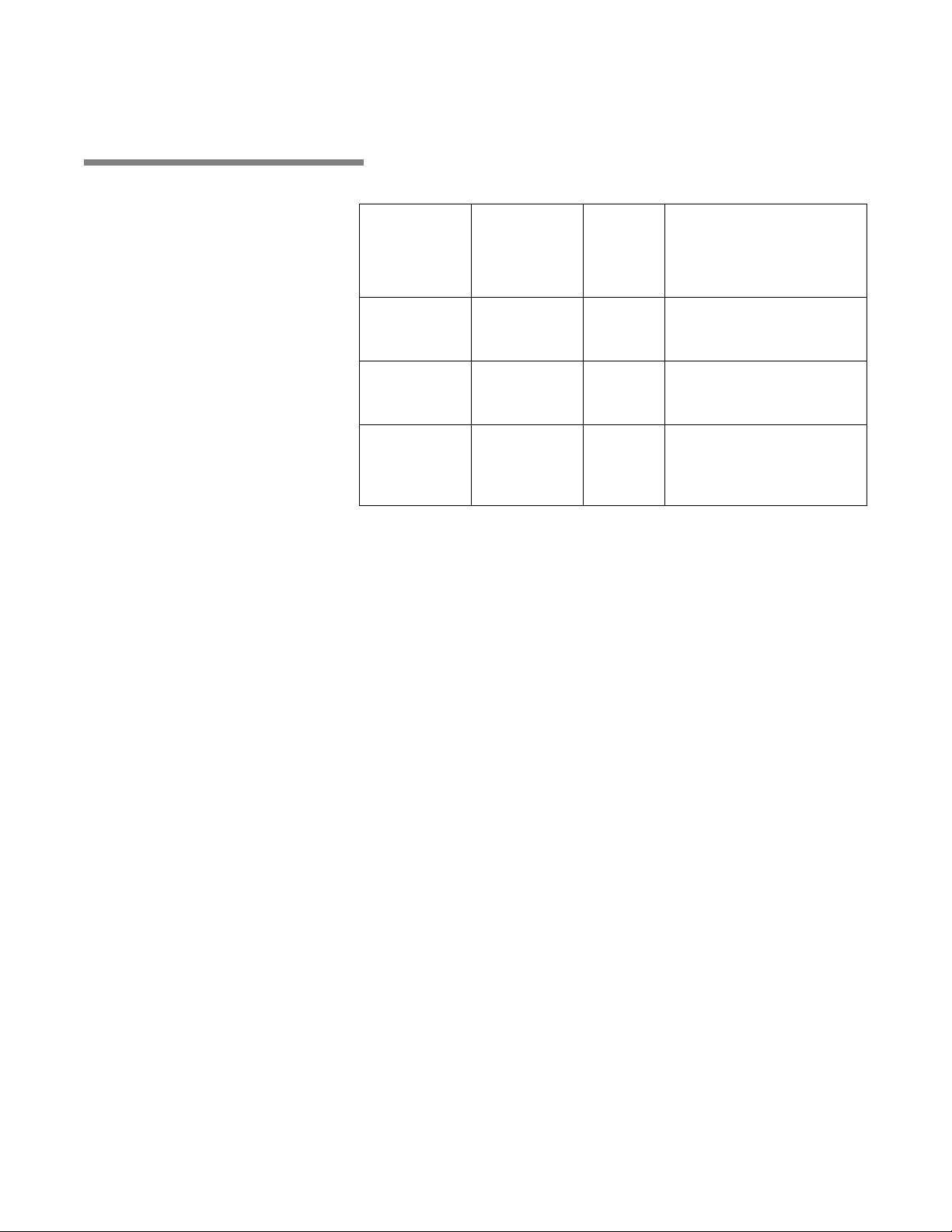

2.3 Chemical Additives

Specifications

The selection of chemical additives is open for customer preference;

however, in order to achieve optimal performance, the selected

chemical additives must meet as a minimum, the following specifica-

tions:

NOTE: When choosing and using chemicals, take note of the follow-

ing:

1) Follow chemical label recommendations for concentration of

chemical to use.

2) Follow chemical manufacturer's recommendations to determine

the temperature of the WASH treatment.

3) Follow chemical manufacturer's recommendations for the amount

of chemical used according to water hardness.

To achieve maximum cleaning efficiency, select chemical appropri-

ate to soil type being processed. STERIS recommends the following

chemicals:

•Cage-Klenz®100 Alkaline Cage Wash Detergent -

(Alkaline) formulated to remove urine, scale, animal fats, oils and

other organic soils from cage materials.

•Cage-Klenz®200 Acid-Based Cage Wash Detergent -

(Acidic) formulated to remove urine, scale, animal fats, oils and

other organic soils from cage materials.

•Liquid Descaler Acid-Based Scale Remover - for

removing scale and other hard water deposits. For use in animal

care centers.

NOTE: Certain products may not be available in your area. Contact

your STERIS representative for availability of these products and for

ordering information.

IMPORTANT: STERIS does not promote, recommend, nor endorse

the use of any other type of chemical additives in the processing of

articles in the Basil 4600/4602 Cage and Rack Washers, such as

drying agents, strong alkaline detergents (pH>12), alcohol rinses and

liquid germicides including hypochloric acid (bleach).

Product

Description

UseDilution

Range oz/

gal (mL/L)

Dilution

pH

Range

at Use

Other Applicable

Requirements

Alkaline

Chemicals

1/4 - 4

(2-32) 9.0 - 12.0

Liquid, non-foaming, and vis-

cosity below 200 SSU

(0.0004623 ft2/sec).

Acidic

Chemicals

1/4 - 4

(2-32) 3.0 - 6.0

Liquid, non-foaming, free

rinsing, and viscosity below

200 SSU (0.0004623 ft2/sec).

Descalers 1/2 -2 <2.5

Liquid, non-foaming, phos-

phoric acid-based, and vis-

cosity below 200 SSU

(0.0004623 ft2/sec).

3

3-1

Component Identification Operator Manual 122997-341

3.1 General Become familiar with location and function of all major components

and controls, as well as their function before operating this unit (see

Figure 3-1).

Two models are available: Basil®4600 Cage and Rack Washer and

Basil®4602 Cage and Rack Washer.

•Basil

4600:

Wash Chamber: 46" W x 85" H x 92" L (1168 x 2159 x 2336 mm)

Overall Unit: 82" W x 102" H x 99" L (2082 x 2590 x 2514 mm)

Equipped with Reusable - Throwaway Detergent Tank

• Basil 4602:

Wash Chamber: 46" W x 85" H x 188" L (1168 x 2159 x 4775 mm)

Overall Unit: 82" W x 102" H x 195" L (2082 x 2590 x 4953 mm)

Equipped with Reusable - Throwaway Detergent Tank

Each model is equipped with a user-programmable microcomputer

control system capable of storing up to twelve treatment cycles to

process a wide variety of loads. Computer control system monitors

and automatically controls all cycle operations.

IMPORTANT: A listing of the Safety Precautions to be observed when operating and servicing this Cage

and Rack Washer can be found in SECTION 1. Do not install equipment until you have become familiar with

this information.

Figure 3-1. Washer Components - Basil 4600 (Typical)

Reusable-Throwaway

Detergent Tank

Chamber Door

and Viewing

Window

Control Console

COMPONENT IDENTIFICATION

3-2

122997-341 Operator Manual Component Identification

3.2 POWER-OFF/

STANDBY Switch

POWER-OFF/STANDBY switch, located behind the printer door,

includes two settings which direct operation of control (see Figure 3-

2):

•POWER – Press top portion of POWER-OFF/STANDBY switch to

initialize control and place control in Ready Mode.

•OFF/STANDBY – Press bottom portion of POWER-OFF/

STANDBY switch to initiate Shutdown Cycle and place control in

Standby Mode.

NOTE: Control should be placed in Standby Mode for last cycle of the

day and when washer is not in use for an extended period of time.

IMPORTANT: POWER-OFF/STANDBY switch does not turn off

electrical power to unit.

3.3 Interior Light Interior light, can be manually controlled by operator through a tog-

gle switch located behind printer door, below control panel, on load

side (see Figure 3-2). Interior light illuminates wash chamber when

loading or unloading washer, or it can left ON during a whole wash-

ing cycle to view washing process.

POWER

OFF

STANDBY

PRINT

PRINT

VALUES

ON

OFF

INTERIOR LIGHT

Figure 3-2. Control Column

Control Panel

3-3

Component Identification Operator Manual 122997-341

3.4 Control Panel Control Panel is used to direct all washer functions (see Figure 3-3).

Operator may program specific cycles, review and select cycles,

start, stop or reset cycle operation, extend or bypass cycle phases,

and monitor cycle performance.

3.4.1 Display Screen Two line alpha-numeric screen displays cycle program data on

demand, in-cycle performance data and operator instructions. Dis-

play screen also indicates certain abnormal conditions that may

occur during a cycle.

3.4.2 Cycle Status Touch

Pads

•CYCLE MENU touch pad – press to view first cycle menu. Press

again to advance screen to next cycle menu. Three menus are

available, each with four cycles.

•SELECT CYCLE touch pad – press until desired cycle name

flashes.

NOTE: When a displayed cycle name or phase value is selected,

corresponding word or digit flashes.

•REVIEW CYCLE touch pad – press to review cycle phases and

values programmed for selected cycle.

•CYCLE/START touch pad – press once to display name of

selected cycle. Press a second time to start cycle.

NOTE: Selected cycle name remains on screen for 5 seconds

Figure 3-3. Control Panel

Display Screen

Cycle Status

Touch Pads

Manual Control

Touch Pads

Program Touch

Pads

3-4

122997-341 Operator Manual Component Identification

after pressing CYCLE/START touch pad once. To start a cycle,

CYCLE/START touch pad must be pressed a second time while

selected cycle name is displayed. If touch pad is not pressed

within 5 seconds, screen automatically returns to Cycle Menu.

•STOP/RESET touch pad – press once to stop cycle operation.

Press a second time to abort cycle and return screen to cycle

menu.

NOTE: When cycle is stopped, press Cycle/Start touch pad once to

resume cycle operation. Cycle operation resumes at beginning of

interrupted phase function (i.e., filling, recirculating, draining). When

cycle is aborted, cycle operation is discontinued and cycle must be

re-started from the beginning.

3.4.3 Manual Control Touch

Pads

•EXTEND PHASE touch pad – press to temporarily increase

selected phase time. On completion of cycle, phase time returns

to programmed setpoint.

•BYPASS PHASE touch pad – press to bypass specific phase in

progress and advance cycle to next phase.

NOTE: Bypass Phase touch pad can only be used when a cycle

is in progress. During cycle, filling and draining functions can not

be bypassed. In addition, a phase can not be bypassed if

Temperature Guarantee feature is selected for that phase.

•MANUAL MENU touch pad – press to view washer functions

which can be controlled manually.

•ALARM REPLY touch pad – press to turn off alarm buzzer and

acknowledge displayed alarm message. Refer to SECTION 7,

TROUBLESHOOTING, for specific alarm conditions and corrective

actions.

3.4.4 Program Touch Pads Program touch pads allow programming of twelve distinct cycles

and changing of previously programmed cycle values to process

different types of loads. Cycle programming may be limited by

access code to ensure process integrity. Refer to SECTION 5, CYCLE

PROGRAMMING, for details on cycle programming and access code

feature.

•CHANGE VALUES touch pad – press to access Change Values

mode. Change Values mode allows authorized operators to

change user-programmable items. Refer to SECTION 5, CYCLE

PROGRAMMING, for details about Change Values Mode.

NOTE: Examples of user-programmable items include cycle

name, phase temperature, phase time, and questions regarding

phase options (e.g., retention of final rinse water).

3-5

Component Identification Operator Manual 122997-341

•CURSOR (left or right) touch pad – press until item to be

changed (word, letter, or number) flashes.

•VALUE (up or down) touch pad – depending on item flashing

(selected), press to either toggle between answer selections or

scroll through alphabet and numbers 0 through 9.

NOTE: Alphabet includes characters for an underline (_) and a

space ( ).

•SAVE VALUES touch pad – press to save changes made, exit

Change Values mode and return screen to cycle menu.

3.5 Printer Printer records pertinent cycle data on 2-1/4" wide thermal paper

(see Figure 3-4). Refer to SECTION 6.7, PRINTER PAPER, for information

on changing paper roll and storing thermal paper.

3.5.1 Printer Function Switch Printer Function Switch controls the following two printer functions:

•PRINT – press top of Printer Function Switch to generate a print

of alkaline and acid detergent setpoints (if conductivity option)

and all RTD temperatures (actual water temperature).

•PRINT VALUES – press bottom of Printer Function Switch to

generate a complete printout of all cycle parameters.

PRINT

PRINT

VALUES

Figure 3-4. Printer

Thermal Paper

Take-Up Spindle

Printer Door

This manual suits for next models

1

Table of contents

Other Steris Washer manuals

Steris

Steris BASIL 9500 User manual

Steris

Steris RELIANCE 400 User manual

Steris

Steris AMSCO RELIANCE 430 User manual

Steris

Steris ML 200 User manual

Steris

Steris ML 222 User manual

Steris

Steris RELIANCE 200 User manual

Steris

Steris AMSCO 5000 Series User manual

Steris

Steris Reliance 1227 User manual

Steris

Steris RELIANCE 400 User manual

Steris

Steris AMSCO 7000 Series User manual