OPERATION

Appliance description

6| SHP-A 220-300 Plus www.stiebel-eltron.com

3. Appliance description

The fully wired appliance enables DHW to be supplied efficiently

to several draw-off points using renewable energy. The appliance

extracts heat from the intake air. This heat is used to heat up the

water in the DHW cylinder with added electric power. The amount

of electric energy and time required to heat up the DHW depend

on the temperature of the air drawn in. When the air inlet tem-

perature drops, the appliance output is reduced and the heat-up

time is extended.

The appliance is designed for indoor installation. The appliance

operates in recirculation air mode and does not require outdoor

air.

Heat extraction can result in a drop in ambient temperature in

the installation room of between 1°Cand3°C. The appliance

also extracts moisture from the air, which turns into condensate.

The condensate is removed from the appliance via the condensate

drain.

The appliance has an electronic control unit with LC display. You

can select the available amount of mixed water at a temperature

of 40 °C, for example. The electronic control unit makes energy

saving adjustments easier. Subject to the power supply and user

draw-off patterns, the water is heated automatically to the se-

lected set temperature.

When the air inlet temperature drops, the appliance output is

reduced and the heat-up time is extended.

External signal transmitters can be integrated via the built-in con-

tact input, e.g. a photovoltaic system to make use of solar power

generated on site.

When a hot water draw-off point is opened, the hot DHW is pushed

out of the appliance by the inflow of cold water.

The heat pump drive unit is located in the upper section of the

appliance. The DHW cylinder is located in the lower section of the

appliance. To protect against corrosion, the DHW cylinder is coated

internally with special enamel and is additionally equipped with

an impressed current anode.

!

Material losses

If you disconnect the appliance from the power supply, it

is no longer protected against frost or corrosion.

Never interrupt the power supply to the appliance.

3.1 Heat pump operating principle

A closed circuit within the appliance contains refrigerant (see

"Specification/Data table"). This refrigerant evaporates at low

temperatures.

In the evaporator, which extracts heat from the air drawn in, the

refrigerant changes from a liquid into a gaseous state. A com-

pressor draws in the gaseous refrigerant and compresses it. This

increase in pressure raises the refrigerant temperature. That re-

quires electrical energy. The energy (motor heat) is not lost, but

reaches the downstream condenser together with the compressed

refrigerant. There, the refrigerant indirectly transfers heat to the

DHW cylinder. An expansion valve then reduces the still prevalent

pressure and the cycle starts again.

Note

Following an interruption of the power supply, the

compressor operation remains blocked for at least one

minute. The PCB delays electronic starting by a minute,

during which the appliance goes through its initialising

process.

If the compressor subsequently fails to start, it may be

locked out by additional safety devices (motor overload

relay or high pressure switch). This block should lift after

1 to 10 minutes.

After the power supply has been re-established, the ap-

pliance continues to operate with the parameters that

were selected before the power supply was interrupted.

3.2 DHW heating

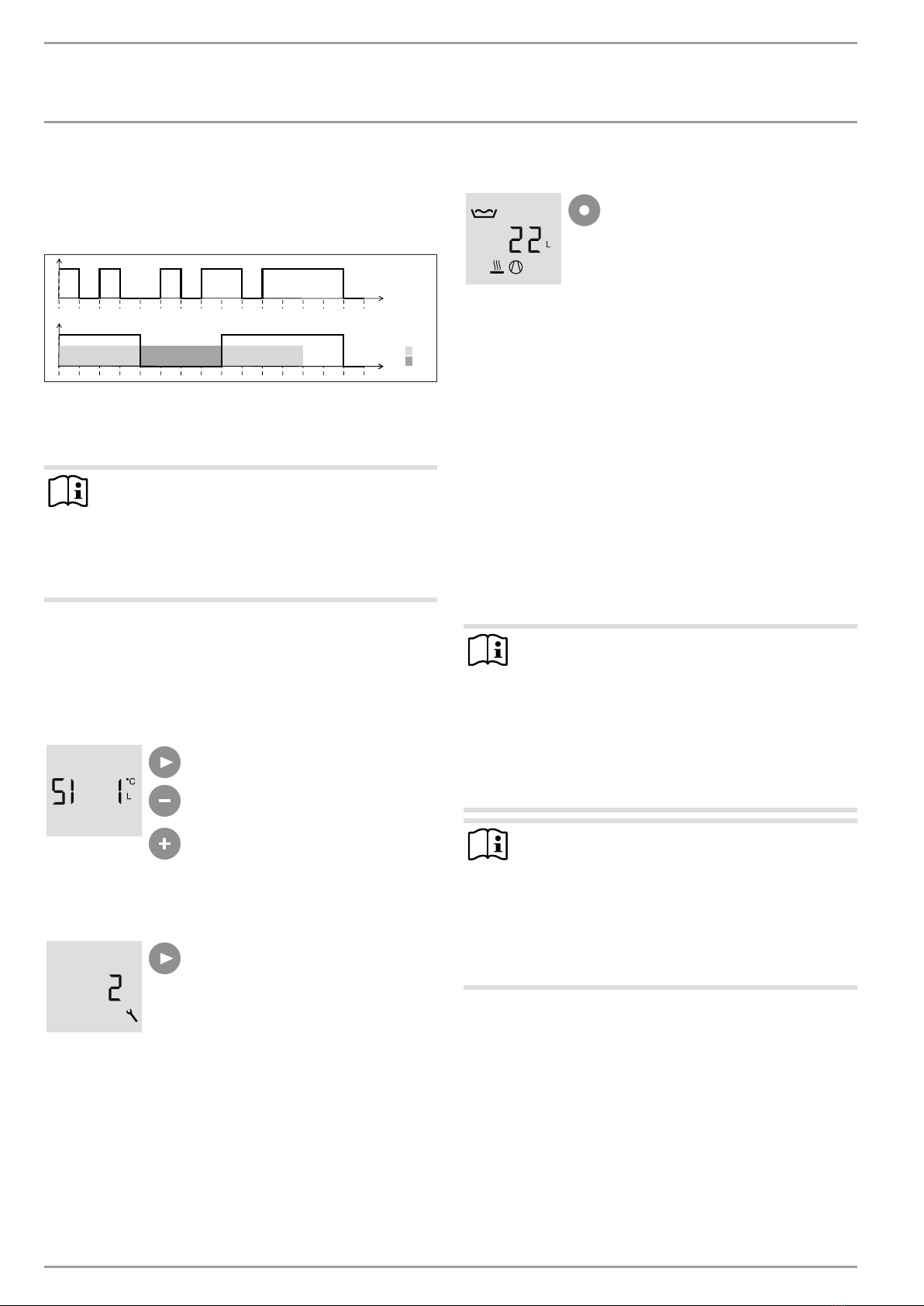

2

D0000050335

1 Cylinder top sensor

2 Integral sensor

The appliance is equipped with two temperature sensors.

- The cylinder top sensor captures the water temperature in

the upper section of the cylinder.

- The integral sensor is a temperature sensor affixed over the

entire cylinder height. The integral sensor determines the

average cylinder temperature.

The appliance display indicates the temperature in the upper sec-

tion of the cylinder, which is captured by the cylinder top sensor.

The appliance control unit uses the average cylinder temperature

captured by the integral sensor.

DHW heating is started when the average cylinder temperature

has fallen and the cylinder holds only 40% of the thermal ener-

gy it held when it was heated fully to the set temperature. The

temperature captured by the sensor at the cylinder top may still

correspond to the set temperature.

For information on the heat-up time, see chapter "Specification".

The calculation of the available amount of mixed water is based

on the average cylinder temperature. The amount of mixed water

is only calculated if the water temperature in the upper section of

the cylinder is higher than 40 °C.

DHW is normally heated by the heat pump of the appliance within

the application limits (see chapter "Specification/ Data table").

Electric emergency/booster heater

In the event of an appliance fault, the electric emergency/booster

heater can be activated in emergency heating mode, provided

a flashing fault key is displayed. See chapter “Operation/’Rapid

heat-up’ key/Emergency heating mode”.

In the event of a higher hot water demand on a single occasion,

use the rapid heat-up key to activate the emergency/booster heat-

er manually for one-off heat-up in addition to the heat pump. See

chapter “Operation/’Rapid heat-up’ key/Rapid/comfort heating”.