StewMac 64 REVERB UNIT User manual

ASSEMBLY INSTRUCTIONS

Reverb you can't

get from a pedal.

With loads of

helpful tips!

’64 REVERB UNITKIT

ORIGINAL 6G15 CIRCUIT

Contents

About this iconic reverb unit ..................................... 1

...................................................

2

Parts list ........................................................... 3

Tools and supplies ................................................ 5

Amp voltages are seriously dangerous! .......................... 6

How to use a snuffer stick ........................................ 6

How to read resistor values ...................................... 7

Capacitor values .................................................. 7

Complete wiring diagram ........................................ 8

Prepping the cabinet ............................................. 9

Prepping the boards ............................................. 10

Installing the chassis-mounted components ................... 11

How to wrap and solder the eyelet board ....................... 17

Tips for great soldering ......................................... 17

Filter cap eyelet board ........................................... 18

Main eyelet board ............................................... 19

Soldering and installing the eyelet boards ...................... 23

Connecting the eyelet board to the chassis components ....... 24

Installing the heater wires ...................................... 27

Completed 6G15 wiring ......................................... 30

Final assembly ................................................... 31

Testing and troubleshooting .................................... 32

Learning more: secrets revealed in the schematic .............. 34

6G15 circuit schematic ........................................... 35

Tube replacement chart ......................................... 39

COPYRIGHT WARNING

This material is protected by copyright and has been created by and solely for the purposes of StewMac.

You may not sell, alter or further reproduce any part of this material, or distribute it to any other per-

son. Where provided to you in electronic format, you may only print from it for your own private use.

Failure to comply with the terms of this warning exposes you to legal action for copyright infringement.

How to build this kit!

stewmac.com © 2018 StewMac

stewmac.com 1 © 2018 StewMac

Reverb you can't

get from a pedal.

Be excited!

This is the unit that put the waves in surf music!

Looks like an amp, sounds like a beach party.

This tube-driven reverb tank relies on good ol’

physics for a perfect eect. Your guitar signal

travels along two large suspended springs to

produce the reverb that launched the iconic

surf sound.

This reverb unit is an ICON

The greats of surf rock used this king of spring to get their submerged,

tubluar tones. Controls for dwell, mix, and tone take you from dark,

atmospheric decay to bright and snappy splash.

StewMac ICON KITS bring classics that are no longer made, or are simply

unaordable, within reach. And the best part is you get to build them with

your own hands.

We give painstaking attention to parts selection, authentic materials, and

instantly recognizable details—everything that makes the originals so

sought after.

Build it with StewMac

These immersive instructions walk you through every step of creating this

tone machine. And you’ll learn a lot, gaining a deep knowledge of your

reverb unit’s inner workings.

Follow our steps closely for safety, too: we’ve carefully laid out a path that

even newcomers can follow in handling electrical components.

Building an electronics kit can seem daunting, but nobody makes it easier

than StewMac. Watch for helpful tips along the way, too—we’re here to help!

Let’s get building!

’64 REVERB UNIT KIT

ORIGINAL 6G15 CIRCUIT

stewmac.com 2 © 2018 StewMac

#10733 © 2018 StewMac

Processing

Gain Gain Processing

Power

Output

REVERB TANK

FOOTSWITCH

FUSE

INPUT

DWELL

IN OUT

V1

12AX7

V2

12AT7

V3

6V6 REVERB

TRANSFORMER

68319-A

POWER

TRANSFORMER

125A12A

+295V

+300V

+130V

+250V

+105V

1

2

+1.8V3

+160V

1

+250V

6

+120V

7

2

3

8

+2V+1.2V

1M.01μF

.0022μF

.047μF

.1μF

.01

.1μF

250pF

1.5K

1.5K

100K

100K

220K

1.5K10K

25μF 25V

1K2W

2.2M

10K

2W

22μF

500V

22μF

500V

22μF

500V

Totube heaters

and pilot light

25μF 25V

1500100K

2.2M

250μF 25V

250KL

TONE

50KL

MIXER

250KL

AC SWITCH

1 amp slow-blow

100Ω

100Ω

+120V

2

+285V

3

4

8

5

7

8

Here’s how to build this kit!

See page

17

Wiring comes later:

1. First, you’ll wrap the leads, connecting them without solder.

2. Then double-check all the connections. Don’t rush!

3. When everything checks out, it's time to solder.

The numbered steps tell you when.

Get the cabinet ready,

starting at Step

1

on page

9

.

You’ll prep the metal chassis

and the eyelet board too.

Learn more:

You don’t need to read the schematic, but it’s fun.

See how your guitar’s signal gets processed into sound.

This is on page 35.

Sort your components by type, using the parts list.

Quick look:

GroundJackTransformer Preamp tube

plate

grid

cathode

Power tube

grid

plate

cathode

screen

Capacitor ElectrolyticCap. Diode

Resistor Potentiometers Rectifier tube

plate cathode

filament

plate

Shielded

cable ’64 REVERB UNIT

6G15 CIRCUIT SCHEMATIC

OutputGain Processing

stewmac.com 3 © 2018 StewMac

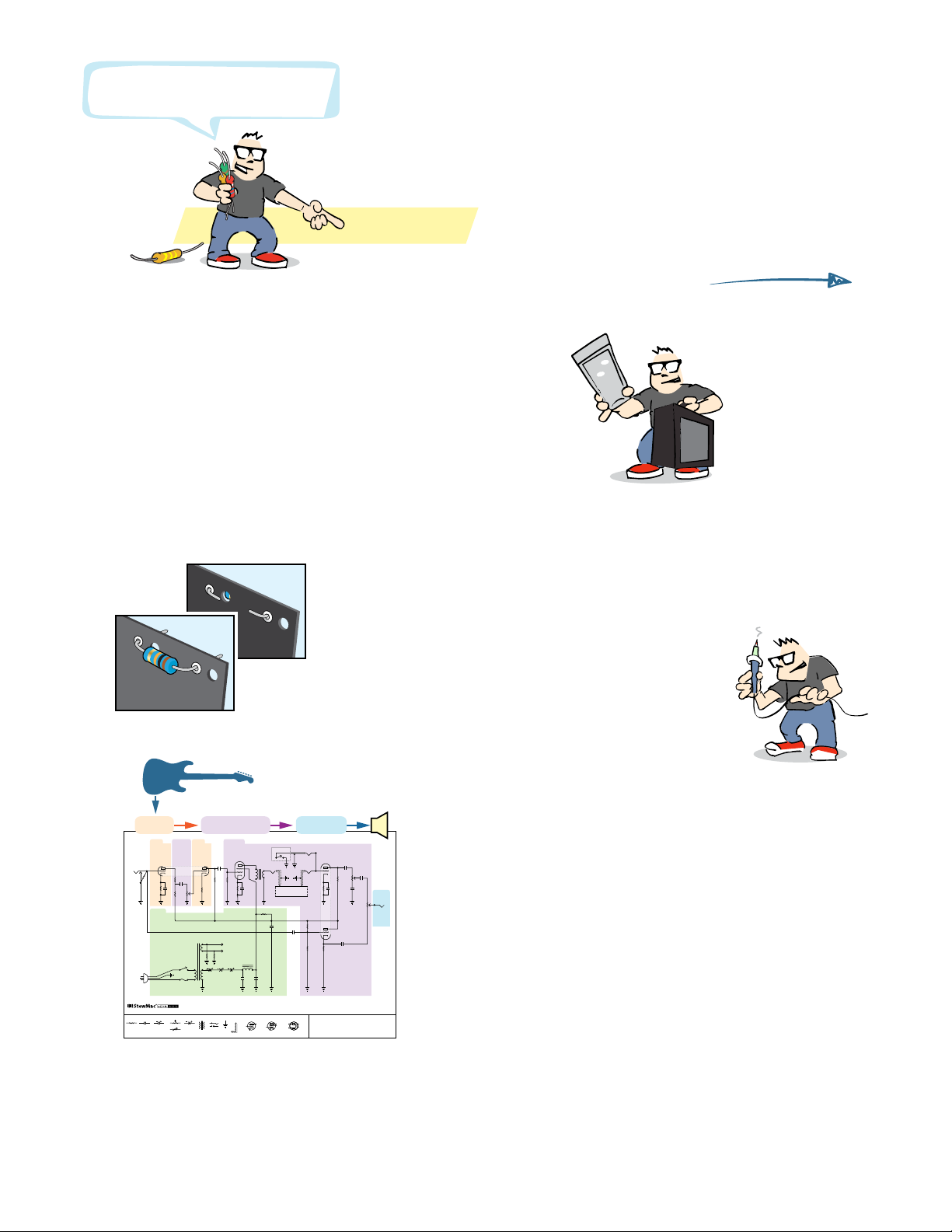

Parts list

Capacitors

r (1) 250pF 500V silver mica

r (1) .0022μF 600V Orange Drop

r (2) .01μF 600V Orange Drop

r (1) .047μF 600V Orange Drop

r (2) .1uF 600V Orange Drop

r (2) 25μF 50V electrolytic

r (3) 22μF 500V electrolytic

r (1) 250μF 25V bipolar electrolytic

222J 600V

+

25µF

103J 600V

473J 600V

104J 600V

Resistors

r (2) 100Ω .5W carbon composite

r (3) 1.5K .5W carbon composite

r (1) 10K .5W carbon composite

r (4) 100K .5W carbon composite

r (1) 220K .5W carbon composite

r (1) 1M .5W carbon composite

r (2) 2.2M .5W carbon composite

r (1) 1K 2W metal oxide

r (1) 10K 2W metal oxide

Brown Black Brown Gold

Brown Green Red Gold

Brown Black Orange Gold

Brown Black Yellow Gold

Red Red Yellow Gold

Brown Black Green Gold

Red Red Green Gold

Brown Black Red Gold

Brown Black Orange Gold

A magnifier helps!

Diode

r

(3) 1N4007 1000V rectifier diode

Cabinet and Chassis

r

(1) Cabinet

r

(1) Capacitor pan

r (1) Chassis

r (2) Eyelet boards

r (2) Insulator boards

250μF

22μF

250 5%

Hardware

r (2) 10-32 machine screw, 1-1/2"

r (2) 10-32 locknut

r (6) 8-32 machine screw, 3/8"

r (6) 8-32 locknut

r (3) 6-32 machine screw, 1/2"

r (3) 6-32 locknut

r (2) 4-40 machine screw, 3/8"

r (4) 4-40 machine screw, 1/4"

r (6) 4-40 locknut

r (4) Self-tapping screw

r (1) Black wood screw

r (1) Power cord clamp

r (1) Strain relief for power cord

r (6) Rubber grommet

stewmac.com 4 © 2018 StewMac

Transformers

r (1) Power transformer

r (1) Output transformer

r (1) Filter choke

Wire

r (1) White wire

r (1) Green wire

r (1) Blue wire

r (1) Red wire

Reverb tank & footswitch

r (1) Reverb tank

r (1) Footswitch

r (1) Reverb wiring kit

(shielded wire and 4 RCA plugs)

Tubes, lamps, fuses, and sockets

r (3) RCA-style jack

r (1) Two-lug jack

r (1) Three-lug jack

r (2) Nine-pin tube socket

r (2) Shield for nine-pin tube socket

r (1) Eight-pin tube socket

r (1) Tension clip for eight-pin tube socket

r (1) 12AX7 preamp tube (also called ECC83S)

r (1) 12AT7 preamp tube (also called ECC81)

r (1) 6V6S power tube

r (1) Fuse socket

r (1) Fuse (1 amp, slow blow)

r (1) Pilot lamp socket with lens

r (1) Pilot lamp bulb (#47)

Terminals, knobs, and cords

r (1) 100K control pot (L-linear taper)

r (2) 250K control pot (L-linear taper)

r (3) Knob

r (1) Three-lug terminal

r (1) Four-lug terminal

r (1) Power switch

r (1) Power cord

6

4

3

2

1

9

8

7

5

4

3

2

1

8

7

6

5

12AT712AX7 6V6

2

5

0

K

L

1

0

0

K

L

Parts list

Vintage-style push-back wire

lets you push the insulation

back instead of cutting it away.

BUT: Trimming the insulation

still works better.

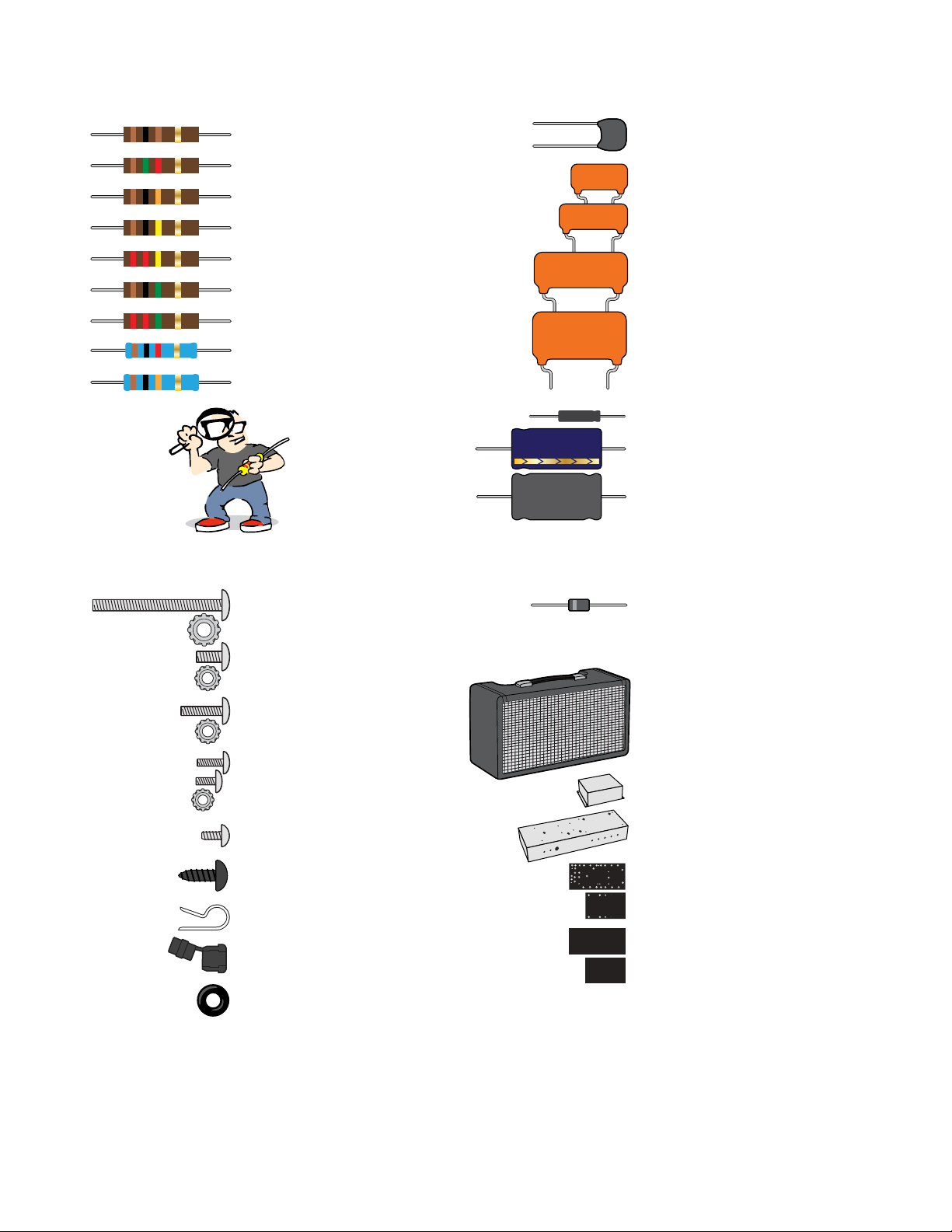

stewmac.com 5 © 2018 StewMac

#0531

StewMac

Solder Monster

#3000

Guitar Tech

Screwdriver Set

#1606

Wire Stripper

#1607

Wire Cutter

#0501

Solomon SL-30

Soldering Station

#1609

Round Nose

Bending Pliers #0505

Kester

Pocket-Pak

Solder

Tools and supplies

Required Phillips screwdrivers, #1 and #2

Item #3000 Guitar Tech Screwdriver Set

Needle nose pliers

Item #1610 Long Nose Pliers

Wire cutter

Item #1607 Wire Cutter

Wire stripper

Item #1606 Wire Stripper

Soldering iron (preferably 40W)

Item #0501 Solomon SL-30 Soldering Station

Solder (at least one Pocket-Pak)

Item #0505 Kester Pocket-Pak Solder

Solder sucker

Item #0503 Solomon Solder Sucker

Drill with a 5/32" bit

5/32" for mounting eyelet board to chassis

Ruler

Item #4905 StewMac Shop Rule

Digital multimeter

Item #3618 Fieldpiece Pocket Multimeter

Snuer stick (bleed resistor)

Item #1552 Snuer Stick

Pencil

Wooden chopsticks

Glue

Wood glue, white glue, or contact

cement for gluing a paper label

inside the cabinet

Butane lighter or matches

For heating heat-shrink tubing

Helpful Round nose bending pliers

Item #1609 Round Nose Bending Pliers

Solder wick

Item #0504 Solder Wick, 5-foot roll

Soldering aids

Item #0521 StewMac Soldering Aids

Soldering stand

Item #0506 Solomon Soldering Stand

Printed circuit board vise

Chassis stand

Item #10750 Chassis Stand

Solder Monster, or helping hand tool

Item #0531 StewMac Solder Monster

Fine tip permanent marker

Scratch awl or center punch

Item #3000 Guitar Tech Screwdriver Set

Tray for loose parts

StewMac’s Solder Monster

holds parts while you solder

stewmac.com 6 © 2018 StewMac

How to use a snuffer stick

To discharge a capacitor, clip the snuer stick lead

to ground—preferably a mounting bolt on the

power transformer. Hold the tip of the stick to the

cap’s positive lead and use your multimeter to

watch the voltage drain to less than 18V.

High voltage, even when unplugged

When you turn on an amp, or in this case a reverb unit, the

capacitors are designed to take on a charge and hold it.

That stored voltage is enough to injure you seriously, or

even kill you.

These components aren’t a threat until the rst time you plug

the unit in. The stored electricity can be safely discharged to

ground with a snuer stick. See how to use it below.

Once your unit has been turned on, don’t touch the wiring

with your bare hands—even after turning the unit o. If

you need to press on a contact, use a chopstick or Sharpie

marker, which are both non-conductive. Don’t use a pencil,

because graphite is conductive.

It’s important that you understand the dangers so you’re

working safely. Here’s how to do it right.

Wear rubber-soled shoes

Rubber soles increase the insulation

between yourself and the ground.

Take off your ring

A metal ring on your finger can

bridge a hot connection to ground.

Wear safety glasses

Rosin-core solder sometimes bubbles up, and it can spew

molten specks into the air. You don’t want molten solder in

your eyes.

It’s better not to work alone

Electrical shocks can incapacitate you, and having someone

available to call 911 can be a lifesaver.

Take breaks and stop when you’re tired

Fatigue leads to mistakes, and no one can aord mistakes

when working with electricity.

Stay suspicious

Whether it’s the rst time you’ve been inside live electron-

ics or the 100th time, don’t become complacent. If you

discharge the caps and walk away for a few minutes, check

again for residual voltage when you return. Capacitors can

self-charge through a phenomenon known as dielectric

memory.

Check before powering up

It’s easy to forget that you a left a stray tool or wire in the

chassis. It’s also easy to forget to re-attach the speaker wire,

and that can fry an output transformer in seconds. Constant

vigilance is your friend when working on electronics.

Always unplug it

Unplug the unit whenever you don’t specically need it

plugged in. Some points are always hot when the unit’s

plugged in, even if the power switch is o. These points

include the lugs on the fuse socket, power switch, and

standby switch.

Amp voltages are seriously dangerous!

Professionals

who work on

amps take these

safety habits

very seriously

stewmac.com 7 © 2018 StewMac

A resistor’s value—the amount of resistance it creates—is

rated in ohms (Ω ). Larger ohm values mean more resistance.

For example, a 100Ω resistor creates ten times as much re-

sistance as a 10Ω resistor.

The resistors used in this unit are too small to have value

numbers printed on them. Instead, a system of colored

bands tells their values. The key to reading these bands is

provided below. However, an easier way to decode these

bands is to download one of the many smartphone apps

for this purpose.

One band will be the nearest to an end of the resistor. That

band tells the rst value. Combine it with the value of band

2 to get a two-digit number (68 in our example below).

Multiply that number by band 3 (68 x 1,000 = 68,000). Thou-

sands are represented by the letter K, so this resistor is 68K

(kilo-ohms, or KΩ).

If there is a fourth band, it will be either silver or gold. This

indicates the tolerance allowed during manufacturing. The

resistors used in this kit have a +/- 5% tolerance, represented

by a gold band 4.

A magnifying glass helps a lot. The bands on a 470Ω resistor

are yellow/violet/brown, and the bands on a 47K resistor are

yellow/violet/orange. They’re easily confused!

Can’t read the colors?

You can always use a multimeter to test a resistor’s value.

Set your meter to ohms and connect the test leads on each

side of the resistor.

Capacitor values are typically printed on the component.

The key values with caps are their capacitance and voltage.

Think of a capacitor as a container that can hold electricity.

Capacitance, measured in farads, refers to how much elec-

tricity this container can hold—its capacity. One farad (1F)

would be much too large for use here. Caps for this unit

are rated in millionths of a farad, called microfarads (μF), or

trillionths of a farad: picofarads (pF). The voltage spec for

a cap refers to how much DC voltage it can handle at any

given time.

A unique property of capacitors is that they don’t allow DC

current to ow past them, only AC current. This is important

in some parts of audio circuits, such as the path between

a preamp stage and a power amp stage. Here, a “coupling

capacitor” will block DC voltage, allowing only the AC guitar

signal to pass.

Filter caps

Capacitors also lter out 60Hz hum, or “ripple,” after the AC

current from the wall is converted to DC. These capacitors

are called lter caps, because they lter out the ripple from

a power supply. The lter caps in this unit are the 22μF

electrolytic capacitors.

Electrolytic caps

Electrolytic capacitors contain electrolyte: a liquid or gel

that gives them a large storage capacity. Electrolytic caps

are typically polarized.

Polarized caps

Some capacitors have polarity and some don’t. It’s extremely

important to install polarized caps correctly in a circuit. The

positive lead of an electrolytic cap will be indicated by an

indented ring around one edge of the capacitor. The nega-

tive lead will often be indicated by a band of arrows pointing

to the negative lead.

Installing capacitors with the polarity backwards will make

the circuit malfunction and quickly destroy the capacitor—

even causing it to explode.

Band 1 Band 2 Band 3 Band 4

1st Digit 2nd Digit Multiplier Tolerance

6 8 x1,000 +/- 5%

Blue

Read this band first (closest to an end)

Gray Orange Gold

BLACK 0 0 1 None +/- 20%

BROWN 1 1 10

RED 2 2 100

ORANGE 3 3 1,000

YELLOW 4 4 10,000

GREEN 5 5 100,000

BLUE 6 6 1,000,000

VIOLET 7 7

GRAY 8 8 0.01 +/- 10% SILVER

WHITE 9 9 0.1 +/- 5% GOLD

68K +/- 5%

K=1,000

NegativePositive

+

25μF

8μf

How to read resistor values Capacitor values

stewmac.com 8 © 2018 StewMac

POWER FUSE PILOT LIGHT DWELL INPUT MIX TONE OUTPUT

REVERB IN

FOOTSWITCH

REVERB OUT

V2

12AT7 V1

12AX7

V3

6V6

4

3

2

1

8

7

6

5

6

4

3

2

1

9

8

7

5

6

4

3

2

1

9

8

7

5

2

5

0

K

L

2

5

0

K

L

1

0

0

K

L

103J 600V

250 5%

14

11

10

M

17

23

31

9

8

7

6

5

13

22

29

35 36 37 38 39

30

4

21

33 34

3

20

27

16

2

12

15

19

25

1

M

18

24

26

32

28

+

25µF

103J 600V

222J 600V

+

25µF

104J 600V

104J 600V

473J 600V

250μF

Our diagrams

show a flat

view of the

metal chassis

Complete wiring diagram

Here’s the complete 6G15 wiring

When you’ve nished the kit, you’ll have connected all the

parts shown in this wiring diagram. If it looks complex now,

don’t worry; we’ll start at the very beginning and do this

one step at a time.

Your circuit-building skills will get stronger with each step!

stewmac.com 9 © 2018 StewMac

Prepare the cabinet for mounting the

chassis by first removing the back

panel.

STEP 1

Mount the power cord clamp

Drill a 5/64" pilot hole to mount the

power cord clamp. Locate the clamp

inside the left wall of

the cabinet, 1-1/2” from

the back panel ledge,

2” from the bottom.

Don’t drill through the cabinet! Use a

piece of masking tape on your drill bit

to mark the depth, or use a StewMac

Depth-stop Drill Bit (item #1712).

Use the black wood screw to mount

the cable clamp. You’ll secure the

power cord with this clamp later, after

the testing.

STEP 2

Glue the tube placement chart

Cut out the tube placement chart on

page 39. Put a thin coat of glue or

contact cement on the back and glue

it to the inside wall of the cabinet.

Also test to make sure you don’t have

continuity between the tip and the

shield of each plug, which would

indicate a short in the cable. If your

multimeter nds unwanted continu-

ity, the likely culprit is the inside (tip)

wire shorting to the outer shield. If

that happens, de-solder the tip con-

nection and redo that solder joint.

STEP 4

Mount the reverb tank

Remove the nuts from the four reverb

tank mounting screws and remove

your reverb tank from its box. Install

the reverb tank with the RCA jacks

facing up.

Reinstall the four reverb tank mount-

ing nuts, tightening each until they

are suciently tight.

Start by prepping the cabinet

Check off each

completed step

V?

12AX7

V?

12AX7

POWER FUSE PILOT LIGHT

V?

6V6

POWER TRANSFORMER

(Mounted outside)

OUTPUT TRANSFORMER

(Mounted outside)

4

3

2

1

8

7

6

5

6

4

3

2

1

9

8

7

5

6

4

3

2

1

9

8

7

5

1

M

A

1

M

A

1

M

A

14

11

10

M

17

23

31

9

8

7

6

5

5

22

29

35 36 37 38 39

30

4

21

33 34

3

20

27

16

2

12

15

19

25

1

M

18

24

26

32

28

’64 REVERB UNIT

ORIGINAL 6G15 CIRCUIT

StewMac®

ICON KITS

Use only 1-amp slow-blow fuse.

DANGER: Unplug the unit before changing tubes.

Tube locations from left to right:

6V6 12AT 7

(ECC81)

12AX7

(ECC83)

V3 V2 V1

#10733

Back

Here

STEP 3

Solder two reverb cables

Cut the shielded wire in the reverb

wiring kit to two 2' lengths. At the

ends of each piece, pull 3/4" of the

wire mesh shielding away to one side

and strip away 3/8" of the internal

cloth shielding. Insert the exposed

wire into an RCA plug so that it reach-

es the tip of the center post.

Solder this lead in place at the tip of

the plug. Don’t leave solder on the

outside of the plug tip, which would

keep it from tting into the jack. See

“Tips for great soldering” on page 17.

After the plug tip cools and the inside

solder joint is set, solder the braided

wire shielding onto the outside of the

plug. Solder the four plugs this way,

one on each end of the two cables.

These two cables will connect the

reverb tank to the chassis later on.

Test for continuity between the tips

of the plugs on each cable, then test

for continuity between the shields of

the plugs in the same way.

stewmac.com 10 © 2018 StewMac

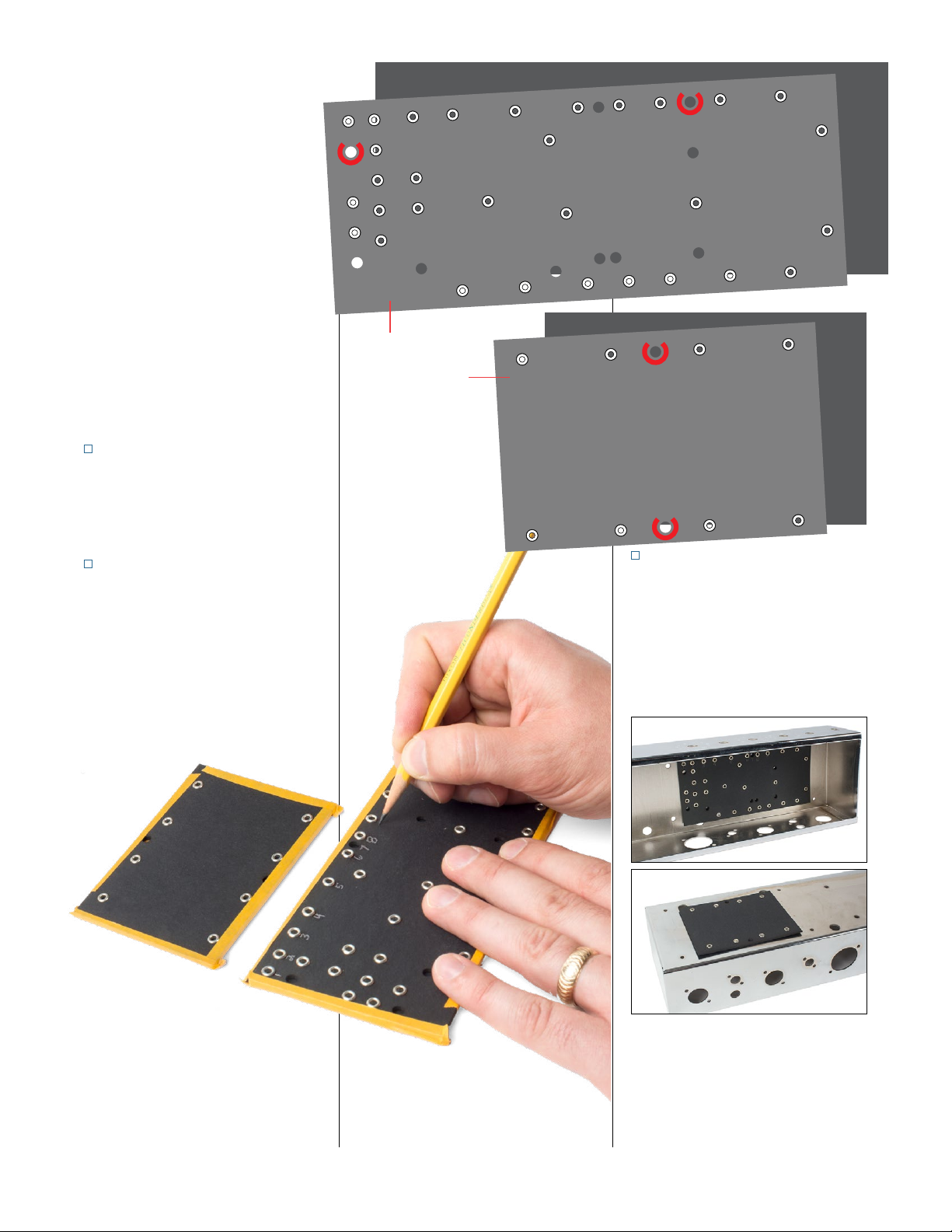

STEP 7

Number the eyelets and holes

These instructions will refer to the

eyelets and holes on the main eyelet

board by number and on the lter cap

board by letter. Use a pencil to mark

these numbers and letters onto the

boards as illustrated above.

The main board will be mounted

inside the chassis, and the lter cap

board will be mounted on the outside.

In the photo above, we’ve positioned

the empty boards just to show their

eventual mounting locations.

14

11

10

M

17

23

31

9

8

7

6

5

13

22

29

35 36 37 38 39

30

4

21

33 34

3

20

27

16

2

12

15

19

25

1

M

18

24

26

32

28

H

D

GM

M

C

F

B

E

A

Main board

Filter cap board

Insulator

Insulator

Prepping the eyelet boards

This circuit is built on two eyelet

boards. Signal processing happens on

the main board, and a smaller board

holds the lter capacitors.

For each eyelet board there’s a blank

board of the same size. These blanks

serve as insulators to keep the eyelet

board circuits from contacting the

metal chassis.

The pairs of boards mount to

the chassis with machine screws.

Mounting holes are already in the

eyelet boards, but you’ll need to

drill matching holes in the insulator

boards.

STEP 5

Tape the boards together

Noting the eyelet holes, align each

eyelet board with its insulator and

tape the paired boards together.

STEP 6

Drill the insulator boards

The mounting holes are pre-drilled

in the eyelet boards. Through them,

you can see the undrilled insulator

board taped behind. Using the holes

marked "M" on the drawing above as

a guide, drill through the insulator

boards with a 5/32" drill bit. Set the

insulator boards aside for later.

stewmac.com 11 © 2018 StewMac

POWER FUSE PILOT LIGHT DWELL INPUT MIX TONE OUTPUT

REVERB IN

FOOTSWITCH

REVERB OUT

V2

12AT7 V1

12AX7

V3

6V6

POWER TRANSFORMER

(Mounted outside)

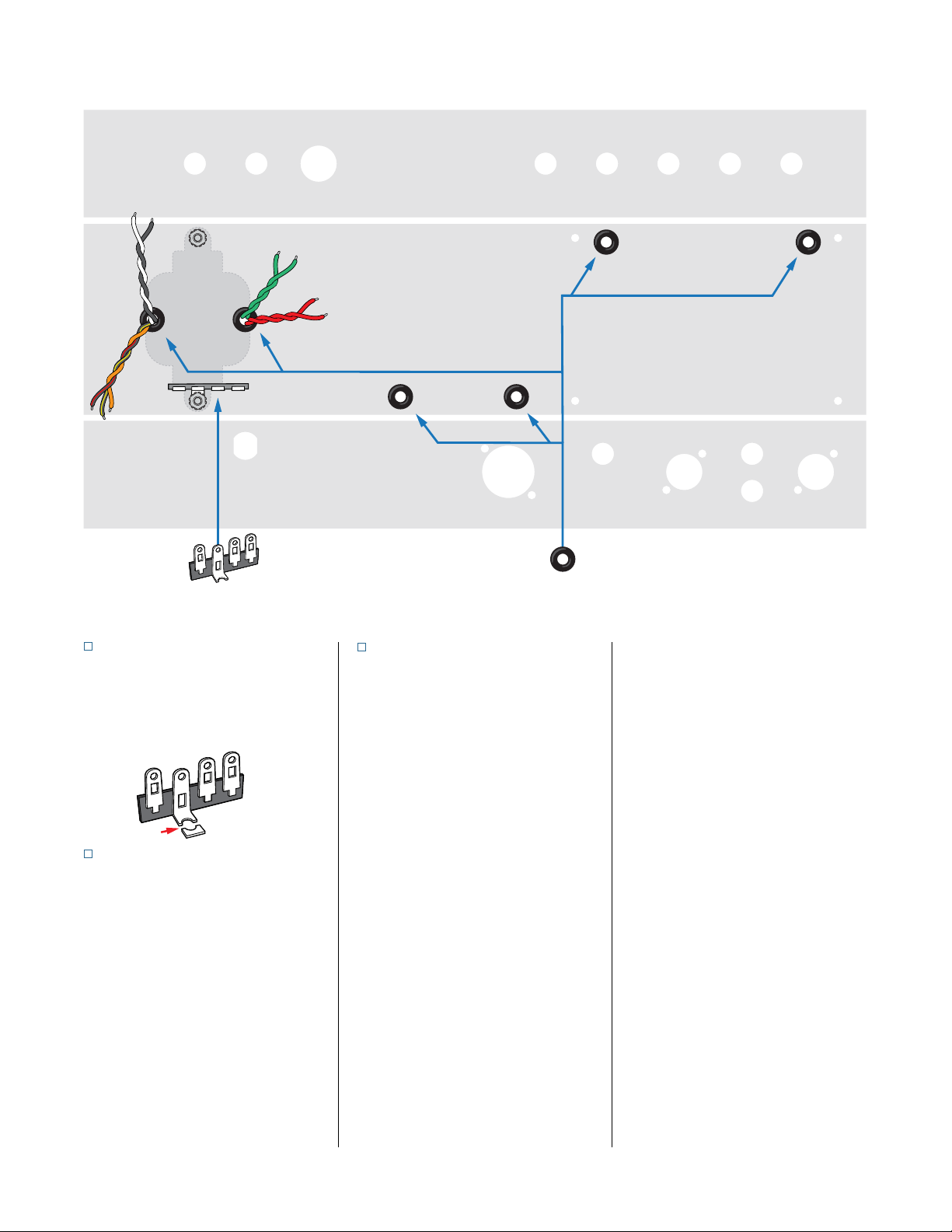

STEP 8

Install six rubber grommets

Squeeze these into the six holes for

strain relief for the wires that will pass

through the metal chassis.

STEP 9

Prep one terminal strip

With a wire cutter, snip the mounting

hole on the four-lug terminal strip as

pictured. You’ll mount this terminal

strip as part of the next step.

Installing the chassis-mounted components

STEP 10

Mount the power transformer

The power transformer has nine leads,

including two pairs with matching

colors, plus ve wires with dierent

colors. Twist the same-color pairs

together.

The other five wires allow you to

wire the unit for dierent voltages,

depending on the electrical system

where you live. The black wire is used

in all cases, and it’s twisted together

with another wire depending on your

country’s voltage:

100V: orange

120V: white

220V: black/yellow striped

240V: black/red striped

In North America for example, you

would twist the white wire together

with the black wire for 120V.

Twist the three unused transformer

wires together. You’ll terminate them

independently in a few steps. Pass the

red and green twisted pairs through

the grommeted hole under the fuse

socket. Pass the rest of the wires

through the grommeted hole closest

to the outside wall of the chassis.

Mount the transformer on the outside

of the chassis using 8-32 machine

screws. Secure the screws inside the

chassis with 8-32 locknuts. Mount the

four-lug terminal strip under the rear

locknut as shown.

Pull these wires tight once the power

transformer is mounted, but make

sure the grommets do not pull out of

their holes.

Snip

stewmac.com 12 © 2018 StewMac

STEP 11

Prep one grounding strip

With a wire cutter, snip the mounting

hole on the three-lug terminal strip as

pictured. Cut a 1" piece of green wire

and remove the insulation. Wrap and

solder the wire across the terminals,

electrically connecting all three lugs.

This will be used as a grounding strip.

STEP 12

Mount the output transformer

The output transformer has red, blue,

and yellow leads. Thread the red and

blue leads through one rubber grom-

met as shown, and the yellow lead

through the other grommet.

Using two 8-32 machine screws and

locknuts, mount the output trans-

former to the outside of the chassis.

STEP 13

Mount the filter choke

The lter choke has two black leads.

Twist these leads together and thread

them through the grommet with the

red and blue output transformer leads

as shown.

Using two 8-32 machine screws,

mount the lter choke to the outside

of the chassis. Mount the modied

three-lug grounding strip under the

front locknut.

STEP 14

Mount socket V3 + tension clip

Orient socket V3 so pin 1 is nearest the

opening of the chassis. Use two 4-40

x 3/8" machine screws to mount the

socket outside of the chassis. As you

install this socket, add the tension clip

to support the tube. This clip is held

by the same machine screws that

mount the socket.

STEP 15

Mount sockets V2 & V1

Use two 4-40 x 1/4" machine screws to

mount each nine-pin socket. Position

the sockets so pin 3 is on the side

toward the opening of the chassis.

STEP 16

Install the RCA jacks

Mount the three RCA jacks in their

respective holes. These jacks are for

the reverb in, reverb out, and the

footswitch.

Solder

Wrap

Snip

POWER FUSE PILOT LIGHT DWELL INPUT MIX TONE OUTPUT

REVERB IN

FOOTSWITCH

REVERB OUT

V2

12AT7 V1

12AX7

V3

6V6

FILTER CHOKE

(Mounted outside)

4

3

2

1

8

7

6

5

6

4

3

2

1

9

8

7

5

6

4

3

2

1

9

8

7

5

OUTPUT TRANSFORMER

(Mounted outside)

stewmac.com 13 © 2018 StewMac

STEP 17

Install the power switch

Mount the power switch with its two

lugs facing up for soldering later.

STEP 18

Install the fuse socket

Mount the fuse socket so its side lug

is facing up, toward the open side of

the chassis. This makes it easier to

solder later.

STEP 19

Install the pilot lamp socket

Mount the pilot lamp socket by screw-

ing the lens from the outside into the

socket assembly. Position the socket

so the tabs are facing up for soldering.

STEP 20

Connect two 100Ω resistors to

the lamp socket

Twist one lead from each of two 100Ω

resistors together to join them. Wrap

the other leads of these resistors to

the lugs of the pilot lamp socket.

Don’t solder the pilot lamp lugs yet,

but solder the twisted resistor leads

to each other and then solder the

twisted leads to the middle lug of

the three-lug terminal strip under the

pilot lamp assembly.

STEP 21

Install the control pots

Mount the pots so their lugs are facing

up. When we refer to these lugs as left

or right, it’s assuming you’re looking

at the pot from the same point of view

as the wiring diagram. Mount them

left to right, as follows:

Dwell: 250KL

Mix: 250KL

Tone: 100KL

POWER FUSE PILOT LIGHT DWELL INPUT MIX TONE OUTPUT

REVERB IN

FOOTSWITCH

REVERB OUT

V2

12AT7 V1

12AX7

V3

6V6

2

5

0

K

L

2

5

0

K

L

1

0

0

K

L

6

4

3

2

1

9

8

7

5

6

4

3

2

1

9

8

7

5

4

3

2

1

8

7

6

5

stewmac.com 14 © 2018 StewMac

STEP 22

Install two jacks

Mount the three-lug jack in the input

hole and the two-lug jack in the out-

put hole. Turn the jacks as pictured,

with the lugs of both jacks facing up.

Run the leads of a 1M resistor through

the right and left lugs of the input

jack, positioning it out of the way

of a guitar cable plug. It doesn’t

matter which direction the resistor is

attached, because resistors aren’t po-

larized. Wrap the lead going through

the left lug through the middle lug.

Solder the left lug and middle lug

connections, but not the right lug

connection yet.

STEP 23

Install one capacitor

Wrap and solder one lead of a .01μF

Orange Drop cap to the left lug of the

tone pot. Solder the other lead of this

cap to the back of the tone pot.

Always set pots to zero before sol-

dering to their housing. This way, if

the inside components do get a little

too hot it won't leave an imprint in a

position you might need to use later.

STEP 24

Install the silver mica capacitor

Wrap one lead of a 250pF silver mica

cap through the right lug of the mix

pot. Wrap the other lead of this cap

through the middle lug of the tone

pot. Solder both leads in place.

STEP 25

Add one jumper

Cut one 4-1/4" white wire.

Wrap one end through the right lug

of the output jack and wrap the other

end through the middle lug of the

mix pot. A connecting wire like this is

called a jumper.

Solder both ends of this jumper in

place.

STEP 26

Install power transformer leads

Run the white lead from the power

transformer to the side lug of the fuse

socket. Trim it to t and solder it. Trim

and solder the black lead to the left

lug on the power switch.

POWER FUSE PILOT LIGHT DWELL INPUT MIX TONE OUTPUT

REVERB IN

FOOTSWITCH

REVERB OUT

V2

12AT7 V1

12AX7

V3

6V6

2

5

0

K

L

1

0

0

K

L

6

4

3

2

1

9

8

7

5

6

4

3

2

1

9

8

7

5

4

3

2

1

8

7

6

5

103J 600V

250 5%

stewmac.com 15 © 2018 StewMac

STEP 27

Power transformer green leads

Run the two green wires from the

power transformer to the lugs on

the pilot lamp socket (either wire can

go to either lug). Trim these wires to

length and wrap them onto the lugs.

Don’t solder these connections yet.

Despite being green, these leads are

not ground wires. They supply power

to the pilot lamp, and after jumper

wires are connected later they will

also power the tube heater laments.

STEP 28

Power transformer red leads

Trim one of the power transformer’s

red leads to an appropriate length

and wrap one lead through one of

the lugs of the three-lug grounding

strip under the pilot lamp assembly.

You can twist the other red lead in

with itself to keep it out of the way.

This lead will be connected to the

eyelet board once the eyelet board

is installed.

STEP 29

Terminate the power

transformer’s unused leads

The three unused leads from the pow-

er transformer will carry hundreds

of volts, so they need to be safely

terminated and not hanging loose in

the chassis.

Cut these wires to length and solder

them to the three ungrounded lugs of

the four-lug terminal strip as shown.

These three lugs are not grounded or

connected to any components, which

makes them a safe place to anchor

these unused live wires. The remain-

ing lug on this strip is grounded to

the chassis, and will be used later to

ground the power cord.

POWER FUSE PILOT LIGHT DWELL INPUT MIX TONE OUTPUT

REVERB IN

FOOTSWITCH

REVERB OUT

V2

12AT7 V1

12AX7

V3

6V6

6

4

3

2

1

9

8

7

5

6

4

3

2

1

9

8

7

5

4

3

2

1

8

7

6

5

stewmac.com 16 © 2018 StewMac

STEP 30

Connect output transformer's

blue and yellow leads

Trim the blue wire from the output

transformer to an appropriate length

and solder it to pin 3 of socket V3.

Trim the yellow wire from the output

transformer to an appropriate length

and solder it to the center lug of the

reverb in jack.

Leave the red output transformer lead

free for now; you will install it to the

eyelet board later on.

STEP 31

Add two jumpers

Add a 2" white jumper between pin 2

of socket V1 and the center lug of the

footswitch jack. Solder this jumper in

to pin 2 of socket V1.

Add a 3/4" white jumper between the

center lug of the reverb out jack and

the center lug of the footswitch jack.

Solder the connection to the center

lug of the reverb out jack.

Solder the connection to the center

lug of the footswitch jack along with

the jumper from socket V1.

STEP 32

Inspect and double-check

This is a good time to step away from

the project for a few minutes and

take a break.

When you’re ready to go at it again,

carefully review every connection

you’ve made so far.

When everything checks out, you're

ready to move on to the eyelet board.

Be suspicious!

Assume there's a mistake and

you’re the one who’ll find it.

POWER FUSE PILOT LIGHT DWELL INPUT MIX TONE OUTPUT

REVERB IN

FOOTSWITCH

REVERB OUT

V2

12AT7 V1

12AX7

V3

6V6

4

3

2

1

8

7

6

5

6

4

3

2

1

9

8

7

5

6

4

3

2

1

9

8

7

5

stewmac.com 17 © 2018 StewMac

Wrap

Don’t solder the components as they

go onto the eyelet board. Instead

wrap all the parts onto the board,

bending their leads tightly so the

parts stay in place without solder.

Inspect

When all the parts are in place, stop

and inspect. Go back over every step.

Careful inspection is the best way to

make sure your unit works the rst

time you turn it on.

Solder

Solder each connection point only

once. Reheating to add another part

makes a messy, faulty solder joint.

Use the soldering tips below to get

professional results.

How to wrap and solder the eyelet board

nDon’t think of solder as glue. Good

mechanical connections make good

electrical connections. Solder’s job

is to nalize an already good joint,

not to hold the parts on the board.

So wrap the leads tightly for good

electrical contact before soldering.

nMelt a small amount of solder onto

the tip of the iron (“tinning" the iron).

Hold the tip against the joint for a few

seconds, until the connection reaches

soldering temperature.

Also tin component leads like multi-

strand wires to help the solder ow.

Tips for great soldering!

nKeep your soldering tip clean by

wiping it often on a damp sponge.

Keep it tinned by occasionally melting

a little solder onto it.

nFeed solder to the connection not

to the iron. Keep the iron on the con-

nection for a second longer to allow

time for all of the ux to cook out of

the joint.

nDon’t ever blow on the hot solder

or touch anything until the joint is

completely cool. A good solder joint

is shiny—a sign that it was left to cool

undisturbed.

nTrim away the excess wires after the

joint has cooled.

nPlan ahead so each joint is only

soldered once. Resoldered joints are

messy and more likely to fail.

nPosition the parts so their specs face

out so you can read them later. Many

builders also align resistor bands to

read in the same direction.

nHow much insulation to strip? With

plastic insulation, strip 3/8" from the

wire ends. Push-back wire works best

when you strip away about 1/4" of the

cloth wrap.

Put the lead through the eyelet Bend it tight against

the opposite side

Solder after

all the parts

are in place

Trim away

excess wire

stewmac.com 18 © 2018 StewMac

A

E

B

F

C

G

D

H

22μF

22μF

22μF

STEP 33

Add three capacitors

Use the small eyelet board for the

three filter capacitors. Note that

these caps are polarized and

must be installed in the correct

orientation.

Add a 22μF electrolytic capacitor

with the positive lead wrapped

through eyelet F and the negative

lead through eyelet B.

Add another 22μF electrolytic cap

with the positive lead through eyelet

G and the negative through eyelet C.

Wrap a third 22μF electrolytic cap

between eyelets H (positive lead) and

D (negative).

STEP 34

Add two jumpers

Wrap a 1-1/4" green jumper between

eyelets B and C.

Add another 1-1/2" green jumper

between eyelets C and D.

STEP 35

Add one resistor

Add a 10K resistor between eyelets

G and H.

STEP 36

Add three more jumpers

Add a 6" green jumper to eyelet B.

Add a 5-1/4" red jumper to eyelet F.

Add a 5-1/4" white jumper to eyelet G.

Set lter cap board aside for now, and

let’s get started on the main board!

Wrapping parts onto the filter cap board

Table of contents

Other StewMac Amplifier manuals