Stierius UNIVERSAL User manual

BODO STIER Hydrotechnik GmbH

Gutenbergstr. 2-4

D-78727 Oberndorf /Neckar

Telefon +49 (0)7423 3321

+49 (0)7423 4711 (Technical Hotline)

Fax +49 (0)7423 82422

Internet: http://www.stierius.com

Owner's Manual

Brake Service Device

Typ

UNIVERSAL

(pneumatic)

In addition to the items stated in the Owner's Manual, the

following safety advice must be followed:

1. Always follow this safety advice for risk-free operation.

2. Always visually check the device for damage before use. Do not use faulty devices;

have them repaired by an authorized professional.

3. Only use the device within the scope of the present Owner's Manual (see

"Preparing for use").

4. The device is exclusively designed for filling hydraulic clutch and brake systems with

pure glycol-based BRAKE FLUID. OTHER MEDIA (mineral oil, fuels, cleaning agents,

etc.) WILL CAUSE PERMANENT DAMAGE TO THE DEVICE!

5. Use personal protective equipment as per the specifications in the safety advice for the

filling medium. In case of contact with the filling medium, perform the actions described

in the safety advice.

6. Clean devices with external soiling. No residues of flammable liquids must remain on

the housing.

7. Do not clean the device with a pressure cleaner!

8. Do not place cloths soaked in oil, fuel or solvent on the device.

9. Use only matching accessories (e.g., bleeding adapters) as per the manufacturer's

specifications (see also the list of adapters [Adapterliste] on the Internet at

www.stierius.com).

10. Observe the respective vehicle manufacturer's instructions!

To ensure the reliability and safety of the device, we recommend having maintenance

performed regularly on the device by qualified staff.

To ensure environmentally-compatible disposal of the used medium, we recommend

using a closed brake fluid disposal system.

Accessories

Catchment container

(Clutch) bleeder hose no. 67

Various adapters

A vehicle-specific application list can be viewed on

www.stierius.com.

Technical data:

460 mm ---

300 mm ---

300 mm ---

Height:

Width:

Depth:

Weight empty: 6,5 kg ---

Content: 5 l0-3,5 bar

Flow rate: approx. 60 l/h 0-4 bar

(at 2.5 bar dynamic pressure/2.0 bar

delivery pressure)0-6,5 bar

Hose length: approx. 3,5 m

Control range:

Operating pressure display:

Standby pressure:

Operating temperature: 0º-45ºC

We expressly reserve the right to make changes for technical reasons, including

design changes.

Brake Service Device

UNIVERSAL

Note:

The UNIVERSAL Brake Service Device reflects the state-of-art in the field of hydraulic brake

system and clutch actuator maintenance. It also meets the requirement for the work being

performed by a single mechanic (observe the vehicle manufacturer's work instructions).

Suitable for all ABS systems and hydraulic clutches.

The device has a very robust design and can be deployed universally. Handling of the device

is so simple that mechanics do not need special training.

However, every mechanic who will be working with this device must be introduced to the

device and instructions on the use of the device must be provided in the form of the

operating instructions. The 5 liter brake fluid tank means that several brake fluid changes can

be performed without refilling the device.

Important!

Soiled brake fluid or water content in the brake fluid can cause the hydraulic brake system to

fail. For this reason, use only brake fluid from brake fluid containers with an original fill.

The hygroscopic properties of brake fluid mean that it absorbs moisture from the ambient air.

Moisture reduces the boiling point of the brake fluid to a dangerous extent. Braking causes

high temperatures in the brake system; in a brake system contaminated with moisture, this

cause boiling bubbles in the brake fluid that can make further braking actions impossible.

Corrosion within the brake system is caused by electrolytic actions of brake fluid with water

content. Boiling bubbles and air inclusions already result in corrosion as the air inclusions

contain oxygen.

It is thus recommended to replace the brake fluid in hydraulic brake systems every 15,000

km.

When changing the brake fluid in hydraulic systems, always push the used brake fluid out of

the system with the new brake fluid.

Condition at delivery/preparing for use

In its condition at delivery, the packaging contains the following parts:

1 Brake Service Device, comprising of:

Device with handle, locking piece with reducer, filling hose

1 Owner's Manual

1 adapter no. 20

1 catchment container (optional)

Check the device for transport damage on unpacking. Report any transport damage to the

appropriate freight forwarder without delay.

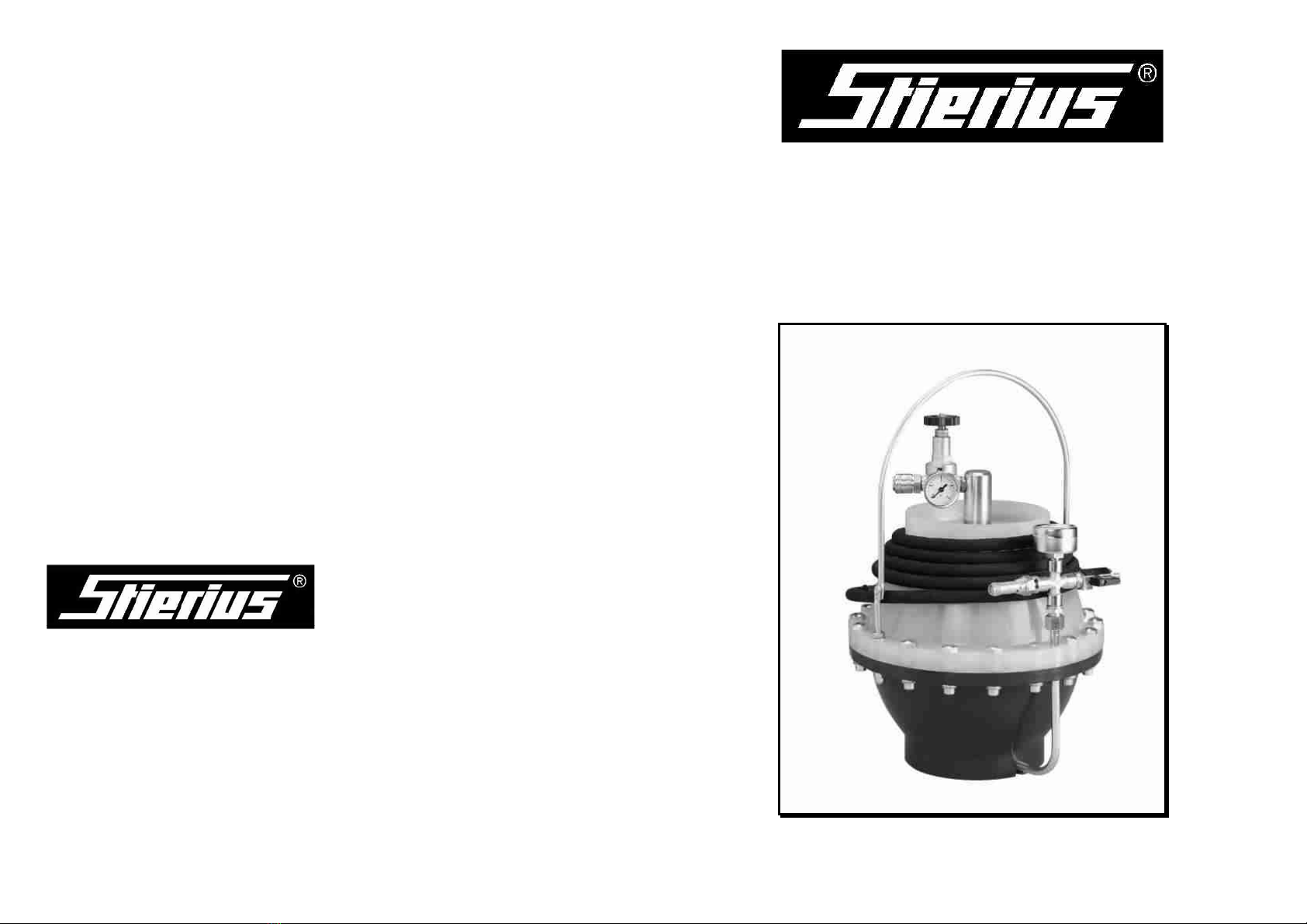

Device description (Fig.):

Part Part designation Part Part designation

10 Filling hose, complete

11 Safety valve

12 Sealing cap coupling

13

14

16

17

1 Shut-off valve of air filling valve

2 Sealing cap complete with pressure reducer

3 Nozzle for air filling

4 Standby pressure gauge (ÿ50)

5 Spindle (handwheel) for pressure reducer

6 Operating pressure gauge (ÿ40)

7 Shut-off valve for filling hose

8 Filling hose coupling

9 Adapter (Fig: no. 20)

<=Fig. 1

Fig. 2=>

Fig. 3=>

We expressly reserve the right to make changes for technical reasons, including design

changes.

Practical advice and tips for effective bleeding of a hydraulic brake or clutch system

After the UNIVERSAL Brake Service Device has been connected to the compensating tank

using a connecting cover (adapter), the procedure for bleeding the system or changing the

brake fluid can begin.

þ Perform bleeding as per the vehicle manufacturer's specifications.

þ Open each bleeding valve until clear, bubble-free brake fluid escapes.

þ To make it easier to check the escaping brake fluid (cleanliness) and precisely measure the

used brake fluid, we recommend the use of our catchment container with a graduation.

þ When completely refilling the brake system, it is useful to open all bleeder screws.The

brake fluid pushes the air out. Because the bleeder screws are open, the air takes the

path of least resistance and immediately escapes without counterpressure and without

any risk of mixing. When clear, clean brake fluid starts to escape at the bleeder screw,

manually screw in the bleeder screw wheel by wheel. After completing this work step,

tighten the bleeder screw again.

þ We recommend slowly and fully actuating the brake or clutch pedal a number of times

during the bleeding and brake fluid change procedure; this guarantees that brake fluid flows

into the annular spaces between the primary and secondary sleeves and that any remaining

air bubbles in the cylinder are loosened.

þ In case of brake systems with a fixed caliper, a greater liquid flushing volume is required for

changing the brake fluid in order to ensure that the brake fluid can be appropriately changed

in those parts of the housing cover that do not have a direct flow. Note that several bleeder

valves can exist in fixed calipers. All bleeder valves must be bled in succession.

þ For vehicles with a load-driven braking force regulator, the hydraulic passageway to the

wheel brakes connected to the compensator may be blocked if the axles are relieved

(vehicle is on a 2-pillar lifting platform).To ensure trouble-free bleeding, or trouble-free

replacement of the brake fluid, the axles should be loaded. Observe the data of the

respective vehicle manufacturer.

þ Clutch bleeding hose no. 67 is recommended for bleeding and filling hydraulic clutch

systems. This hose is connected to and locked onto the bleeder valve on the master

cylinder by means of a push-on, lever-action nipple. The used brake fluid is vacuumed out

of the compensating tank prior to this. Following this, the system is bled and filled from the

bottom upward.

Further bleeding adapters are available for all vehicles.

When does the device need to be refilled?

If the pressure at the operating pressure gauge (6) drops to zero, although the standby pressure

(4) is greater than 1 bar, the brake fluid tank is empty => Refilling the device, see

"Preparing for use" The air tank is designed to allow the complete brake fluid (5 liters) to be

extracted at a pressure of at least 1.5 bar. There is typically no need to fill up with compressed

air.

Storage

In case of extended periods without use, the compressed air can be released. When you need to

use the device again, fill with compressed air as per step 7 under "Preparing for use" or refill as

described beginning with step 1 under "Preparing for use".

Safety

The owner must call in an authorized expert to perform tests as per Section 10 BetrSichV

(German Industrial Safety Regulations).

Repairing the device

Repairs to the device must be performed by an authorized customer service agent!

Only ship in suitable packing! STIERIUS accepts no liability for any transport damage. Shipping

costs to be paid by the sender.

Disposal

The device can be returned to the manufacturer/sales partner (shipping and transport costs to

be paid by the sender); or it must be disposed of taking national and local waste disposal

regulations into account.

Preparing for use:

1. IMPORTANT! Open the shut-off valve (1) at the air filling valve (longitudinal position:

air escapes fully from the air tank) and leave it open.

2. Disconnect the filling hose (10) from the sealing cap coupling (12) (Fig. 2).

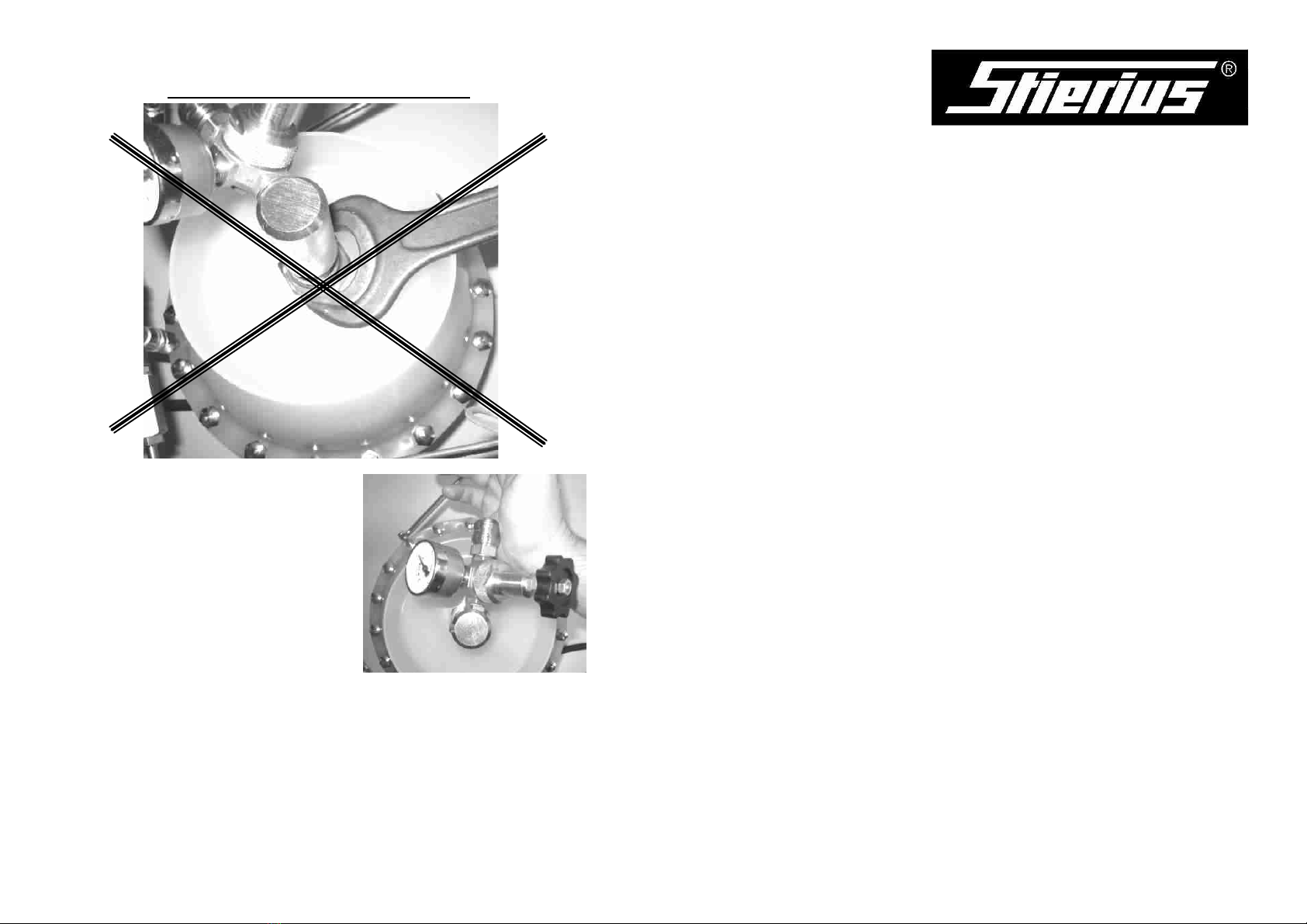

3. Unscrew and remove the sealing cap from the device (Fig. 3). NEVER OPEN AT

HEXAGON NUT SW41! (See "CAUTION! Never open the upper part of the

device!")

4. Slowly fill the device with fresh brake fluid up to the top edge of the fitting. Allow the

fluid in the device to degasify for longer than 10 minutes.

5. Check the fill level; fill up again if needed; screw in the sealing cap (2) (hand-tight

to the stop, NO FARTHER!).

6. Connect the filling hose (10) to the sealing cap.

7. Fill the device with compressed air via the air filling valve (3) until the standby

pressure gauge (4) shows 6.5 bar. Then close the shut-off valve (1) (transverse

position).

8. Turn in the handwheel (5) on the pressure reducer up to the lock nut (the operating

pressure gauge (6) then shows the preset pressure; factory setting: 2 bar).

9. Connect an adapter or nozzle to the filling hose coupling (8); open the shut-off valve

(7) for the filling hose (longitudinal position) and allow the brake fluid to run into a

suitable container until it is bubble free (approx. 1/4 liter). The device is now ready for

use.

10. Mount a suitable adapter on the master cylinder compensating tank and connect

the filling hose with quick coupling (8) to the plug-in nipple on the bleeding adapter.

Now perform bleeding or the brake fluid change as required. Note the approach

specified by the vehicle manufacturer in question; this applies in particular to vehicles

with an ABS system and/or load-driven braking force regulators.

11. Depressurize the filling hose after the bleeding action; to do so: Shut off the shut-off

valve on the filling hose (7) and relieve the pressure via the bleeder nipple on one

wheel cylinder (catchment container!). This means that the filling hose coupling (8) can

be disconnected from the adapter without spilling brake fluid.

12. Mount the original cap on the compensating tank again.

ATTENTION!

NEVER OPEN THE DEVICE UPPER PART

When closing the device, only hand-tighten

the device upper part up to the stop!

To open (relieve the compressed air; see step 1

under "Preparing for use"), tap lightly with the

ball of your hand in counterclockwise direction.

Never push down the separating diaphragm with

objects of any kind (screwdrivers, wire, etc.); this

happens automatically on filling the device!

Never fill the device with compressed air via the upper part or filling hose!

Tip: Fill the device with warm brake fluid (22 °C room temperature) if possible;

if the brake fluid is cold (=higher viscosity), allow the device to degasify for

longer before filling with compressed air (see step 4 under "Preparing for use").

General instructions

After bleeding or changing the brake fluid, if you notice that the brake or clutch pedal

actuation path is too long, or that pressure build-up is too "soft", you then need to bleed

the brake or clutch system again after firmly actuating the brake or clutch system multiple

times.

Setting the correct operating pressure

The pressure reducer (5) is factory set to an operating pressure of 2 bar. This prevents

the compensating tank deforming during bleeding or a brake fluid change via the

compensating tank, thus avoiding the risk of leakage in the secondary sleeve. Bleeding or

a brake fluid change at a lower operating pressure (as required for some vehicle types) is

easily possible; a higher operating pressure is desired in a few exceptional cases.

Lower operating pressure: Shut off the shut-off valve (7) on the filling hose. Turn out the

handwheel (5) on the pressure reducer. Connect the filling hose to the vehicle as

described in step 10 under "Preparing for use". Open the shut-off valve (7) and slowly turn

the handwheel (5) on the pressure reducer until the desired pressure is shown at the

operating pressure gauge (6).

ATTENTION!

After bleeding with a lower or higher operating pressure, be sure to set the

pressure reducer back to 2 bar operating pressure.

Low pressure leak test

The UNIVERSAL Brake Service Device can also be used for low pressure testing of

hydraulic brake systems. The device remains connected to the compensating tank by

means of a bleeder adapter. Note that all bleeder screws must be closed for this. Apply

the device's operating pressure (2 bar) to the brake system. The pressure reducer is

closed by turning the handwheel on the pressure reducer (5) counterclockwise. The

operating pressure shown on the pressure gauge (6) must not drop within 5 minutes. If

the operating pressure drops within the test period, the brake system has a leakage.

Table of contents

Other Stierius Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Witt

Witt GP 42 Operation & service manual

VERACHTERT

VERACHTERT PW Series operating manual

SNR

SNR NTN SNOE 200 Series Assembly, servicing and maintenance instructions

schmersal

schmersal AZM201Z-I1-SK-T-1P2PW Instructions for operation

Centa

Centa CENTAX-L Assembly and operating instructions

ABB

ABB HT843322 Operation manual

Numberall

Numberall 250P manual

WPG

WPG FLEXR Series operating instructions

Zimmer

Zimmer DKPS1000 Series Installation and operating instructions

Sure-Feed Engineering

Sure-Feed Engineering SE-900-EI Operations & parts manual

Tektronix

Tektronix IntelliFrame VX1410A instruction manual

ABB

ABB HT576242 Operation manual