Steris ML 222 User manual

Operating Instructions for

ML 222

Washer/Disinfector

To prevent accidents

and reduce the risk of ö

damaging the machine,

read the Operating Instructions before

installing or using the machine. M.-Nr. 04 666 562

Contents

Guide to the machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Indications for use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

High-level disinfection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Cleaning without disinfection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

WARNINGS AND SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

WARNINGS AND SAFETY INSTRUCTIONS (detachable) . . . . . . . . Center pages

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Plumbing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Help to protect our environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Adjusting the water softener. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Opening and closing the door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Loading the washer/disinfector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Loading accessory baskets/inserts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Loading the washer/disinfector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Loading examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Adjustable upper basket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Loading instructions for MIS injector mobile unit ME00-450. . . . . . . . . . . . . . 24

Adding ML Neutral pH Detergent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Priming the neutralizer dispensing system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Adding detergent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Adding liquid detergent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Priming the liquid dispensing system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Cycle selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Contents

2

Washer/Disinfector operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Cycle Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Cycle phase indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Selecting an additional cycle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Interrupting a cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Unloading the washer/disinfector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Programming special functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Reactivating the water softener . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Cleaning and care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Maintaining the filter assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Maintaining the dispensing system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Maintaining the drying unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Correcting minor problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Read all instructions before using the washer/disinfector.

This equipment is suitable for the applications mentioned in the operating instruc-

tions. Do not use for purposes other than those for which it was designed, as

these may be dangerous. The manufacturer cannot be held responsible for dam-

age caused by improper use.

Contents

3

Guide to the machine

1 CHECK WATER INLET/DRAIN

indicator light

2 REACTIVATE WATER SOFTENER

indicator light

3 ADD LIQUID DETERGENT

indicator light

4 ADD NEUTRALIZING AGENT

indicator light

5 Cycle phase indicator lights

6 Indicator display field

7 Door release button

8 On-Off button

9 Cycle selector touch pads

Guide to the machine

4

10 Dispenser for detergent (blue) and

neutralizing agent (red)

11 Filter assembly

12 Safety fuse (anti-block feature) for

Drying unit

13 Operating hours counter for

Drying unit

14 Temperature selector for

Drying unit

15 Service panel

16 Dispenser for liquid surfactant

with dosage selector

17 Level indicator

18 Filter combination

19 Salt container socket

(water softener)

Guide to the machine

5

Indications for use

High-level disinfection

The ML 222 Washer/Disinfector is suit-

able for automatic treatment of medical

instruments and accessories. It cleans

and, when using the disinfection cycles

simultaneously, thermally disinfects at

200°F (93°C) instruments and acces-

sories.

Areas of effectiveness are physical

removal or thermal inactivation of vege-

tative bacteria including mycobacteria,

fungi, fungal spores, and viruses.

These categories include the Mycobac-

terium tuberculosis and the Entero-

coccus faecium.

IMPORTANT: Only the cycles labeled

‘DISINFECTION’ disinfect! Only use

these cycles when handling contami-

nated items. All other cycles are de-

signed to clean items without disinfect-

ing them!

The ML 222 Washer/Disinfector

achieves high-level disinfection as

defined by the Spaulding categorization.

IMPORTANT: Centers for Disease Con-

trol Publication PB85-923404, Guide-

line for Handwashing and Hospital Envi-

ronmental Control, 1985, defines the

processing requirements for critical,

semicritical and non-critical instru-

ments. Refer to these definitions to

determine when and under what condi-

tions the ML 222 Washer/Disinfector

can be used.

Instruments Suitable for Processing

in the Washer/disinfector

All instruments, accessories, and other

items to be cleaned and disinfected in

the ML 222 Washer/Disinfector must

have the following properties:

Heat resistance to temperatures of at

least 200°F (93°C)

Corrosion resistance in the presence

of heat, alkalinity and water.

Certain items and materials are not

suitable for processing in the

Washer/disinfector.

Do not process:

carbon steel devices as they may

corrode;

flexible endoscopes, light cables,

fiber optics, rotating devices, motors

or other electrical equipment unless

the processing is approved by the

device manufacurer.

Indications for use

6

NOTE: Aluminium devices can only be

processed using the DISINFECTION

VARIO 93°C – 10 MIN cycle with ML

Neutral PH Detergent as they may dis-

color otherwise.

NOTE: Always contact the device

manufacturer to confirm processing

compatibility if you have any concerns

about the suitability of a specific item.

The ML 222 Washer/Disinfector is an ef-

fective processor for many medical in-

struments and accessories. It is an effi-

cient washer and, when a disinfection

cycle has been selected, it thermally

disinfects at 200°F (93°C).

WARNING –POTENTIAL BIOHA-

ZARD: Always use DISINFECTION

cycles when processing medical in-

struments and accessories. Only

DISINFECTION cycles provide high

levels of disinfection.

Cleaning without disinfection

All other cycles are designed to clean

goods without disinfecting them. These

programs are:

RINSE

WASH 93°C

Please refer to "Cycle selection" for de-

tailed information.

Indications for use

7

WARNINGS AND SAFETY INSTRUCTIONS

The following is a summary of the safety precautions which must be observed

when operating and servicing this equipment. These precautions are repeated (in

whole or in part), where applicable throughout the manual.

All relevant safety procedures must be obeyed. Relevant safety procedures

include, but are not limited to, the Centers for Disease Control’s Recom-

mended Infection Control Practices and the OSHA Bloodborne Pathogens

Standard.

READ ALL INSTRUCTIONS BEFORE

USING THE APPLIANCE

WARNING –

The manufacturer cannot accept responsibility for damage caused when the

appliance is not used according to the instructions, or for uses other than

those for which it was intended.

The manufacturer cannot be held responsible for problems or injuries result-

ing from improper installation, use or operation of this equipment.

WARNING –PERSONAL INJURY

HAZARD: Do not allow small child-

ren or unauthorized personnel access

to the washer/disinfector or its controls.

WARNING –EXPLOSION

HAZARD: Do not install the

washer/disinfector in areas where

flammable compounds/vapors are

present.

WARNING –PERSONAL INJURY/

EQUIPMENT DAMAGE HAZARD:

Repair work must be carried out only

by a qualified and competent service

technician. Repairs by unqualified per-

sons or installation of unauthorized

parts could cause personal injury, re-

sult in costly equipment damage or

void the washer/disinfector warranty.

WARNINGS AND SAFETY INSTRUCTIONS

8

WARNING –BURN HAZARD:

Except for emergency, do not

open door when cycle is in process. In

an emergency, first stop the cycle by

pressing ON/OFF button. Press DRAIN

touch pad and wait for washer/disinfec-

tor to drain. Wear protective gloves and

face shield whenever reaching into

wash cabinet.

WARNING –ELECTRICAL SHOCK

HAZARD: Disconnect all utilities to

equipment before servicing. Do not ser-

vice equipment unless all utilities have

been properly locked out.

WARNING –PERSONAL INJURY

HAZARD: The water in this

washer/disinfector is not suitable for

drinking.

WARNING –PERSONAL INJURY/

EQUIPMENT DAMAGE HAZARD:

Only use detergents which have been

approved of by STERIS. Use of any

other products may cause personal in-

jury, invalidate the disinfection results

or void the washer/disinfector warranty.

WARNING –CHEMICAL BURN

HAZARD: Wear protective gloves

and goggles and use care when hand-

ling liquids such as detergents or neu-

tralizing agents. Read and follow the in-

structions and safety procedures on

the packaging and in the Material

Safety Data Sheet (MSDS).

WARNING –PERSONAL INJURY/

EQUIPMENT DAMAGE HAZARD:

Empty containers and glassware be-

fore placing in the washer/disinfector.

Do not allow any acids or solvents, es-

pecially hydrochloric acid and

chlorides, to get into the wash cabinet.

WARNING –PERSONAL INJURY

HAZARD: Be careful when sorting

instruments with sharp pointed ends. If

possible, place the pointed end down-

wards.

WARNING –PERSONAL INJURY/

EQUIPMENT DAMAGE HAZARD:

Internal cleaning and disinfecting to a

measurable standard can only be

achieved with instruments that can be

dismantled and where the jets, sleeves

and adapters are used appropriately. A

special examination, over and above a

visual one, of the cleanliness of the

inner area of the instruments should be

made. Minimally invasive surgical (MIS) in-

struments should preferably be processed

using the DISIN VARIO 93°C-10 MIN or

DISIN 93°C-10 MIN program with recom-

mended detergents.

WARNINGS AND SAFETY INSTRUCTIONS

9

WARNING –BURN HAZARD:

Allow accessories to cool to room

temperature before unloading. Any

water which may have collected in in-

correctly loaded items will be very hot

and should be emptied into the wash

cabinet.

WARNING –BURN HAZARD:

Do not touch the heating elements

in wash cabinet after the end of a cycle.

WARNING –TIPPING HAZARD:

Do not sit or lean on the open door.

This could cause the washer/disinfec-

tor to tip.

WARNING –FALL HAZARD:

To prevent falls, keep floors dry by

immediately wiping up any spilled

liquids in washer/disinfector loading

and unloading areas.

WARNING –ELECTRIC SHOCK

HAZARD: Washer/disinfector must

be correctly grounded!

WARNING –POTENTIAL BIOHA-

ZARD: Always use DISINFECTION

cycles when processing medical instru-

ments and accessories. Only DISIN-

FECTION cycles provide high levels of

disinfection.

WARNING –PERSONAL INJURY/

EQUIPMENT DAMAGE HAZARD:

Do not fill container with cleaning deter-

gent! Fill with reactivation salt only!

Otherwise the pressurized container

may cause injuries by unscrewing.

WARNINGS AND SAFETY INSTRUCTIONS

10

CAUTION: Washer/disinfector

must not be used without all filters

in place.

CAUTION: Use only accessories

specifically designed for this equip-

ment. Load accessories into washer/

disinfector in accordance with the in-

structions provided.

CAUTION: The operator is respon-

sible for monitoring and guarante-

eing the standard of disinfection in the

routine disinfection cycle. Disinfection

parameters should be checked regu-

larly using chemical indicators, and

contamination levels checked and do-

cumented periodically using biological

indicators.

SAVE THESE

INSTRUCTIONS

WARNINGS AND SAFETY INSTRUCTIONS

11

Installation

WARNING –EXPLOSION HAZARD:

Do not install the washer/disinfector

in area where flammable com-

pounds/vapors are present.

IMPORTANT: The machine should only

be installed by a competent contractor.

The contractor should be experienced

in installing machines that require elec-

trical hook-up as well as plumbing.

The machine can be installed in the fol-

lowing ways:

Free-standing

Under counter.

The recess should be at least

23-3/4" (60 cm) wide, 23-3/4" (60 cm)

deep, and 33-1/4" (85 cm) high.

Washer/disinfector can be built into a

recess of 32-1/4" (83 cm) high by remov-

ing the washer/disinfector top.

If necessary the washer/disinfector top

can be removed as follows:

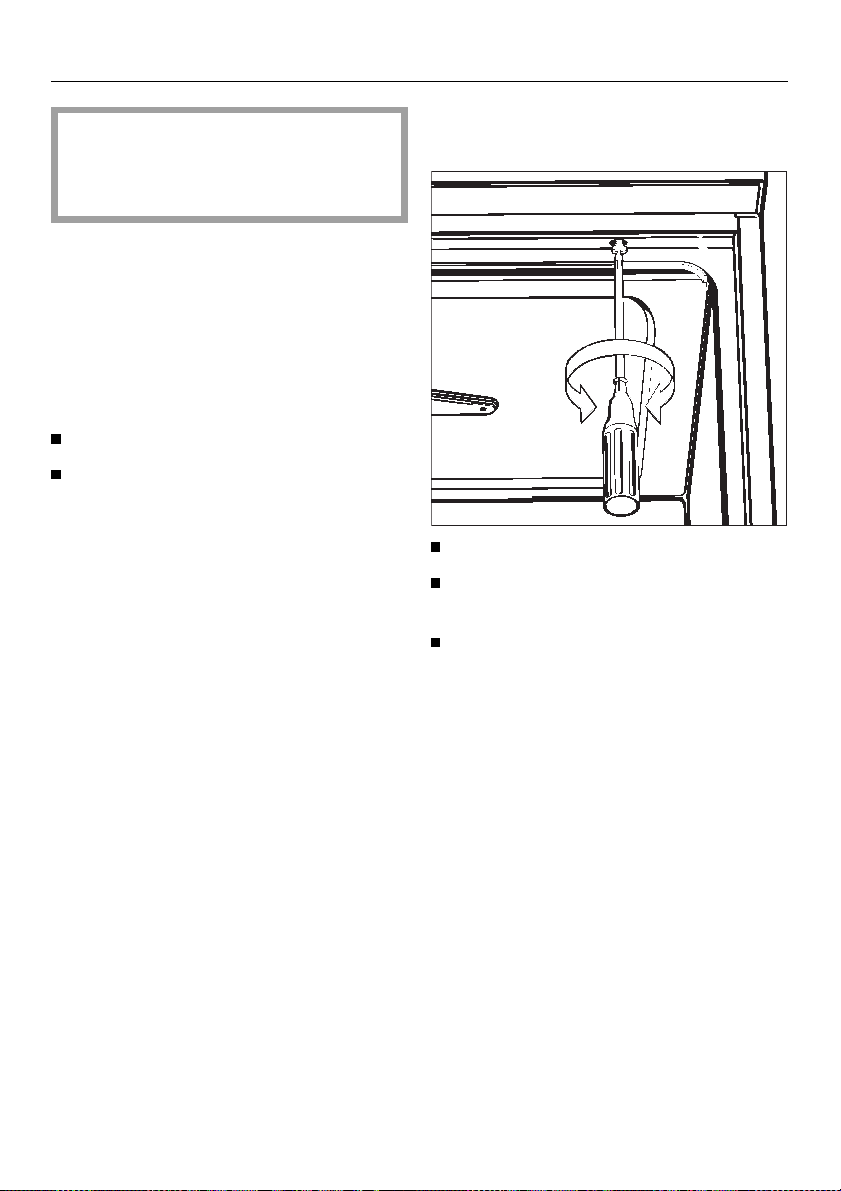

Open the door.

Remove the screws on the left and

right, using a Philips screw driver.

Pull the top forward, lift and remove.

Installation

12

The machine must be installed and

leveled correctly. Any unevenness in

the floor can be compensated for by

screwing the adjustable feet in or out

as necessary. To level this unit, the ser-

vice panel and kickplate must first be

removed.

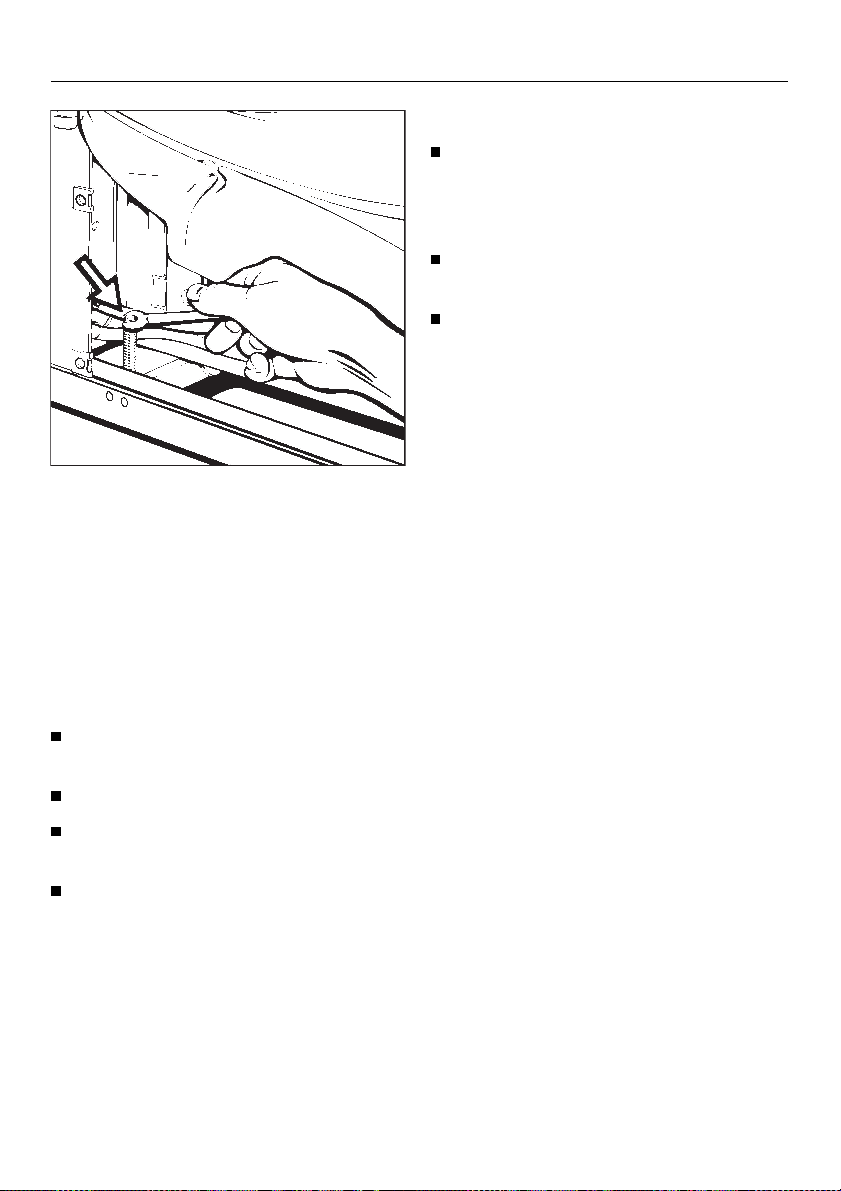

To remove the service panel and kick-

plate:

Take hold of the service panel at the

top of both sides and pull forward.

Remove all four kickplate screws.

Disconnect grounding lead if ne-

cessary.

Remove plastic protective cap.

To re-assemble:

Replace plastic protective cap, kick-

plate facing and service panel in the

reverse order which they were

removed.

Make sure the grounding lead is re-

connected.

Do not use silicone sealant to seal

the gaps between the machine and

any neighboring units as this will hin-

der ventilation to the circulation

pump.

Depending on the installation require-

ments, the following kit is available:

Steam deflector (P-16 MLE)

For use where the machine will be in-

stalled under a wooden countertop.

The underside of the work surface is

protected from steam damage by a

plate of stainless steel.

Installation

13

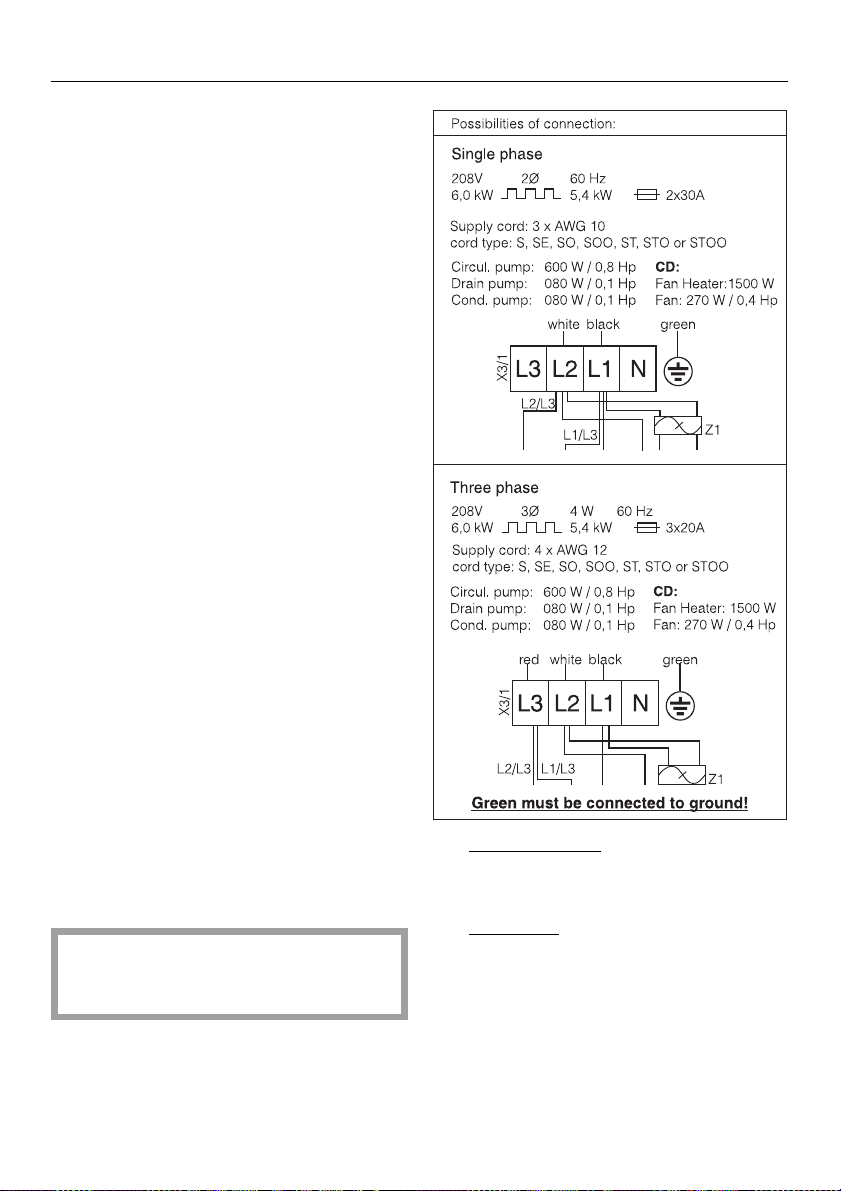

Electrical connection

IMPORTANT: All electrical work must

be carried out by a qualified electrician

and in compliance with all local and na-

tional electrical codes.

Before making any connections, check

that the voltage shown on the data

plate corresponds to your power sup-

ply. Data plate is located on back of

unit and behind service panel.

The washer/disinfector is supplied as

standard for connection to a 208 V,

60 Hz, single phase power supply and

is fitted with a power supply cord 6 ft

(1.8 m) long with a cross-section of

AWG 10-4. Connect washer/disinfector

to the main power supply (junction box

or electrical cord to outlet) according to

the opposite chart.

NOTE: If an electrical cord is used,

make sure cord is the proper size and

voltage/current rating for the washer/

disinfector as identified on the data

plate.

Voltage: 208 V, single phase

Frequency: 60 Hz

Rated load: 6.0 kW

Circuit breaker: 30 A per phase

The washer/disinfector can be con-

verted for connection to a 3-phase

power supply.

WARNING –ELECTRICAL SHOCK

HAZARD: Washer/disinfector must

be correctly grounded!

The wiring diagram can be found be-

hind the kickplate on the left hand side,

attached to the floor of the machine.

The data plate with serial and model

numbers is on the rear of the machine

and on the kickplate behind the service

panel.

Electrical connection

14

Plumbing

Connection to the cold water inlet

The machine must be connected to

the water supply in accordance with

all local and national plumbing

codes.

The machine is constructed with an

air gap/anti-siphoning device on

both the intake and the drain sides.

No such additional devices are

necessary or recommended, as they

will impede the water inflow into and

out of the washer.

The water pressure must be be-

tween 35 and 145 psi (2.5 - 10.0

bar). If the water pressure is not

within this range, STERIS Engineer-

ing Service can advise you of the

measures to be taken (see "Pro-

gramming special functions").

This machine is designed for cold

water connection only. Both inlet

hoses (water supply and steam con-

denser) must be connected to the

valves for cold water. Cold water sup-

ply must be provided with shut off

valves (by others).

Valves with 3/4’’ male hose thread

should be provided near the washer,

and should be easily accessible.

For additional protection of the

valves against impurities in the water

supply, large surface area filters are

enclosed in the kit supplied with the

machine (see diagram in "Cleaning

and care, Maintaining the filter as-

sembly").

Hose Color Water type

Blue

Green

Cold water

Demineralised water

WARNING –PERSONAL INJURY

HAZARD: The water in the washer/

disinfector is not suitable for drink-

ing.

Drainage

The drain system is equipped with a

non-return valve which prevents dirty

water from flowing back into the

washer/disinfector.

The machine is supplied with two

5 ft (1.5 m) long flexible drain hoses

with an inner diameter of 3/4’’ (2 cm).

They should not be shortened or at-

tached to any fittings that would cause

a reduction in water flow.

Longer drain hoses up to a length of

13 ft (3.3 m) are available if required.

Both hoses can be attached to exist-

ing drain lines through the use of a 1-

1/2’’ (3.5 cm) or larger stand pipe /

P-trap combination. Alternately, the

hoses can be connected directly to

existing drain lines, provided any fit-

tings or adapters used do not re-

duce the water flow.

The drain hoses must not exceed

13 ft (3.3 m) in length, or be at-

tached to the main drain at a point

higher than 3 ft (1m) above the floor.

A floor drain is permissible.

Plumbing

15

Help to protect our environment

Disposal of the packaging material

The transport and protective packa-

ging is mostly manufactured from the

following reusable materials:

corrugated paper/cardboard

polystyrene (CFC-free)

polyethylene foil (transparent)

untreated wood

Rather than throwing these materials

away, please take them to the nearest

recyclables collection point.

Disposal of your old machine

Old machines contain materials which

can be recycled. Please contact your

local salvage yard about potential recy-

cling options before disposal.

Before disposing, run the DRAIN pro-

gram to make sure that no residual

fluids are left in the sump of the ma-

chine.

When disposing of an old machine,

make sure the door catch is removed.

This will prevent children at play from

being accidentally locked in.

Help to protect our environment

16

Adjusting the water softener

To avoid the build-up of calcium de-

posits on items being cleaned and dis-

infected in the washer/disinfector, the

water may need to be softened (where

the supply hardness exceeds 107 ppm

CaCO3).

To ensure a steady supply of soft water,

the water softener must always be:

correctly set

regenerated with salt as soon as the

REACTIVATION indicator light comes

on.

The water softener should be set to

correspond with the water hardness

upon installation of the washer/ disinfec-

tor.

Your local water authority can advise

you on the water hardness in your area.

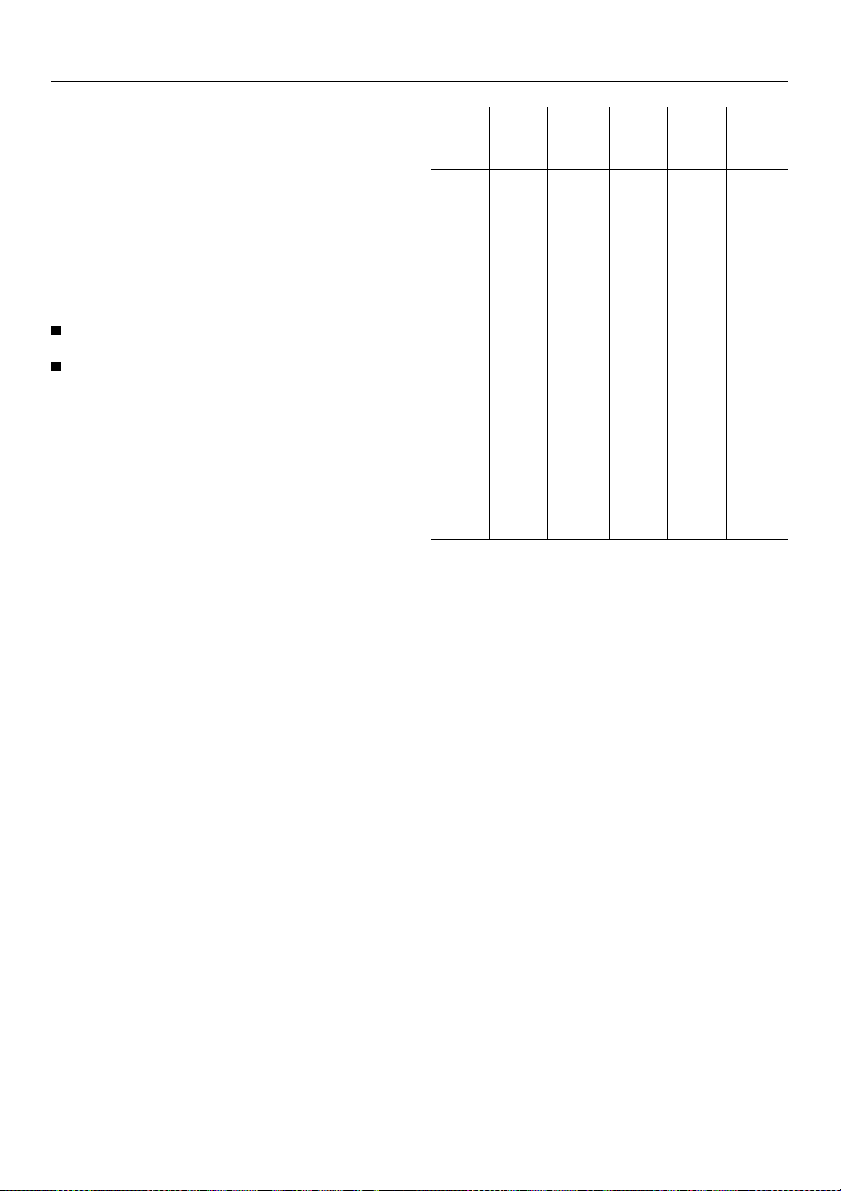

Setting the water softener

The hardness range is divided into 18

units and a zero position. The washer/

disinfector is set at the factory for a

water hardness setting of 8, corre-

sponding to 339 ppm CaCO3. If your

water supply is harder or softer than

this, change the setting as follows:

Time

set-

ting

°d

gr/gal

mmol/

l

°f °eppm

CaCO3

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

6

7

8

9

10

11

12

13

15

17

19

22

24

28

32

38

48

71

1.07

1.25

1.42

1.60

1.78

1.96

2.14

2.31

2.67

3.03

3.38

3.92

4.27

4.98

5.70

6.76

8.54

12.64

10.7

12.5

14.3

16.0

17.9

19.6

21.4

23.2

26.8

30.4

33.9

39.3

42.8

50.0

57.1

67.8

85.7

126,7

7.5

8.8

10.0

11.3

12.5

13.8

15.0

16.3

18.8

21.3

23.8

27.5

30.0

35.0

40.0

47.6

60.1

88.9

107

125

143

160

179

196

214

232

268

304

339

393

428

500

571

678

857

1267

1. Using table provided, identify correct

"Display Field" number that corre-

sponds to your local water hardness.

2. Press the DRAIN and DRYING touch

pads simultaneously and, while de-

pressed, turn the machine on, using

the main ON/OFF switch.

"P3" will appear in the display field.

3. Press the REACTIVATION touch pad.

The "P3" will disappear and setting

"0" will appear in the display field.

Adjusting the water softener

17

4. Press the DRYING touch pad as

many times as necessary for the

desired value to appear in the dis-

play field.

5. Press the START touch pad.

"SP" appears in the display field.

6. Press START once more. The setting

will now be stored. The display field

clears.

7. The washer/disinfector is now ready

for operation.

If the water hardness in your area is

permanently below 107 ppm CaCO3,

you do not need to soften the water.

Please deactivate the water softener by

selecting the setting "0" in the display

field according to above instructions.

The REACTIVATION indicator light will

not come on and the water softener will

not need to be reactivated.

For instructions on reactivating the

water softener, see "Reactivating the

water softener".

Adjusting the water softener

18

Opening and closing the door

To open the door

Press the DOOR button on the con-

trol panel and open the door.

WARNING –BURN HAZARD: Ex-

cept for emergency, do not open

door when cycle is in process. In an

emergency, first stop the cycle by

pressing ON/OFF button. Press

DRAIN touch pad and wait for

washer/disinfector to drain. Wear

protective gloves and face shield

whenever reaching into wash

cabinet.

The door should only be opened dur-

ing cycle operation for emergencies,

e.g. if articles are knocking together.

(Refer to "Interrupting a cycle".)

WARNING - TIPPING HAZARD: Do

not sit or lean on open door.

To close the door

Lift the door upwards and push until

it clicks into position. Do not press

the DOOR button.

Opening and closing the door

19

Loading the washer/disinfector

CAUTION: Use only accessories

specifically designed for this equip-

ment.

The washer/disinfector normally uses

an upper and a lower basket.

Depending on the type and shape of

the items being cleaned, accessory

baskets and inserts can be utilized. Se-

lect baskets and inserts which are ap-

propriate for the application (see separ-

ate product literature).

Loading accessory baskets/

inserts

WARNING –PERSONAL INJURY/

EQUIPMENT DAMAGE HAZARD:

Empty containers and glassware be-

fore placing in the washer/disinfec-

tor. Do not allow any acids or sol-

vents, especially hydrochloric acid

and chlorides to get into the wash

cabinet.

1. Empty all items to be cleaned before

loading into the accessories.

2. Remove gross soil/debris from all

items to be cleaned before loading

into accessories.

WARNING –PERSONAL INJURY

HAZARD: Be careful when sorting

instruments with sharp pointed

ends. If possible, place pointed end

downwards.

3. Load the items to be cleaned so the

water will come into contact with all

surfaces. This ensures that they will

be properly cleaned and disinfected.

Do not place items to be cleaned in-

side other pieces where they may be

concealed.

Vessels should be inverted and

placed in the correct accessory in-

serts.

Deep-based items should be placed

at enough of an angle for water to

run off them freely.

Tall and narrow pieces should be

placed in the center of the basket to

ensure good coverage with water.

4. In order to avoid corrosion, it is rec-

ommended that only heat and corro-

sion resistant items be cleaned in

the washer/disinfector. For the suita-

bility of instruments, please refer to

”Indications for use”.

5. The spray arms must not be blocked

by items which are too high for the

basket or which hang down in its

path. If necessary, manually rotate

the spray arm to test it.

Loading the washer/disinfector

20

Table of contents

Other Steris Washer manuals

Steris

Steris Basil 4600 User manual

Steris

Steris ML 200 User manual

Steris

Steris RELIANCE 400 User manual

Steris

Steris AMSCO 7000 Series User manual

Steris

Steris AMSCO 5000 Series User manual

Steris

Steris Reliance 1227 User manual

Steris

Steris BASIL 9500 User manual

Steris

Steris AMSCO RELIANCE 430 User manual

Steris

Steris RELIANCE 200 User manual

Steris

Steris RELIANCE 400 User manual