EFA EFA VB 315 User manual

OM NO.: 001 580 603

Stand / Version

04 / 2017

Originalbetriebsanleitung

Translation of the original Operating manual

Stunning device

Stunning Device

EFA VB 315

Wichtige Informationen: Diese Anleitung unbedingt dem Bedienpersonal aushändigen!

Important Information: Please forward these operating instructions to your operating personnel!

Schmid & Wezel GmbH

Maschinenfabrik

Maybachstraße 2

75433 Maulbronn, Germany

Phone: +49(0)7043 / 102-0

Fax: +49(0)7043 / 102-78

E-mail: verkauf@efa-germany.de

Website: www.efa-germany.de

Schmid & Wezel

Seite / Page

2 of 13

Stand / Version

04 / 2017

Table of contents

1Use, scope of supply, accessories................................................................... 3

1.1 Symbols used in this manual................................................................................................... 3

1.2 Intended use............................................................................................................................ 3

1.2.1 Application area........................................................................................................ 3

1.2.2 Residual risks ........................................................................................................... 3

1.3 Delivery content....................................................................................................................... 3

2Safety instructions............................................................................................. 4

2.1 General safety instructions...................................................................................................... 4

2.2 Conduct at the workplace........................................................................................................ 4

3Connection and start-up.................................................................................... 4

3.1 Initial Operation........................................................................................................................ 4

3.1.1 Spring balancer......................................................................................................... 4

3.1.2 Compressor.............................................................................................................. 5

3.1.3 Connecting the stunning device ............................................................................... 5

3.1.4 Uncoupling the stunning device................................................................................ 5

3.2 Working with the stunning device............................................................................................ 5

3.2.1 Operation.................................................................................................................. 6

3.2.2 Operating safety ....................................................................................................... 6

4Assembly............................................................................................................ 6

4.1 Replacing parts........................................................................................................................ 6

4.2 Adjustment of the spring balancer........................................................................................... 7

5Maintenance ....................................................................................................... 7

6Repair and troubleshooting .............................................................................. 8

7Cleaning and maintenance...............................................................................10

7.1 Disinfection and cleaning during operation ........................................................................... 10

7.2 Daily cleaning after completion of the slaughter.................................................................... 10

7.2.1 Cleaning the stunning device ................................................................................. 10

7.3 Maintenance.......................................................................................................................... 10

7.3.1 Before and during slaughtering: ............................................................................. 10

7.4 After slaughtering................................................................................................................... 11

7.5 Wear...................................................................................................................................... 11

7.6 Maintenance unit ................................................................................................................... 11

Repairs........................................................................................................................................... 11

8Transport and storage......................................................................................11

9Return of waste electrical equipment..............................................................11

Appendix

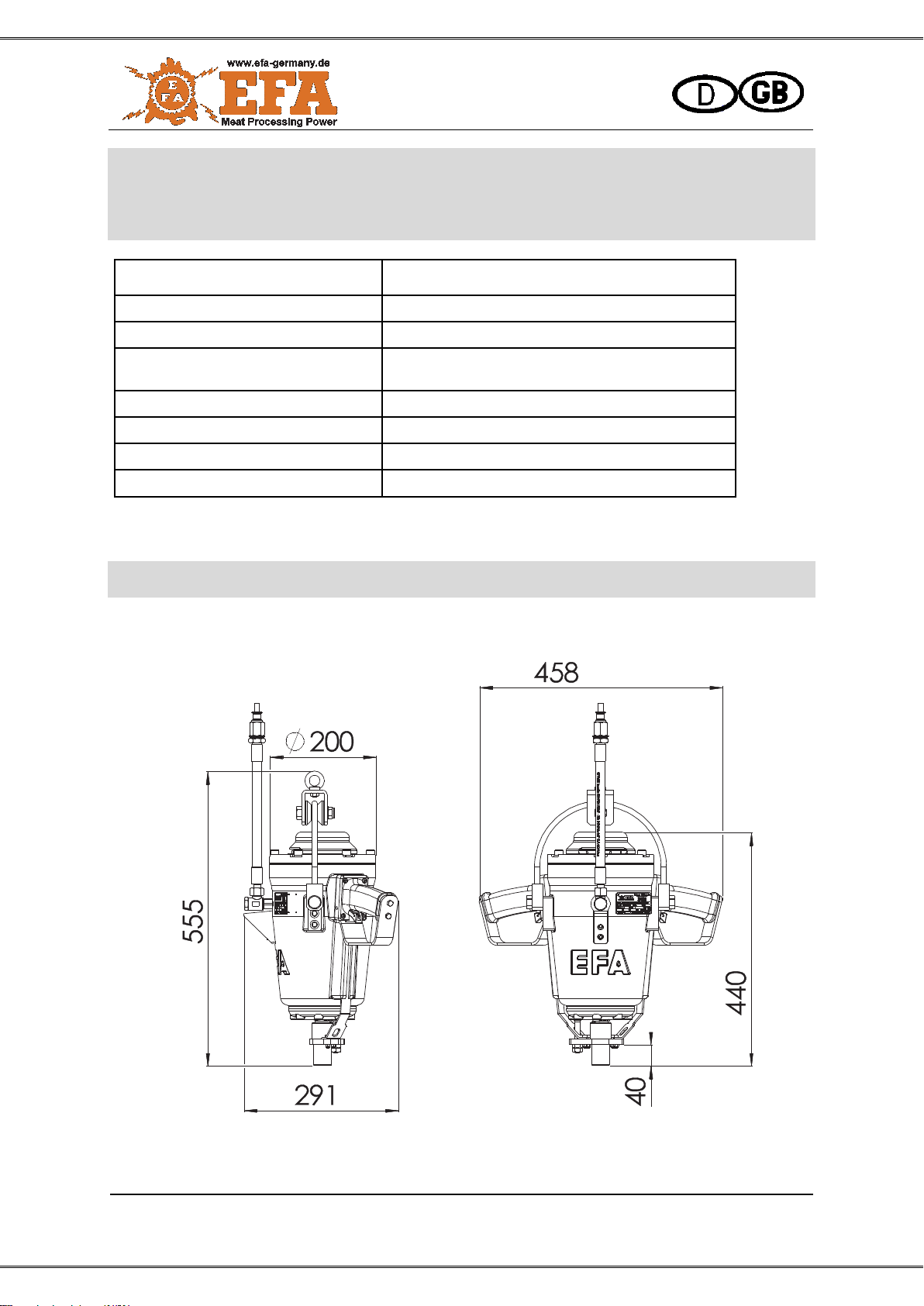

A1 Technische Daten / Technical Data .................................................................12

A2 Maßblatt / Dimension sheet..............................................................................12

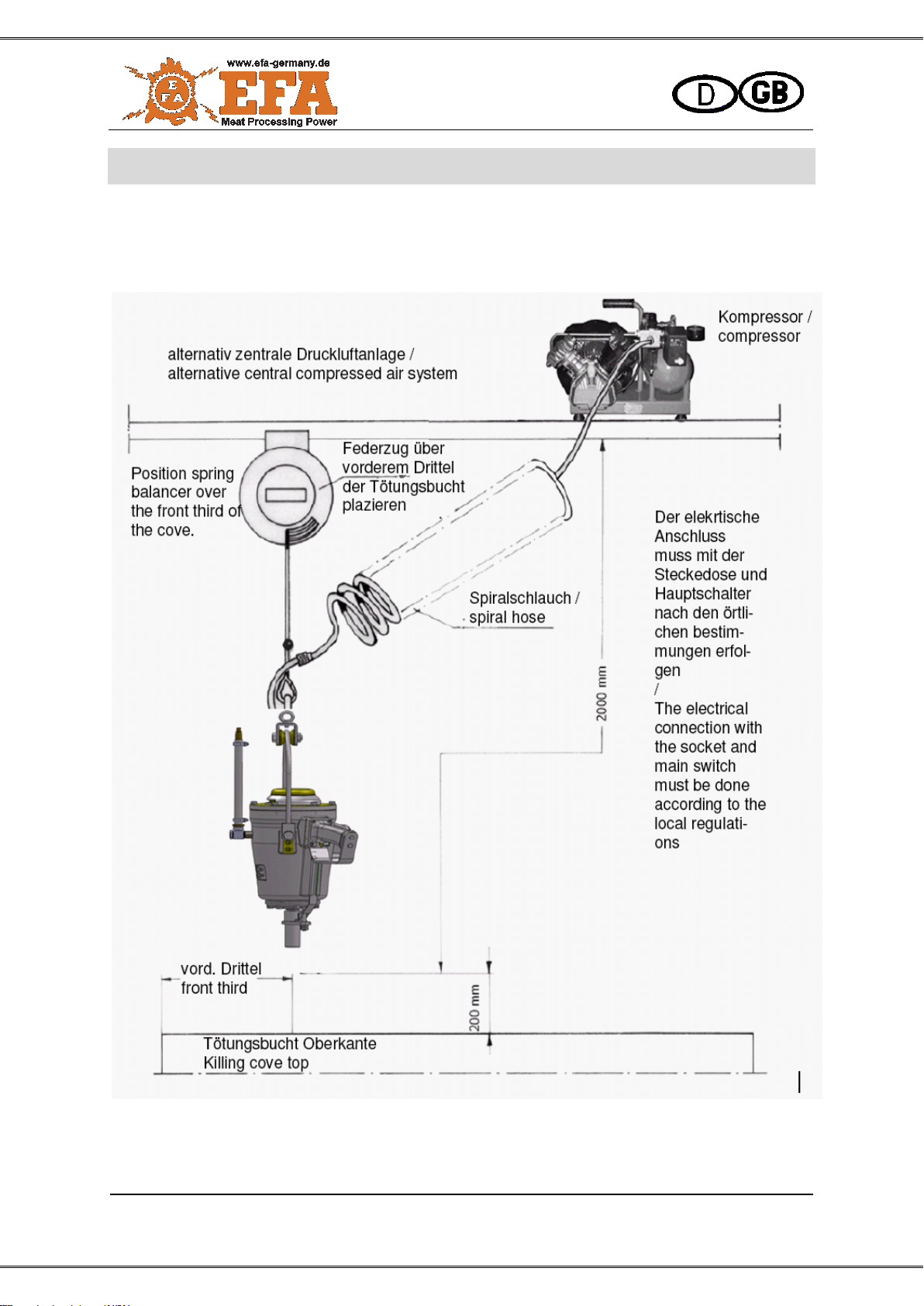

BInstallationsplan / Installation Plan..................................................................13

Schmid & Wezel

Seite / Page

3 of 13

Stand / Version

04 / 2017

1 Use, scope of supply,

accessories

Information that must be read!

This manual is intended for the machine opera-

tor. Keep it in a safe place!

The stunning device is operated with com-

pressed air.

The stunning device may only be used:

In technically sound condition, for the

intended use and in awareness of

safety and dangers.

With all the safety devices attached.

In compliance with the safety instruc-

tions.

After operating personnel have read

and understood these instructions, par-

ticularly Chapter 2 “Safety instructions”

and Chapter 3 “Connection and start-

up”. Only in this way can incorrect oper-

ation be avoided and hazard situations

correctly assessed.

Never aim the device at peo-

ple!

Never reach into the area of

the piston, otherwise you

could injure yourself.

Wear ear protectors during

work!

1.1 Symbols used in this man-

ual

Hazard symbol:

Non-compliance results in an imminent risk of

injury for the operating personnel and/or third

parties. In addition the machine may get dam-

aged.

This symbol is used for situa-

tions where extreme caution is

advised.

Information symbol:

Texts marked with this

symbol contain im-

portant information and

useful tips.

1.2 Intended use

1.2.1 Application area

The stunning device EFA VB 315 is

adapted for stunning calves, cattles,

cows and bulls with 121mm depth of im-

pact.

The machine is not equipped for a different type

of use. If the operator wishes to use the device

for other purposes, please consult Schmid &

Wezel GmbH.

For all other applications, the risk of injury

and/or increased wear must be noted. In the

event of non-compliance, the liability shall be

borne by the user alone.

1.2.2 Residual risks

Since the stunning device is intended for indus-

trial use on animal carcasses, there is a risk of

injuring yourself and, in the case of extreme

misuse, of fatally injuring others. Misuse may

result in immediate death or death from bleed-

ing. Therefore, please make sure that you han-

dle the machine correctly.

1.3 Delivery content

Stunning device EFA VB 315

Operating manual

Schmid & Wezel

Seite / Page

4 of 13

Stand / Version

04 / 2017

2 Safety instructions

2.1 General safety instructions

Be sure to observe the following safety precau-

tions when working with the stunning device.

It is assumed that all work involving op-

eration of the stunning device is always

completed by adequately skilled operat-

ing personnel.

Select your personal protective equip-

ment according to the regulations appli-

cable on the premises.

Installation, maintenance and repair

work may only be carried out by author-

ised and qualified personnel.

Stunning devices from Schmid & Wezel

comply with the relevant safety regula-

tions.

2.2 Conduct at the workplace

Keep your workplace tidy and in good

working condition. Untidiness can lead

to accidents.

Take into account environmental influ-

ences. Ensure good lighting (min. 500

lux).

Keep other persons away from your

workplace. Remain focused and act

with caution during your work. Do not

use the stunning device when you are

unconcentrated and/or tired.

Keep the stunning device in a safe

place. Store unused equipment in a dry

place.

Work clothing: Do not wear loose cloth-

ing or jewellery as these could become

tangled up in moving parts. Wear sturdy

shoes during your work.

Avoid abnormal body postures. Ensure

safe footing and keep your balance at

all times.

Service your tools with care.

Only use EFA original accessories. Use

of other tools or accessories may result

in injury to yourself.

Use of non-original accessories will

void the warranty.

Modifications and alterations to the ma-

chine are not permitted and exempt

S&W from any warranty and liability.

3 Connection and start-

up

Checking the impact energy of the stun-

ning device

Testing is only possible with the tester MEVB

100 - (008011633 and corresponding attach-

ment 003013881). The test cycle must be de-

termined according to the operating standards.

Place of work

The operator requires a working space of at

least 1.5 sq. m. No other place of work should

extend into this area, as the movements with

the stunning device could result in the risk of in-

jury.

The illumination at the place of work must be at

least 500 lux.

3.1 Initial Operation

Switch off the stunning device

before connecting to the com-

pressor!

Important information, e.g.

technical data sheets, draw-

ings and parts lists can be

found in Appendix A.

3.1.1 Spring balancer

Operate the stunning device always in combi-

nation with a weight relief (spring balancer).

Thereby, the stunning device should be posi-

tioned over the killing cove at the spring bal-

ancer. Use a sliding trolley to attach the spring

balancer to a higher element above the work-

place or to the ceiling. Information on fine ad-

justment of the spring balancer is provided in

Chapter 4.2 “Adjustment of the spring bal-

ancer”.

Suspend the stunning device so that it is as top-

heavy as possible. The vertical position can be

adjusted if necessary.

Schmid & Wezel

Seite / Page

5 of 13

Stand / Version

04 / 2017

Due to the weight of ap-

prox. 19 kg, there is a risk

of injury through the unit

slipping or falling down

when fixing or loosening

the weight relief system.

Pay attention that the de-

vice does not catch on

the snap hooks or the

hook of the stunning de-

vice. Work cautiously!

Set aside an unused stunning device in such a

way that unintentional contact is impossible.

3.1.2 Compressor

A compressor is intended for the operation of

the stunning device

3.1.3 Connecting the stunning device

Installation work may only be

carried out by authorized

specialist personnel.

Switch off the device before

connecting to the com-

pressed air supply!

Procedure (see installation of the device in

Appendix A “Installationsplan / Installation

plan”

To ensure that the required

operating pressure is availa-

ble at the workplace, a

maintenance unit must be

permanently installed.

Before connecting:

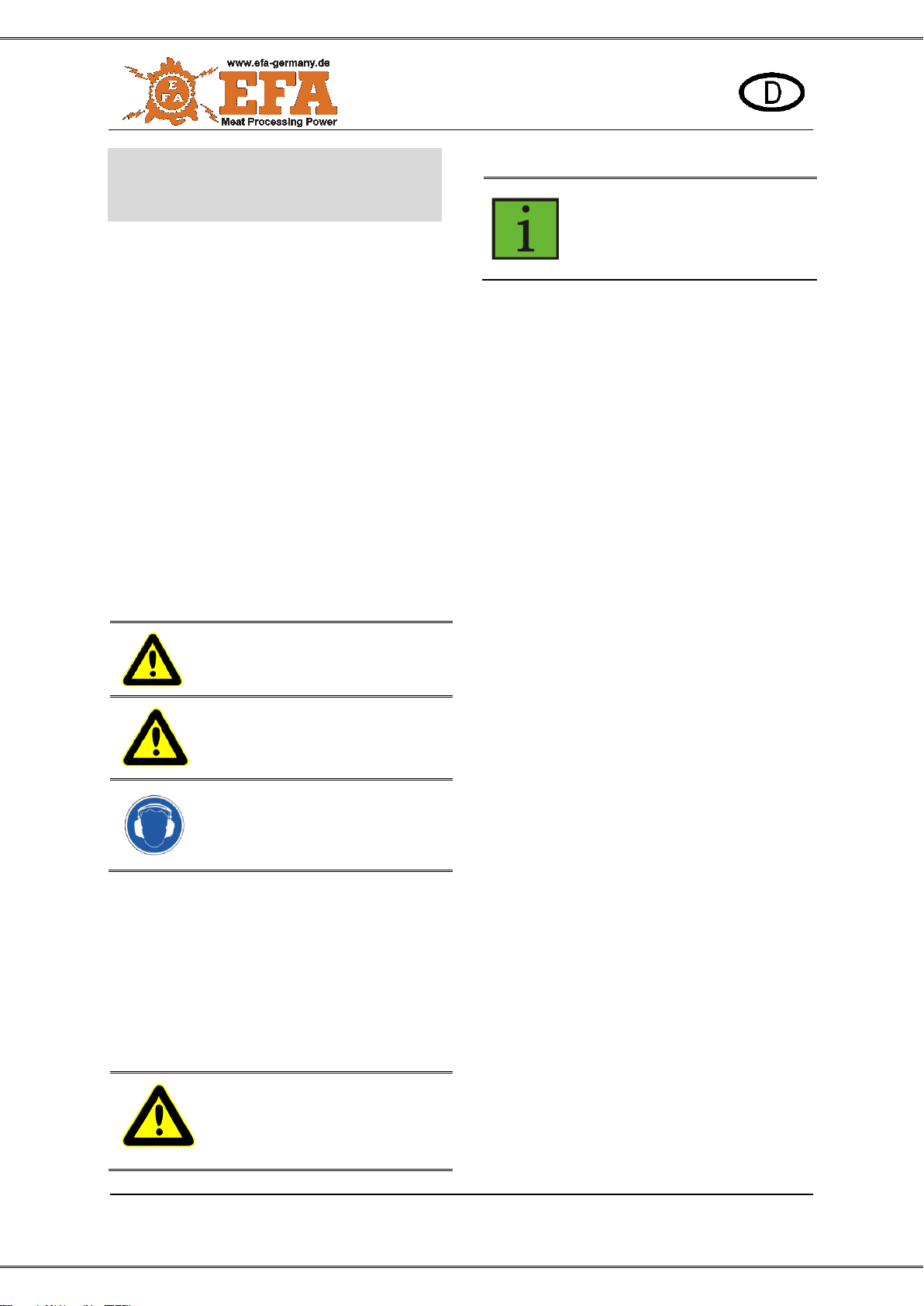

Before connecting the stunning device,

check that the trigger and the safety

bushing are smooth-running (see Fig.

1Safety bushing).

Check if the operating pressure is pre-

sent.

For coupling, pull back the knurled

shaft of the quick connect, lock in the

quick coupling to the hose plug and re-

lease teh knurled shaft.

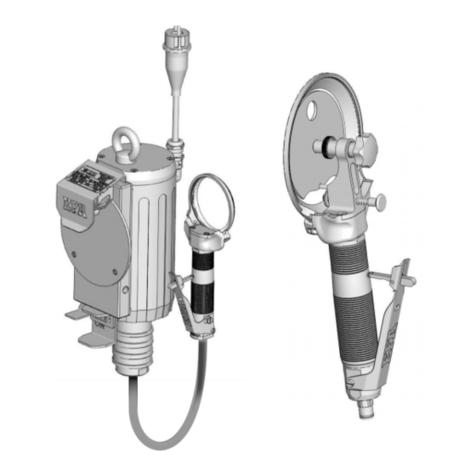

Fig. 1 Safety bushing and trigger

The device is not secured

against exceeding the max.

operating pressure of 14 bar.

3.1.4 Uncoupling the stunning device

When uncoupling, the com-

pressed air system must be

depressurized.

Pull back the knurled shaft of the quick

coupling and hold against the stop.

After venting the pressurised chambers

of the device, bring the knurled shaft to

its initial position and pull off spiral pres-

sure hose.

3.2 Working with the stunning

device

Do not use the stunning de-

vice until you have read this

manual and made the correct

connection!

Never reach into the area of

the piston if the stunning de-

vice is connected!

Never aim the stunning device

at people!

Schmid & Wezel

Seite / Page

6 of 13

Stand / Version

04 / 2017

Wear ear protectors during

work!

3.2.1 Operation

Preparation

Before use, check that the operating data of

compressed air supply and device match.

Before starting work, also check whether

the operating pressure of 14 bar is set

for cows, bulls and calves as suggested

by EFA.

the stunning device is functioning

the device is tight

the general safety instructions in Chap-

ter 2.1 “General safety instructions”

(Page 5) have been followed

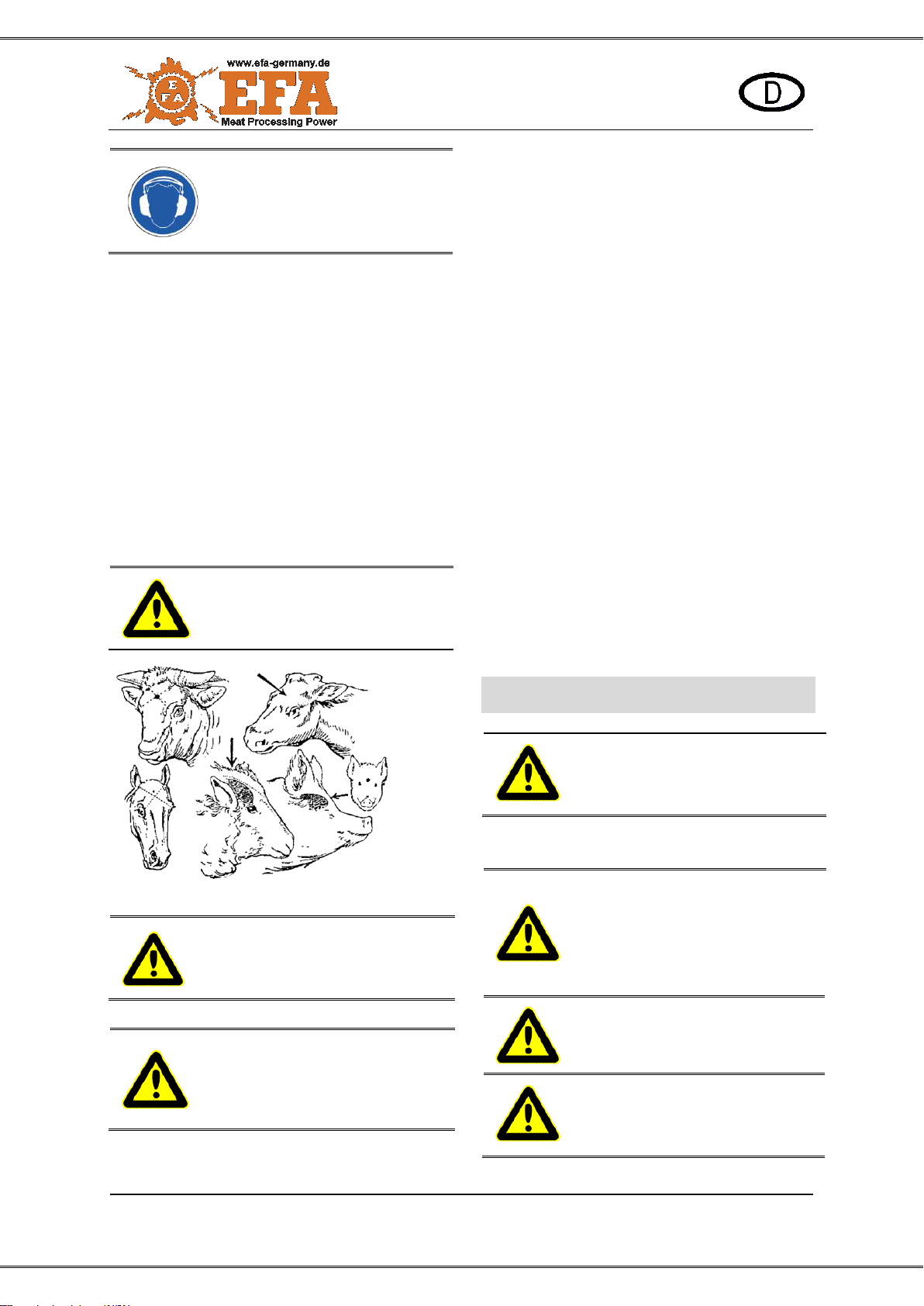

Fig. 2 Stun points

For stunning, place the device

on the animal's head as shown

in Fig. 2.

The device must be guided on both handles.

The operator's head must be at

the side of the stunning device

to prevent injury when it re-

coils!

Operate the trigger on the handles and

place the stunning device on the ani-

mal's head.

The safety bushing triggers the shot.

Lift the stunning device immediately

from the animal's head after the shot

has been fired.

Let go of the trigger on the handles at

the same time.

The stunning device is then ready for

operation again.

After letting go of the triggers, the piston moves

back to its initial position.

3.2.2 Operating safety

Stunning device

Act with particular caution when con-

nected.

Never operate the trigger when the

stunning device is not in operation.

Lift the stunning device immediately

from the animal's head after the shot

has been fired.

For safer handling (guidance), the stun-

ning device must be suspended from a

spring balancer.

4 Assembly

Disconnect the stunning device

from the air pressure net before

any assembly!

4.1 Replacing parts

Only use EFA original accesso-

ries. Use of other tools or ac-

cessories may result in injury

to yourself. Use of non-original

accessories will void the war-

ranty.

Only authorized specialist per-

sonnel may replace parts.

Replace parts only when the

device is disconnected from

compressed air.

Work only with a fully function-

ing device; otherwise, there is

a risk of accident.

Schmid & Wezel

Seite / Page

7 of 13

Stand / Version

04 / 2017

Caution: Non-observance of the stipulated

tightening torque can lead to breaking of the

thread inserts in the housing.

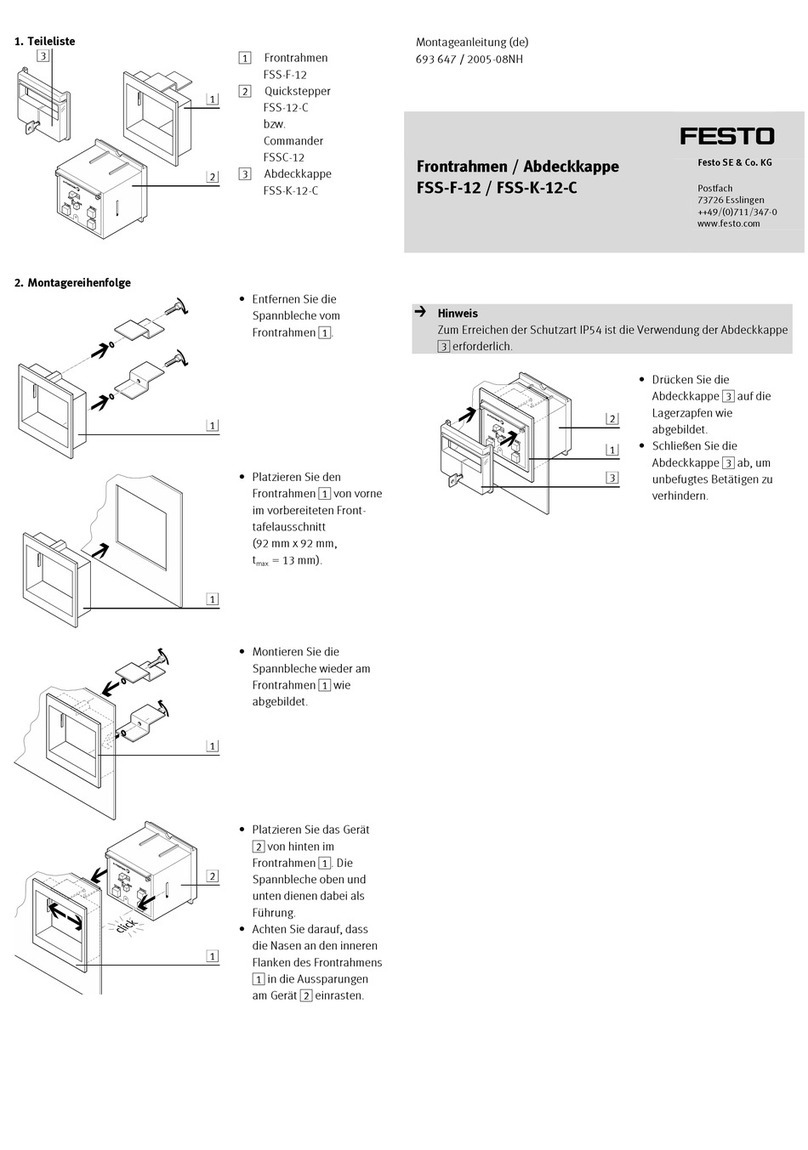

4.2 Adjustment of the spring

balancer

The spring balancer setting is fine-tuned by

means of the PLUS/MINUS screw on its hous-

ing (see Fig. 3).

Fig. 3 Spring balancer

Turn the screw in MINUS direction until

the device is in free-floating in balance

(with the tension spring) at working

height.

If pulling out is not possible, the spring balancer

is jammed, and a readjustment is necessary:

Turn the screw in PLUS direction until

the saw can be pulled out and start the

fine adjustment again (see above).

5 Maintenance

Malfunctions may occur during operation, but

these are generally relatively simple to remedy.

Table 1: “Malfunctions and their remedy” lists

these malfunctions with possible causes and

possible remedies.

To remedy malfunctions, be

sure to disconnect the unit

from the compressed air hose

Have all work carried out only

by qualified, trained specialist

personnel.

Schmid & Wezel

Seite / Page

8 of 13

Stand / Version

04 / 2017

6 Repair and trouble-

shooting

Malfunctions may occur during operation, but

these are generally relatively simple to remedy.

Table 1: “Malfunctions and their remedy” lists

these malfunctions with possible causes and

possible remedies.

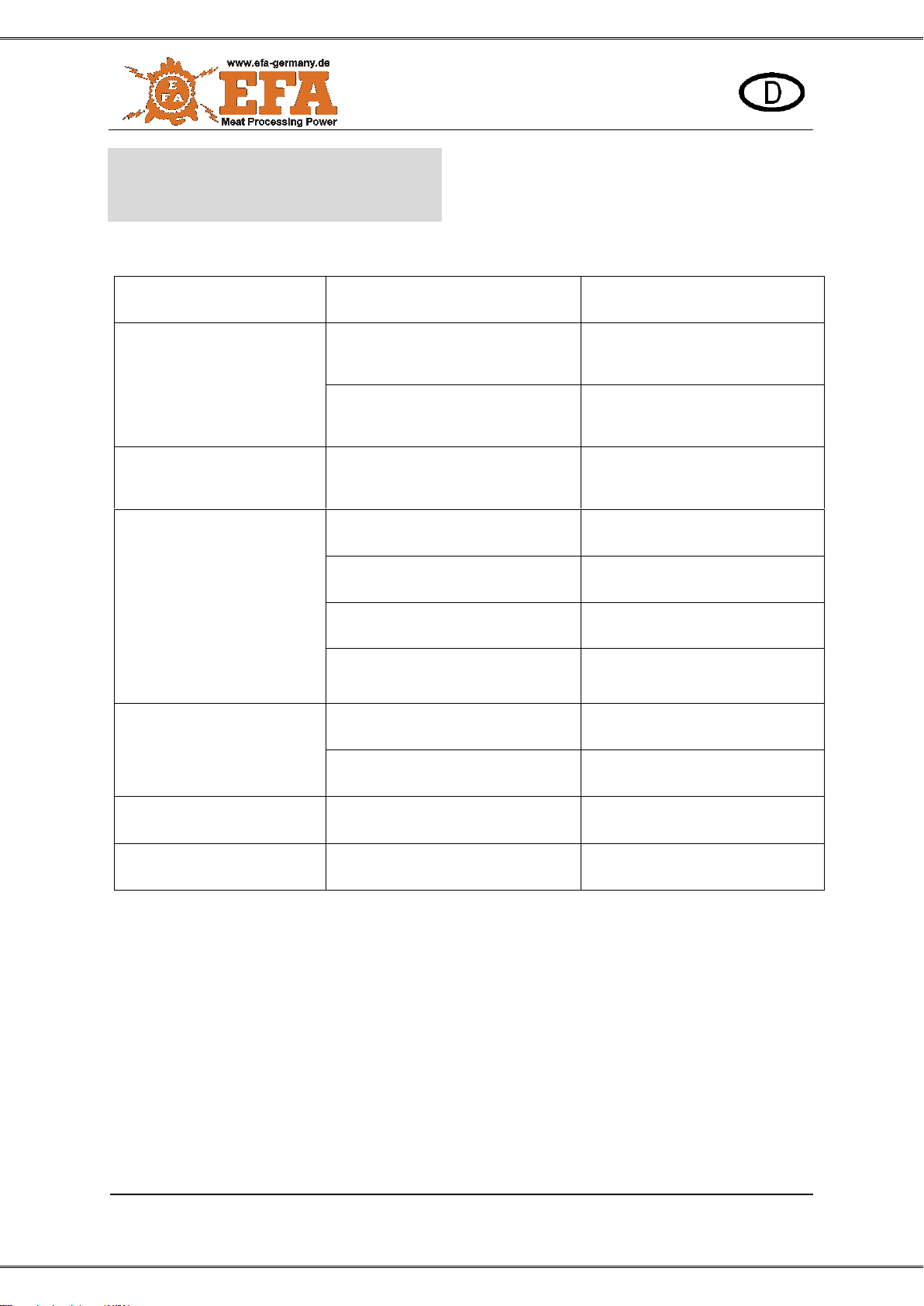

Malfunction

Possible cause

Remedy

Pressure escapes from the

cover or air diffuser cap

One of the O-rings is damaged or run-

ning surfaces of the cover are dam-

aged

Clean or replace O-rings

Running surfaces of the gate valve

gate are damaged.

Polish running surfaces or replace

cover

Pressure escapes from the re-

lease valve (light blowing is ac-

ceptable)

Release valve is defective

Replace trigger valve

Too low shot capacity

Air pressure is too low

Correct pressure setting

Trigger point is set wrong

Re-adjust trigger point

Release valve is defective

Replace trigger valve

Lack of lubrication

For lubrication settings, see Chapter

3.1 “Initial Operation”

Too low or no return stroke

One of the O-rings is damaged

Replace O-ring

Cushion damaged, worn

Replace cushion

Trigger plates are bent

Trigger is delayed

Replace trigger plates

The O-ring falls out of the gate

valve repeatedly

The gate valve is worn

Replace the gate valve

Table 1 Possible malfunctions

Schmid & Wezel

Seite / Page

9 of 13

Stand / Version

04 / 2017

Repairs may only be carried out by authorised

specialists. Our service department is at your

disposal for any repairs needed. If your equip-

ment needs to be repaired, please contact the

nearest authorized service center or our head

office.

Upon request, spare parts lists can be pro-

vided to any authorized service center.

Defective devices should never

be repaired on site because, in

most cases, the necessary tools

and levels of cleanliness are not

available. This is particularly the

case when the defective device

is in the direct vicinity of food

processing areas.

Disconnect the unit from the

mains power supply before

starting any repair work!

If the cause of the fault can not be localised

then the unit should always be returned to S&W

for repairs.

For other malfunctions, which can be eliminated

by the operator, the list of malfunctions may

provide information about the cause of the mal-

function and its remedy.

Schmid & Wezel

Seite / Page

10 of 13

Status / Version

04 / 2017

7 Cleaning and mainte-

nance

Disconnect the stunning de-

vice from the compressed air

network before cleaning.

Clean the stunning device

with hot water using a cloth

or sponge.

Note the safety and hygiene

requirements (DIN EN 1672).

According to Section 3 (2) of the Animal Protec-

tion - Slaughter Act, the facility for stunning the

animals must be maintained so that rapid and

effective stunning and slaughtering is possible.

7.1 Disinfection and cleaning during op-

eration

According to the EU requirements it is neces-

sary to have adequate documentation about

cleaning and maintenance by means of clean-

ing plans in the frame of duty to care and self

check by the person in duty for the device.

7.2 Daily cleaning after completion of

the slaughter

Trouble-free, continuous operation can be en-

sured only if the stunning device is permanently

kept in a clean, hygienic condition. The ma-

chine should normally be disinfected before

each cleaning. At least daily cleaning and

maintenance is necessary on individual slaugh-

ter days, as well as added cleaning as required

in the case of identifiable contamination.

Note the safety and hygiene requirements in

DIN EN 1672

Daily cleaning of gate valves, safety bushing

and rocker is recommended.

Do not use any aggressive

solvents! Do not use a steam

blaster or high-pressure

cleaner! Do not immerse the

device in water!

7.2.1 Cleaning the stunning device

Take the stunning device to your work-

shop.

Remove coarse dirt with a brush and

warm water (about 45 ... 55 °C). If nec-

essary, soak stubborn or encrusted dirt.

Put cleaning agent into warm water.

Distribute the foam onto the cleaning

surface and allow the cleaning agent to

work in for 15...20 minutes.

Wash wash off the loosened dirt with

warm water.

Wash and dry the complete stunning

device with clean water.

Recommended cleaning agents

Diversey Lever Tego 2000: Surface-ac-

tive disinfectant

Diversey Lever GmbH Mallaufstr. 50-

56, 68219 Mannheim/Germany

Alternatively: P3-topax 91: Surface-ac-

tive disinfectant Henkel-Ecolab

Deutschland GmbH Postfach 13 04 06,

40554 Düsseldorf/Germany

A cleaning plan and further details can be ob-

tained from the above company addresses.

The above-mentioned cleaning agents are only

recommendations. When using other cleaning

agents, the customer must check material com-

patibility and hygiene regulations.

7.3 Maintenance

Only authorized specialist

personnel may carry out

maintenance.

Disconnect the stunning de-

vice from the compressed air

network before any mainte-

nance

7.3.1 Before and during slaughtering:

For trouble-free operation, a mainte-

nance unit R 3/8" with filter, regulator

and lubricator must be used for the

compressed air supply.

Use only acid-free, branded oil (order

no. 001 365 612).

Oiler setting:

1 drop of oil every approx. 10-15 shots.

Schmid & Wezel

Seite / Page

11 of 13

Status / Version

04 / 2017

Check regularly whether there is

enough oil in the reservoir.

Drain regularly condensate in the water

seperator.

7.4 After slaughtering

After completion of slaughter, uncouple

the device (see Chapter 3.1.4 “Uncou-

pling the stunning device” (Page 6)).

Oil the moving parts such as the safety

bush, trigger and rocker and check for

smooth running. Clean if necessary.

After checking and cleaning the stun-

ning device, tighten the screws daily or

every 1000 shots: screws of the

lid;

screws of the handles;

screws of the bar;

screws of the base plate;

7.5 Wear

Check the cushion after 15000 shots

and replace if damaged!

If the axially sealing O-ring repeatedly

falls out after a few shots, the gate

valve should be replaced.

Replace a guide tube that shows traces

of wear on the flat surface.

7.6 Maintenance unit

Inspect at regular intervals, but at least

2 x per month, drain the condensate

and top up the special oil.

Special oil for maintenance system:

EFA special oil 0.5 l part no. 001 365

611

EFA special oil 5.0 l part no. 001 365

612

Repairs

Only authorized specialist

personnel may carry out re-

pairs.

Before starting repairs, al-

ways disconnect the stunning

device from the compressed

air supply.

Use only original spare parts

8 Transport and storage

Store the machine in a dry, ventilated room.

The machine must be cleaned as described in

7.2.1 and transported in dry condition.

Ensure that the device is not damaged during

transport.

9 Return of waste elec-

trical equipment

Return your waste electrical equipment to our

head office.

Schmid & Wezel

Seite / Page

12 of 13

Stand / Version

04 / 2017

A Anhang / Appendix

A1 Technische Daten / Technical Data

EFA VB 315

Betriebsdruck / Operating pressure

14 bar

Luftverbrauch / Air consumption

20 Liter pro Schuss / 20 liters per shot

Druckluftanschluß / Compressed air con-

nection

R 3/8"

Schlagbolzen / Firing pin

Ø14.5 mm

Einschlagtiefe / Impact depth

121 mm

Abmessung L / W / H / Dimension

458 x 291 x 447 mm

Gewicht / Weight

19 kg

Table 2 Technische Daten / Table 1 Technical Data

A2 Maßblatt / Dimension sheet

Schmid & Wezel

Seite / Page

13 of 13

Stand / Version

04 / 2017

B Installationsplan / Installation Plan

Fig. 4 Installationsplan / installation plan

Table of contents

Other EFA Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

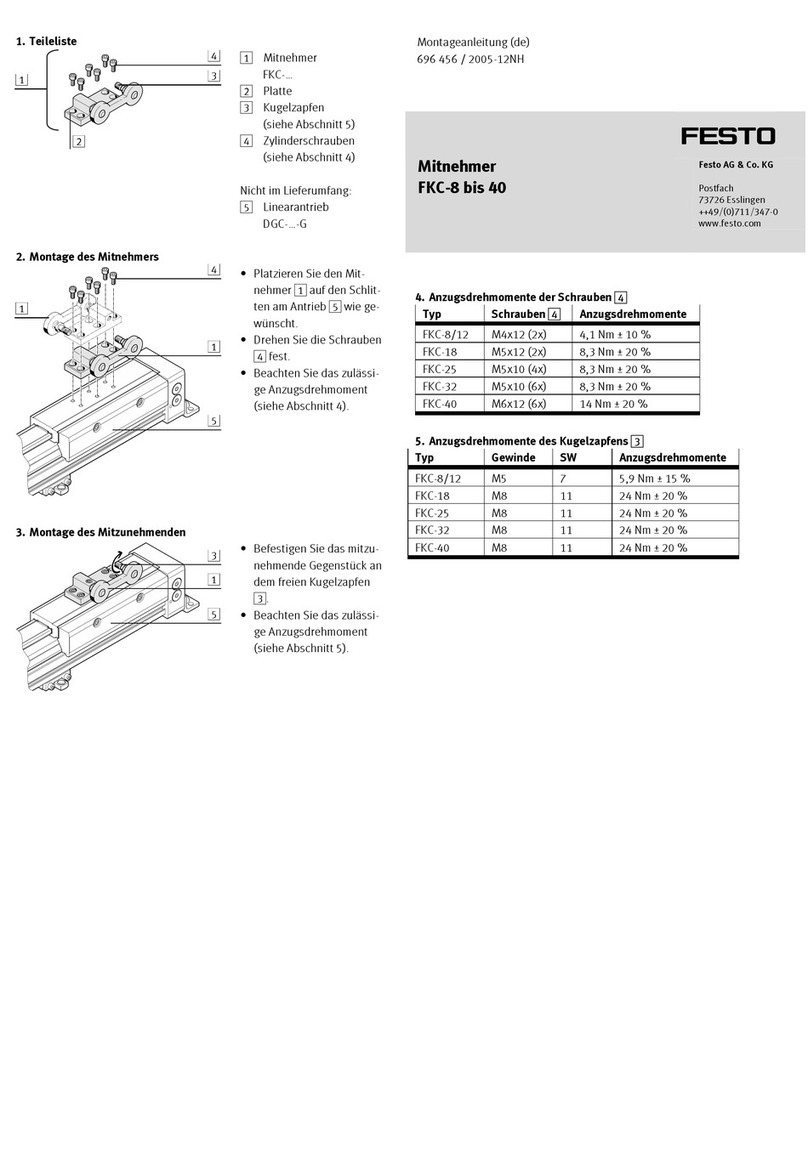

Festo

Festo FKC Series Assembly instructions

CFE

CFE LFP4820S3 Product user manual

Emerson

Emerson Daniel 3410 Series Maintenance and troubleshooting manual

Sonny's

Sonny's SF50 owner's manual

EVAPCO

EVAPCO Mr. GoodTower EAW-FD Series Additional Installation, Operation and Maintenance Instructions

Festo

Festo FLSM Series operating instructions