Stewart Warner Diesel/Alternator Tachometer 3-3/8” & 5” User manual

118031

Rev 1: 12/15/04

Installation Instructions

Diesel/Alternator Tachometer 3-3/8” & 5”

1

PRECAUTIONS:

Read ALL instructions before installing instrument.

Follow ALL safety precautions when working on vehicle-wear

safety glasses!

ALWAYS disconnect (-) negative battery cable before making

electrical connections.

HELP?:

If after reading these instructions you don’t fully understand

how to install your instrument(s), contact your local Stewart

Warner distributor, or contact our Technical Support Team toll

free at 1-866-797-7223 (SWP-RACE).

Additional applications information may be found at

www.SW-Performance.com

.

GENERAL APPLICATION:

12-volt DC negative (-) ground electrical systems (11-20 VDC

operating voltage range for the tachometer, 11-16 VDC for the

Light bulb).

Signal source from alternator AC tap (R terminal).

Adjustment range: 10.7 – 21.3 PPR (Pulses Per Revolution).

PPR = (Poles/2)*(Crank pulley dia./Alternator pulley dia.)

2

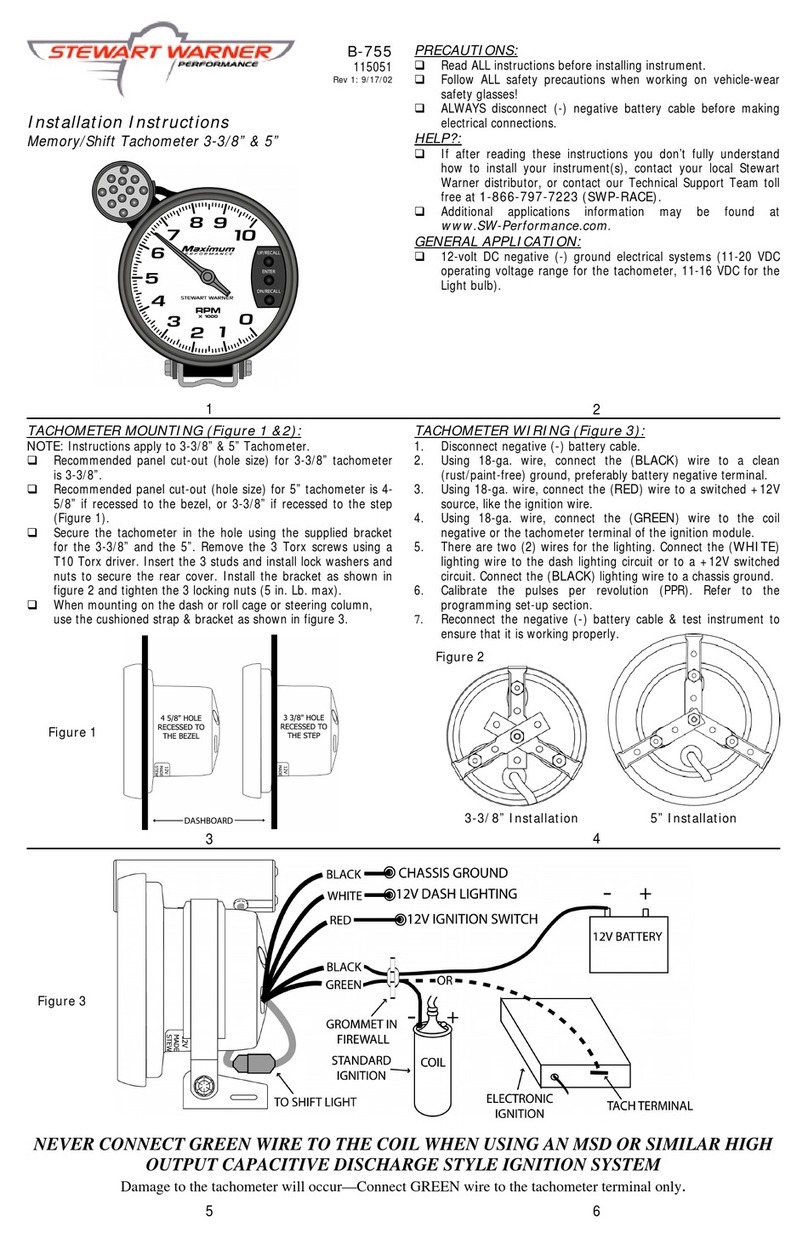

TACHOMETER MOUNTING (Figure 1 & 2):

NOTE: Instructions apply to 3-3/8” & 5” Tachometer.

Recommended panel cut-out (hole size) for 3-3/8” for the 3-

3/8” tachometer 4-5/8” for the 5” tachometer if recessed to the

bezel, or 3-3/8 if recessed to the step (figure 1).

Secure the tachometer in the hole using the supplied bracket

for the 3-3/8” and the 5”. Remove the 3 Torx screws using a

T10 Torx driver. Insert the 3 studs (no more than 8 turns) and

install lock washers and nuts to secure the rear cover. Install

the bracket as shown in figure 2 and tighten the 3 locking nuts

(5 in. Lb. max).

TIP: Calibrate the tachometer before final installation.

When mounting on the dash or roll cage or steering column,

use the cushioned strap & bracket as shown in figure 3.

3

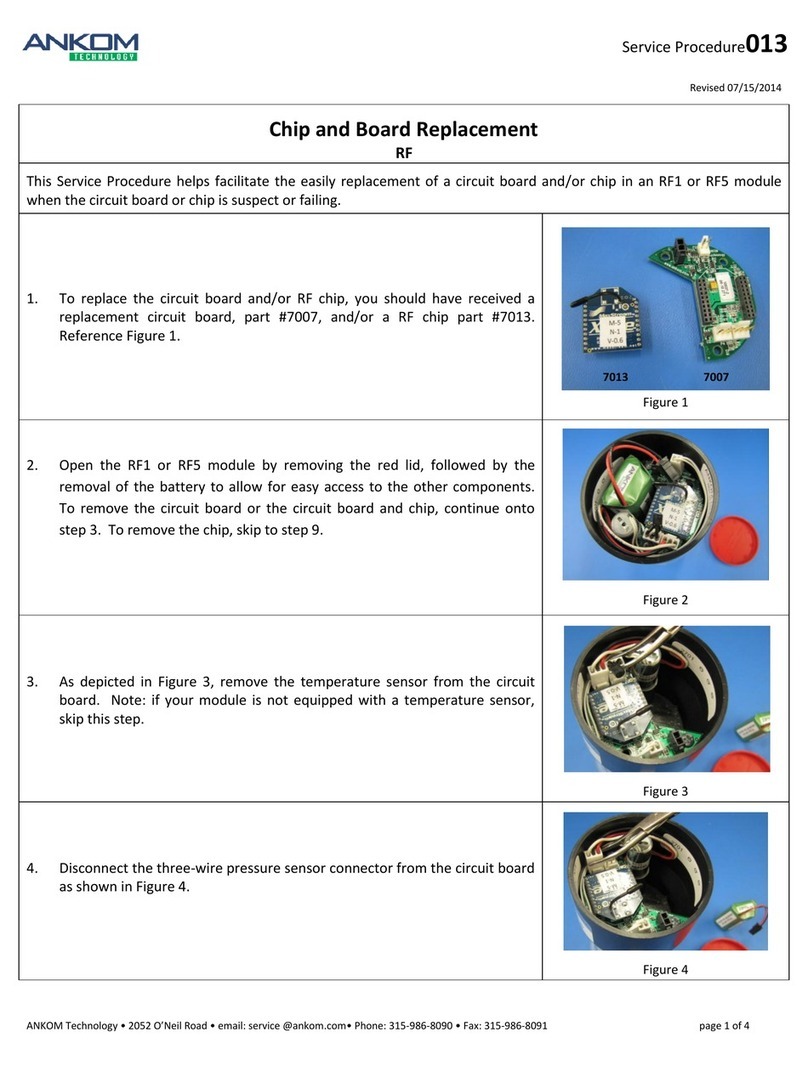

TACHOMETER HOOK-UP (Figure 3):

1. Disconnect negative (-) battery cable.

2. Using 18-ga. wire, connect the (BLACK) wire to a clean

(rust/paint-free) ground, preferably battery negative terminal.

3. Using 18-ga. wire, connect the (RED) wire to a switched +12V

source, like the ignition wire.

4. Using 18-ga. wire, connect the (GREEN) wire alternator AC tap

terminal (R terminal).

5. There are two (2) wires for the lighting; Connect the (WHITE)

lighting wire to the dash lighting circuit or to a +12V switched

circuit. Connect the (BLACK) lighting wire to a chassis ground.

6. Reconnect the negative (-) battery cable & test instrument to

ensure that it is working (will not be accurate until calibrated).

7. Calibrate the tachometer. Refer to the calibration set-up

section.

4

5 6

Fi

g

ure 3

Fi

g

ure 1

3-3/8” Installation 5” Installation

Fi

g

ure 2

TACHOMETER SIGNAL INFORMATION:

Since diesel engines do not have an ignition system, the engine

speed signal is supplied from the alternator AC tap or

sometimes called the “R” terminal.

This signal comes from the windings in the alternator before it’s

rectified to DC and regulated to the system charge voltage. Not

all alternators come with this terminal.

•It’s best to check with the alternator manufacturer, or a

good local alternator shop for AC tap availability.

•If it is not available, it may be possible to add the terminal

to the alternator. Consult a local alternator repair shop for

exact details.

Since the signal comes from the alternator, the number of

cylinders in the engine has nothing to do with the tachometer

calibration.

The PPR (Pulses Per Revolution) calibration range is 10.7 to

21.3 (refer to the

SIGNAL CALCULATION

section for

additional information).

7

SIGNAL CALCULATION:

Given the continual introduction of alternator styles, it is

advisable to determine the PPR of the application before

installation.

The PPR calculation is PPR = P*R/2

•“P” is the number of poles in the alternator.

•“R” is the pulley ratio. Determine the pulley ratio by

dividing the crank pulley diameter by the alternator pulley

diameter.

Example:

•# of poles 18

•Crank pulley diameter is 4.5”

•Alternator pulley diameter is 2”.

•PPR = (18*(4.5/2))/2 = 20.25 PPR, which falls into the

calibration range and should work well.

8

CALIBRATION SET-UP (Figure 4):

NOTE: Stewart Warner Performance Diesel Tachometers must be

calibrated after installation for accurate operation. See “

DIP-switch

setting chart

” for additional applications.

1. Remove the 3 Torx screws using a T10 Torx driver.

2. Start the engine and determine the actual engine RPM using a

reference tachometer (optical, non-contact tachometer

recommended).

3. Set the DIP Switches, as a course calibration, so that the tach

indicates the closest to actual engine RPM.

TIP: A small screwdriver or pick may aide in the switch setting.

4. Adjust the calibration potentiometer, as a fine adjustment, until

the tachometer indicates actual engine RPM.

TIP: A 5/32” or 2mm hex driver works best to adjust the calibration

potentiometer.

5. Replace the rear cover and 3 Torx screws. Be sure that the rear

sealing o-ring stays in place.

9 10

TROUBLESHOOTING:

Q: My tachometer does not respond at all, what do I do?

A: Check all of the wiring connections and power to the

tachometer.

1. If the tachometer needle goes to zero when powered up,

but does not respond when the engine is started, there is

no signal to the green wire. Check to ensure that the

green wire is hooked to the proper location for a valid

signal.

2. If the tachometer needle doesn’t go to zero when powered

up, the tachometer is not grounded properly or does not

have power to the (RED) wire. Check to ensure a good

chassis ground, preferably at the battery ground. Verify

that the (RED) wire has a 12VDC supply.

Q: My tachometer does not read correctly, what do I do?

A: The Diesel Tachometers must be calibrated for each installation

for proper operation.

1. Recalibrate the tachometer (refer to the

CALIBRATION

SET-UP

section for more information).

2. Be sure that the reference tachometer is functioning

properly and providing accurate RPM values.

11

CLEANING DIRECTIONS:

For proper cleaning of instrumentation/accessories, use a glass

cleaner or mild detergent with a spray on and wipe method.

WARRANTY INFORMATION:

TWO (2) YEAR LIMITED WARRANTY. SWP products are

warranted against defects in workmanship and materials for a period

of two (2) years from the date of purchase. Proof-of-purchase is

required; otherwise, the warranty period shall default to two (2)

years from date-of-manufacture (as indicated by the date code on

the product). See detailed Warranty Policy for other Terms &

Conditions.

STEWART WARNER PERFORMANCE

1-866-SWP-RACE (797-7223)

www.SW-Performance.com

12

Fi

g

ure 4

Other Stewart Warner Measuring Instrument manuals