Stewart Warner 240 Series User manual

SERVICE

INSTRUCTIONS

240

SERIESELECTRICFUELPUMP

6V

& 12V

Coil

Kits

KITNO.

426947

(Fig.

2}

(A)

1-425617

Coil,

6

Volt

(B)

1-425651

Base

Gasket

(C)

1-425660Switch

Gasket

(large)

(D)

1-425655Switch

Gasket

(small)

(E)

2-425650

Switch

Sleeve

(F)

1-432975

Bowl

Gasket

KITNO.

426948

(Fig.

2)

(A)

1-425664

Coil,

12

Volt

(B)

1-425651

Base

Gasket

(C)

1-425660Switch

Gasket

(large)

(D)

1-425655SwitchGasket

(small)

(E)

2-425650SwitchSleeve

(F)

1-432975BowlGasket

1.

Insert

coilassembly

(A)

intopump

with

notch

In

contactplateoppositethat

of

switch

opening.

When

coil

is

properlyindexed

and

seated,

the

terminals

andtop

of

coil

will

be

clearlyvisible

through

the

switchopening.

2.

Replacetensionwasher

with

the

roundedpor-

tion

to

the

coll.

3.

Replacenewgasket(B)anduslngtool(T-281843)

screw

in

coll

base

until

it

seats

firmly

against

gasket.

4.

Place

"O"

ringaroundprotrudingportion

of

pistontube.

5.

Place

washer

ontopof"O"

ring.

TOPOF

COIL

FIGURE

1

6.

Installcontact

sleeves

(E)

onto

the

collter-

minals

(Figure

1).

7.

Trip

actuator

armof

switchupward

(Fig.

3).

8

Insert

piston.

9.

With

finger

pressure

holdpiston

toits

upper-

mostposition,then

release

piston

approxi

-

mately

1/8".

THE

PISTON

MUST

BEIN

THIS

POSITION

TO

INSTALL

SWITCH.

f—

/I

<MMM

*

FIGURE

2

10.

With

gaskets

(C)and(D)in

place,

press

switch

Into

pump

body

making

certain

the

switch

contactsengagewith

the

contact

sleeves.

Dueto

alignment

slot

on

switch,

it

can

only

be

installed

one

way.

11.

Replace

switch

cover

and

secure.

Note:vent

hole

in

covermustfacedownward.

FIGURE

3

12.

Insert

powerspringafterpiston

and

replace

the

intake

valve.

Valvemust

be

firmly

seat-

ed

againstwasher.

Usea

wrench

but

take

care

notto

over

tighten.

Donot

seat

valve

on

coil

base.

.-.

-,

13.

After

inspection

or

cleaning

of

sedimentbowl,

assemble

filter

as

shown

in

Figure

4.

Make

certain

that

bowl

gasket

(F)is

properly

seat-

ed.

14.

Checkoperation

of

pump

beforeinstallation

on

vehicle.

IMPORTANT:

Always

usenew

gaskets

and

seal

ringsduring

reassembly.

FIGURE

4

Printed

in

U.S.A.

P.N.

434357

STEUJRRT-UJflRnER

CORPORHTIOH

1826

W.

DiverseyParkway

Chicago,Illinois60614

SER

4750

ISy

m

b o 1

of

SERVICE

INSTRUCTIONS

Stewart

240

SERIES

ELECTRIC

FUEL

PUMPS

The

Stewart-Warner

Model

240

FuelPump

is

electrically

operated

and

will

deliver

a

volume

in

excess

ofany

electric

fuel

pump

of

comparable

voltage.

The

fuel

pump

is

available

for6,12and

24

volt

Installations.

The

average

current

con-

sumption

is

1.5

amperes,

andit

is

so

designed

that

no

polarity

is

involved

at

Installation.

Modelsthathave

a

pressure

regulator

are

factory

adjusted

at4

Ibs.

pressure.

This

pressure

is

adequate

forthe

majority

of

vehicle

installations.

This

regulator

maintainsboth

an

adequate

pres-

sure

at

idle

withoutflooding

the

carburetor

with

an

adequatevolume

of

fuel

under

peak

load

con-

ditions.

If

more

or

less

pressure

is

required

at

the

carburetor,

the

pressure

regulator

canbe

adjusted

- BUT

ONLYAFTER

THE

PUMP

IS

INSTALLED

ONTHE

VEHICLE

(See

Section

C,

page

6

under"Regulating

Pressure").

PREPARATION

TOOLSREQUIRED:

T-281843

SocketWrench

for

coil

base

T-308430

Restaking

Tool

12

x

1/2"

Rodtouse

withT-281843

1-1/8"

SocketWrench

7/8"

End

Wrench

Screwdriver

Long

nosed

Pliers

Unit

replacement

kits

are

available

for

servicing

the

switch,

coll,

piston

and

valve,

andthe

regu-

lator

assemblies.

These

kits

contain

the

parts

and

essential

gaskets

necessary

to

make

there-

pairs.

DISASSEMBLY

CAUTION:

Beforedismantlingpump,

be

sure

all

fuel

has

beencompletely

drained

out.

Avoid

getting

fuel

into

the

switch.

Ifthe

coil

gets

wet,

it

must

be

thoroughly

dried

out

before

reinstalling.

A.

FILTERBOWL

1.

Unscrewbail

nutat

bottom

of

pump

and

swingbail

toone

side.

2.

Removesedimentbowl,gasket,filter,

filter

base

and

spring.

B.

INTAKE

VALVE

1.

Using

a

1-1/8"

open

end

wrench,

remove

Intake

valve

by

turningcounter-clockwise

(A,

Figure

3).

C.

SWITCH

1.

Remove

red

seal

with

a

small

pin

punch.

2.

Using

a

7/8"

wrench,turnswitch

cover

counter-clockwise

until

coverdisengages

from

the

studs

onthe

body

ofthe

pump

(Figure

2).

3.

Moistenwirelead

at

cover

grommet

and

slide

switch

cover

back.

4.

Pull

switchawayfrompumpbody

to

remove.

5.

Removecontact

sleeves

fromswitch

and/

or

coil

(Figure

4).

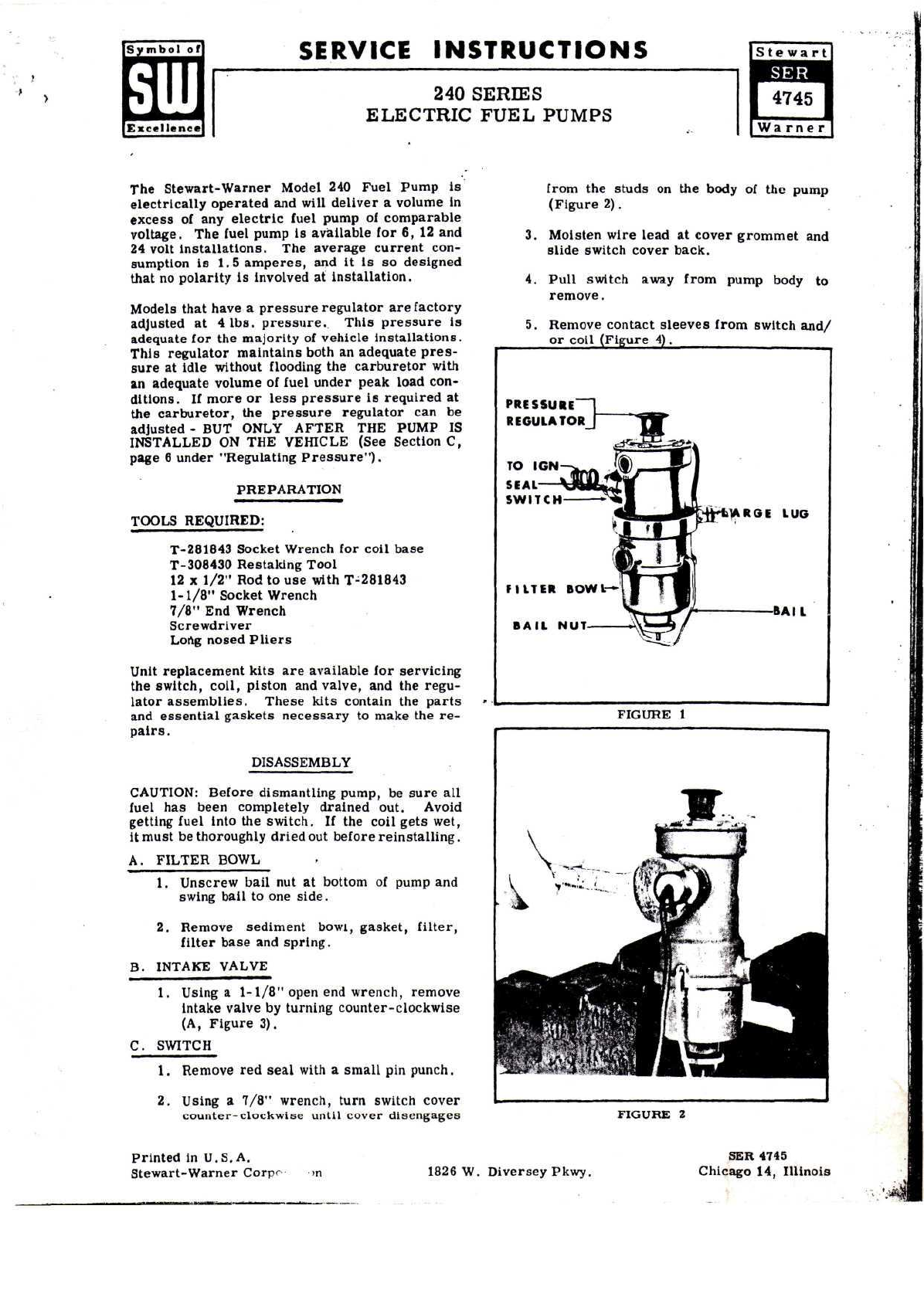

PRE

SSURE

I

REGULATOR_T~

|ji/

_..^S

>ARGI

LUG

FILTER

BOWL-

BAIL

NUT

BAIL

FIGURE

1

FIGURE

2

Printed

in

U.S.A.

Stewart-Warner

Corpo

1826

W.

Diversey

Pkwy.

SER

4745

Chicago

14,

Illinois

(Symbol

of

SERVICE

INSTRUCTIONS

240

SERIESELECTRICFUELPUMP

SWITCH

KITNO.

426944

Stewart!

(A)

(B)

(C)(D)

oO

CONTENTS

OF

KIT

(A)

1-427879

Seal

(D)

2-425650Sleeve

(C)

1-425655Gasket(Small)

(D)

1-425660Gasket(Large)

(E)

1-425601Switch

&

Lead

Assem.

(F)

1-432975Bowl

Gasket

After

the

switch

has

beenremoved,

It

will

be

necessary

to

partiallydisassemble

the

pump

before

the

switch

canbe

replaced.

Failure

to

follow

theseInstructions

will

result

In

damaging

the

actuator

arm

bushing.Correct

procedure

Is

as

follows:

1.

Install

the

switchcontact

sleeves

onto

the

coll

terminals.

2.

Unscrew

ball

nutat

bottom

of

pump

and

swing

ball

toone

side.

3.

Remove

sediment

bowl,

gasket,filter,filter

base

and

spring.

4.

Using

a

suitablewrench,removeIntakevalve

assembly

by

turningcounter-clockwise.

5.

Trip

actuator

armof

switch

upward.

(Fig.

1).

Figure

1.

6.

With

finger

pressure

hold

piston

to

its

upper-

most

position,

then

release

pistonapproxi-

mately

1/8".

THIS

ISTHE

ONLY

POSITION

OFTHE

PISTON

THAT

THE

SWITCH

CAN

BE

REINSTALLED.

IMPORTANT:

Always

usenew

gaskets

and

seal

rings

during

reassembly.

7.

With

gaskets

In

place,

press

switch

Intopump

body

making

certain

the

switchcontactsengage

with

the

contact

sleeves.

Dueto

alignment

slot

on

switch,

It

can

only

be

Installedoneway.

8.

Replaceswitchcover

and

secure.

Note:

Vent

hole

In

covermustfacedownward.

9.Be

certain

the

"O"

ring

andthe

washer

are

In

place

atthe

protrudingportion

ofthe

piston

tube.

10.

Insertpowerspring

after

the

piston.Replace

Intake

valve,tighteningclockwiseuntil

itis

snug.Overtightening

will

cause

the

piston

tube

to

collapse.

When

properlyassembled

there

will

bea

space

between

the

valve

and

coll

base.

11.

After

inspection

or

cleaning

of

sediment

bowl,

assemblefilter

as

shown

In

Fig.

2.

Figure

2.

12.

Check

operation

of

pump

before

installation.

For

moredetailedinformation

see

SER-SW

4745

Printed

in

U.S.

A.

STEUJflRT-LUflRPER

CORPORflTIOR

1826

W.

DlverseyParkway

Chicago,

Illinois

60614

P.N.

434354

SER

4746

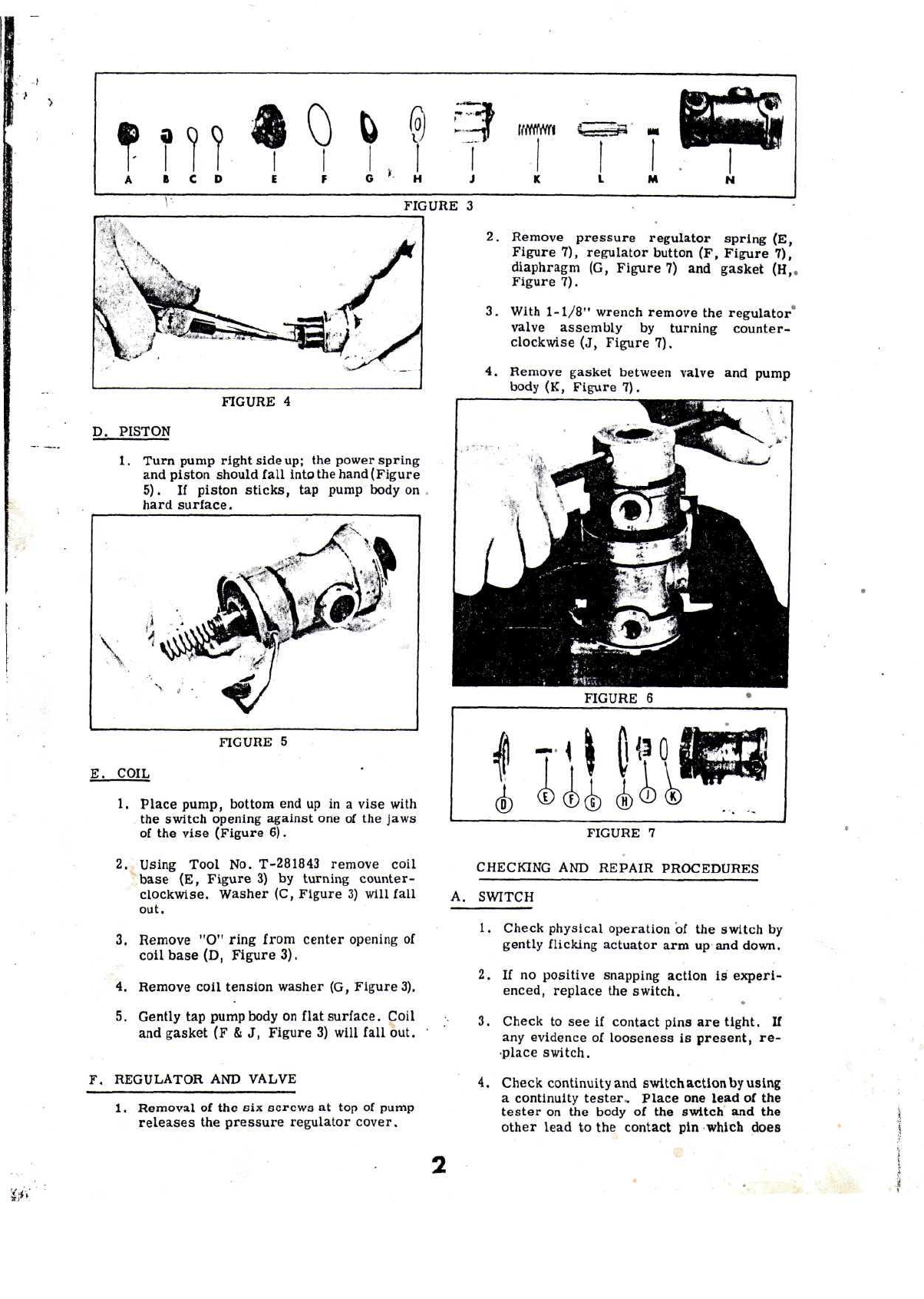

T

0

b

((

IWWWI

A

B

C D E F

G'H

M

FIGURE

3

FIGURE

4

D.

PISTON

1.

Turn

pump

right

side

up;

the

powerspring

and

pistonshouldfallinto

the

hand(Figure

5).

If

piston

sticks,

tap

pump

body

on

hardsurface.

\

FIGURE

5

E.

COIL

1.

Placepump,bottom

endupina

vise

with

the

switchopeningagainst

oneofthe

jaws

of

the

vise

(Figure

6).

2.

Using

Tool

No.

T-281843

removecoil

base

(E,

Figure

3)by

turning

counter-

clockwise.Washer

(C,

Figure

3)

will

fall

out.

3.

Remove

"O"

ring

from

center

opening

of

coil

base

(D,

Figure

3).

4.

Removecoiltensionwasher

(G,

Figure

3).

5.

Gently

tap

pump

body

on

flat

surface.

Coil

and

gasket

(F& J,

Figure

3)

will

fall

out.

•

F.

REGULATOR

AND

VALVE

1.

Removal

of

the

six

screws

attopof

pump

releases

the

pressure

regulator

cover.

2.

Remove

pressure

regulatorspring

(E,

Figure

7),

regulator

button

(F,

Figure

7),

diaphragm

(G,

Figure

7)and

gasket

(H,,

Figure

7).

3.

With

1-1/8"

wrench

remove

the

regulator"

valve

assembly

by

turningcounter-

clockwise

(J,

Figure

7).

4.

Removegasket

between

valve

and

pump

body

(K,

Figure

7).

FIGURE

6

f

T'.H'H

(D

cn

FIGURE

7

CHECKING

AND

REPAIR

PROCEDURES

A.

SWITCH

1.

Check

physical

operation

ofthe

switch

by

gently

flicking

actuator

armupand

down.

2.Ifno

positive

snapping

action

is

experi-

enced,

replace

the

switch.

3.

Check

toseeif

contactpins

are

tight.

If

any

evidence

of

looseness

is

present,

re-

•place

switch.

4.

Check

continuity

and

switch

action

by

using

a

continuity

tester.

Place

one

lead

ofthe

tester

onthe

body

ofthe

switch

andthe

other

lead

tothe

contact

pin

which

does

not

have

the

switchleadwireattached.

Flick

actuator

armofthe

switch,

circuit

should

indicate

open

and

closed

onthe

meter.

NOTE:

This

switch

isnot

serviceable,

andisto

be

replaced

asan

assembly.

.Use

Unit

Replacement

KitNo.

426944.

NOTE:

If

contact

sleeves

(A)are

damaged,

replace.

FIGURE

8

B.

INTAKE

VALVE

1.

This

unit

canbe

checked

by

placing

the

threadedportion

to

your

lips

and

forcing

air

into

the

valve.

2.Ifthe

valve

leaks,

theair

will

escape

and

must

be

replaced.

NOTE:

This

valve

isnot

serviceable

andistobe

replaced

asan

assembly.

Use

Unit

Re-

placement

KitNo.

426946.

C.

PISTON

1.

Inspect

bumper

spring.

The

minimum

measurement

ofthe

power

spring

ofa 6

volt

pump

is

1-21/32"

while

that

ofthe12

and

24

volt

pumpsmeasures

1-7/8"

(Fig-

ure

10).

FIG,

9

il

6v

12v+J4v

FIG.

10

FIG.

11

2.

Place

the

bumperspring

opening

ofthe

piston

tothe

lips

and

force

airtothe

pistoncheckvalve.

Ifair

escapes,

re-

place

the

piston.

3.

Light

score

marks

will

be

present

after

piston

has

been

in

useand

in

no

way

affects

the

performance

ofthe

pump.

The

normal

appearance

ofthe

piston

after

use

Is

shown

in

Figure

11.

Inspect

the

pistontube

for

nicks

or

scars.

A

tube

which

indicatesnormalwearwill

have

a

slight

ring

atthe

lower

end.

This

will

be

felt

by

running

the

finger

inside

the

tubeopening.

Check

whetherpistontube

is

properly

sealed

by

placingindexfinger

onendof

tube

and,

without

force,attempt

to

wiggle

(Figure

12).

Thereshould

beno

move-

ment

ofthe

pistontube.

IMPORTANT:

To

properly

rebuild

the

pump

and

Insure

against

leakage,

the

piston

tube

must

be

re-staked.

Use

Tool

No.

T-308430(Figure

13).

The

re-staking

toolconsists

oftwo

parts;

base

and

piston

tube

guide

anda

stakingpunch.

Touse

this

tool,

place

the

pump

casting

over

the

base.

The

pistontubeguide

will

auto-

matically

center

both

the

casting

andthe

pistontube.Place

the

restaking

punch

over

the

pistontube.Using

a

1-1/2pound

hammer,

strike

the

punch

sharply

oneor

two

blows.

FIGURE

12

FIGURE

13

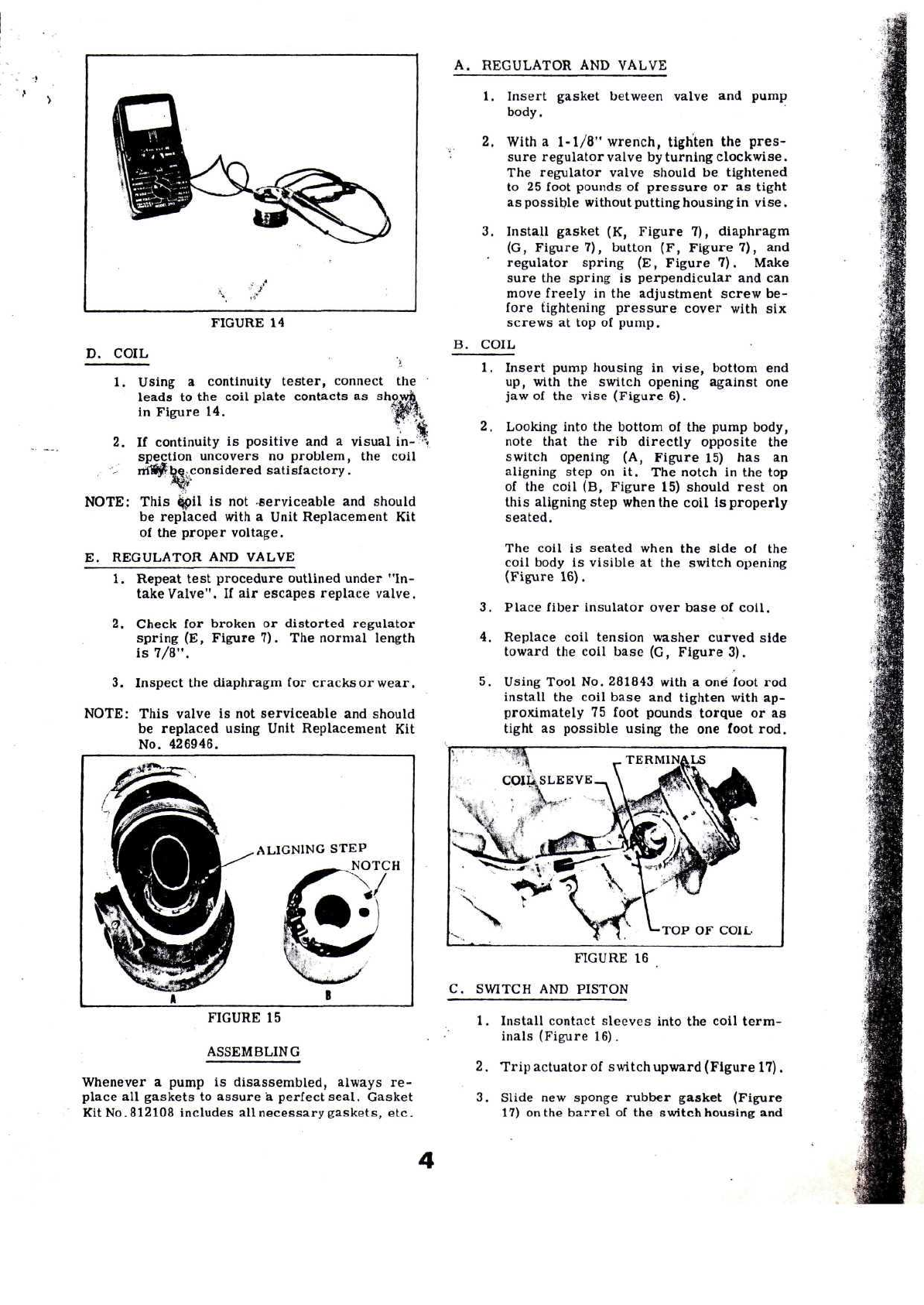

FIGURE

14

D.

COIL

the

1.

Using

a

continuity

tester,

connect

leads

tothe

coilplatecontacts

as

in

Figure

14.

2.If

continuity

is

positive

anda

visual

in-''

spectionuncovers

no

problem,

the

coil

ml^

bec

considered

satisfactory.

NOTE:

This

$pil

isnot

.serviceable

and

should

be

replaced

with

a

Unit

Replacement

Kit

of

the

propervoltage.

E.

REGULATOR

AND

VALVE

1.

Repeat

test

procedure

outlinedunder"In-

take

Valve".

Ifair

escapesreplace

valve.

2.

Check

for

broken

or

distortedregulator

spring

(E,

Figure?).

The

normallength

is

7/8".

3.

Inspect

the

diaphragm

for

cracks

or

wear.

NOTE:

Thisvalve

isnot

serviceable

and

should

be

replaced

using

Unit

Replacement

Kit

No.

426946.

ALIGNING

STEP

NOTCH

FIGURE

15

ASSEMBLING

Whenever

a

pump

is

disassembled,always

re-

place

all

gaskets

to

assure

a

perfect

seal.

Gasket

Kit

No.812108

includes

all

necessarygaskets,etc.

A.

REGULATOR

AND

VALVE

1.

Insertgasket

between

valve

and

pump

body.

2.

With

a

1-1/8"

wrench,tighten

the

pres-

sureregulatorvalve

by

turning

clockwise.

The

regulator

valve

should

be

tightened

to25

foot

pounds

of

pressure

oras

tight

as

possible

without

putting

housing

in

vise.

3.

Installgasket

(K,

Figure

7),

diaphragm

(G,

Figure

7),

button

(F,

Figure

7),and

regulatorspring

(E,

Figure

7).

Make

sure

the

spring

is

perpendicular

andcan

move

freely

inthe

adjustment

screw

be-

fore

tightening

pressure

cover

with

six

screws

attopof

pump.

B.

COIL

1.

Insert

pump

housing

in

vise,bottom

end

up,

with

the

switch

opening

against

one

jaw

ofthe

vise(Figure

6).

2.

Looking

into

the

bottom

ofthe

pump

body,

note

that

therib

directlyopposite

the

switch

opening

(A,

Figure

15)hasan

aligning

step

onit.The

notch

inthetop

of

the

coil

(B,

Figure

15)

should

rest

on

this

aligning

step

when

the

coil

is

properly

seated.

The

coil

is

seated

when

the

side

ofthe

coil

body

is

visible

atthe

switch

opening

(Figure

16).

3.

Place

fiberinsulatorover

base

of

coil.

4.

Replacecoiltensionwashercurvedside

toward

the

coil

base

(G,

Figure

3).

5.

Using

Tool

No.

281843

with

a one

foot

rod

install

the

coilbase

and

tighten

with

ap-

proximately

75

foot

poundstorque

oras

tight

as

possibleusing

theone

foot

rod.

TOPOF

COIL

FIGURE

16

C.

SWITCH

AND

PISTON

1.

Install

contact

sleeves

into

the

coil

term-

inals

(Figure

16).

2.

Trip

actuator

of

switch

upward(Figure

17).

3.

Slide

new

sponge

rubber

gasket

(Figure

17)

on

the

barrel

ofthe

switchhousing

and

sealinggasket

on

otherend.

4.

Slideswitchcontactpinspartiallyinto

the

coilterminals.

Donot

press

switch

all

thewayinat

thistime.

5.

Installpiston.

a.

Lay

pump

on

side.

b.

Slidepistonintotubeuntil

it

touches

the

end.

c.

Using

a

finger

asa

stop,tilt

the

pump

and

allowpiston

to

slidebackabout

1/4".

Thiswillallow

the

switchact-

uator

pinto

slide

into

the

cut-away

section

of

the

piston.

6.

Press

switch

alltheway

into

the

housing.

7.

With

gaskets

in

place,

press

switchinto

pumpbody,making

certain

the

switch

contactsengage

with

the

contact

sleeves.

Due

tothe

alignment

slot

onthe

switch,

it

can

only

be

installed

one

way.

8..

Secureswitch

cover

by

engagingcover

with

studs

onthe

pump

body

and

turn

clockwiseusing

a

7/8"wrench.Make

certain

the

smallhole

inthe

switchcover

faces

the

bottom

ofthe

pump.

9.On

later

modelpumpslineup

the

seal

hole

in

the

switchcover

with

the

hole

inthe

pump

body

andtapa new

switch

seal

into

place.

IMPORTANT:

Although

the

switch

canbe

removed

without

partialdisassembly

of

the

pistonassembly,

it

cannot

be

rein-

stalled

inthe

samemanner.

Failure

to

lower

the

piston

when

reinstalling

the

switch

willresult

in

damage

tothe

actu-

ator

armand

bushing.

FIGURE

17

D.

INTAKE

VALVE

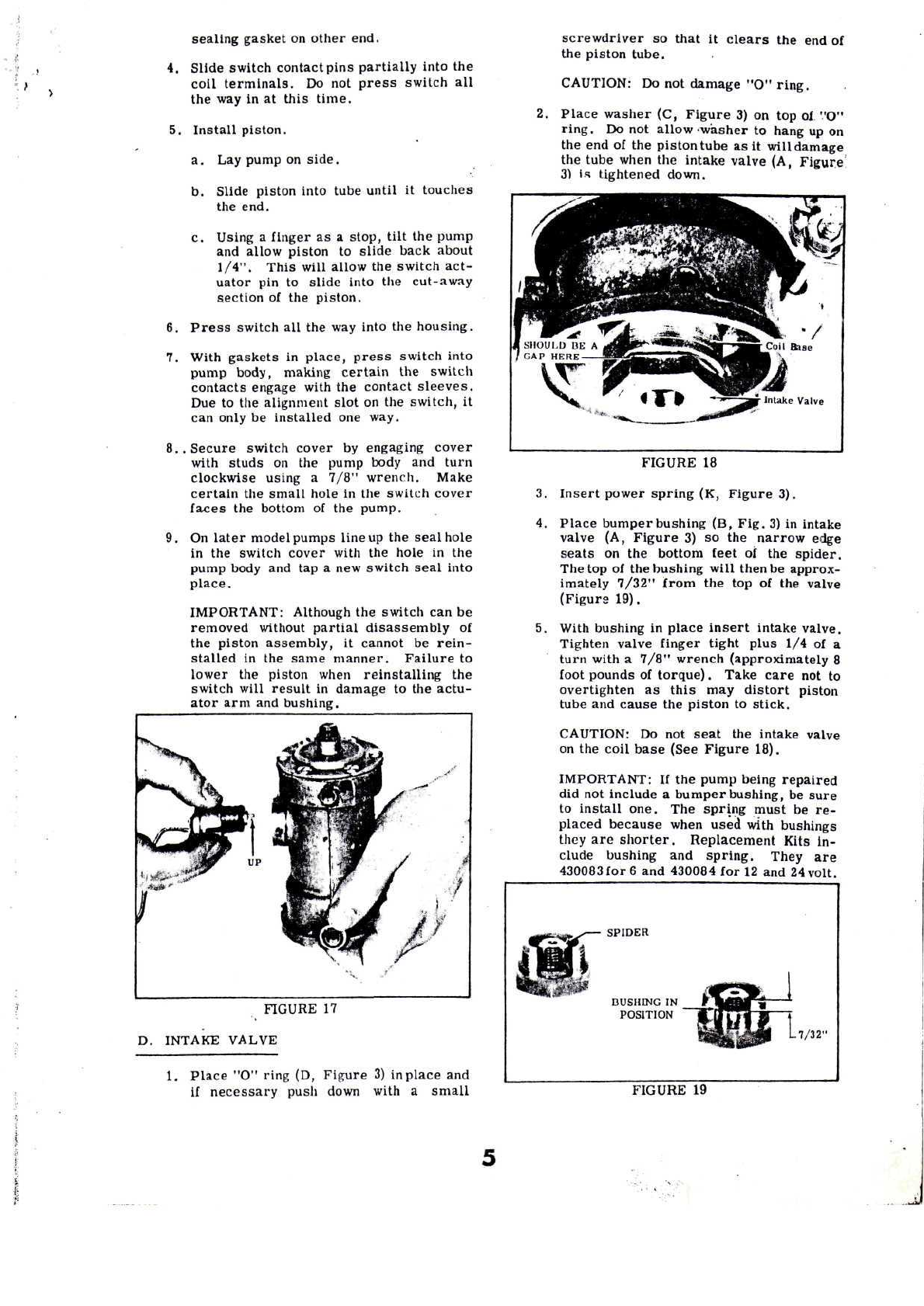

1.

Place

"O"

ring

(D,

Figure

3)in

place

and

if

necessarypush

down

with

a

small

screwdriver

so

that

it

clears

theendof

the

pistontube.

CAUTION:

Donot

damage

"O"

ring.

Place

washer

(C,

Figure

3)ontop

of

"O"

ring.

Donot

allow'washer

to

hang

upon

the

endofthe

pistontube

asit

willdamage

the

tube

when

the

intakevalve

(A,

Figure

31

Is

tighteneddown.

FIGURE

18

3.

Insertpower

spring

(K,

Figure

3).

4.

Place

bumper

bushing

(B,

Fig.

3)in

intake

valve

(A,

Figure

3)sothe

narrowedge

seats

onthe

bottomfeet

ofthe

spider.

Thetopofthe

bushingwill

then

be

approx-

imately7/32"from

thetopofthe

valve

(Figur°

19).

5.

With

bushing

in

place

insert

intakevalve.

Tighten

valvefingertightplus

1/4ofa

turn

with

a

7/8"wrench(approximately

8

foot

pounds

of

torque).

Take

care

notto

overtighten

as

this

may

distort

piston

tube

and

cause

the

piston

to

stick.

CAUTION:

Donot

seat

the

intakevalve

on

the

coil

base

(See

Figure

18).

IMPORTANT:

Ifthe

pumpbeing

repaired

did

not

include

a

bumperbushing,

be

sure

to

installone.

The

spring

must

bere-

placed

because

whenusedwithbushings

they

are

shorter.

ReplacementKits

in-

cludebushing

and

spring.

They

are

430083

for6 and

430084

for12and24

volt.

SPIDER

BUSHING

IN

POSITION

7/32"

FIGURE

19

FIGURE

20

E.

FILTER

BOWL

ASSEMBLY

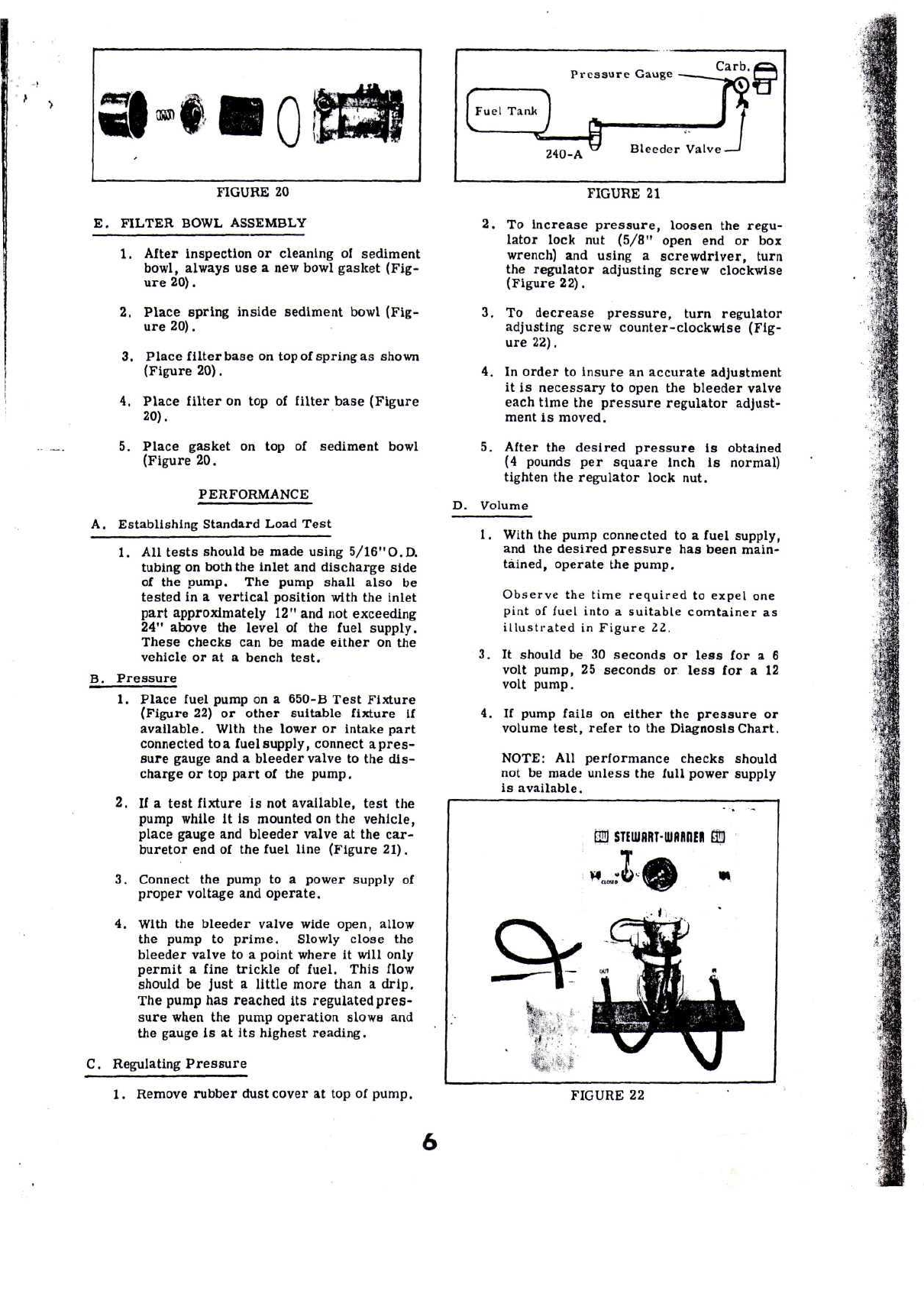

1.

Afterinspection

or

cleaning

of

sediment

bowl,

always

usea new

bowl

gasket(Fig-

ure

20).

2.

Place

spring

inside

sedimentbowl(Fig-

ure

20).

3.

Place

filter

base

ontopof

spring

as

shown

(Figure

20).

4.

Place

filter

ontopof

filter

base

(Figure

20).

5.

Place

gasket

ontopof

sedimentbowl

(Figure

20.

PERFORMANCE

A.

EstablishingStandardLoad

Test

1.

All

tests

should

be

madeusing

5/16"O.D.

tubing

on

both

the

inlet

and

discharge

side

of

the

pump.

The

pump

shall

also

be

tested

ina

verticalposition

with

the

inlet

part

approximately

12"andnot

exceeding

24"

above

the

level

ofthe

fuel

supply.

Thesechecks

canbe

madeeither

onthe

vehicle

orata

bench

test.

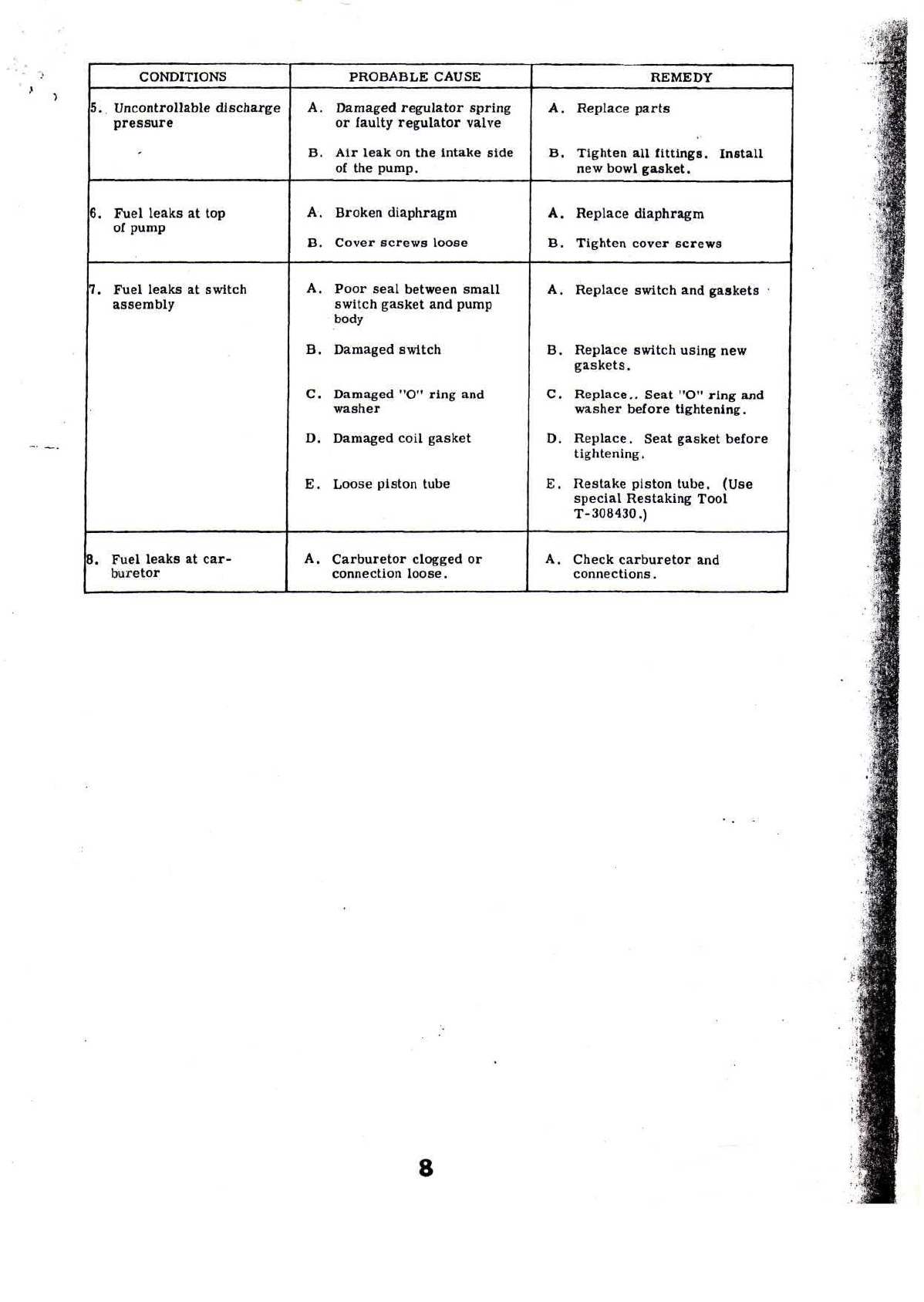

B.

Pressure

1.

Place

fuel

pump

ona

650-BTestFixture

(Figure

22)or

other

suitable

fixture

if

available.

With

the

lower

or

intakepart

connected

to

a

fuel

supply,

connect

a

pres-

sure

gauge

anda

bleeder

valve

tothe

dis-

charge

ortop

part

ofthe

pump.

2.

Ifa

test

fixture

isnot

available,

test

the

pump

while

itis

mounted

onthe

vehicle,

placegauge

and

bleedervalve

atthe

car-

buretor

endofthe

fuel

line(Figure

21).

3.

Connect

the

pump

toa

power

supply

of

propervoltage

and

operate.

4.

With

the

bleedervalve

wide

open,allow

the

pump

to

prime.

Slowly

close

the

bleedervalve

toa

pointwhere

it

will

only

permit

a

fine

trickle

of

fuel.

This

flow

should

be

just

a

littlemorethan

a

drip.

The

pump

has

reached

its

regulated

pres-

sure

when

the

pump

operation

slows

and

the

gauge

Is

atits

highestreading.

C.

Regulating

Pressure

1.

Removerubberdustcover

attopof

pump.

240-A

Bleeder

Valve

-

FIGURE

21

2.To

increase

pressure,

loosen

the

regu-

lator

lock

nut

(5/8"open

endorbox

wrench)

and

using

a

screwdriver,

turn

the

regulatoradjustingscrewclockwise

(Figure

22).

3.

To

decrease

pressure,

turnregulator

adjusting

screwcounter-clockwise

(Fig-

ure

22).

4.In

order

to

insure

an

accurateadjustment

it

is

necessary

to

open

the

bleedervalve

each

time

the

pressure

regulatoradjust-

ment

is

moved.

5.

After

the

desired

pressure

is

obtained

(4

pounds

per

square

inch

is

normal)

tighten

the

regulatorlocknut.

D.

Volume

1.

With

the

pump

connected

toa

fuel

supply,

and

the

desired

pressure

has

beenmain-

tained,operate

the

pump.

Observe

the

time

required

to

expel

one

pint

of

fuel

into

a

suitable

comtainer

as

illustrated

in

Figure

22.

3.It

should

be30

seconds

or

less

fora 6

volt

pump,

25

seconds

or

less

fora 12

volt

pump.

4.If

pump

fails

on

either

the

pressure

or

volume

test,

refer

tothe

Diagnosis

Chart.

NOTE:

All

performancechecksshould

not

be

madeunless

the

full

powersupply

is

available.

FIGURE

22

CONDITION

PROBABLE

CAUSE

REMEDY

1.

Pump

stalls

andishot

to

touch

or

pump

operates

intermittently,

delivers

little

orno

fuel.

A.

Poorground

or

wirecon-

nections

B.

Wronggaugewire

C.

Damagedswitch

D.

Damaged

piston

tube

binding

onthe

piston

A.

Make

sure

pump

is

properly

grounded...

B.

UseNo.10

gaugewire

C.

Replaceswitch

D.

Replace

pumpbody.

2.

Pumpdoes

not

operate

A.

Open

circuit

in

switch

B.

Open

circuit

in

coil

C.

No

ground

or

break

in

wiring

A.

Replaceswitch

B.

Replacecoil

C.

Connectground

wire.

Solder

all

wireconnections,

replacing

broken

or

worn

wiring.

3.

Pump

operates

inter-

mittently

or

delivers

little

orno

fuel

A.Bad

connection

of

wire

lead.

B.Bad

groundconnection

C.

Intakelineclogged

D.

SedimentBowlclogged

E.

Broken

or

damagedspring

in

contactswitch

F.

Nylon

bushingpushedback

on

switchactuating

arm

G.

Damagedpistontube

binding

on

piston

A.

Check

all

pumpwiring

and

connections

B.

Using

a

jumperwire,hold

one

end

to

pump

body

and

ground

the

other.

If

pump

operates,

make

a

permanentground

connection

C.

Disconnect

line

from

pump

inlet

port.

If

pump

operates,

removeintakeline,clean

and

drain

fuel

tank.

D.

Removesedimentbowl

and

filter.

Cleanthoroughly

and

replace

using

new

bowl

gasket

E.

Removeswitch

and

check

physical

operation.

F.

Replaceswitch

G.

Replace

pump

body.

Pump

races

or

delivers

little

orno

fuel

A.

Fueltankempty

B.

Leak

in

intakeline

C.

Leakaroundsediment

bowl

D.

Vapor

in

lines

E.

Faulty

or

dirtyintakevalve

F.

Filter

clogged

.

A.

Check

fuel

supply

B.

Checkline

and

fittings

for

leak

at

intake

port.

Replacefittings

using

a

sealingcompound

C.

Replacegasket

and

tighten

bail

nut

D.

See

that

pump

is

mountedaway

from

extreme

heat.

E.

Inspectintake

and

pistoncheck

valves.

See

PistonAssembly,

page

3.

Replace

as

necessary.

F.

Removesedimentbowl

and

clean

parts

thoroughly.

Re-

using

new

how!

gasket

CONDITIONS

5.

Uncontrollable

discharge

pressure

-

6.

Fuelleaks

attop

of

pump

7.

Fuelleaks

at

switch

assembly

8.

Fuel

leaks

at

car-

buretor

PROBABLE

CAUSE

A.

Damaged

regulator

spring

or

faulty

regulatorvalve

B.Air

leak

onthe

intakeside

of

the

pump.

A.

Brokendiaphragm

B.

Coverscrews

loose

A.

Poor

seal

between

small

switch

gasket

and

pump

body

B.

Damagedswitch

C.

Damaged

"O"

ring

and

washer

D.

Damagedcoilgasket

E.

Loose

piston

tube

A.

Carburetorclogged

or

connection

loose.

REMEDY

A.

Replace

parts

B.

Tighten

all

fittings.

Install

new

bowl

gasket.

A.

Replacediaphragm

B.

Tightencover

screws

A.

Replaceswitch

and

gaskets

•

B.

Replaceswitchusing

new

gaskets.

C.

Replace..

Seat

"O"

ring

and

washerbefore

tightening.

D.

Replace.Seatgasketbefore

tightening.

E.

Restakepistontube.(Use

special

Restaking

Tool

T-308430.)

A.

Checkcarburetor

and

connections.

8

SYMBOL

OF

SERVICE

INSTRUCTIONS

STEWART

EXCELLENCE

240

SERIES

ELECTRIC

FUEL

PUMPS

REGULATOR

Kir

NO.

426945

^DIAPHRAGM

*

VALVE

ASSEMBLY

*

BODY

GASKET

*VALVE

ASSEMBLY

GASKET

WARNER

REGULATOR

SPRING

PUMP

BODY

DISTRIBUTION

PLATE

„

-'(6)

COVER

ADJUSTMENT

PUMP

BODY

COVER

^J

PULSE

CHAMBER

LOCKNUT

1

*

INDICATES

PARTS

CONTAINED

IN

KIT.

KIT

CONTENTS

(1)

425654

Valve

Gasket

(1)

425645

Diaphragm

(1)

425626

Valve

Assembly

(1)

425646

Regulator

Spring

(1)

425656

Body

Gasket

CAUTION:

//

adjustment

screw

is

removed

or

loosened',

the

pump

will

require

rccalibration

for

proper pressure delivery.

DISASSEMBLY

1.

Place

fuel

pump

ina

vice

inthe

uprightposition

and

secure.

2.

Remove

thesix(6)

screws

on

cover

of

pump.

NOTE:

While

removing

the

screws hold cover

down

with

hand.

The

cover

is

under

pressure

due to the

adjustment

screw

and

regulator

spring.

3,

Slowlyremovecover,regulatorspring

and

distri-

bution

plate.

4.

Remove

diaphragm

and

body

gasket.

5.

Using

a

wrench

(box

endor

socket),

turn

counter-

clockwise

to

remove

the

valve

assembly

and

valve

assembly

gasket.

CAUTION:

Donot

nick,

scratch

ormar

body

machined

surface

for

gasket

425656.

This will

prevent

leaks.

NOTE:

Before

assembly

clean

the

surfaces

ofthe

pump

body

to

insure

proper

seating

of

gaskets. This

will reduce

the

possibilities

of

leaks.

1.

Place

new

valve

gasket

onnew

valve

assembly.

2.

Insert

new

valve

assembly

and

gasket

intobody

of

pump.Turnclockwise

with

suitable

wrench(box

end

or

socket)

until

firmly

seated.

3.

Place

new

body

gasket

and

diaphragm

on

body

of

pump.Align

the

holes

in

gasket

and

diaphragm

to

those

in

pumpbody.

ASSEMBLY

4.

Center

distributionplate

on

diaphragm.

NOTE:

Pilot

on

distribution

plate

must

beontop

to

align

with

regulator spring.

5.

Place

regulator

spring

on

distribution

plate

(over

pilot).

6.

Replace

the

cover

and

position

the

holes

in

cover

to

align

with

holes

in

body

of

pump.

NOTE:

Pressure

may

have

to

be

applied

on

cover

to

start

the

screws back

in to

pump

body.

If

so

hold

cover

down

against

pump

body

and

insert screws,

then

tighten screws.

Printed

in

U.S.A.

FOR

FURTHERSERVICE,CONTACTYOURLOCAL

STEWART-WARNER

DISTRIBUTION

CENTER

STEUJflRT-LURRnEB

CORPORRTIOd

1826

W.

Diversey

Parkway

Chicago,

Illinois60614

P.N.434355

SER

4747

Popular Water Pump manuals by other brands

Agilent Technologies

Agilent Technologies DS40M user manual

Goulds

Goulds J5 instruction manual

Xylem

Xylem Rule 27SA instruction manual

Sealey

Sealey WPW9355 instructions

NEPTUN classic

NEPTUN classic NCGP-E 70 Original operating instructions

Grundfos

Grundfos DWK Series Installation and operating instructions

Tunze

Tunze Osmolator 3155 Instructions for use

Pentair

Pentair FAIRBANKS HIJHUIS 5800 Instruction and maintenance manual

Renkforce

Renkforce 2302374 operating instructions

Sicce

Sicce Syncra Nano instructions

Pfeiffer Vacuum

Pfeiffer Vacuum HIPACE 350 operating instructions

aquate

aquate 1350 Series Installation and operating manual