Steris BASIL 9500 User manual

OPERATOR MANUAL

BASIL® 9500

Cage and Rack Washer

(10/18/01) P-122998-050

Rev. 3

LIMITATIONS OF LIABILITY AND INDEMNITY

IN NO CASE, WHETHER AS A RESULT OF A BREACH OF CONTRACT, BREACH OF WARRANTY

OR TORT (INCLUDING STERIS'S OR CUSTOMER'S WILLFUL ACTS OR NEGLIGENCE OR STRICT

LIABILITY) SHALL STERIS OR CUSTOMER BE LIABLE TO THE OTHER FOR ANY CONSEQUEN-

TIAL OR INCIDENTAL DAMAGES INCURRED BY THE OTHER, INCLUDING, BUT NOT LIMITED TO,

LOSS OF REVENUE, PROFITS OR GOODWILL. HOWEVER, NOTHING CONTAINED IN THIS

AGREEMENT IS INTENDED TO RELIEVE EITHER STERIS OR CUSTOMER FROM CLAIMS,

LIABILITY, DAMAGES OR EXPENSES RESULTING FROM BODILY INJURY, INCLUDING DEATH,

OR FROM PROPERTY DAMAGE INCURRED DUE TO THE WILLFUL ACTS, THE NEGLIGENCE OF

OR THE STRICT LIABILITY OF THAT PARTY.

STERIS AGREES TO DEFEND, INDEMNIFY AND HOLD CUSTOMER HARMLESS FROM ANY AND

ALL CLAIMS, LIABILITY, DAMAGES OR EXPENSES DUE TO PERSONAL INJURIES, INCLUDING

DEATH, TO EMPLOYEES OF STERIS AND CUSTOMER AND TO THIRD PARTIES AND FOR

PROPERTYDAMAGETOTHEEXTENTOFTHEWILLFULACTSOFTHENEGLIGENCEOFSTERIS

OR THE STRICT LIABILITY OF STERIS CAUSED BY THE ACTS OR OMISSIONS OF STERIS.

CUSTOMER AGREES TO DEFEND, INDEMNIFY AND HOLD STERIS HARMLESS FROM ANY AND

ALL CLAIMS, LIABILITY, DAMAGES OR EXPENSES DUE TO PERSONAL INJURIES, INCLUDING

DEATH, TO EMPLOYEES OF CUSTOMER AND STERIS AND TO THIRD PARTIES AND FROM

PROPERTY DAMAGE TO THE EXTENT OF THE WILLFUL ACTS OR THE NEGLIGENCE OF

CUSTOMER OR THE STRICT LIABILITY OF CUSTOMER CAUSED BY THE ACTS OR OMISSIONS

OF CUSTOMER.

WARNING - COPYING PROHIBITED

This manual is protected by Federal Copyright Law, which

provides for damages of up to $20,000, as well as

criminal fines and imprisonment, for unauthorized copying.

i

Introduction OperatorManual 122998-050

This manual contains important information on the proper use of this

washer. Refer to

Routine Maintenance, Section 6

for instructions in

routine care of this equipment. All personnel and department heads

are urged to carefully review and become familiar with the warnings,

cautionsandinstructionscontainedherein.Theseinstructionsshould

beretainedinaconvenientlyaccessibleareaforquickreference.This

washer is specifically designed only for the uses outlined in this

manual, otherwise, safety hazards may occur.

IMPORTANT

:

Alisting of thesafetyprecautionsto be observedwhen

operating this washer can be found in section 1. Do not operate the

washer until you have become familiar with this information.

The Basil®9500 Cage and Rack Washer is intended for use in the

sanitation of soiled, reusable animal care devices such as cages,

racks,debrispans,feederbottlesandothermiscellaneousitemsby

providing thorough cleaning, and optional drying.

Thiswasherisspecificallydesignedtoonlyprocessgoodsasoutlined

in this manual. If there is any doubt about a specific material or

product, contact the manufacturer of the product for recommended

washing technique.

STERISdoesnotintend,recommendnorrepresentinanywaythatthis

Basil 9500 Cage and Rack Washer be used for the sterilization of any

animal care or other device which has been contaminated with

pathogenic microorganisms.

Any alteration of the washer not authorized or performed by STERIS

Engineering Service which could affect its operation will void the

warranty, could adversely affect washing efficacy, could violate

national, State, and local regulations, and could jeopardize your

insurance coverage.

A thorough preventive maintenance program is essential to safe and

proper equipment operation. You are encouraged to contact your

STERIS representative concerning extended service maintenance

agreements to give your washer planned maintenance, assuring

equipment performance according to factory specifications.

A global network of skilled service specialists can provide periodic

inspections and adjustments to assure low-cost peak performance.

STERISrepresentativescanprovideinformationregardingtheAnnual

Maintenance Agreements.

STERIScarriesacompletelineofaccessoriesforuseinthisequipment.

A STERIS representative will gladly review these with you.

© 2001 - STERIS Corporation All rights reserved. Printed in Canada

12345678901234567890123456789012123456789012345678901234567

1

234567890123456789012345678901212345678901234567890123456

7

12345678901234567890123456789012123456789012345678901234567

12345678901234567890123456789012123456789012345678901234567

1

234567890123456789012345678901212345678901234567890123456

7

12345678901234567890123456789012123456789012345678901234567

Service Information

A WORD FROM STERIS CORPORATION

Indications For Use

12345678901234567890123456789012123456789012345678901234567

12345678901234567890123456789012123456789012345678901234567

12345678901234567890123456789012123456789012345678901234567

1

234567890123456789012345678901212345678901234567890123456

7

12345678901234567890123456789012123456789012345678901234567

Advisory

12345678901234567890123456789012123456789012345678901234567

12345678901234567890123456789012123456789012345678901234567

12345678901234567890123456789012123456789012345678901234567

1

234567890123456789012345678901212345678901234567890123456

7

12345678901234567890123456789012123456789012345678901234567

ii

122998-050 OperatorManual Introduction

Sales: Direct Technical Assistance:

STERIS Corporation STERIS Engineering Services

5960, Heisley Road 2424 West, 23rd Street

Mentor, Ohio 44060 Erie, PA 16506

Tel.: 440 354 2600 Tel.: 814 452 3100

Fax: 440 639 8199 Fax: 814 870 8400

ManufacturingPlant: Authorized EU Representative:

STERIS Canada Corporation STERIS Limited

415, rue des Alleghanys STERIS House

Beauport (Québec) Jays Close

Canada G1C 4N4 Viables

Tel.: 418 664 1549 Basingstoke

Fax.: 418 664 0188 Hampshire

RG22 4AX

Tel.: 44 1256 840400

Fax: 44 1256 866502

STERIS HAS OFFICES WORLDWIDE

Benelux 32 2 523 24 88

Canada 800 661 3937

France 33 1 4488 2688

Germany 49 2233 6999 0

Hong Kong 852 2 563 3623

Italy 39 02 66 80 53 10

Japan 81 78 321 2271

Korea 82 2 554 1661

Latin America 305 442 82 02

Nordic 358 9 25851

Singapore 65 841 7677

Spain 3491 658 5920

Sweden 46 152 228 30

United Kingdom 44 1256 840400

Visit our web site at: www.steris.com

iii

Introduction OperatorManual 122998-050

TABLE OF CONTENTS

SECTION TITLE PAGE

1 LISTING OF WARNINGS, CAUTIONS

AND SYMBOLS ...................................................... 1-1

Symbols ................................................................................. 1-4

2 INSTALLATION VERIFICATION ............................. 2-1

Installation Checklist................................................... 2-1

Technical Specifications............................................. 2-2

Certification ................................................................ 2-3

Chemical Additives Specifications.............................. 2-4

3 COMPONENT IDENTIFICATION ............................. 3-1

POWER-OFF/STANDBY Switch................................ 3-2

Main Control Panel..................................................... 3-2

Display Screen ............................................... 3-2

Touch Pads .................................................... 3-3

Printer ........................................................................ 3-4

Printer Function Switch.................................. 3-4

Typical Printouts ............................................ 3-5

Remote Control Panel (Double Door Units)................ 3-8

Emergency Safety Features....................................... 3-9

Photoelectric Sensors ................................... 3-9

Emergency Exit Safety Doors ....................... 3-9

Emergency Stop Guard Rails........................ 3-9

Emergency Stop Pushbutton(s) .................... 3-9

Interior Light ................................................ 3-10

Safety Delay................................................ 3-10

4 OPERATING INSTRUCTIONS................................. 4-1

Before Operating Washer........................................... 4-1

Priming Procedure ..................................................... 4-2

Doors ......................................................................... 4-3

Door Operation ............................................. 4-3

Double Door Units with Interlock Feature...... 4-4

Opening Doors During a Power Failure ........ 4-4

Accessories................................................................ 4-5

How to Load Accessories Into Wash

Chamber ...................................................... 4-5

How to Load Central Spray Header

Manifold(option) .......................................... 4-7

How to Load Bottle Washing Cart (option) ... 4-7

iv

122998-050 OperatorManual Introduction

Typical Cycle Operation............................... 4-9

To Begin Cycle Operation ............................ 4-9

Drain Cycle .............................................................. 4-12

Pause Cycle operation ............................................. 4-14

Abort Cycle operation............................................... 4-15

Acknowledge Alarm Condition.................................. 4-15

Shutdown ................................................................. 4-16

Manual Shutdown ..................................... 4-16

Automatic Shutdown ................................. 4-17

5 CYCLE AND CONTROL VALUE

PROGRAMMING ..................................................... 5-1

Cycle Description Chart..................................................... 5-2

Change Values Mode ........................................................ 5-3

Sequence of Display Screens ............................. 5-3

How to Modify a Cycle......................................... 5-3

Review Cycle Values ...................................................... 5-11

6 ROUTINE MAINTENANCE...................................... 6-1

Preventive Maintenance Schedule ................................... 6-1

Cleaning Procedures ........................................................ 6-4

Daily Cleaning ..................................................... 6-4

Weekly Cleaning ................................................. 6-6

Horizontal Spray Headers and Spray Jets.. ........ 6-7

Central Spray Header Manifold (Option) ............. 6-7

Rotary Spray Arms on Bottle Washing Cart

(Option)............................................................... 6-7

Strainers ............................................................. 6-7

Vertical Self Cleaning Filter ................................. 6-8

Descaler Cycle ................................................................. 6-8

Manual Descaler Cycle ....................................... 6-8

Automatic Descaler Cycle ................................. 6-12

Chemical Container Replacement .................................. 6-15

Injection Pumps Lubrication and Replacement ............... 6-16

Printer Paper Roll Replacement ..................................... 6-17

Thermal Paper Storage .................................................. 6-19

7 TROUBLESHOOTING ............................................. 7-1

TABLE OF CONTENTS (CONT'D)

SECTION TITLE PAGE

1-1

Listing of Warnings, Cautions and Symbols OperatorManual 122998-050

LISTING OF WARNINGS, CAUTIONS

AND SYMBOLS

The following is a listing of the safety warnings and cautions which must be observed when operating or

servicing this unit. WARNING indicates the potential for danger to personnel and CAUTION indicates the

potential for damage to equipment. These precautions are repeated in whole or in part, where applicable,

throughout the manual. Carefully read them before proceeding to use or service the unit.

WARNING – BURN HAZARD:

After pressing STOP/RESET touch pad, wait until water flow stops before opening doors. Hot water/

steam may be sprayed through door opening if doors are opened too soon.

Except for emergency, do not open door when cycle is in progress. In an emergency, first stop cycle

by pressing the EMERGENCY STOP PUSHBUTTON and wait for water flow to stop. Wear appropriate

personal protective equipment (PPE) whenever reaching into or entering wash chamber.

Except for emergency, do not open door when cycle is in progress. In an emergency, first stop cycle

by pressing the STOP/RESET touch pad and wait for water flow to stop. Wear appropriate personal

protective equipment (PPE) whenever reaching into or entering wash chamber.

Inner surfaces of washer are very hot after cycle completion. Operator should wear appropriate

personal protective equipment (PPE) and avoid all contact with inner walls when entering chamber

to unload washer.

WARNING – FALL HAZARD:

To prevent falls, keep floor dry. Promptly clean up any spills or drippage.

WARNING – PERSONAL INJURY AND/OR EQUIPMENT DAMAGE HAZARD:

Regularly scheduled preventive maintenance, in addition to the faithful performance of the minor

maintenance described within this manual, is required for safe and reliable operation of this

equipment. Contact STERIS Engineering Service to schedule preventive maintenance.

Only fully qualified service personnel should make repairs and adjustments to this equipment.

Maintenance done by inexperienced, unqualified personnel or installation of unauthorized parts

couldcausepersonalinjury,invalidatethewarranty,orresultincostlydamage.ContactyourSTERIS

sales or service representative regarding service options.

To open doors from inside wash chamber, press Emergency Safety Guard Rails. Washer operation

will automatically stop. Then, push firmly between door panels using shoulder and upper arm,

applying upper body force. Do not push between the two doors, but between the door panels.

To test or demonstrate Emergency Exit Safety Doors, first press Emergency Stop pushbutton

(locatedundercontrol) or EmergencySafety Guard Rails(insidewash chamber) toturnpower OFF.

If power is still on while adjusting or servicing doors, the photoelectric sensor will detect the

movement of the door panels and doors will open automatically.

Before servicing or cleaning exterior of unit, always press EMERGENCY STOP pushbutton to

de-energize unit.

Always wear appropriate personal protective equipment (PPE) when cleaning or removing debris

from bottom of the wash chamber and over the suction plate.

1

(See next page for additional Warnings and Cautions)

1-2

122998-050 OperatorManual Listing of Warnings, Cautions and Symbols

WARNING – PERSONAL INJURY HAZARD:

When doors are closing, a pinch point is created at the hinges. Keep fingers away from door hinges

in order to prevent pinching.

Never perform cleaning of wash chamber until full cycle has been completed. If cycle has not been

completed, contaminated debris or water may remain in the bottom of the wash chamber

Keep hands/fingers away from closing doors in order to prevent crushing between the two doors.

Ifdoorsarestillslightlyopen(lessthan2inches[5cm])whenpowerisrestoredafterapowerfailure,

controlwillapplypressuretocompleteclosing.Lockbuildingelectricalsupplydisconnectswitchin

OFF position and close unit air supply when opening doors after a power failure.

WARNING – ELECTRICAL SHOCK AND/OR BURN HAZARD:

Disconnectallutilitiestowasherbeforeservicing.Donotservicewasherunlessallutilitieshavebeen

properly locked out. Always follow local occupational health and safety regulations, as well as

electric and plumbing codes.

WARNING – CHEMICAL BURN AND/OR EYE INJURY HAZARD:

Wear appropriate personal protective equipment (PPE) when using a descaling product. Avoid

contactwitheyesorskin.Ifspilledorsplashed,flushwithwaterfor15minutes.Ifswallowed,DONOT

induce vomiting. Administer an alkali with plenty of water. Seek medical attention immediately.

Always use non-foaming chemical for effective cleaning and proper pump and water level control

operation. Follow manufacturer's recommendations for amount of chemical to be used.

Washerchemicals arecausticandcancauseadverseeffects toexposed tissues.Do notgetineyes,

on skin or attempt to ingest by mouth.

• Read and follow the precautions and instructions on the chemical label and in the Material Safety

Data Sheet (MSDS) prior to handling chemicals, refilling chemical containers or servicing the

chemical injection pumps and lines.

• Wear appropriate personal protective equipment (PPE) whenever handling chemicals or servicing

chemical injection pumps and lines.

CAUTION - POSSIBLE EQUIPMENT DAMAGE HAZARD:

Always use a silicone lubricant to lubricate squeeze tubes. Petroleum-based lubricants, such as

Vaseline®or grease, will cause squeeze tubes to melt.

When choosing a chemical, select one with a low chloride content. Chloride is harmful to stainless

steel and will deteriorate washer.

AlwayspositionCentralHeaderManifoldoverthemanifoldedcouplingsystembeforeoperatingunit.

Ifmanifold isnotpositioned correctly,damage mayresultand unitwill beunableto effectivelywash

load.

AlwayspositionBottleWashingCartovercentralwaterinletconnectorbeforeoperatingunit.IfBottle

Washing Cart is not positioned correctly, damage may result and unit will be unable to effectively

wash load.

(See next page for additional Warnings and Cautions)

1-3

Listing of Warnings, Cautions and Symbols OperatorManual 122998-050

Avoid product damage. Always select a cycle appropriate for the items being processed.

Use non-abrasive cleaners when cleaning unit. Follow directions on containers and rub in a back-

and-forthmotion, insamedirectionassurface grain. Abrasivecleaners willdamagestainlesssteel.

Cleanersrubbed inacircular motionorapplied witha wirebrushor steelwoolon doorand chamber

assemblies can be harmful to stainless steel. Do not use these cleaners on painted surfaces.

Keep away from doors to prevent load detection sensor from stopping doors from closing.

Alwaysleaveplentyofspacebetweenloadanddoors.Leaningloadagainstdoorswilldamagedoors

and also prevent them from opening or closing.

Remove all cellulose type bedding from cages and pans before processing. Cellulose bedding may

clog filters and piping.

1-4

122998-050 OperatorManual Listing of Warnings, Cautions and Symbols

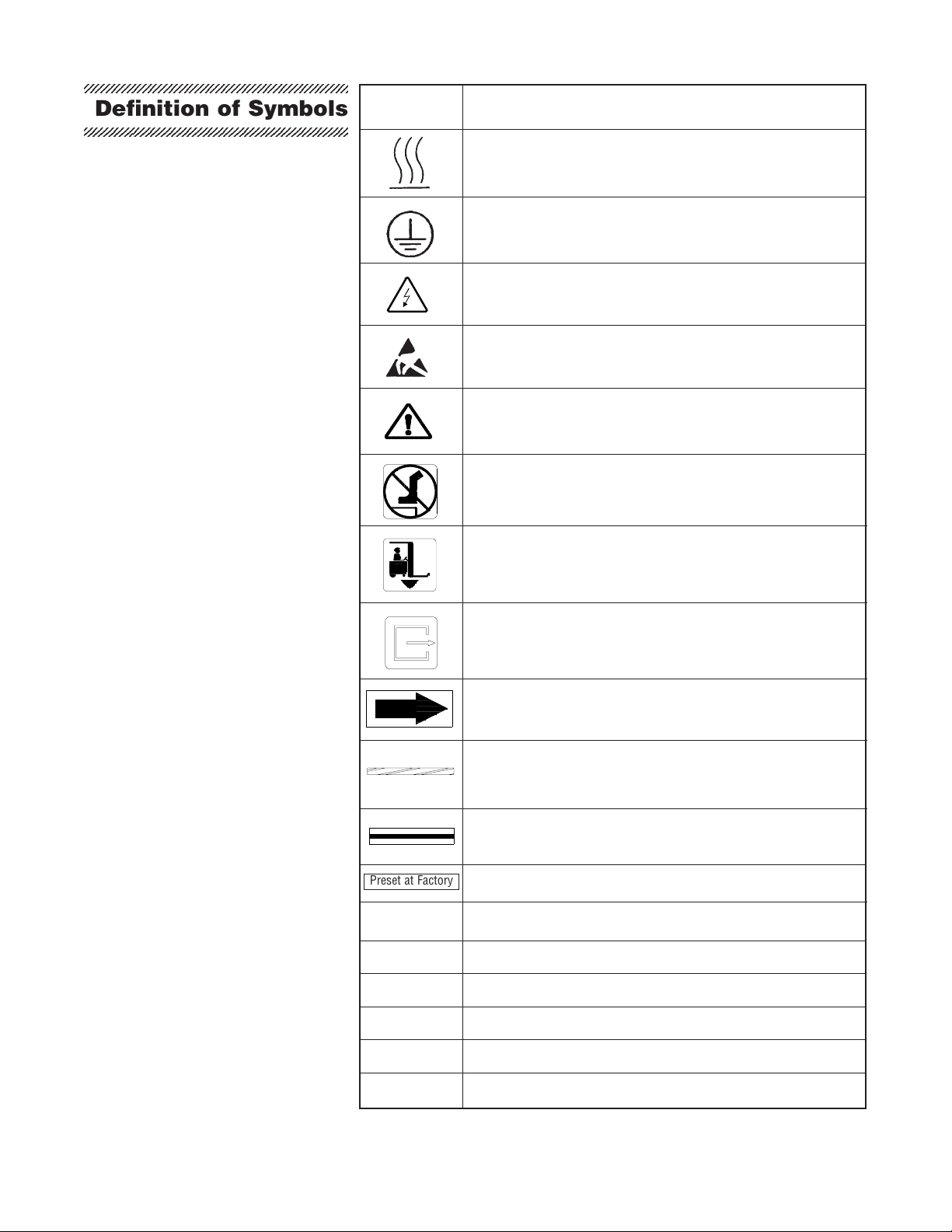

Symbol Definition

Transfer of Heat, Hot Surface

Protective Earth (Ground)

Warning! Risk of Electrical Shock

Electrostatic Sensitive Device

Attention, Consult Manual for Further Instructions

Warning! Do not step here.

Fork Lift: Place forks of the fork lift here.

Safety Exit: Push here in case of an emergency.

Rotation: Direction of the rotating device.

Emergency Stop Guard Rails: Push to stop the washer

and de-energize control.

Load delimitation: Do not place load over these marks.

Factory adjustment: Do not adjust.

AAmperage Rating of the unit

VVoltage Rating of the unit

~Alternating Current

kW Power Rating of the unit

Hz Frequency of the unit

fPhase of the unit

123456789012345678901234567890121234567890123456789

1

2345678901234567890123456789012123456789012345678

9

123456789012345678901234567890121234567890123456789

123456789012345678901234567890121234567890123456789

1

2345678901234567890123456789012123456789012345678

9

123456789012345678901234567890121234567890123456789

Definition of Symbols

Preset at Factory

2-1

InstallationVerification OperatorManual 122998-050

AnEquipmentDrawing,showingallutilityandspacerequirements,

wassenttoyouaftertheorderforthisequipmentwasreceived.The

clearancespace,specifiedonEquipmentDrawing,isnecessaryfor

proper installation, operation and maintenance. Uncrating and In-

stallationInstructionswereprovidedwiththewasher.Ifanyofthese

documents are missing or misplaced, contact STERIS giving the

serial, equipment and model numbers of the unit. Replacement

copies will be sent to you promptly.

After installing the washer according to the Uncrating and Installa-

tion Instructions, complete the following checklist to assure com-

plete and correct installation. Or contact your STERIS representa-

tive to schedule a technician to test your installation and demon-

strate proper equipment operation.

❑Shutoff valves (not by STERIS) capable of being locked in OFF

position only for maintenance purposes, installed on steam, air

andwaterlinesand in compliance withlocaloccupationalhealth

and safety regulations, as well as electric and plumbing codes.

❑Disconnectswitches(notbySTERIS)capableofbeinglockedin

OFFpositiononlyformaintenancepurposes, installed in electri-

cal supply lines near the unit and in compliance with local

occupational health and safety regulations, as well as electric

code. Disconnect switches must bear the identification of the

equipment to which they are connected.

NOTE:Ifunitisinstallednexttootherequipment,shutoffvalvesand

disconnect switches should be located so that service can be shut

off to one piece of equipment at a time.

❑Unit positioned, as shown on Equipment Drawing, with

requiredclearancespace andinrelationtobuildingsupply

lines.

❑Washer is level.

❑Building cold water line supplies water to unit as specified on

Equipment Drawing (required only if Cold Water Injection, Drain

Discharge Cooldown or pH Neutralizing System is present).

❑Building hot water line supplies water to unit as specified on

EquipmentDrawing.

❑Building steam line provides steam to unit as specified on

EquipmentDrawing.

❑Building condensate return line is connected to unit as specified

on Equipment Drawing.

❑Building air line supplies air to unit as specified on Equipment

Drawing.

❑BuildingwastelineisavailableasspecifiedonEquipmentDraw-

ing.

2

INSTALLATION VERIFICATION

Installation Checklist

123456789012345678901234567890121234567890123456789012345678

123456789012345678901234567890121234567890123456789012345678

123456789012345678901234567890121234567890123456789012345678

123456789012345678901234567890121234567890123456789012345678

2-2

122998-050 OperatorManual InstallationVerification

(continued)

❑Building ventilation system is connected to unit as specified on

EquipmentDrawing.

❑Electrical supply for unit is as specified on Equipment Drawing.

❑Floor surrounding unit has a non-slip surface (not by STERIS).

❑Check for any construction and/or installation debris, inside and

outside wash chamber, under floor gratings and sump suction

plate. Clean or discard.

❑Verify all electrical connections, to make sure that they are

plugged in and/or connected.

❑Verify electrical boxes. Make sure that there are no foreign

objectsinside electrical boxes. Also check for any unconnected

wires.

❑Verify all clamps and unions on washer and mechanical core.

Tighten if necessary.

❑Verify spray headers and spray header cables. All cables are

properlytightened.

❑Verify that headers travel to the top and bottom of the wash

chamber without touching top or bottom pulleys and guides.

Verify proper installation.

❑Inspect the doors for alignment and smooth movement. Inspect

door cables for tightness and proper installation.

❑Check that all excessive silicone has been removed.

❑Check that all the protective paper has been removed from

stainless steel.

IMPORTANT: After a few weeks of operation, inspect unit for

leaks. Re-tighten all clamps and connections.

Technical Specifications

12345678901234567890123456789012123456789012345678901234567

1

234567890123456789012345678901212345678901234567890123456

7

12345678901234567890123456789012123456789012345678901234567

12345678901234567890123456789012123456789012345678901234567

1

234567890123456789012345678901212345678901234567890123456

7

12345678901234567890123456789012123456789012345678901234567

Thesespecificationsareintendedtodescribethetechnicalinforma-

tion given on the nameplate of your washer and to state other

relevant information. Check Equipment Drawing or Identification

nameplate,locatedonframeofmobilemechanicalcore,belowmain

electrical box, for proper voltage and amperage.

This unit operates either on 208 V~, 3-phase, 60 Hz,

380/400/415 V~, 3-phase, 50 Hz or 480 V~, 3-phase, 60 Hz. Refer

toUncrating/InstallationManual(P-122998-049)forproperconnec-

tion.

A protective ground conductor is required (Class 1 Equipment).

Installation Category is Overvoltage II.

2-3

InstallationVerification OperatorManual 122998-050

AMPERAGE AND POWER CONSUMPTION

The maximum currents and power consumptions, for units with or

without drying, are:

kW A

208 V 37,0 13,3

380/400/415 V 13,0 9,3

480 V 17,5 14,6

NOISE LEVEL

EquivalentSoundPressureLevelatworkstation(measured1meter

awayfrom equipment and at 1,6 meters from ground):76.6 dB (A)

for a freestanding unit with side panels and 72.6 dB (A) for an

enclosed unit. (Results determined according to

ISO-3746: 1979

Standard: AcousticsDeterminationofSoundPowerLevelsofNoise

Sources Survey Method

).

PERMISSIBLE ENVIRONMENTAL CONDITIONS

This washer is designed to give optimal results in an environment

where maximum relative humidity is less than 85% and maximum

operating temperature is 104°F (40°C).

ThisBasil9500CageandRackWashercomplieswiththefollowing

standards:

• American and Canadian Standards:

ConformtoANSI/ULstd.3101-1conformtoCAN/CSAstd.C22.2

1010.1

• Governing Directive for the Affixing of the CE Mark:

Machinery Directive (98/37/CE).

• Conformity to Other Applicable Directives:

ElectromagneticCompatibilityDirective(89/336/EEC)andamend-

ments (92/31EEC, 93/68/EEC), Low Voltage Directive (73/23/

EED) and amendment (93/68/EC).

• Standards applied to demonstrate conformity to the direc-

tives:

IEC1010-1(1990) A1(1992)A2(1995),EN50081-2,EN55011,

CISPR 11, EN 50082-2, EN 61000-4-2, EN 61000-4-3/ENV

50140, ENV 50204, EN 61000-4-4, EN 61000-4-6/ENV 50141.

Certification

12345678901234567890123456789012123456789012345678901234567

12345678901234567890123456789012123456789012345678901234567

12345678901234567890123456789012123456789012345678901234567

1

234567890123456789012345678901212345678901234567890123456

7

12345678901234567890123456789012123456789012345678901234567

2-4

122998-050 OperatorManual InstallationVerification

Theselectionofchemicaladditivesisopenforcustomerpreference,

however, in order to achieve optimal performance, the selected

chemical additives must meet as a minimum, the following specifi-

cations:

Product Use Dilution pH Range Other Applicable

Description Range Oz/Gal at Use Dilution Requirements

(ml/l)

Alkaline liquid, non foaming and viscosity

chemicals 1/4 - 4 9.0 - 12.0 below 200 ccsu.

(2 - 32)

Acidic liquid, non foaming, free rinsing and

chemicals 1/4 - 4 3.0 - 6.0 viscosity below 200 ccsu.

(2 - 32)

Descalers 1/2 - 2 < 2.5 liquid, non foaming, phosphoric acid

(4 - 16) based and viscosity below 200 ccsu.

NOTE:Followchemicallabelrecommendationsforconcentrationof

chemical to use.

NOTE:Followchemicalmanufacturer'srecommendationstodeter-

mine the temperature of the WASH treatment.

NOTE: Follow chemical manufacturer's recommendations for the

amount of chemical used according to water hardness.

Toachievemaximumcleaningefficiency,selectchemicalappropri-

atetosoiltypebeingprocessed.STERISrecommendsthefollowing

chemicals:

• Cage-Klenz®100 - (Alkaline) formulated to remove urine,

scale,animalfats,oilsandotherorganicsoilsfromcagematerials.

• Cage-Klenz®200 -(Acidic) formulatedtoremoveurine, scale,

animal fats, oils and other organic soils from cage materials.

• LIQUID DESCALER -forremovingscaleandother hardwater

deposits. For use in animal care centers.

NOTE:Certainproductsmaynotbeavailableinyourarea.Contact

yourSTERISrepresentativeforavailabilityoftheseproductsandfor

orderinginformation.

IMPORTANT: STERIS does not promote, recommend nor en-

dorse the use of any other type of chemical additives in the

processing of articles in the Basil 9500 Cage and Rack Washer,

suchasdrying agents, strong alkaline detergents (pH>12),alcohol

rinses, and liquid germicides including hypochloric acid (bleach).

Chemical Additives

Specifications

12345678901234567890123456789012123456789012345678901234567

1

234567890123456789012345678901212345678901234567890123456

7

12345678901234567890123456789012123456789012345678901234567

12345678901234567890123456789012123456789012345678901234567

12345678901234567890123456789012123456789012345678901234567

WARNING-CHEMICALBURNAND/

OR EYE INJURY HAZARD: Always

use a non-foaming chemical for ef-

fective cleaning and proper pump

and water level control operation.

Follow manufacturer's recommen-

dations for amount of chemical to

be used.

3-1

ComponentIdentification Operator Manual 122998-050

TheBasil®9500CageandRackWasherisdesignedforhighcapacity,efficient

cleaning and sanitization of cages, racks, debris pans, feeder bottles and

other miscellaneous items used in the care of laboratory animals.

Washer is equipped with a fully-programmable microprocessor control sys-

tem capable of storing up to 12 cycles for processing a wide variety of loads.

The control system monitors and automatically controls all cycle operations

and functions.

Beforeoperatingthewasher,itisimportantto become familiar withthelocation

and function of all major components and controls (see Figure 3-1).

COMPONENT IDENTIFICATION 3

Drying

Option

Printer

Indicator

Lights

Control

Panel Tip

Indicator

Exhaust Fan

Damper

Electrical

Supply Box

Side Tanks

Flowmeters

Cool Down

Tank

Vertical Self-

cleaning Filter

Main Electrical

Box

Emergency

Stop

Pushbutton

Identification

Namepate

Figure 3-1. Component Identification

3-2

122998-050 Operator Manual ComponentIdentification

Become familiar with all control locations and functions before operating

the unit. (See Figure 3-1).

The

POWER-OFF/STANDBY

switch,locatedbehindtheprinterdoor,includes

two settings which direct operation of the control (see Figure 3-2).

•POWER - press top portion of

POWER-OFF/STANDBY

rocker switch to

initialize control and place control in Ready Mode. Tanks fill with water.

When control is in Ready Mode, interior chamber light is on and display

screen shows:

then:

•OFF/STANDBY -press bottomportion of

POWER-OFF/STANDBY

rocker

switch to initiate Shutdown Cycle and place control in Standby Mode.

When control is in Standby Mode, interior chamber light is off and display

screen shows:

IMPORTANT: POWER-OFF/STANDBY switch does not turn off electrical

power to the unit.

NOTE:Controlshould be placedinStandby Mode forlast cycle of theday and

when washer is not in use for an extended period of time.

The Control Panel is used to direct all washer functions. It can be placed on

eithertheloadside or theunloadsideof double doorunits(seeFigures 3-2 and

3-3). The operator may select and review cycles and treatments, start, stop or

reset cycle operation and monitor cycle performance and washer status from

the control panel.

The two-line, alphanumeric screen displays cycle program data on demand,

cycle performance data and operator instructions. Display screen also indi-

cates certain abnormal conditions that may occur during a cycle.

» Display Screen

Main Control Panel

Figure 3-2. Load End

Control Panel and Printer

Power-Off/Standby

Switch

Factory-set

Cycles

STATUS

RODENTS BOTTLES

RABBITS PRIMATES

indicates flashing position.

STATUS

* STERIS *

* BASIL 9500 *

STATUS

00:00:00 A Current time

of day

Printer

Function

Switch

Display

Screen

Printer

Power-Off/

Standby

Switch

3-3

ComponentIdentification Operator Manual 122998-050

» Touch Pads

•CYCLE MENU - Press to view the cycle menus. Three cycle menus are

available.

•SELECT CYCLE - Press to select one of the four cycles available from

each cycle menu.

NOTE: Whenadisplayedcycleortreatmentvalueisselected,thecorrespond-

ing word or digit flashes.

•REVIEW CYCLE-Press to reviewtreatments and valuesprogrammed for

a selected cycle.

•CYCLE/START - Press to start selected cycle.

•STOP/RESET - Press once to stop cycle operation. Press a second time

to abort cycle or to interrupt opening or closing of doors.

•EXTEND CYCLE - Available in Service Mode only.

•ALARM REPLY - Press to stop intermittent alarm buzzer and acknowl-

edge the displayed alarm message.

•DOOR OPEN - Press to automatically open door(s).

SELECT

CYCLE

CYCLE

MENU

REVIEW

CYCLE

CYCLE

START

STOP

RESET

EXTEND

CYCLE

ALARM

REPLY

Figure 3-3. Control Panel

CHANGE

VALUES

CYCLE STATUS

CYCLE

MENU SELECT

CYCLE REVIEW

CYCLE CYCLE

START STOP

RESET

EXTEND

CYCLE DOOR

CLOSE

ALARM

REPLY DOOR

OPEN

PROGRAM

CURSOR VALUE SAVE

VALUES

Display Screen

Touch Pads

DOOR

OPEN

3-4

122998-050 Operator Manual ComponentIdentification

•DOOR CLOSE - Press to automatically close door(s).

•CHANGE VALUES (CVTP) - Press to modify treatments from pro-

grammed cycles and to confirm selected values from programmed cycles.

•CURSOR

arrows

- Press to move left or right on the display screen.

•VALUE

arrows

- Press to move up or down on the display screen and,

depending on selected item, press to either toggle between answer selec-

tions or to scroll through the alphabet, numbers 0 through 9, and symbols.

NOTE: Alphabet includes characters for an underline and a space ( ).

•SAVE VALUES (SVTP) - Press to store all treatment values and cycle

changes.

The printer records all cycle data on 2-1/4 inch (5.5 cm) wide, single-ply

thermal paper. Printer is always located above control panel beside POWER-

OFF/STANDBY switch (see Figure 3-2). Printer can be placed on either the

soiled or the clean side on double door units.

The PRINTERFUNCTIONswitch (PRINT/PRINT VALUES) controls the follow-

ing two printer functions:

•PRINT-Presstopportionof the rockerswitchtodisplayprintmenu.Display

shows:

Press SELECTCYCLEto select a function and CYCLE/STARTto generate

the selected printout.

ANALOG

-Generatesaprintoutoftheactualin-line heat exchanger water

temperature,actual air temperature at theexhaust (Drying option),actual

solution temperature in cooldown tank (Drain Discharge Cooldown Tank,

Direct Drain Discharge Cooldown or pH Neutralizing options), actual

waterpressureandactualpHsolutioninthecooldowntank(pHNeutralizing

option). See Figure 3-4.

CONSUMP- Generates a printout ofthewaterandchemicalconsumption

over a determined period of time. Report can be either in gallons or in

liters (see Figure 3-5).

CHANGE

VALUES

s

t

CURSOR

VALUE

st

SAVE

VALUES

Printer

» Printer Function Switch

DOOR

CLOSE

CYCLE

START

SELECT

CYCLE

STATUS

ANALOG CONSUMP.

CYCLE DUPLICATE

indicates flashing position.

3-5

ComponentIdentification Operator Manual 122998-050

CYCLE - Generates a complete printout of all programmed cycles and

treatment values (see Figure 3-6).

DUPLICATE - Generates a second printout of last cycle, with or without

cycle validation according to the cycle configuration.

•PRINT VALUES - Press bottom portion of toggle switch to generate a

complete cycle review printout including all treatments values of selected

cycle (cycle flashing in Cycle Menu when

PRINT VALUES

was pressed).

(See Figure 3-6).

Figure 3-7 is an example of a typical cycle printout without cycle validation

for Model 9500 washer. Figure 3-8 is an example of a printout with cycle

validation.

•Power Up - When POWER/OFF-STANDBY switch is set to POWER, the

generated printout lists time and date the control was turned on, model and

unit number (see Figure 3-9).

•Cycle Start - When CYCLE/START touch pad is pressed to begin

selectedcycle,thegeneratedprintoutlists name ofselectedcycle,timeand

date cycle was started as well as cycle number and unit serial number.

•Cycle Performance - During a cycle, the generated printout indicates

beginning and end of each treatment.

•End-of-cycle Performance Summary

- At the end of a cycle, the

generated printout lists time the cycle was completed, total cycle process-

ing time and time the door was opened.

•Alarm Printout

- When an alarm condition occurs, the generated printout

lists the type of alarm and time it occurred. Once the operator presses

ALARM REPLY, the generated printout lists the time the alarm was

acknowledged (see Figure 3-10).

NOTE : Refer to Section 7 for listing of possible alarm conditions.

» Typical Printouts

3-6

122998-050 Operator Manual ComponentIdentification

Figure 3-7. Typical cycle

Printout, without Cycle

Validation

Figure 3-6. Typical Printout

if CYCLE is Selected

Figure 3-4. Typical Printout

if ANALOG is Selected

BOOSTER = 88.1F (31.16C)

DRYING = 80.1F (26.72C)

COOL DOWN = 78.2F (25.66C)

PRESSURE =0.11P(0.0075B)

pH = 08.00

Figure 3-5. Typical Printout

if CONSUMP is Selected

=========================

CONSUMPTION

REPORT

8:16:26P 99/09/23

UNIT S/N 36XXXXXXXX

=========================

CYCLE CNT =00000002

WATER: 1197 gal

LAST RESET : 0/00/00

ALKALINE: 0.625 gal

LAST RESET : 0/00/00

ACIDIC 0.000 gal

LAST RESET : 0/00/00

========================

CYCLE - RODENTS

========================

CYCLE START 4:45:04P

CYCLE DATE 99/09/24

CYCLE NUMBER 000000003

UNIT NUMBER 3600000000

TREATMENT TIME

------------------------

PRE-WASH 4:45:27 PM

4:46:19 PM

WASH 1 4:46:19 PM

WATER TEMP. = 99.6 F

4:50:18 PM

FINAL R. 4:50:18 PM

WATER TEMP. = 107.9 F

5:00:05 PM

EXHAUST 5:00:05 PM

5:01:07 PM

DRYING 5:01:07 PM

5:16:08 PM

COMPLETED 5:16:08 PM

TOTAL CYCLE = 0:31:04

========================

= READY TO UNLOAD =

========================

=========================

= CYCLE PROGRAM REVIEW =

= CYCLE - RABBITS =

=========================

REVIEW TIME 9:28:23A

REVIEW DATE 0/02/05

UNIT NUMBER 3633900006

CYCLEAUTHORIZED: YES

PRE-WASH

DURATION = 00:20

FINAL R.

DURATION = 08:00

TEMP. = 185.0F

EXHAUST

DURATION = 01:00

DRYING

DURATION = 05:00

TEMP. = 180.0F

ALKALINE REFRESH 15%

ACID REFRESH 15%

FLOOR TILT = NO

MANIFOLD COUPLING = YES

============================

Table of contents

Other Steris Washer manuals

Steris

Steris ML 200 User manual

Steris

Steris AMSCO RELIANCE 430 User manual

Steris

Steris RELIANCE 400 User manual

Steris

Steris ML 222 User manual

Steris

Steris AMSCO 5000 Series User manual

Steris

Steris RELIANCE 400 User manual

Steris

Steris Basil 4600 User manual

Steris

Steris Reliance 1227 User manual

Steris

Steris AMSCO 7000 Series User manual

Steris

Steris RELIANCE 200 User manual