- 2 -

Working Instructions & Maintenance

Contents

1 GENERAL INFORMATION ........................................................................................................................................................ 3

2 SAFETY WARNINGS

2.1 Product Operation ....................................................................................................................................................... 3

2.2 Prevalent Use ............................................................................................................................................................. 3

2.3 Transport .................................................................................................................................................................... 3

2.4 Long-Term Storage ..................................................................................................................................................... 3

2.5 Environmental Management ....................................................................................................................................... 3

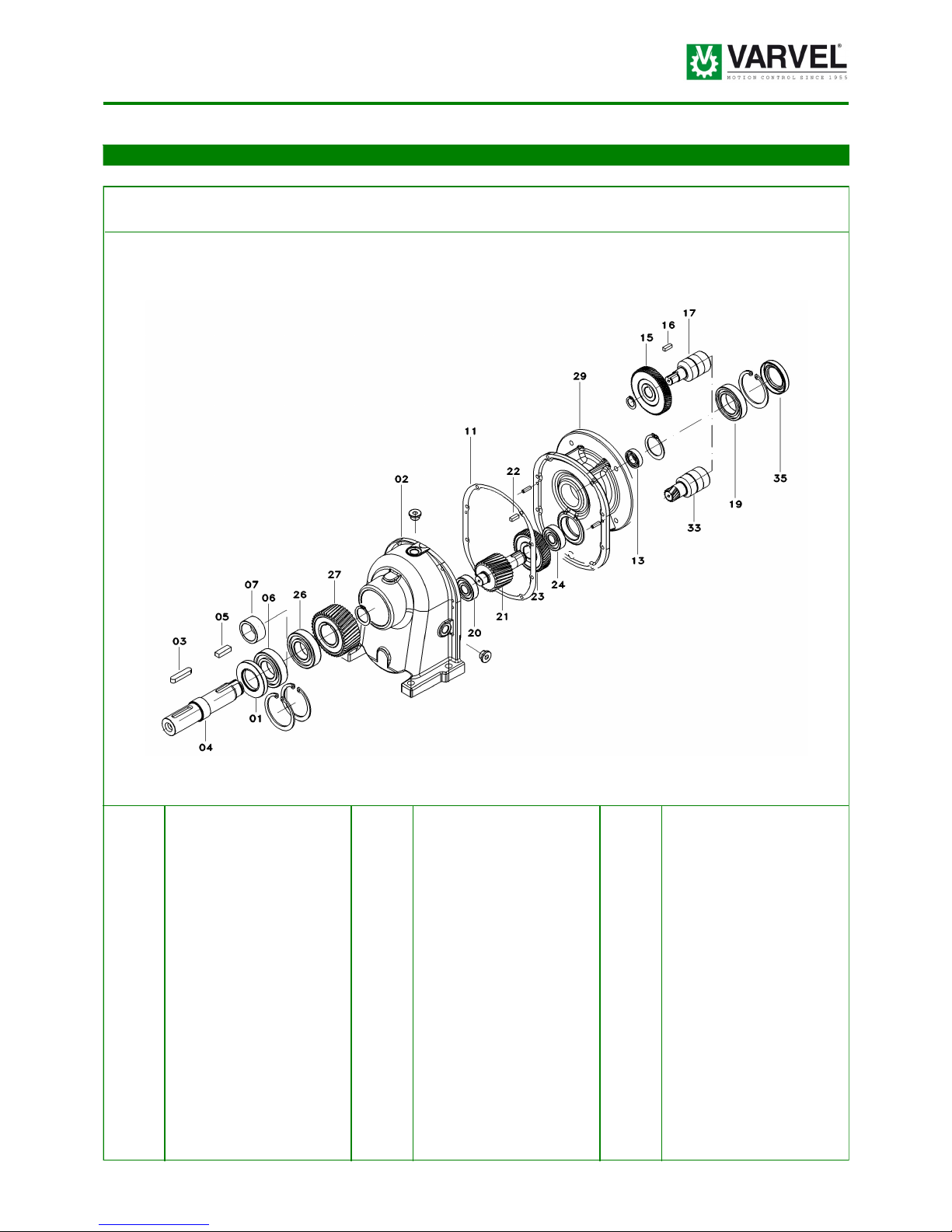

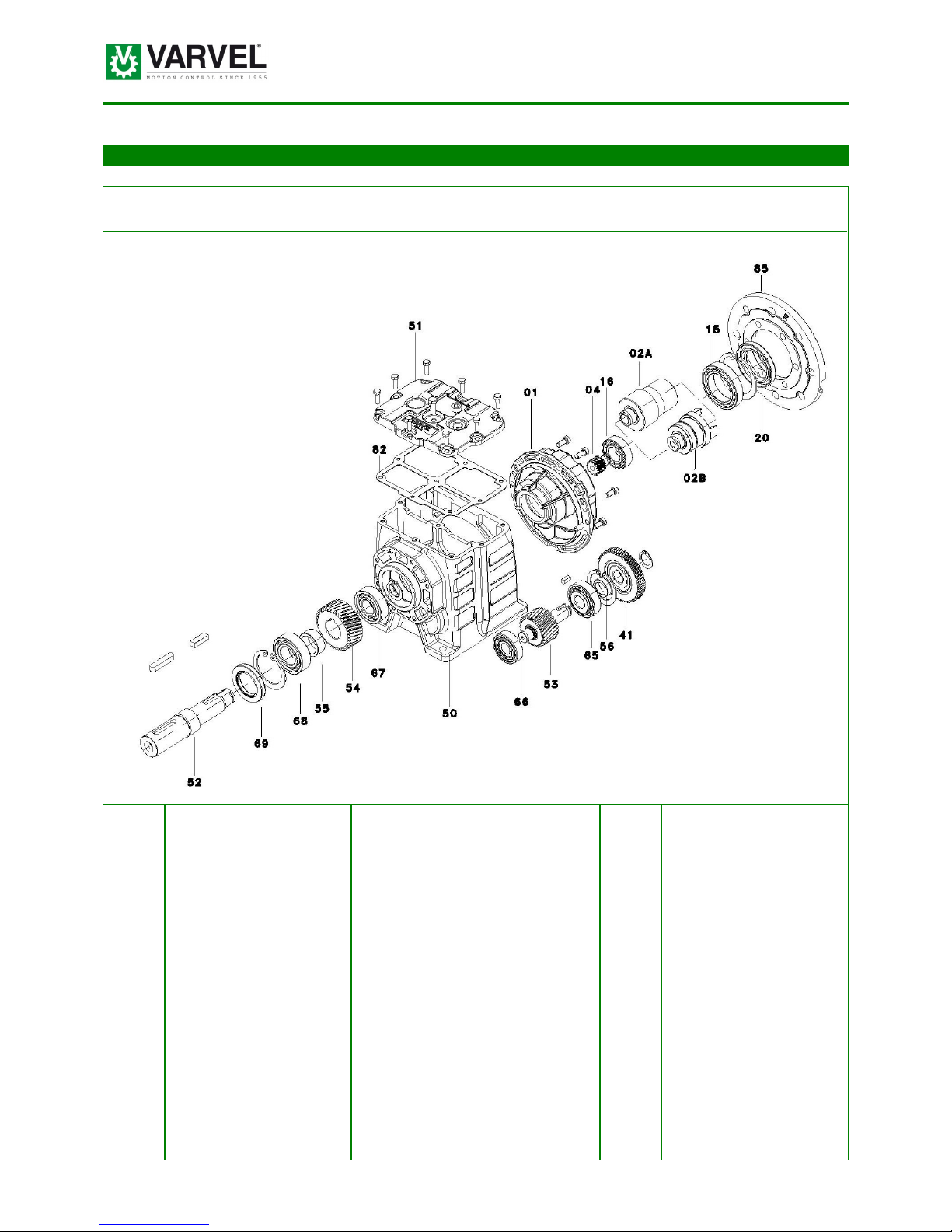

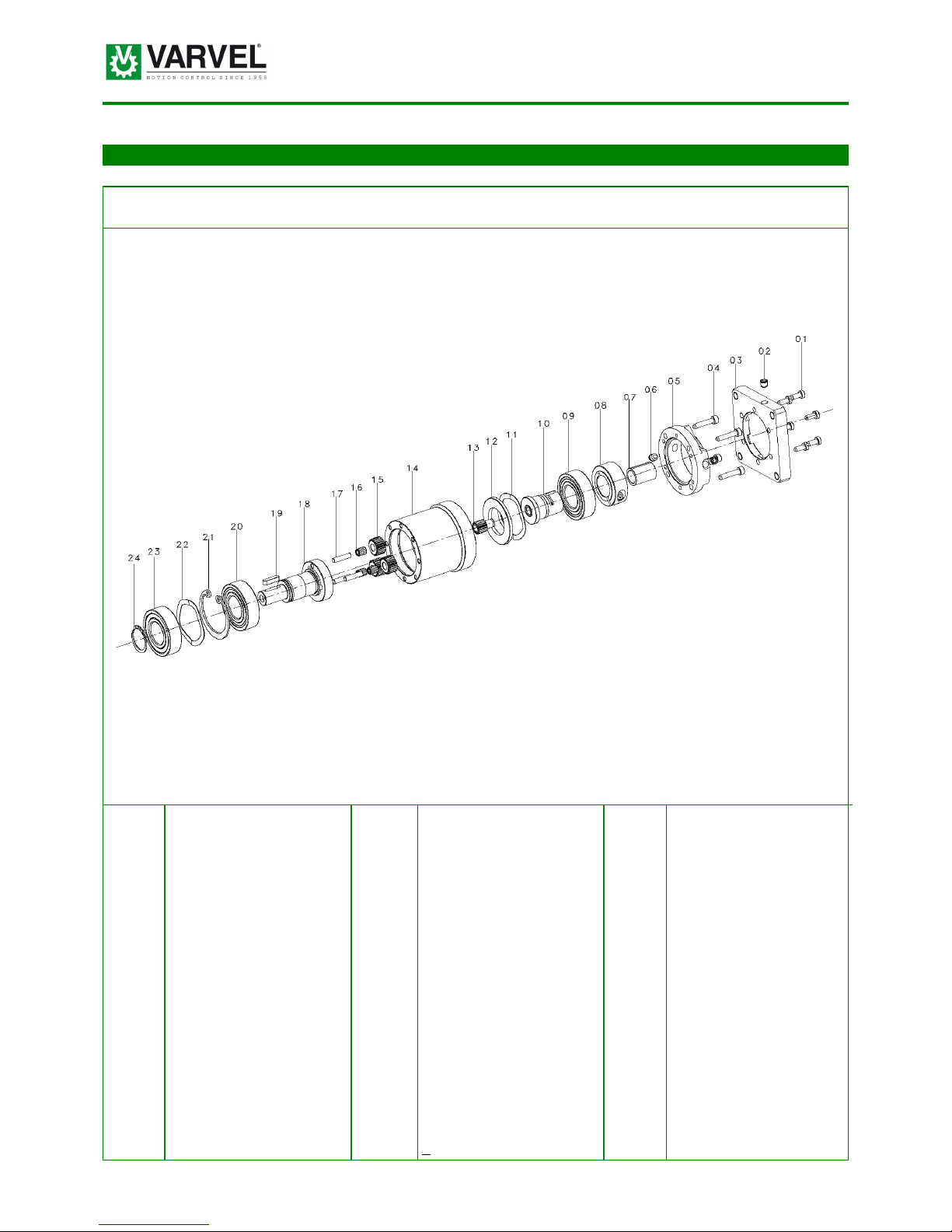

3 PRODUCT LAYOUT ..................................................................................................................................................................... 3

Elastic Coupling G ............................................................................................................................................................ 4

Gearboxes Series RC ....................................................................................................................................................... 5

Gearboxes Series RD ....................................................................................................................................................... 6

Gearboxes Series RG ....................................................................................................................................................... 8

Gearboxes Series RN ..................................................................................................................................................... 10

Gearboxes Series RO ..................................................................................................................................................... 12

Gearboxes Series RV ..................................................................................................................................................... 13

Gearboxes Series RP/XA ............................................................................................................................................... 14

Gearboxes Series RS ..................................................................................................................................................... 15

Gearboxes Series RT ..................................................................................................................................................... 16

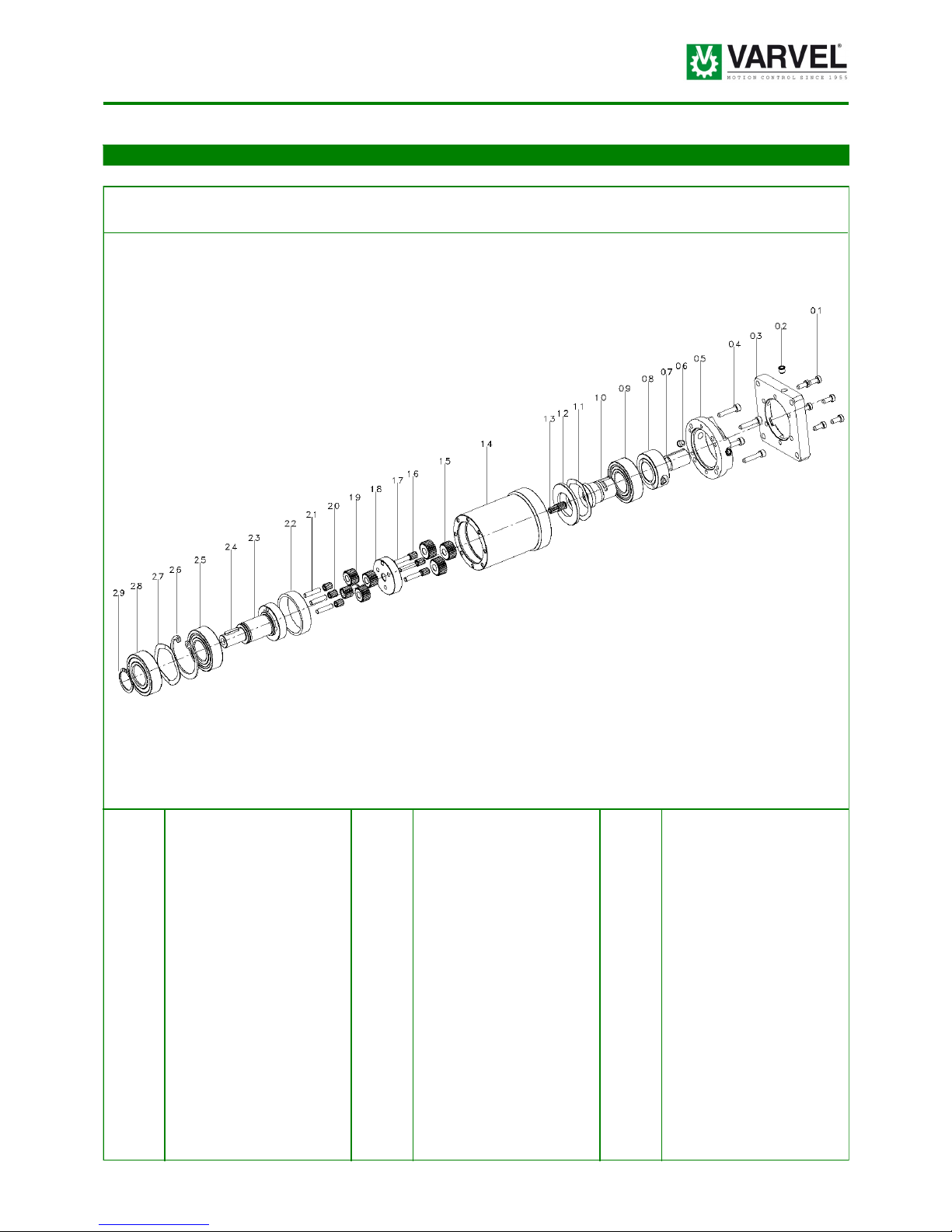

Torque Limiter Option TLE ............................................................................................................................................. 17

Torque Limiter Option TLI ............................................................................................................................................... 18

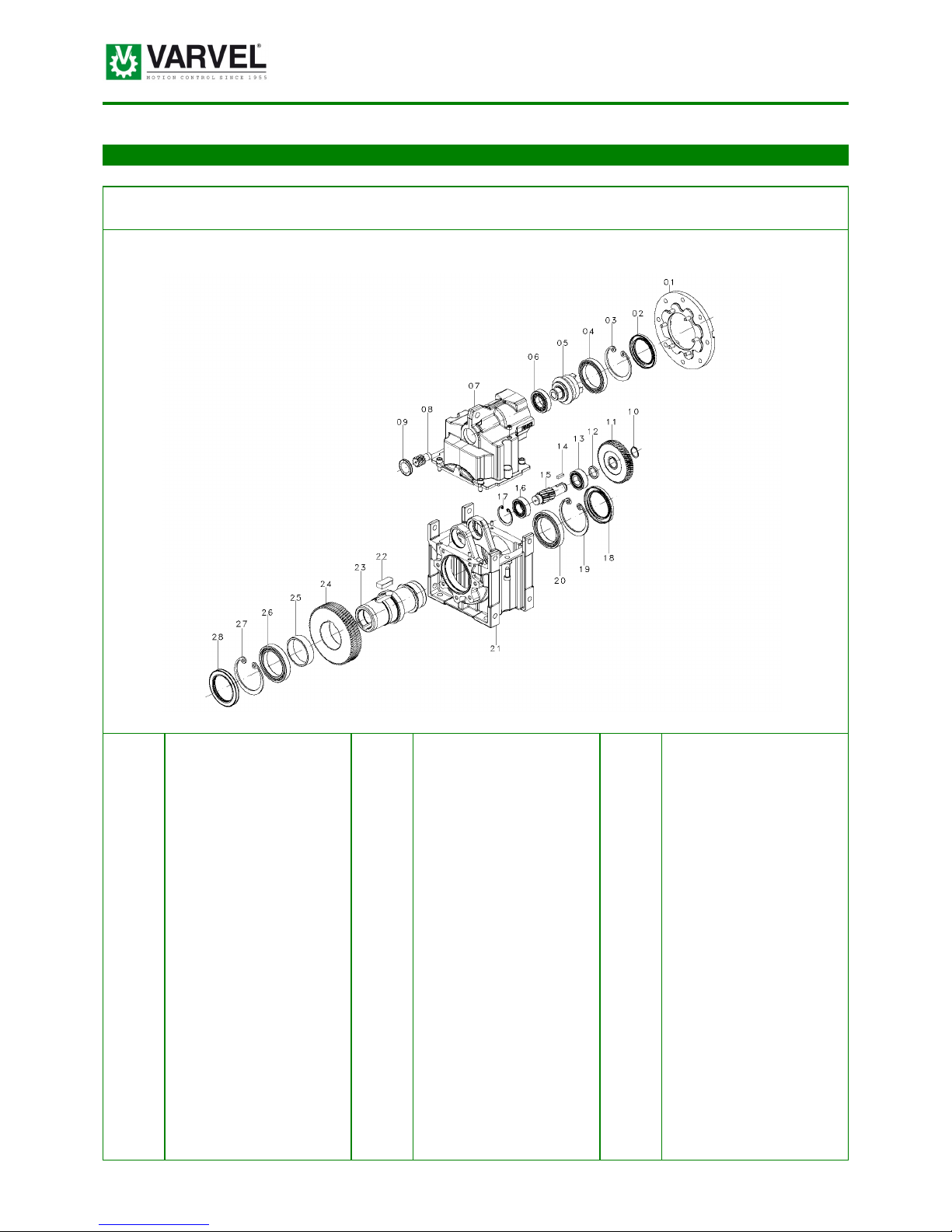

Variators Series VR ........................................................................................................................................................ 19

Variators Series VS ........................................................................................................................................................ 20

4 INSTALLATION ............................................................................................................................................................................ 21

4.1 Tolerances ................................................................................................................................................................ 21

4.2 Precautions ............................................................................................................................................................... 21

4.3 Groundwork .............................................................................................................................................................. 21

4.4 Set up ....................................................................................................................................................................... 21

4.5 Pinions, Couplings .................................................................................................................................................... 21

4.6 Torque Arms ............................................................................................................................................................. 21

4.7 Painting ..................................................................................................................................................................... 21

5 STARTING ..................................................................................................................................................... 22

5.1 Series RS, RT ........................................................................................................................................................... 22

5.2 Series RC, RD, RP, XA, VR ...................................................................................................................................... 22

6 INSPECTIONS AND MAINTENANCE .................................................................................................................................. 22

6.1 Intervals .................................................................................................................................................................... 22

6.2 Maintenance Service ................................................................................................................................................ 22

7 MALFUNCTIONING ..................................................................................................................................................................... 24

7.1 Major Events ............................................................................................................................................................. 24

7.2 Customers Service ................................................................................................................................................... 24

8 LUBRICANTS ............................................................................................................................................................................... 25

8.1 Recommended Types ............................................................................................................................................... 25

8.2 Quantity .................................................................................................................................................................... 25

9 DIRECTIVE 94/9/CE - (ATEX) ............................................................................................................................................... 28

10 DECLARATION OF CONFORMITY .................................................................................................................................... 32

.