3

1.4 Operation

The operation is split over three control

levels. Control levels 1 and 2 are accessible to

users and contractors alike. Control level 3 is

reserved for contractors:

Control level 1 (control flap closed)

At this level, parameters, such as room

temperature, DHW temperature, heating

programs, etc. can be adjusted (for this, see

section 1.8.2).

Control level 2 (control flap open)

At this level, parameters, such as room

temperature, DHW temperature, heating

programs, etc. can be adjusted (for this, see

section 1.8.2).

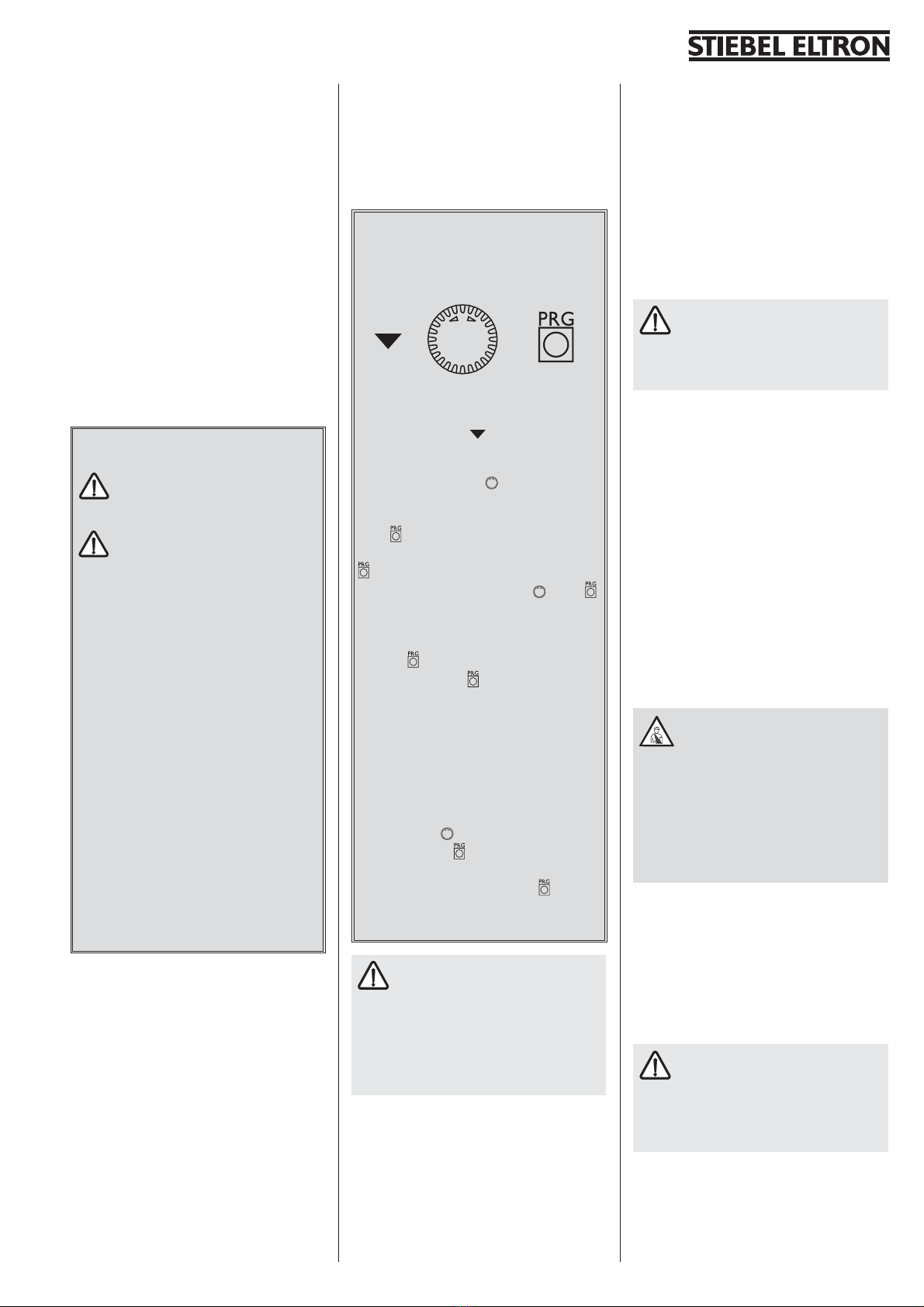

Vital facts in brief

Settings

All settings follow the same pattern:

Opening the control flap toggles the WPMi

into programming mode.

An indicator symbol is shown at the

bottom of the display at system parameter

1..,3$,/.

Turning rotary selector allows you to

move the indicator to the parameter you

want to change.

Press to change the value of the

parameter. Whenever the red indicator above

illuminates, you can modify the current

value by turning rotary selector . Press

again; the illuminator then extinguishes and

the new set value has been saved. You can

modify further values for this parameter by

pressing , if the red indicator has not been

extinguished above . The programming

step can only be terminated when the red

indicator has extinguished.

Terminate programming

You can terminate the process after entering

and saving the required parameter changes

by closing the control flap. However, if you

want to make further changes, turn the

rotary selector until the display shows

! "*, then press This will return you to

the previous level. Closing the control flap

with illuminated indicator above returns

the WPMi into its original position. The

modified value will then not be saved.

1.5 What to do if . . . ?

. . . there is no hot water or the heating

system stays cold:

Check the fuse/circuit breaker in your fuse box.

If it has blown/tripped, replace/reset the fuse/

MCB. Notify your local contractor if the fuse/

MCB blows/trips again.

1.3 Important information

The heat pumps must only be

installed and maintained by qualified

contractors.

Never:

zuse process media, which are not

expressly approved

zheat liquids other than heating water

zinstall the equipment

a) outside

b) in rooms where there is a risk

from frost

c) in wet areas, e.g. bathrooms

d) in rooms where there is a risk of

heavy dust contamination

e) in areas, where there is a risk of

explosions

zoperate the equipment

a) outside the stated temperature limits

b) without minimum flow rate on the

heat source and heat utilisation side

The DHW cylinder is at mains water pressure.

During heat-up, expansion water drips from

the safety valve, if no DHW expansion vessel

is installed. Inform your local contractor of

water drips from the system after the heat-

up process has ended.

Control level 3 (for contractors only)

This level is protected by a code and should

only be used by contractors. At this level,

heat pump and system-specific details are

determined (for this, see sections 2.11 and

2.13).

During commissioning, a system

check will be implemented,

e.g. all sensors that are currently connected

are displayed upon request. Sensors not

connected before the system went ‘live’

are not registered by the WPMi and are

therefore not displayed. The indicator

symbol skips that parameter.

Summary of WPMi functions

zRS 232 interface for adjustment and

monitoring via a PC

zSystem expansion through the FEK and

FE 7 remote control units

zInput of the system and heat pump frost

protection limits

zAt least 24 h backup power for the clock

zAutomatic pump kick-start

zReset option

zStored fault list with precise fault code

indication, together with date and time

display

zRapid and accurate fault diagnostics using

system analysis including temperature

scan for heat pump and peripheral

equipment without regarding additional

equipment.

zFactory settings for time switch programs

for all heating and DHW circuits

. . . the DHW flow rate is too low:

Remove the contamination and/or scaling

from perlators in water taps or shower heads.

. . . the red signal indicator illuminates:

Ask your local contractor to check or replace

the signal anode, if required.

Notify your local contractor in case of all other

faults.

1.6 Maintenance, care and safety

Maintenance work, e.g. checking

the electrical safety, must only be

carried out by a qualified contractor. Protect

the equipment from dust and dirt ingress

during building work.

A damp cloth is sufficient for cleaning all

plastic and sheet steel parts. Never use

scouring or solvent-based cleaning agents.

Scaling

Almost every type of water deposits limescale

at high temperatures. This settles inside the

appliance and affects both the performance

and service life. If a flanged immersion heater

is installed, the heating elements must be

descaled from time to time by a heating

contractor. A heating contractor who knows

the local water quality will tell you when the

next service is due.

Check the taps regularly. You can remove

limescale deposits at the tap outlets using

commercially available descaling agents.

Risk of injury

Where children or persons with

limited physical, sensory or mental

capabilities are to be allowed to control this

appliance, ensure that this will only happen

under supervision or after appropriate

instructions by a person responsible for

their safety.

Children should be supervised to ensure

that they do not play with the appliance.

1.7 Operating and installation

instructions

Subject to the relevant system, also observe

the operating and installation instructions

of the components of which the system

comprises.

Keep these operating and

installation instructions safely and

pass them on to any new user, should the

equipment change hands, and let your

contractor check their content in conjunction

with any maintenance and repair work.