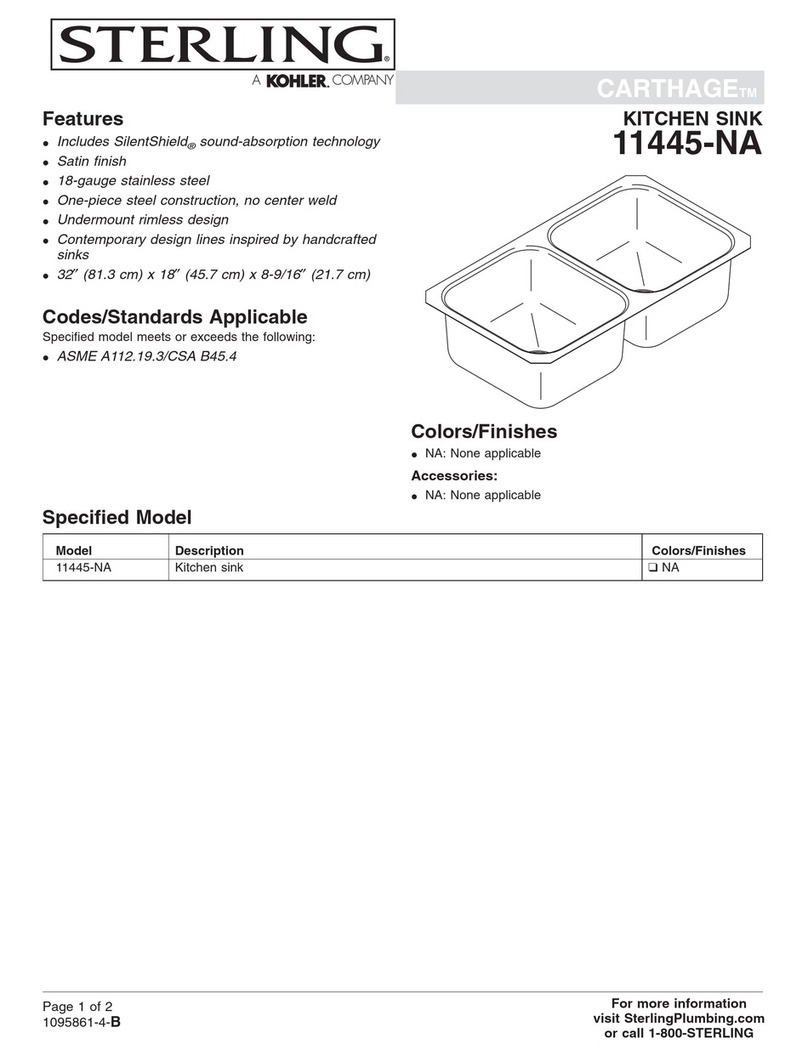

Ster0009

Ster0011

Ster0048

CP/BB/MB/BN

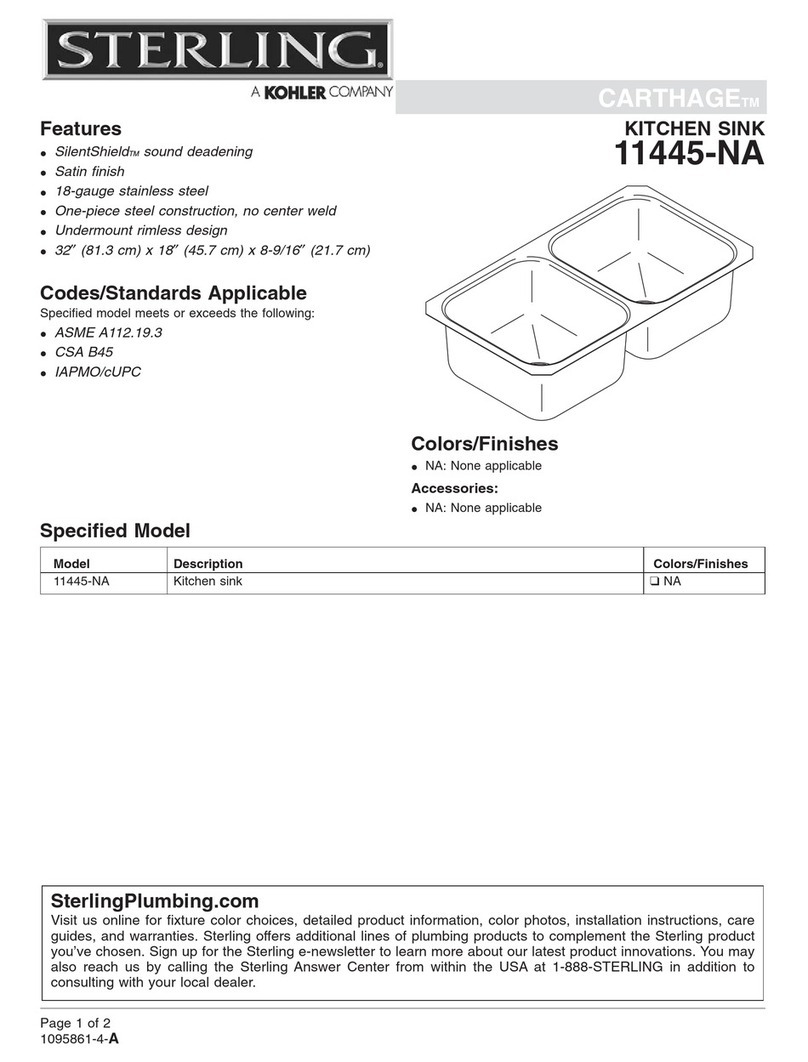

Ster0026

CP/BB/MB/BN

Ster0027

Ster0028

Ster0052

CP/BB/MB/BN

Ster0049

Ster0050

Ster0051

Ster0053

CP/BB/MB/BN

Ster0072

CP/BB/MB/BN

Ster0040

CP/BB/MB/BN

Ster0032

Ster0054

Ster0010

Ster0013

In the unlikely event you find a part missing please contact our Customer Service Helpline

on 01684 299555 for immediate despatch of part.

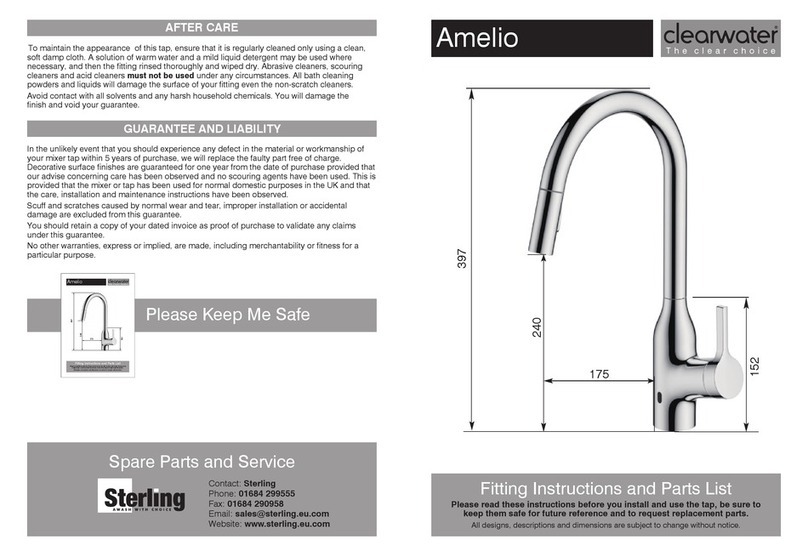

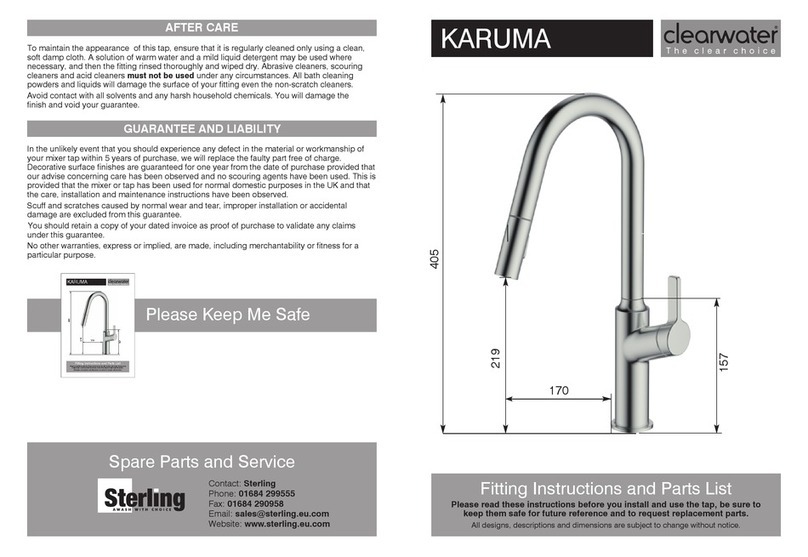

MAINTENANCE

REMEMBER

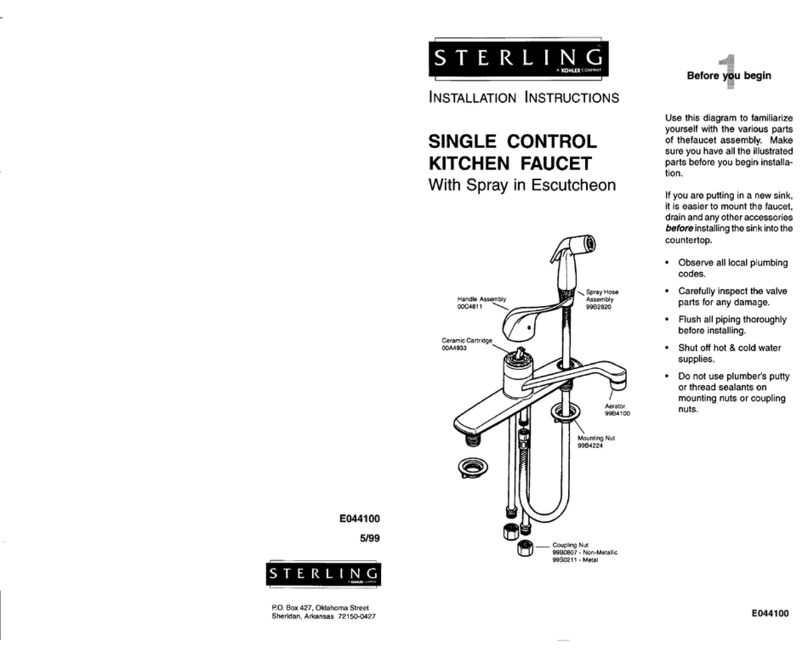

PARTS LIST MARINER

Ref. MAL10

IF THE FITTING BEGINS TO DRIP

1Turn off the water supply

2Loosen grub screw under handle lever,remove handle and valve

3Carefully clean seating, rubber washer and ceramic disc

4Replace valve and handle, then turn on the water supply

5If problem persists contact our helpline quoting the product code

Where an aerator is fitted to the outlet of the spout, it will need occasional cleaning.

This will be evident when the water flow slows down to an unacceptable level. To accomplish

this unscrew the outlet in an anti-clockwise direction and remove the mesh. Immerse the mesh

in a suitable descaling fluid overnight, rinse throughly in clean water and re-install.

Maximum water supply pressure 5 bar (75PSI) Minimum water supply pressure 0.5 bar

Maximum hot water supply temperature 70˚C

Recommended hot water supply temperature 65˚C

If these temperatures or water pressure are exceeded, damage to the tap can result. A pressure

reducing valve may be required to be fitted in high water pressure situations.

PREPARATION

We strongly recommend installing particle filters and isolation valves to both hot and cold feeds.

This willhelp to prevent premature failure of valves and make any future maintenence easier.

Flush the plumbing system before installing the mixer tap. This is to void plumbing residues

clogging the mesh of the aerated outlet, or possibly damaging the valve’s washers. This is

especially important where extensive plumbing work has been carried out.

First shut off your water heating system then, with your mains stop cock closed, open the lowest

hot and cold taps in the house and allow to run until the cold storage tank and pipes are empty.

(The hot water storage cylinder always remains full).

INSTALLATION

It is very important that you read through the following instructions

BEFORE you install and use the tap.

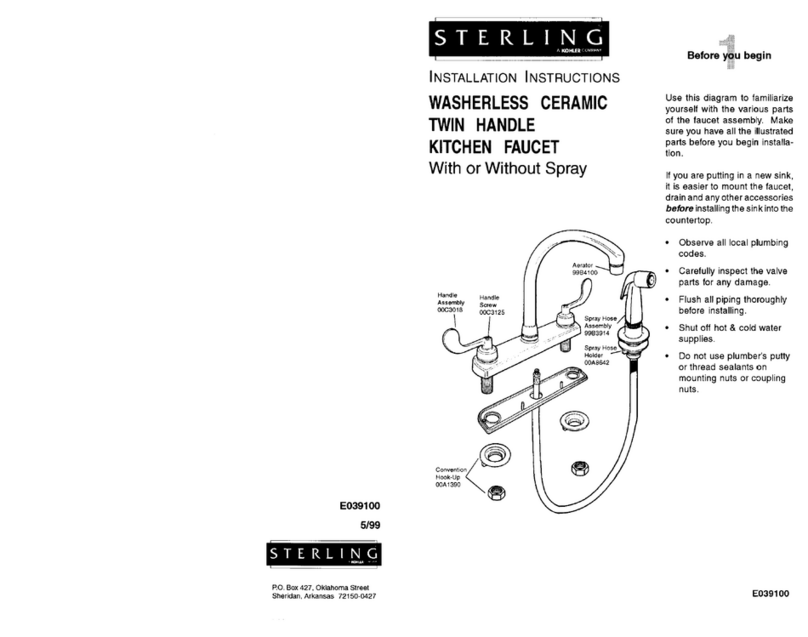

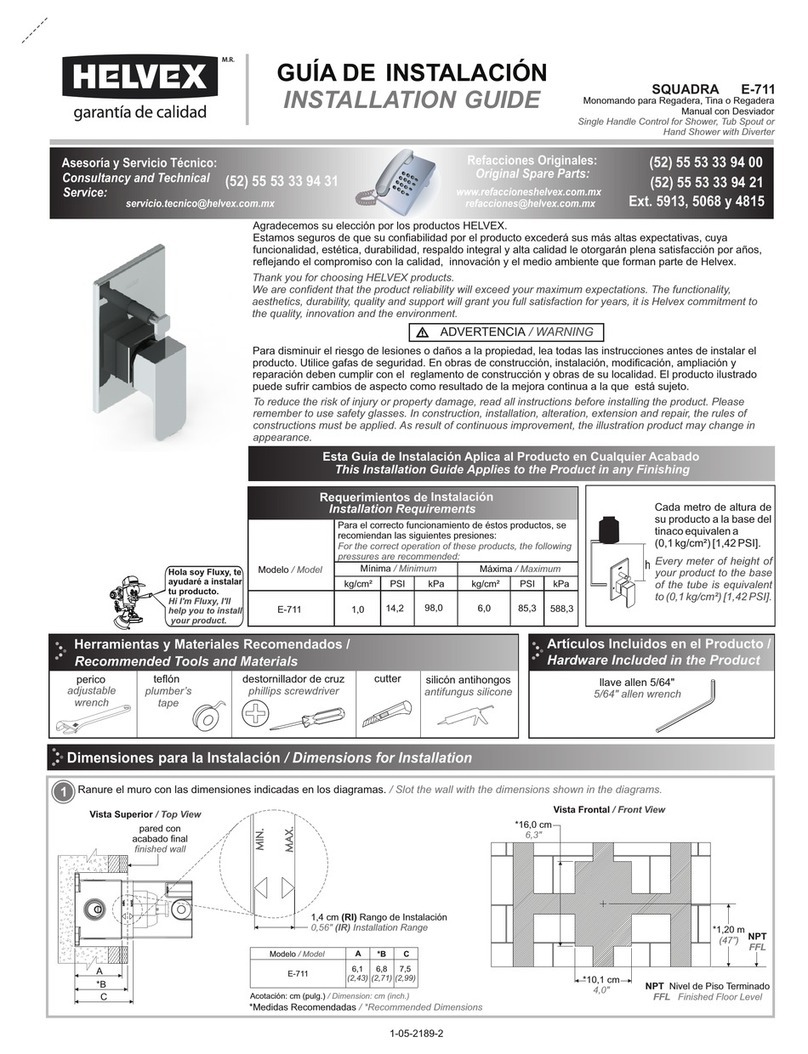

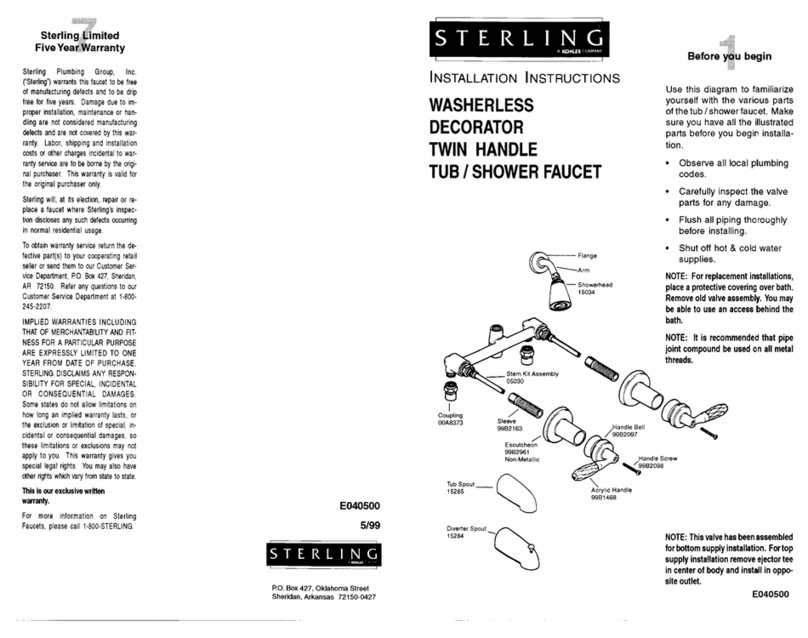

Slide the base ring and seal (Ster0040) up the pre fitted tails and pipe and locate into the base of the

tap.

Pass the hoses and threaded shank through the tap hole from above and place the mixer in position

on the sink or counter.

Slide the flat washers and fixing nut up the flexible hoses as pictured. Then screw the nut all the way

up making sure the tap is in the correct position. Then tighten the locking screw.

(Note:The thickness of sink >35mm no need to use the mounting seat.)

Connect the check valve to the 3 way tee first, and then to the cold end flexible hose using the seal

provided.

Connect The three-way tee (Ster0011) to the cold mains using a 15mm compression isolation valve.

Install the twist lock head to the cupboard carcass leaving adequate room for the filter to be

attached and removed.

Install the twist lock cartridge.

Connect the ¼" tube with push fit connector to the tee and the filter inlet. Then connect the remaining

¼'' tube coming from the tap to the out let of the filter head.

Connect the john guest isolation valve to the 1/4 tubing going to the filter inlet. If using a flow pro, install

the unit after the filter, before the tap.

Having first checked all the new connections, turn on the mains stop cock, close all taps except the

new mixer and as the system starts to refill check for leaks.

FOR BEST RESULTS

Run off around 5 litres of water from the filter line prior to drinking.

Reduce the filter water flow to around 2 litres per minute by adjusting the John guest isolation valve.

This will maximise the filter contact time.

The filter must be changed at least every 12 months. We suggest changing the cartridge every

6 months in normal household usage (filter life 4000 litres usage).

Other filter systems & water softeners can be used in conjunction with this tap. Make sure that the

filter line isn’t over pressurised, as this filter line is only design for a maximum of 4 litres per minute

and may fail if over pressurised. Install a pressure reducing valve in such instances.

OTHER

Remember to fill in and send off your free post warranty form.

TAP

Hot MMains

Cold Mains

ree Way Tee

Check Valve

Ster0011

Thr

with

Twist Lock

Cartridge

P6C1

Filter Tube

FILTER

check valve

Ster0013

push fit

connector

add FlowPro

here

Ster0082

add John Guest

Isolation here