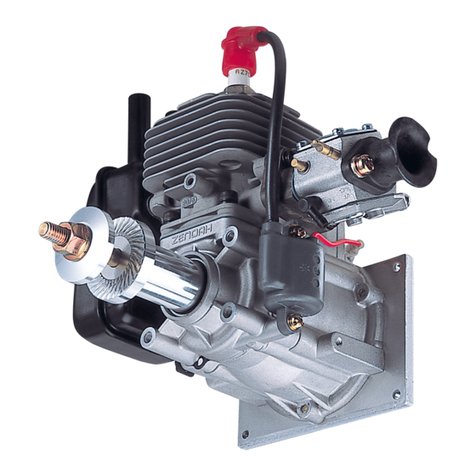

STEYR MOTORS MO114K33 Installation guide

1

www.steyr-motors.com

STEYR MOTORS GmbH

Im Stadtgut B1, A-4407 Steyr-Gleink, AUSTRIA

STEYR MOTORS MARINE ENGINES

OPERATION,

MAINTENANCE AND

WARRANTY MANUAL

P/N Z001140-0 1st Edition Jannuary 2013

4 CYLINDERS

+ 6 CYLINDERS

4 CYLINDERS

+ 6 CYLINDERS

WELCOME ABOARD

Congratulations on your decision of choosing a STEYR MOTORS marine

engine for your boat, and we hope you will enjoy it.

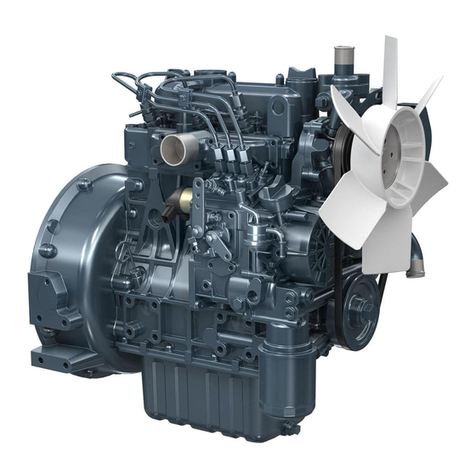

STEYR MOTORS GmbH has developed a high-speed diesel engine with

two stage high-pressure fuel injection specifically for the marine environ-

ment. STEYR MOTORS marine engines are designed to be adapted to

various propulsion systems.

To come up to your expectations, please study thoroughly this manual for

your new STEYR MOTORS marine engine to get sufficient information on

its operation and handling and to permit an optimal use of the various built-

in functions.

With kind regards,

STEYR MOTORS GmbH

STEYR MOTORS GmbH

After Sales Service

Im Stadtgut B1

4407 Steyr, Austria

www.steyr-motors.com 1st Edition, 2013 P/N Z001140-0

YOUR STEYR MOTORS

MARINE DEALER

3

4

How to use this manual

Table of Contents

GENERAL PART PAGE 5 – 18

This section contains user instructions and general notes on safety for

STEYR MOTORS marine engines.

START-UP AND FUNCTIONS PAGE 19 – 46

This section contains brief instruction, function description and normal operation,

as well as correct start-up and handling of STEYR MOTORS marine engines.

FUEL AND LUBRICANTS PAGE 47 – 50

This section defines the requirements as to fuel and lubricants for STEYR MOTORS

marine engines.

TECHNICAL DATA PAGE 51 – 60

This section contains technical data and product description of STEYR MOTORS

marine engines.

MAINTENANCE, TROUBLE SHOOTING PAGE 61 – 92

This section contains instructions for required maintenance and notes on the fault

finding on your STEYR MOTORS marine engine.

DEALER´S RESPONSIBILITIES PAGE 93 – 108

This section contains instructions for installation acceptance tests, propeller

selection, removal from service, start-up after storage, adequate disposal and

dealer´s test list.

WARRANTY, DISTRIBUTORS PAGE 109 – 120

This section contains warranty conditions (services and obligations) for owners

and manufacturers of STEYR MOTORS marine engines.

full load

speedrange

100%

90%

80%

70%

60%

50%

40%

30%

5

GENERAL PART

General ...................................................................................................... 6

MARINE ENGINE OVERVIEW ................................................................. 7

Product References, Illustrations and Specifications .............................. 13

Insurance ................................................................................................. 13

Stolen Unit ............................................................................................... 13

Owner Identification Card ........................................................................ 13

Installation and pre-delivery inspection log ............................................. 14

Dealer Service – Maintenance ................................................................ 14

Illustration Symbols ................................................................................. 14

Repair Service ......................................................................................... 15

Replacement Parts .................................................................................. 15

Before Casting Off ................................................................................... 15

Engine Submersion ................................................................................. 16

Bottom Painting ....................................................................................... 16

Boat Bottom ............................................................................................. 16

Boating Responsibilities .......................................................................... 17

Safety ...................................................................................................... 17

WARNING ............................................................................................... 17

Symbols ................................................................................................... 18

6

General

This MANUAL is published by STEYR MOTORS GmbH with the main intention to provide information in form of

technical data and know-how based on our experience in the marine diesel engine business, which will enable you,

after thorough study to operate and check the engines on your boat, ensuring their operating safety, reliability and

long service life.

CE conformity:

Under regular maintenance, as described in the chapter “Maintenance and Trouble Shooting”, the exhaust gas emis-

sion levels adhere to the limits stipulated, for pleasure boat operation, throughout the life time of the engine.

All warranty claims to be addressed to your local STEYR MOTORS Marine Dealer.

(We have to rely on your assistance however) For continuous improvement with regard to form and contents of the

information required.

Your comments on the following questions would be much appreciated

– Which descriptions or terms are not understandable?

– Which enlargements or complements do you suggest?

– Where did content-related mistakes slip in?

Please address your comments and ideas to your STEYR MOTORS – Marine Dealer.

Since this manual covers the whole family of STEYR MOTORS marine engines, differing sections are marked as

follows:

1.)

whole page applies to all engines

2.)

MO144K33

whole page applies to specified engine types only

3.)

GENERAL

MO114K33 <3700 rpm whole page applies in principle for

all engine types, but different data,

e.g. technical data, is marked.

7

MARINE ENGINE OVERVIEW

MAKE STEYR MOTORS M 14 TCAM

engine type

displace-

ment

[cm³]

rated power

[kW]

exhaust

back

pressure

[mbar]

tolerance

exhaust

back

pressure

± [mbar]

charge-air

pressure

[mbar]*

charge-air

pressure

tolerance

± [mbar]

max. intake

depression

@ rated

power

[mbar]

MO114K33 2100 81 100 ±50 1900 ±100 50

MO144V38 2100 106 100 ±50 2280 ±100 50

MO144M38 2100 106 100 ±50 2250 ±100 50

MO164M40 2100 120 100 ±50 2740 ±100 50

MO174V40 2100 125 150 +0/–50 3100 ±50 50

MAKE STEYR MOTORS M 14 TCM

engine type

displace-

ment

[cm³]

rated power

[kW]

exhaust

back

pressure

[mbar]

tolerance

exhaust

back

pressure

± [mbar]

charge-air

pressure

[mbar]*

charge-air

pressure

tolerance

± [mbar]

max. intake

depression

@ rated

power

[mbar]

MO84K32 2100 55 100 ±50 1900 ±100 50

MO94K33 2100 66 100 ±50 1900 ±100 50

MAKE STEYR MOTORS M 14 NAM

engine type

displace-

ment

[cm³]

rated power

[kW]

exhaust

back

pressure

[mbar]

tolerance

exhaust

back

pressure

± [mbar]

charge-air

pressure

[mbar]*

charge-air

pressure

tolerance

± [mbar]

max. intake

depression

@ rated

power

[mbar]

MO54NA33 2100 40 80 +0/–50 – – 50

* at standard reference conditions according to ISO 15550

8

ENGINE

TYPE SE126E25 SE156E26 SE196E35 SE236E40 SE236S36 SE266E40 SE266S36 SE286E40 SE306J38

NUMBER OF

CYLINDERS 666666666

BORE (MM) 85 85 85 85 85 85 85 85 85

STROKE (MM) 94 94 94 94 94 94 94 94 94

DISPLACE-

MENT (CM³) 3200 3200 3200 3200 3200 3200 3200 3200 3200

RATED

POWER (KW) 88 110 140 170 170 190 190 205 215

RATED

SPEED (RPM) 2500 2600 3500 4000 3600 4000 3600 4000 3800

FULL POWER

SPEED

RANGE (RPM)

2175 - 2550 2350 – 2650 3050 - 3550 3550 - 4100 3350 - 3650 3550 - 4050 3350 - 3650 3500 - 4100 3600 - 3850

MAX.

TORQUE (NM) 390 450 445 470 540 530 600 570 588

MAX.

TORQUE

(LB-FT)

288 360 328 347 398 391 443 420 434

SPEED AT

MAXIMUM

TORQUE

(RPM)

1800 1800 2050 2550 1800 2300 1800 2550 3300

MAXIMUM

TEST SPEED

(RPM)

2500 2600 3500 4000 3600 4000 3600 4000 3800

TORQUE AT

MAXIMUM

TEST SPEED

(NM)

336 404 382 406 451 454 504 489 540

LOWER

TOLERANCE

OF MAXIMUM

POWER (%)

555555555

UPPER

TOLERANCE

OF MAXIMUM

POWER (%)

555555555

FUEL RATE

AT RATED

SPEED

(MM³/

STROKE)

54.5 65.9 65.2 71.3 75.9 81.1 86.4 86.3 93.4

FUEL RATE

AT MAXIMUM

TORQUE

(MM³/

STROKE)

58 66.8 65 72 78.9 80.5 89.8 85.9 96.3

MEAN

EFFECTIVE

PRESSURE

(BAR)

13.2 15.9 15 15.9 17.7 17.8 19.8 19.2 21.2

SPECIFIC

POWER

(LBS/HP)

6.26 5.01 3.94 3.24 3.24 2.9 2.9 2.69 2.56

DRY WEIGHT

(KG) 340 340 340 340 340 340 340 340 340

9

ENGINE

TYPE SE126E25 SE156E26 SE196E35 SE236E40 SE236S36 SE266E40 SE266S36 SE286E40 SE306J38

SPECIFIC

POWER

(KG/PS)

2.84 2.27 1.79 1.47 1.47 1.32 1.32 1.22 1.16

IDLE SPEED

(RPM) 630 630 630 630 630 630 630 630 630

ASPIRATION TCA TCA TCA TCA TCA TCA TCA TCA TCA

TURBO

SYSTEM WG WG WG GEOM VTG WG VTG WG WG

FUEL CONS.

AT IDLE

SPEED (KG/H)

0.52 0.52 0.52 0.52 0.52 0.52 0.52 0.52 0.52

AIR MASS

FLOW @

RATED

POWER (KG/H)

490 520 710 965 808 980 860 1040 1020

FUEL CONS.

@ RATED

POWER (KG/H)

20.1 25.4 33.7 42.5 40.9 47.3 46.1 51 52.2

EXHAUST

MASS FLOW

@ RATED

POWER (KG/H)

510.1 545.4 743.7 1007.5 848.9 1027.3 906.1 1091 1072.2

MAX. INLET

DEPRESSION

AT RATED

POWER

(MBAR)

30/50 30/50 30/50 30/50 30/50 30/50 30/50 30/50 30/50

SPEC. FUEL

CONSUMPTI-

ON AT RATED

POWER

(G/KWH)

228 230 240 249 240 249 243 248 243

MIN SPEC.

FUEL CON-

SUMPTION

(G/KWH)

205 205 205 210 202 205 205 210 210

COMPRES-

SOR OUTLET

TEMPERATU-

RE AT RATED

POWER (°C)

130 140 145 200 160 165 175 180 180

BOOST

PRESSURE

ADJUSTMENT

VALUE 1MM

DEFLECTION

(MBAR)

1680 1680 1880

GEOMETRI-

CAL TUR-

BOCHARGER

ELECTRO-

NIC CON-

TROLLED

1920

ELECTRO-

NIC CON-

TROLLED

2040 2040

BOOST

PRESSURE

ADJUSTMENT

VALUE 3MM

DEFLECTION

(MBAR)

1880 1880 2020

GEOMETRI-

CAL TUR-

BOCHARGER

ELECTRO-

NIC CON-

TROLLED

2100

ELECTRO-

NIC CON-

TROLLED

2240 2240

MAP AT RAT-

ED POWER

(MBAR)

2130 2200 2280 2790 2560 2840 2740 2990 3060

MAP TOL-

ERANZ (+/-)

[MBAR]

75 75 75 100 50 75 50 75 75

MAP (MBAR) 2180 2240 2440 2900 2690 2840 2800 3000 3060

10

ENGINE

TYPE SE126E25 SE156E26 SE196E35 SE236E40 SE236S36 SE266E40 SE266S36 SE286E40 SE306J38

SPEED @

MAX. MAP

(1/MIN)

2200 2350 2800 3550 3050 4000 3300 3800 3800

COMPRESSI-

ON RATIO ε= 17,0 ε= 17,0 ε= 17,0 ε= 17,0 ε= 17,0 ε= 17,0 ε= 17,0 ε= 17,0 ε= 17,0

MAX. EX-

HAUST BACK-

PRESSURE

(MBAR)

150 150 150 150 150 150 150 150 150

BACK-

PRESSURE

TOLERANCE

(MBAR)

000000000

MAX. ENGINE

COOLING

WATER

OUTLET

TEMP. (°C)

81 83 83 85 86 86 86 86 87

EXHAUST GAS

TEMPERATU-

RE (°C)

375 445 480 415 506 510 535 510 525

OIL SUMP

TEMPERA-

TURE (°C)

88 88 95 96 96 97 98 98 98

GOVERNED

SPEED (RPM) 2550 2650 3550 4100 3650 4100 3650 4150 3850

MIN. ENGINE

COMPART-

MENT

PRESSURE

(MBAR)

10 10 10 10 10 10 10 10 10

MIN. FUEL

SUPPLY

PRESSURE

BLOCK INLET

[MBAR] - REL.

3500 3500 3500 3500 3500 3500 3500 3500 3500

MAX. ENGINE

COOLANT

OUTLET TEM-

PERATURE

[°C]

105 105 105 105 105 105 105 105 105

RAW WATER

FLOW (L/MIN) 105 105 135 150 150 150 150 150 140

RAW WATER

SUPPLY

PRESSURE

(BAR)

0.37 0.37 0.67 0.8 0.8 0.8 0.8 0.8 0.75

TENSION

TIMING BELT

[N]

600 +/- 30 600 +/- 30 600 +/- 30 600 +/- 30 600 +/- 30 600 +/- 30 600 +/- 30 600 +/- 30 600 +/- 30

UNIT

INJECTOR

OPENING

PRESSURE

(KPA)

26000 / 36000

KPA

26001 / 36000

KPA

26002 / 36000

KPA

26003 / 36000

KPA

26004 / 36000

KPA

26005 / 36000

KPA

26006 / 36000

KPA

26007 / 36000

KPA

26008 / 36000

KPA

UI

ADJUSTMENT

(MM)

9.2 9.1 8.85 8.85 8.74 8.65 8.74 8.7 8.65

11

ENGINE

TYPE SE126E25 SE156E26 SE196E35 SE236E40 SE236S36 SE266E40 SE266S36 SE286E40 SE306J38

UI

ADJUSTMENT

TOLERANCE

±0,02 ±0,02 ±0,02 ±0,02 ±0,02 ±0,02 ±0,02 ±0,02 ±0,02

UI ADJUST-

MENT CHECK

VALUE AFTER

ENGINE

BRAKING-IN

9.25 9.15 8.9 8.9 8.79 8.7 8.79 8.75 8.7

UI BASE

ADJUSTMENT

VALUE (MM)

9.3 9.2 8.95 8.95 8.84 8.75 8.84 8.8 8.75

VALVE TIMING

ADJUSTMENT

+ TOLERANCE

(MM)

3,59±0,02 3,59±0,02 3,59±0,02 3,59±0,02 3,59±0,02 3,59±0,02 3,59±0,02 3,59±0,02 3,59±0,02

VALVE

CLEARANCY

(MM)

0,25 / 0,25 0,25 / 0,25 0,25 / 0,25 0,25 / 0,25 0,25 / 0,25 0,25 / 0,25 0,25 / 0,25 0,25 / 0,25 0,25 / 0,25

RCD EU

94/25/EC

(2003/44/EC)

WITHOUT

INTEGRAL

EXHAUST

XXXXXXXXX

COMMERCIAL

97/68/EG

(2004/26/EG)

XXXXXXXXX

CERT. NR.

MED-B-5675 XXXXXXXXX

PERFOR-

MANCE

RATING

PR, INT, MCD PR, INT, MCD PR, INT, MCD PR, INT, MCD PR, HO PR, INT PR, HO PR, INT PR, INT

PROPELLER

SHAFT XXXXXXXX

JET-

POWERTRAIN X X X X X X

Z-POWER-

TRAIN XXXXX

RCD 85.36 106.7 135.8 164.9 164.9 184.3 184.3 198.85 208.55

RCD 86.68 108.35 137.9 167.45 167.45 187.15 187.15 201.925 211.775

UNIT

INJECTOR 2176554-0 2176554-0 2176554-0 2176554-0 2176554-0 2176554-0 2176554-0 2176554-0 2176554-0

ENGINE

BLOCK 2180996-0 2180996-0 2180996-0 2180996-0 2180996-0 2180996-0 2180996-0 2180996-0 2180996-0

CAMSHAFT

2177843-0

OR

2177843-B

2177843-0

OR

2177843-B

2177843-0

OR

2177843-B

2177843-0

OR

2177843-B

2177843-0

OR

2177843-B

2177843-0

OR

2177843-B

2177843-0

OR

2177843-B

2177843-0

OR

2177843-B

2177843-0

OR

2177843-B

CHARGE AIR

COOLER 2180876-0 2180876-0 2180876-0 2180876-0 2180876-0 2180876-0 2180876-0 2180876-0 2180876-0

PISTON

2181025-0 2181025-0 2181025-0 2181025-0 2181025-0

2181120-0 2181120-0 2181120-0 2181146-0 2181120-0 2181146-0 2181146-0 2181146-0 2181146-0

2181146-0 2181146-0 2181146-0 2181146-0

PISTON BOWL 2179531-3 2179531-3 2179531-3 2179531-3 2179531-3 2179531-3 2179531-3 2179531-3 2179531-3

FUEL

DELIVERY

PUMP

2173396-6 2173396-6 2173396-6 2173396-6 2173396-6 2173396-6 2173396-6 2173396-6 2173396-6

12

ENGINE

TYPE SE126E25 SE156E26 SE196E35 SE236E40 SE236S36 SE266E40 SE266S36 SE286E40 SE306J38

FUEL FILTER 2180831-0 2180831-0 2180831-0 2180831-0 2180831-0 2180831-0 2180831-0 2180831-0 2180831-0

WATER PUMP,

RATIO 2180867-1 2180867-1 2180867-1 2180867-1 2180867-1 2180867-1 2180867-1 2180867-1 2180867-1

HEAT-

EXCHANGER 2180883-0 2180883-1 2180883-2 2180883-3 2180883-0 2180883-3 2180883-0 2180883-3 2180883-3

OIL COOLER 2180824-0 2180824-0 2180824-0 2180824-0 2180824-0 2180824-0 2180824-0 2180824-0 2180824-0

LUBRICANT

RESERVOIR 2180643-0 2180643-0 2180643-0 2180643-0 2180643-0 2180643-0 2180643-0 2180643-0 2180643-0

CHARGE

AIR COOLER

MODULE

2180768-0 2180768-0 2180768-0 2180768-0 2180768-0 2180768-0 2180768-0 2180768-0 2180768-0

AIR FILTER /

MARK / TYPE 2180286-0 2180286-0 2180286-0 2180286-0 2180286-0 2180286-0 2180286-0 2180286-0 2180286-0

ELECTRIC

SYSTEM

VOLTAGE (V)

12V /24V 12V /24V 12V /24V 12V /24V 12V /24V 12V /24V 12V /24V 12V /24V 12V /24V

ALTERNATOR 2180569-0 2180569-0 2180569-0 2180569-0 2180569-0 2180569-0 2180569-0 2180569-0 2180569-0

STARTER 2040077-1 2040077-1 2040077-1 2040077-1 2040077-1 2040077-1 2040077-1 2040077-1 2040077-1

FLYWHEEL /

DESCRIPTION 2180676-0 2180676-0 2180676-0 2180676-0 2180676-0 2180676-0 2180676-0 2180676-0 2180676-0

FLYWHEEL

TORQUE

OF INERTIA

(KGM²)

0.1446 0.1446 0.1446 0.1446 0.1446 0.1446 0.1446 0.1446 0.1446

CLUTCH 2179164-0 2179164-0 2179164-0 2179164-0 2179164-0 2179164-0 2179164-0 2179164-0 2179164-0

CLUTCH

TORQUE

OF INERTIA

(KGM²)

0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032 0.032

GEAR BOX

DESCRIPTION ZF 45 ZF 45 ZF 45 ZF 45 ZF 45 ZF 45 ZF 45 ZF 45 ZF 45

GEARBOX

TORQUE OF

INERTIA (IDLE

POSITION)

(KGM²)

0.0427 0.0427 0.0427 0.0427 0.0427 0.0427 0.0427 0.0427 0.0427

PROPELLER

INFORMATION

3-4, 17-19

INCH

3-4, 17-19

INCH

3-4, 17-19

INCH

3-4, 17-19

INCH

3-4, 17-19

INCH

3-4, 17-19

INCH

3-4, 17-19

INCH

3-4, 17-19

INCH

3-4, 17-19

INCH

TURBO

CHARGER

NO.

2203505-0 2203505-0 2205034-5 2173969-0 2201765-0 2181154-0 2201765-0 2179202-0 2179202-0

EXHAUST

MANIFOLD 2179798-0 2179798-0 2179798-0 2179798-0 2179798-0 2179798-0 2179798-0 2179798-0 2179798-0

ELECTR.

CONTROL

MODULE NO.

2181056-0 2181057-0 2181058-0 2181059-0 2181060-0 2181061-0 2181062-0 2181063-0 2181007-0

13

Product References, Illustrations and Specifications

When reference is made in this manual to a brand name, number, product or specific tool, an equivalent product may

be used in place of the product referred to unless specifically stated otherwise. Equivalent products which are used

must meet all current local regulations and standards to avoid hazards.

Some countries may apply additional internal regulation. Please follow their advices appropriately, example:

Austria: Bundesamt für Schiffahrt

Sweden: Navigation Office

Finland: Navigation Office

Norway: DNV = Det Norske Veritas

USA: USCG = United States Coast Guard

USA: ABYC = American Boat Yacht Council

USA: NMMA = National Marine Manufacturers Association

England: LR = Lloyds Register of Shipping

France: BV = Bureau Veritas

Germany: GL = GERMANISCHER Lloyd

Italy: RINA = Registro Italiano Navale

All information, illustrations and specifications contained in this manual are based on the latest product informa-

tion available at the time of printing. STEYR MOTORS GmbH reserves the right to make changes at any time,

without notice, to specifications and models and also to discontinue models, as well as the right to change

specifications or parts at any time without incurring any obligation to equip same on models manufactured

prior to date of such change.

Continual accuracy of this manual cannot be guaranteed.

All illustrations used in this manual may not depict actual models or equipment and are intended as representative

views for reference only.

Insurance

Insurance on your STEYR MOTORS Marine Engine and boat should be obtained as soon as practical for protection

against loss by fire, theft, etc. Consult your local insurance agent.

Stolen Unit

The model and serial numbers on your engine are important for you. As to the location of these important numbers,

refer to Model and Serial Numbers in the section Technical Data.

Record each of these numbers in the spaces provided at the end of this manual and on a separate sheet. Store the

separate sheet in a safe place other than your boat.

In case of theft, report the model and serial numbers to your local authorities and your insurance agent.

Owner Identification Card

When you purchases your boat, your dealer was obliged to issue an owner identification card for your STEYR MOTORS

Marine Engine.

This owner identification card gives proof and is to be submitted in case of warranty claims.

14

Installation and pre-delivery inspection log

Your STEYR MOTORS Marine dealer is also obliged to complete the installation and pre-delivery inspection log

(Chapter “DEALER’S RESPONSIBILITIES”). Required tests and measurements are to be carried out accordingly.

A copy of the installation and pre-delivery inspection log and engine registration card are to be forwarded to

STEYR MOTORS GmbH.

Dealer Service – Maintenance

NOTE: Please do not forget to have confirmed in your manual that the installation and maintenance

have been carried out in accordance with the guidelines.

This is also an opportunity to clarify with your STEYR MOTORS marine dealer possible questions arisen during the

first running hours on your boat, and to establish a service- and maintenance routine.

Services will be performed by STEYR MOTORS Marine Dealers at local rates.

Costs for service material to be paid by the owner.

Illustration Symbols

Refer to the photograph or drawing

described in that paragraph.

Refer to specific items or features

described in the text and illustrated on the

photograph.

Refer to the general subject of the text.

Refer to an item or feature not clearly

visible on the photograph.

15

Repair Service

All repair works on your STEYR MOTORS marine engine should be carried out by a licensed STEYR MOTORS

Marine Dealer with his professional knowledge, trained staff and special-purpose tools to solve all occuring problems.

Preferably, all work on your STEYR MOTORS marine engine should be carried out by the STEYR MOTORS Marine

Dealer that sold the equipment to you – he knows you and the equipment.

If problems occur during a trip, bring your engine to the next STEYR MOTORS Marine Dealer.Information on Deal-

ers and Distributors can be found at the end of this manual.

Replacement Parts

Your STEYR MOTORS Marine Engine was designed to operate in a marine environment use STEYR MOTORS

original replacement parts.

Before Casting Off

Check the weather report, wind and water conditions. Tell someone where you are going to and when you expect to

arrive or return.

Recommended Minimum

On-Board Tools

Screwdriver Set lubrication oil spray

Metric Socket Set 12-volt pilot lamp

Metric Allen Key Set flashlight

Metric Spanner Set insulating tape

long nose pliers sharp knife

Recommended Minimum

On-Board Spare Parts

propeller and small parts for propeller mounting fuses

fuel filter ( pre- & finefilter) bulbs

impeller for raw water pump sealing compound

These lists represent a suggested MINIMUM,and are not intended to cover all boats or possible boating conditions.

16

Engine Submersion

Remove engine from water as quickly as possible and contact your local STEYR MOTORS Marine dealer for service.

It is imperative that your dealer removes all water from the engine and immediately relubricates all internal parts.

Electrical devices must be replaced. Delay in completing these actions may allow extensive engine damage.

Frequently check engine compartment for excessive water accumulation; water depth in bilge should be kept well

below flywheel housing. Engine compartment must enable proper venting to avoid condensation to build up on inner

surfaces.

Bottom Painting

If your boat is in water where marine growth is a problem, the use of an antifouling paint will reduce the growth rate.

* Tin base antifouling paint (TBTA or TBTF) is recommended where its use is permitted.

* Copper base antifouling paint may be used, but will require more frequent inspection and replacement of sacrificial

anodes. DO NOT PAINT any part of the drive unit with copper base antifouling paint.

NOTE: Painting the drive unit with copper base paint will accelerate galvanic corrosion.

* Vinyl-butyl base antifouling paint is a recommended alternative.

*DO NOT USE any graphite base antifouling paint.

NOTE: Never paint anti-corrosion anodes, or their effectiveness will be lost.

See your STEYR MOTORS Marine contract partner for an antifouling paint that is suitable for

your area.

Boat Bottom

The condition of the boat bottom can affect your boat’s performance. Marine growth, present in fresh water as well

as salt water, will reduce boat speed. A boat bottom with evidence of marine growth causes a reduction in top speed

of 20 percent or more. Periodically clean the bottom of your boat following the manufacturer’s recommendations.

17

Boating Responsibilities

As a boat owner, you have certain responsibilities to others. Be sure that all operators read this manual.

You are legally responsible for all occupants of your boat. Instruct at least one of your passengers in the basic fun-

damentals of handling your boat in case of an emergency. Show all hands the location of emergency equipment and

how to use it. You are required by law to have one locally approved life jacket for each person aboard, plus one ap-

proved throwable device for man overboard protection.

Learn the waterway rules of the location in which you are going to operate your boat. Navigable waterways are con-

trolled by Federal regulations while inland lakes are controlled by local jurisdictions. Obey these regulations to protect

yourself, your passengers and fellow boating enthusiasts.

Thoroughly familiarize yourself with weather station warning system signals and waterway traffic signs.

Contact your local Coast Guard station and take advantage of their seasonal boat inspections and training courses.

Safety

This manual contains certain information related to the personal safety of you the operator, your passengers and

bystanders.

The Safety symbol qATTENTION: appears next to important information to prevent you and others from being

hurt.

The symbol NOTE: appears next to important information to keep machinery from being damaged.

Observe all notes and safety warnings contained in this manual.

WARNING

q

CALIFORNIA: PROPOSITION 65 WARNING

Diesel engine exhaust and some of its constituents are known to the state of California to cause cancer, birth defects,

and other reproductive harm.

18

Symbols

Certain symbols or combinations of symbols may appear on your STEYR MOTORS Marine Engine or on its acces-

sories. It is very important that you understand their meaning or purpose. If any symbol is not clearly understood, see

your DEALER.

“Safety Warning” Symbols

“Position Indicator” Symbols

“Condition” Symbols

“Functional Description” Symbols

“Instructional” Symbols

Means risk of SERIOUS injury is present.

Follow instructions in the Operation,

Maintenance & Warranty Manual before

using motor or accsessory.

Indicates that contents are under

pressure.

Indicates upward movement.

Example: While boat is at planing speed,

activating trim switch to raise the bow of

the boat.

Means place shift control in NEUTRAL

before starting motor. Follow instructions in

Operation, Maintenance & Warranty Manual

before starting motor.

Identifies poisonous material.

Indicates that ELECTRICITY of more than

50 volts is present.

Indicates a potential fire hazard.

Indicates gear shift control positions:

FORWARD, NEUTRAL and REVERSE

Indentifies the meter which indicates

accumulative running hours of engine.

Identifies battery or a meter wich

indicates status of battery-generator

charging system.

Identifies the meter which indicates

engine coolant temperature.

Identifies the meter which indicates

battery voltage or amperage.

Indicates the amount of liquid in tank.

FILTER: Identifies a device which

removes contaminants from engine’s

oil system.

Identifies the meter which indicates

engine speed expressed in revolutions

per minute.

Indentifies the meter which indicates

engine coolant pressure.

Identifies the meter which indicates the

pressure of engine’s lubricating system.

FILTER: Identifies a device which

removes contaminants from fuel.

Identifies the negative ground or

negative voltage connection.

Identifies the STOP SWITCH.

It may also identify STOP position of

the throttle control.

Identifies the EMERGENCY IGNITION

CUT-OFF SWITCH.

Emergency engine stop.

Identifies engine drain plugs and fittings.

FUSE: Identifies a device which protects

the electrical system from overload.

Identifies the operating device for starting

the motor.

Indicates FUEL is to be used or

FUEL is present.

Indicates OIL is to be used or

OIL is present.

Means read your Operation,

Maintenance & Warranty Manual

before operating the product. It contains

information or instructions vital for

operation of product.

ENGINE OIL FILL: Location for

introduction of oil into the engine.

Indicates areas to be lubricated.

Indicates lubricating oil used in

transmissions.

Indicates downward movement.

Example: While boat is at planing

speed, activating trim switch to lower

the bow of the boat.

or

19

START-UP AND FUNCTIONS

Before Starting ......................................................................................... 21

Starting the Engine (key switch version) ................................................. 22

Stopping the Engine ................................................................................ 22

Starting the Engine (push button version) ............................................... 23

Stopping the Engine (push button version) ............................................. 23

Run In Procedure After Major Overhaul .................................................. 24

Definitions ................................................................................................ 24

Procedure, Work steps ............................................................................ 24

Engine Break-In procedure ...................................................................... 25

First Ten Hours ........................................................................................ 25

Final Ten Hours of Break-in ..................................................................... 25

Operation after Break-In .......................................................................... 26

Shifting ..................................................................................................... 27

Remote Control Operating Instructions ................................................... 28

How to Shift and Control Speed .............................................................. 29

Fuel Economy .......................................................................................... 29

Gear Box – Information ........................................................................... 29

High Altitude Operation ............................................................................ 29

Instrument panel (key switch version) ..................................................... 30

Instrument panel, standard ...................................................................... 30

Instrument indication during normal operation ........................................ 31

Instrument panel (push button version) ................................................... 32

Instrument indication during normal operation (push button version) ..... 33

Emergency cut off switch (Lanyard) ........................................................ 34

Warning lights and audible alarm ............................................................ 35

Electronic Engine Control Unit (ECU) ...................................................... 36

20

START-UP AND FUNCTIONS

Diagnostic system ................................................................................... 37

Twin Installations ..................................................................................... 38

Optional Propellers .................................................................................. 38

Propellers ................................................................................................ 38

Propeller Torque ...................................................................................... 39

Propeller care .......................................................................................... 39

Water Jet ................................................................................................. 39

Operating Procedure for Freezing Temperatures .................................... 39

Salt Water Operation ............................................................................... 39

High Altitude Operation ............................................................................ 39

Fuel Pump ............................................................................................... 40

Fuel System Checks ................................................................................ 40

Fuel Contamination ................................................................................. 40

Cooling System ...................................................................................... 41

Electrical Equipment ................................................................................ 43

Alternator ................................................................................................. 43

Battery ..................................................................................................... 43

Circuit Breakers & Fuses 4 Cylinder Marine Engine ............................... 44

Circuit Breakers & Fuses 6 Cylinder SE Marine Engine .......................... 44

Inversion Switch ...................................................................................... 45

Interrupt crankshaft housing ventilation ................................................... 45

Instrument Panel ..................................................................................... 45

Dry Operation .......................................................................................... 45

This manual suits for next models

16

Table of contents

Other STEYR MOTORS Engine manuals