STIF VIGIBELT TOUCH User manual

INSTRUCTION MANUAL GB–1/5

www.stifnet.com - DOC NO. BE0455061-A

USE

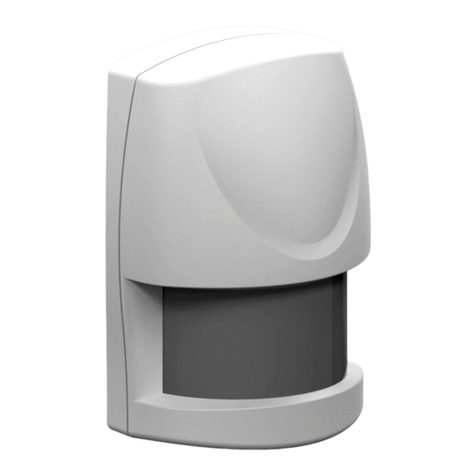

- The VIGIBELT®TOUCH is a lateral displacement detector that prevents the offset of elevator straps or conveyor

belts, and or incidentally the elevator pulley offset. It reacts to the pressure of the strap or strip, which comes into

contact with the front face of the detector. The detectors are normally installed face to face in pairs preferably on the

rising leg near the pulleys for the lifts, and on the stretched strand side near the drums for the conveyors.

The detectors can be directly connected to a programmable logic controller, or for total safety to an independent

central unit "monitoring M-JET". The electrical circuit can thus control an alarm or a machine stop.

For elevators taller than 20 meters, we advise to equip the head with a second kit VIGIBELT®always on the rising

sheath side.

The sensors are triggered when the strap exerts a load of about 5 daN.

description

- The VIGIBELT®TOUCH kit is composed of two detectors, four elastomeric wedges of 3mm (NBR), and the fixing

screws (M6).

Composition:

PRECAUTIONS

The VIGIBELT®TOUCH kit must be installed, connected and put into service only by competent personnel. The

personnel need to have electrical accreditation, a knowledge of the regulation and the disposition concerning

the installation of those device, especially for Ex II3D version integrated in ATEX zones.

- Carry out beforehand an electrical connection study to install the VIGIBELT® TOUCH (standardized electrical

diagram, power supply and electrical protection, plc control, ATEX zones).

- Check that the temperature range of use of the VIGIBELT®TOUCH (variable according to version) corresponding

at application.

- Check during the first commissioning of the bucket elevator in the handling phase, that there is no sealing defect

(dust leak) between the sheath of the elevator and the VIGIBELT®TOUCH.

- Shut down the bucket elevator or belt conveyor to a standstill (off) before any installation or intervention on the

VIGIBELT®TOUCH (intervention information to be indicated on the machine).

Z.A. de la lande - 49170 Saint-Georges-sur-Loire - France

Head office, purchasing and factory: tel.: +33 2 41 72 16 80 - Fax +33 2 41 72 16 85

France Export Commercial Service: tel.: +33 2 41 72 16 82 - Fax +33 2 41 39 32 12

email: sales@stifnet.com - Website: www.stifnet.com

SAS with a capital of € 800,000 - R.C.S. Angers B 328 876 503 - 84B12 APE 2511Z - VAT number FR 35 328 876 503

2x VIGIBELT®Touch

8x Fastening Bolts(M6)

4x elastomeric wedges (ep.3)

INSTRUCTION MANUAL GB–2/5

www.stifnet.com - DOC NO. BE0455061-A

installation

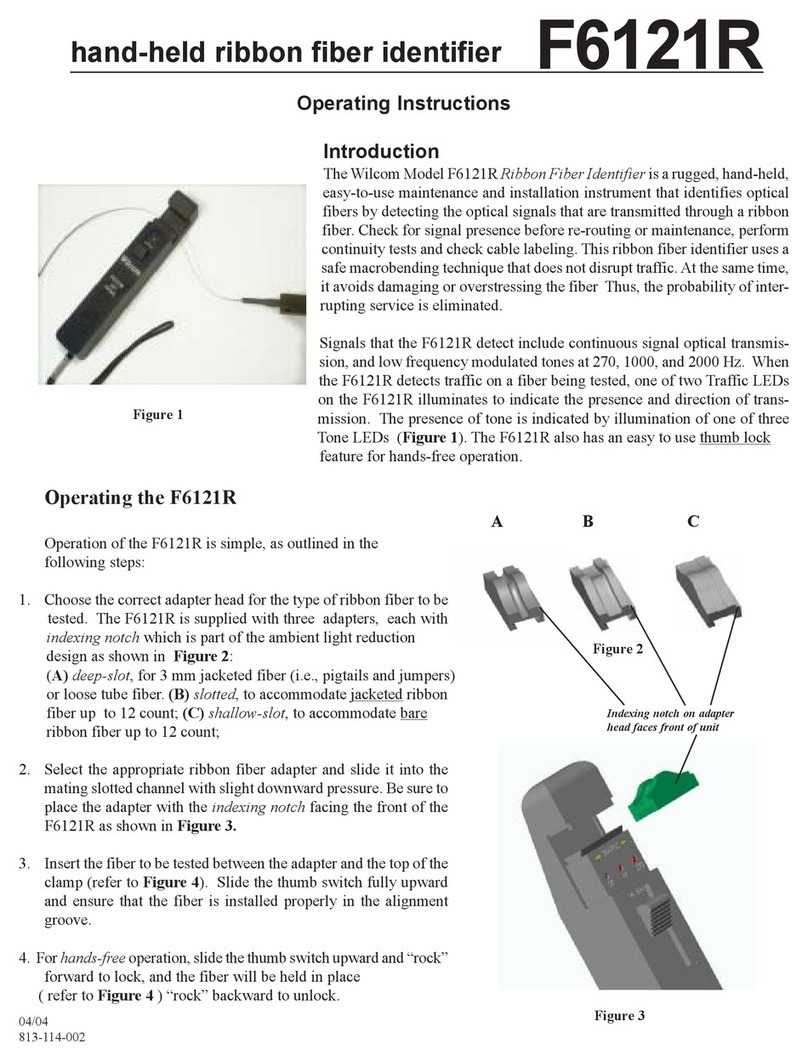

1) Make two symmetrical round openings (opening Ø56mm + 4 holes Ø7 on Ø72) on each side on the riser of the

elevator: figure-A

Figure A

On a bucket lift, position the VIGIBELT®TOUCH

detectors on the rising leg side close to the axis of the

pulleys and the strap.

On a belt conveyor, position the VIGIBELT®

TOUCH detectors side stretched strand close to the

axis of the drums and the strip.

Make an opening of

Ø56 in the axis of the

strap

strap

INSTRUCTION MANUAL GB–3/5

www.stifnet.com - DOC NO. BE0455061-A

2) Assemble the M6 pan screws with the low nuts on the sheath (clamping torque 6 N.m): figure-B.

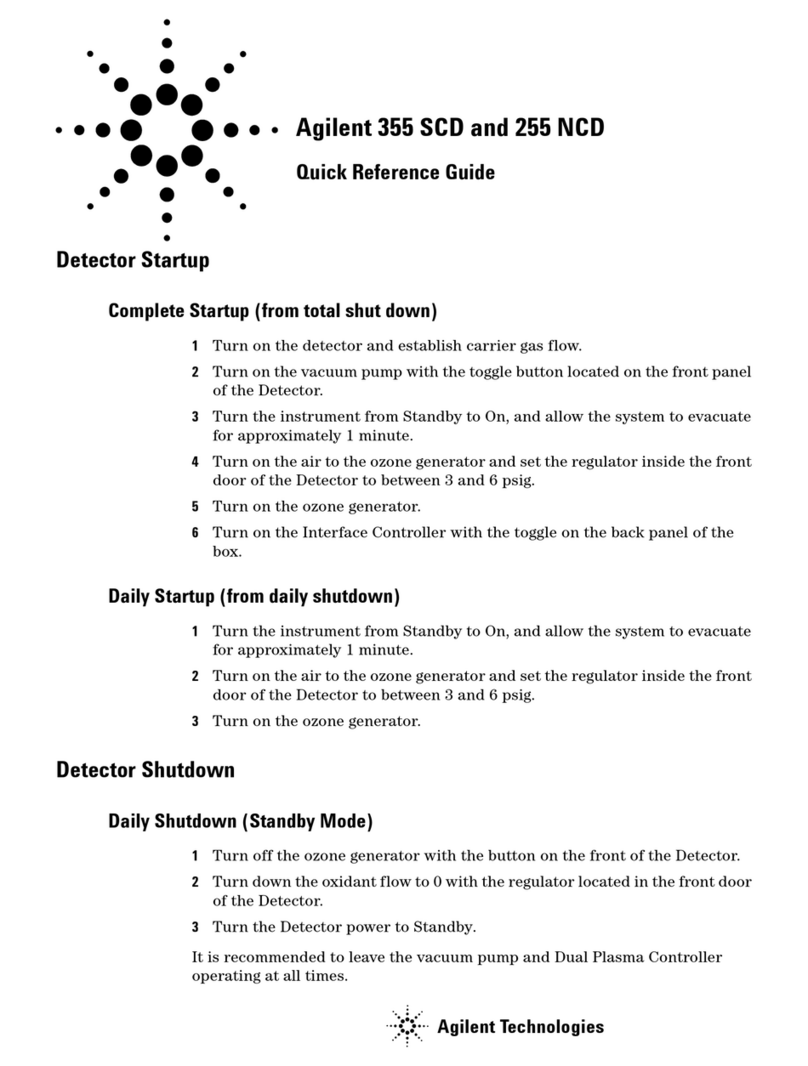

3) Adjust the trigger distance of the VIGIBELT®TOUCH detectors. This distance corresponds to the dimension

between the inner wall of the elevator and the contact face of the detector.

For this, you have the possibility to make three figure-C detection settings:

No. 1 - Detector without additional wedge, thickness elevator (example 3mm), i.e. a distance of 20mm

No. 2 - Detector with an additional wedge, thickness elevator (example 3mm), i.e. a distance of 17mm

No. 3 - Detector with two additional wedges, thickness elevator (example 3mm), i.e. a distance of 14mm

Figure B

Inner face of the sheath

Assembly of pa-head screws + low nuts

Figure C

20mm

17mm

14mm

Setting N°1

Distance of 20mm,

No additional hold

Setting N°3

Distance of 14mm,

With two additional wedges

Setting N°2

Distance of 17mm,

With an additional wedge

INSTRUCTION MANUAL GB–4/5

www.stifnet.com - DOC NO. BE0455061-A

4) Position the VIGIBELT® TOUCH detectors on the openings and screw the M6 brake nuts with the washers

(clamping torque 4 N.m) according to Figure-D.

5) Connect the VIGIBELT®TOUCH according to the electrical scheme E or F:

NC detector = positive safety, permanent control of the proper functioning of the sensor

Signal loss indicates that there is a strap offset problem

Electrical wire cut off

3-wire/NC connection scheme E

colours

BN = Brown

BU = Blue

BK = Black

PVC cable 3x0.11mm² 2m for ATEX zone and non-

ATEX

3-wire connection scheme F

Colours

1 = Black

2 = Grey

4 = Blue

PVC cable 2m for non ATEX 3x0.25mm²

figure D

Attach the VIGIBELT®Touch with

washers and lock nuts

For low voltage sensor, ATEX or not

- 3-wire cable connection

- L=2m cable

- Voltage 12-24V DC

- Voltage limits, including ripple, 10-36V DC

- Switching power ≤100 mA

- temperature Operating: -25... 70°C (Non-ATEX)

-20... 60°C (ATEX)

- Protection - IP67

Caution: Any connection must be made outside the

ATEX zone

For mechanical sensor, out of ATEX zone

- 3-wire cable connection

- L=2m cable

- Tension 12… 250V AC/DC

- NC : Black wire (1) / Grey wire (2)

- NO : Black wire (1) / Blue wire (4)

- Operating temperature: -20... 105°C

- Protection - IP67

Caution: Any connection must be made outside the

ATEX zone

INSTRUCTION MANUAL GB–5/5

www.stifnet.com - DOC NO. BE0455061-A

6) After completing the mechanical and electrical installation of the VIGIBELT®TOUCH, you must proceed to the

verification of each detector to ensure that they are all operational. For this, you need to trigger each VIGIBELT®

TOUCH by pressing their contact face. This simulation makes it possible to validate that the fault information is

communicated to the control system (M-JET monitoring, control plc, ...).

CONTROL & PERIODIC MAINTENANCE

1) To ensure the functional integrity of VIGIBELT®TOUCH, you must schedule periodic inspections. The frequency

of inspections must be sufficient to avoid dangerous situations (situations that affect the intrinsic functioning of the

VIGIBELT®TOUCH).

2) During these inspections, check that the VIGIBELT®TOUCH are not affected by the following defects: dust layer

>2mm, dust leak between the sheath of the elevator and the VIGIBELT®TOUCH, non-operational power supply

voltage, degraded electrical wiring, shocks on the envelope of the VIGIBELT®TOUCH, triggering of the detector with

a charge > 5 daN, etc...

3) In the case of one or more defects found, you must proceed with the restoration in order to correct the defect(s)

before you can use the bucket lift or belt conveyor again.

4) Only personnel trained and authorized in maintenance procedures for these equipment are able to carry out

inspections for VIGIBELT®TOUCH.

DISPOSAL

When dismantling the VIGIBELT®TOUCH, the user must ensure the proper disposal of this device and hand over

to the specialized harvesting centers the components according to their nature (stainless steel, electrical

equipment, seal, etc.).

In the event that the VIGIBELT®TOUCH kit is used, controlled, under conditions contrary to the precautions

described in this instruction manual, STIF declines all responsibility for damage caused to man, animal,

environment, material property.

Table of contents

Popular Security Sensor manuals by other brands

jablotron

jablotron JA-158P quick start guide

Bosch

Bosch DS308EA installation guide

Metasys

Metasys 5451 manual

Hitachi

Hitachi SOR-NEC Installation and operation manual

Niko

Niko Swiss Garde 360 DALI Secondary A-Comfort high ceiling... installation instructions

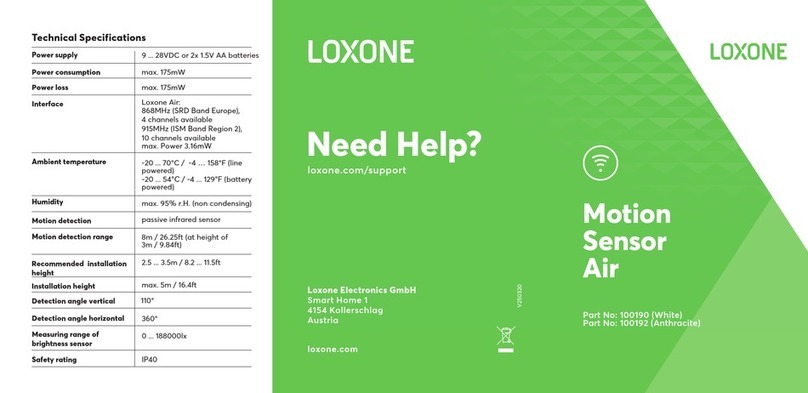

LOXONE

LOXONE Motion Sensor Air Series quick start guide