Stewart Warner Ultra-Shift Light User manual

118799

Rev 1: 10/10/04

Installation Instructions

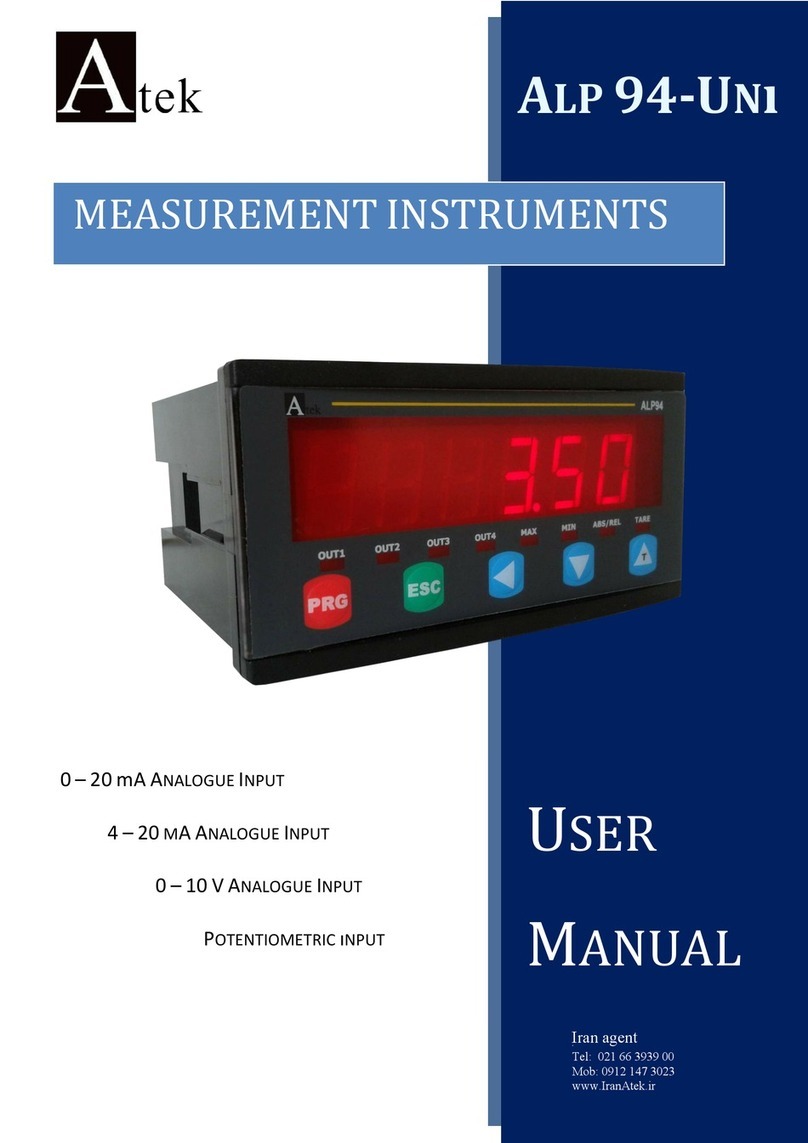

Ultra-Shift Light With RPM Activated Window Switch

PRECAUTIONS:

Read ALL instructions before installing instrument.

Follow ALL safety precautions when working on vehicle-wear safety

glasses!

ALWAYS disconnect (-) negative battery cable before making

electrical connections.

HELP?:

If after reading these instructions you don’t fully understand how to

install your instrument(s), contact your local Stewart Warner

distributor, or contact our Technical Support Team toll free at

1 866-797-7223 (SWP-RACE).

Visit

www.SW-Performance.com

for additional information.

GENERAL APPLICATION:

12-volt DC negative (-) ground electrical systems (11-20 VDC

operating voltage range).

The upper rpm limit of the shift light is variable, dependent upon the

PPR setting. The upper RPM limit for the PPR settings are .5-2 PPR=

18,000 RPM, 2.5-4 PPR= 15,000 RPM, and 5-6 PPR= 13,000 RPM.

Programmable RPM dependent switched output that will sink

(ground) 1 amp maximum (short circuit protected).

1

SHIFT-LIGHT MOUNTING:

The

Ultra-Shift Light

may be mounted on a roll cage, steering

column, dash, or other locations of high visibility.

To mount the

Ultra-Shift Light

, use the bracket and screws provided,

or secure using a hose clamp.

To mount on an existing tachometer, loosen the mounting strap and

insert the base of the

Ultra-Shift Light

bracket under strap and

retighten the mounting strap.

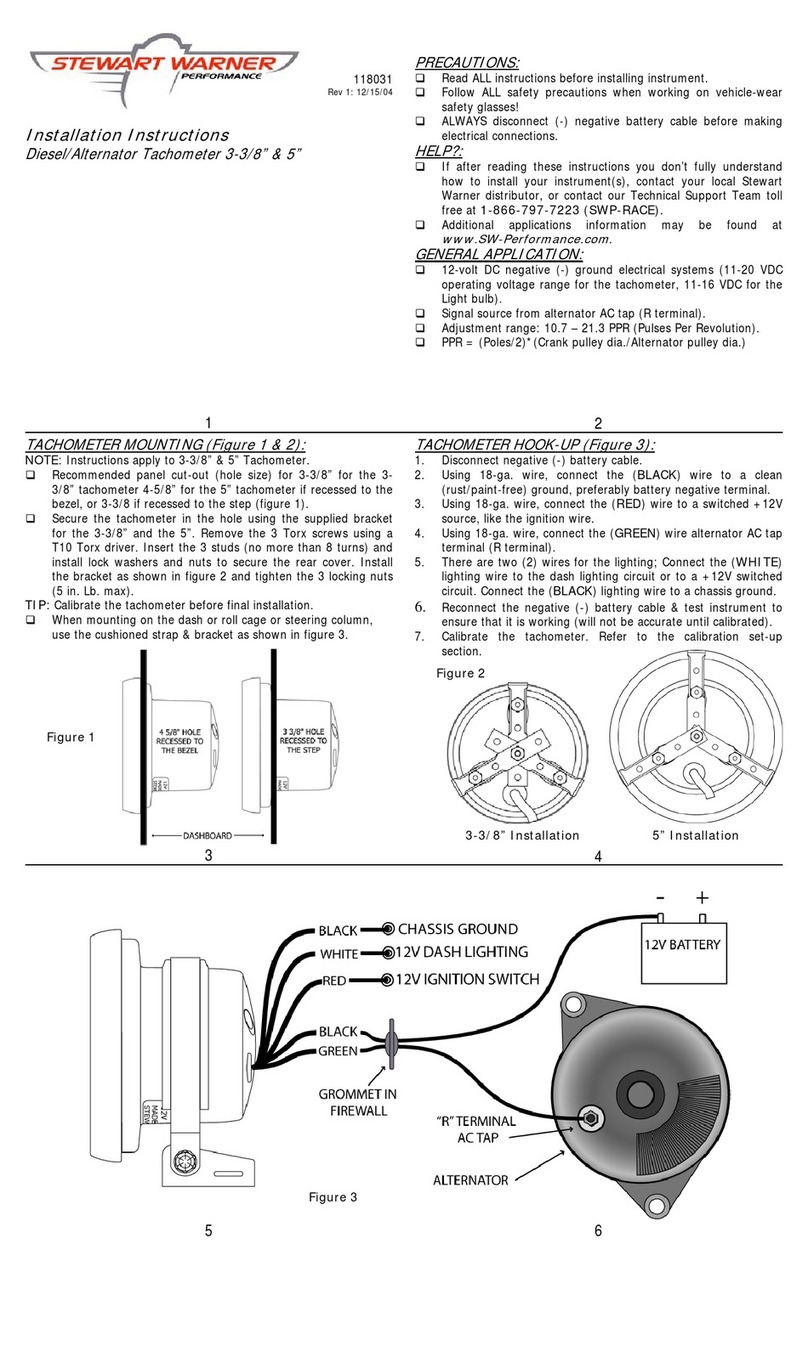

SHIFT-LIGHT WIRING (FIGURE 1):

1. Disconnect negative (-) battery cable.

2. Using 18-ga. wire, connect the (BLACK) wire to a clean (rust/paint-

free) ground, preferably battery negative terminal.

3. Using 18-ga. wire, connect the (RED) wire to a switched +12V

source, like the ignition wire.

4. Using 18-ga. wire, connect the (GREEN) wire the coil negative or

the tachometer terminal of the ignition module.

5. Using 18-ga. wire, connect the (WHITE) wire to the relay coil

negative. This wire will supply the ground (1 amp maximum) to

energize the relay and activate the desired device.

NOTE: The (WHITE) wire provides an output (switched to ground)

whenever the engine RPM is between the programmable L0 and HI

set points. This switch can be used to activate/deactivate any device

within a specific RPM range.

WARNING: Always use an, in-circuit

“Arming”

switch to disable any

device controlled by the RPM window switch. In addition to the

“Arming”

switch, a wide-open-throttle switch MUST also be used

to deactivate a nitrous oxide, or similar system, when the engine is

no longer at wide-open-throttle.

6. Reconnect the negative (-) battery.

2

3

ULTRA-SHIFT WITH RPM WINDOW SWITCH OPERATION:

Once the Ultra-Shift Light™ with RPM Window Switch is installed and

set up, the digital display, if Disp option is set to 0n, will show the

actual engine RPM, otherwise the display will be blank.

The peak RPM recall may be viewed at anytime during normal

operation. The peak RPM value is the maximum RPM attained since

the last time the peak was cleared.

1. At any time during normal operation, display the max RPM

recall by pressing the

SCROLL

button.

2. The internal display will show PEAC then display the peak RPM.

3. To clear the stored peak value, press and hold the

SCROLL

button. The display will read PEAC then display the peak RPM,

and then return to normal operation.

The shift indicator LED cluster will illuminate whenever the engine

RPM exceeds the programmable SHP RPM setting (refer to the Shift

RPM Setup section for programming information).

The shift indicator LED cluster brightness may be changed to one of

four levels at anytime during normal operation. These are used to

adjust to the changing racing conditions for the best visibility.

1. To change the intensity of the LED cluster, press and hold

SELECT

button. The LED cluster will rotate through the four

levels.

2. To select an intensity level, simply release the

SELECT

button

when the LED cluster is at the desired intensity.

The switched output (WHITE) wire will switch to ground whenever

the engine RPM is between the programmable L0 and HI set points,

otherwise the output is off or floating (refer to the Window Switch

section programming and circuit wiring information). The switched

output may be used to control most any device where engine RPM is

a factor used to turn a device on or off, such as Nitrous Oxide

systems, CO2 and water sprayers for intercoolers, or even automatic

shifters.

4

SET-UP MENU, OPTIONS, & DESCRIPTIONS:

The Set-up Menu sets the different options and calibrations to establish

the overall operation of the Ultra-Shift Light™, and should be set up

before the RPM window switch option is used.

ShP – Sets shift point RPM.

NOTE: The upper rpm limit of the shift light is variable, and depends

upon the PPR setting. The upper RPM limit for the PPR settings are

.5-2 PPR= 18,000 RPM, 2.5-4 PPR= 15,000 RPM, and 5-6 PPR=

13,000 RPM.

Disp – Display options (0n, 0ff). This determines the information

shown on the display.

•0n - Current engine RPM is shown on the display.

•0ff - Nothing displayed. Recall information can still be viewed.

ppr – Pulses/revolution of the tach signal (.5,1,1.5, 2, 2.5, 3, 4, 5, 6).

WARNING: An improper PPR setting will cause the RPM display, shift

light activation, and switch activation to be inaccurate.

L0 – Set switched output activation RPM (Range: 500 to18.00).

HI – Set switched output deactivation RPM (Range: l0 setting

to18.00).

5

SHIFT RPM SET-UP (Range 1000 to 18,000 RPM):

1. Enter programming mode by pressing both

SCROLL

&

SELECT

buttons at the same time, and then release both buttons.

2. Scroll to the SHP parameter using the

SCROLL

button, and then

press the

SELECT

button.

3. The display will show the current shift point RPM (the default is 3000

RPM for a new shift light).

4. Hold down the

SCROLL

button to increment slowly. After holding

down for one second, the value will increment quickly. Simply

release the

SCROLL

button and press it again to go back to

incrementing slowly. Press the

SCROLL

button repeatedly to

increment one step (10 RPM) at a time. If the desired shift RPM is

missed simply continue to hold the

SCROLL

button and the value

will wrap around and start at 1000 RPM again.

NOTE: When scrolling above 9990 RPM, a decimal point will appear in

the center of the display to indicate that the far right digit will not be

displayed (refer to figure 2).

5. Once the desired shift RPM is displayed, press the

SELECT

button to

return to the

MAIN MENU

.

6. To exit programming mode, do not press any buttons for 5 seconds.

All changes will automatically store and the unit will return to normal

operation.

NOTE: The upper rpm limit of the shift light is variable, and depends

upon the PPR setting. The upper RPM limit for the PPR settings are

0.5-2 PPR= 18,000 RPM, 2.5-4 PPR= 15,000 RPM, and

5-6 PPR= 13,000 RPM.

6

NEVER CONNECT GREEN WIRE TO THE COIL

WHEN USING AN MSD OR SIMILAR HIGH

OUTPUT CAPACITIVE DISCHARGE STYLE

IGNITION SYSTEM

Damage to the shift light will occur—Connect GREEN wire

to the tachometer terminal only.

Fi

g

ure 1

PPR SET-UP (.5,1,1.5,2,2.5,3,4,5,6 PPR):

WARNING: An improper PPR setting will cause the RPM display, shift

light activation, and switch activation to be inaccurate.

1. Enter programming mode by pressing both

SCROLL

&

SELECT

buttons at the same time, and then release both buttons.

2. Scroll to the PPr parameter using the

SCROLL

button, and then

press the

SELECT

button.

3. The display will show the current setting (the default setting for a

new unit is 4PPR).

4. Press the

SCROLL

button to change the setting.

5. Once the desired setting is displayed, press the

SELECT

button to

return to the

MAIN MENU

.

6. To exit programming mode, do not press any buttons for 5 seconds.

All changes will automatically be stored and the unit will return to

normal operation.

TIP: When connecting to an engine with a distributor, generally, the old

rule, half the number of cylinders = PPR, still applies. When

connecting to the signal wire to a coil pack that drives 2 cylinders,

generally, the PPR = 1. When connecting to a “coil on plug” ignition

or one coil for each cylinder, the best option is to look for a tach

signal coming out of the ECU, but the .5 PPR setting may work when

directly connected to any one of the coils. If this connection is erratic

or does not function correctly, a tachometer adapter may be

required. Call technical support a 1-866-797-7223 or visit

www.SW-Performance.com for more information.

7

RPM DISPLAY ON/OFF:

1. Enter programming mode by pressing both

SCROLL

&

SELECT

buttons at the same time, and then release both buttons.

2. Scroll to the dISP parameter using the

SCROLL

button.

3. Select the dISP parameter option using the

SELECT

button.

4. The display will show the current (0n, 0FF)

”

setting (the default

setting is 0n).

5. To change the setting press the

SCROLL

button to toggle between

0n & 0FF.

6. Once the desired setting is displayed, press the

SELECT

button to

return to the

MAIN MENU

.

7. To exit programming mode, do not press any buttons for 5 seconds.

All changes will automatically store and the unit will return to normal

operation.

8

RPM WINDOW SWITCH ACTIVATION RANGE SETUP:

TIP: If both HI and L0 values are set the same, the switched output is

disabled and will not activate. The default settings for both HI and

L0 values are 3000, so the switched output is disabled.

1. Enter programming mode by pressing both

SCROLL

&

SELECT

buttons at the same time, and then release both buttons.

2. Scroll to the L0 parameter using the

SCROLL

button, and then press

the

SELECT

button.

3. The display will show the current switch activation setting (the

default is 3000 RPM for a new shift light).

4. Hold the

SCROLL

button to increment slowly. After one second, the

values will increment quickly. Simply release the

SCROLL

button

and press it again to go back to incrementing slowly, or press the

SCROLL

button repeatedly to increment one step (10 RPM) at a

time. If the desired RPM is missed, simply continue to hold the

SCROLL

button and the value will wrap around and start at 500

RPM again.

NOTE: When scrolling above 9990 RPM, a decimal point will appear in

the center of the display to indicate that the far right digit will not be

displayed (refer to figure 2).

5. Once the desired RPM is displayed, press the

SELECT

button to

return to the

MAIN MENU

.

6. Scroll to the HI parameter using the

SCROLL

button, and then press

the

SELECT

button.

7. Set the desired upper RPM threshold by following the above

procedure.

NOTE: The lower RPM limit of the HI parameter is the L0 set point.

8. Press the

SELECT

button to return to the

MAIN MENU

.

9. To exit programming mode, do not press any buttons for 5 seconds.

All changes will automatically store and the unit will return to normal

operation.

9

NITROUS OXIDE SYSTEM CONTROL WIRING:

¾The switched output is very useful for controlling Nitrous Oxide

activation/deactivation. Set the programmable L0 value to the

desired engine RPM where the device activates and the HI value to

the desired RPM where the device to deactivate (usually just before

the engine rev limiter triggers to prevent catastrophic engine

damage).

¾Wire the Nitrous Oxide System, as illustrated below, using the

supplied relay and the

“Arming”

and

“Wide-Open-Throttle”

switch supplied with the Nitrous Oxide System.

¾The

“Arming”

switch will deactivate the system so it can’t be

activated unexpectedly. The

“Wide-Open-Throttle”

switch will

only allow activation when the throttle is wide open, so the system

will shut down during shifts or deceleration, even if the engine RPM

is still in the activation range.

10

INTERCOOLER SPRAYER CONTROL WIRING:

¾The RPM switched output, when used in conjunction with a pressure

switch is very efficient at controlling an intercooler CO2 or water

sprayer system during high boost and high engine RPM when the

efficiency of the intercooler falls off. This set-up works well to

conserve the CO2 or water supply for when it’s needed most.

¾The pressure switch is used to activate the system only when the

boost pressure is high.

¾The RPM switch is used to control the RPM at which the system is

activated so the system does not activate at low RPM when the

intercooler can easily cool the lower airflow.

11

CLEANING DIRECTIONS:

For proper cleaning of instrumentation/accessories, use a glass

cleaner or mild detergent with a spray on and wipe method.

WARRANTY INFORMATION:

TWO (2) YEAR LIMITED WARRANTY. SWP products are warranted

against defects in workmanship and materials for a period of two (2)

years from the date of purchase. Proof-of-purchase is required;

otherwise, the warranty period shall default to two (2) years from date-

of-manufacture (as indicated by the date code on the product). See

detailed Warranty Policy for other Terms & Conditions.

STEWART WARNER PERFORMANCE

1-866-SWP-RACE (797-7223)

www.SW-Performance.com

12

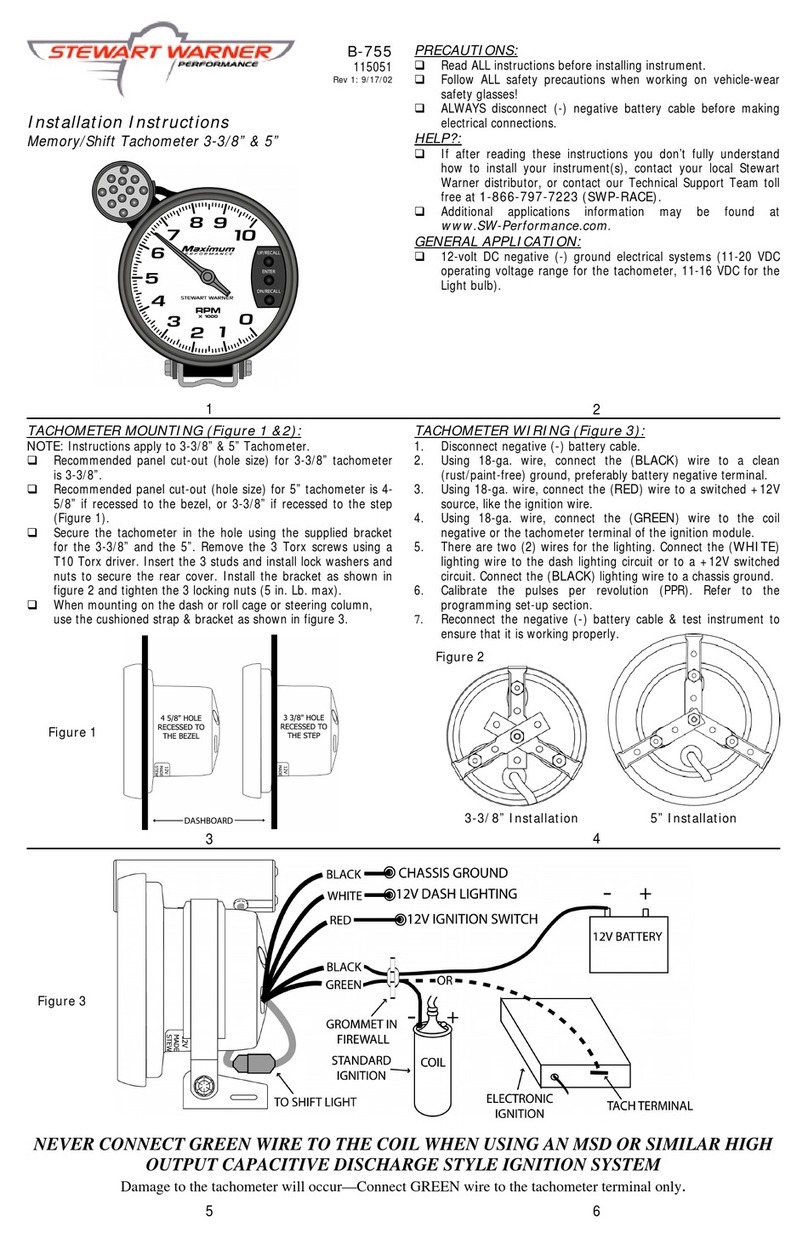

REAR VIEW FRONT VIEW

SCROLL

BUTTO

N

SELECT

BUTTON

ULTRA-BRIGHT

LEDs

In order to display

up to 18,000 RPM

with only 4 digits, a

decimal point is

displayed and the

right most digit is

dropped when the

RPM exceeds 9990.

TACHOMETER

DISPLAY

Fi

g

ure 2

Table of contents

Other Stewart Warner Measuring Instrument manuals