FS 40, FS 40 C, FS 50, FS 50 C

English

6

gets smaller), impaired hearing,

dizziness, or impaired concentration –

these symptoms may possibly be the

result of too-high exhaust gas

concentration – Risk of accidents!

Operate your power tool so that it

produces a minimum of noise and

emissions – do not run the engine

unnecessarily, accelerate the engine

only when working.

To reduce the risk of fire, do not smoke

while operating or standing near your

power tool. Note that combustible fuel

vapor may escape from the fuel system.

Dusts, mist and fumes emissions during

the work may be hazardous to your

health. Wear respiratory protection in

case of heavy dust or smoke emission.

If your power tool is subjected to

unusually high loads for which it was not

designed (e.g. heavy impact or a fall),

always check that it is in good condition

before continuing work – see also

"Before Starting". Check in particular

that the fuel system has no leaks and the

safety equipment is fully operative.

Never use a power tool that is no longer

safe to operate. In case of doubt, contact

a dealer.

Do not operate your power tool with the

choke lever in the warm start position <

– the engine speed cannot be controlled

in this position.

Be particularly careful when working on

difficult, densely grown terrain.

When mowing in tall scrub, under

shrubbery and hedges: Hold the cutting

tool at a working height of at least 15 cm

– this avoids risks to animals.

Always shut off the engine before

leaving the unit unattended.

Check the cutting tool regularly at

frequent intervals, and immediately if

you notice a change in its behavior:

–Stop the engine, hold the machine

securely, allow the cutting

attachment to come to a stop

–Check condition and tightness of

connections, look out for fine cracks

–Immediately replace defective

cutting tools, also in case of minor

hairline cracks

Clean grass and plant residue off the

cutting attachment mounting at regular

intervals – remove any accumulated

material from the cutting attachment and

deflector.

To reduce the risk of injury, shut off the

engine before replacing the cutting

attachment.

Do not continue using or attempt to

repair damaged or cracked cutting

attachments by means of welding,

straightening or modifying the shape

(unbalanced).

Particles or pieces may come off and hit

the operator or a bystander at a high

speed – risk of most severe injuries!

If a rotating cutting attachment touches a

rock or another hard object, sparks may

be generated which may possibly ignite

combustible materials. Also dried-out

plants and brushwood are combustible,

above all in hot and dry weather. If there

is a risk of fire, do not use cutting

attachments in the vicinity of

combustible materials, dried-out plants

or brushwood. It is mandatory that you

ask the responsible forestry office about

current fire hazards.

Using mowing heads

Only use the deflector with a properly

mounted blade that ensures the mowing

line is restricted to the permissible

length.

Always switch off the engine to adjust

the mowing line for manually adjustable

mowing heads – risk of injury!

Misuse with mowing lines that are too

long reduces the working speed of the

engine. The constant slipping of the

clutch causes overheating and damage

to important components (e.g. clutch,

plastic housing parts) – e.g. due to the

cutting attachment rotating during idling

– risk of injury!

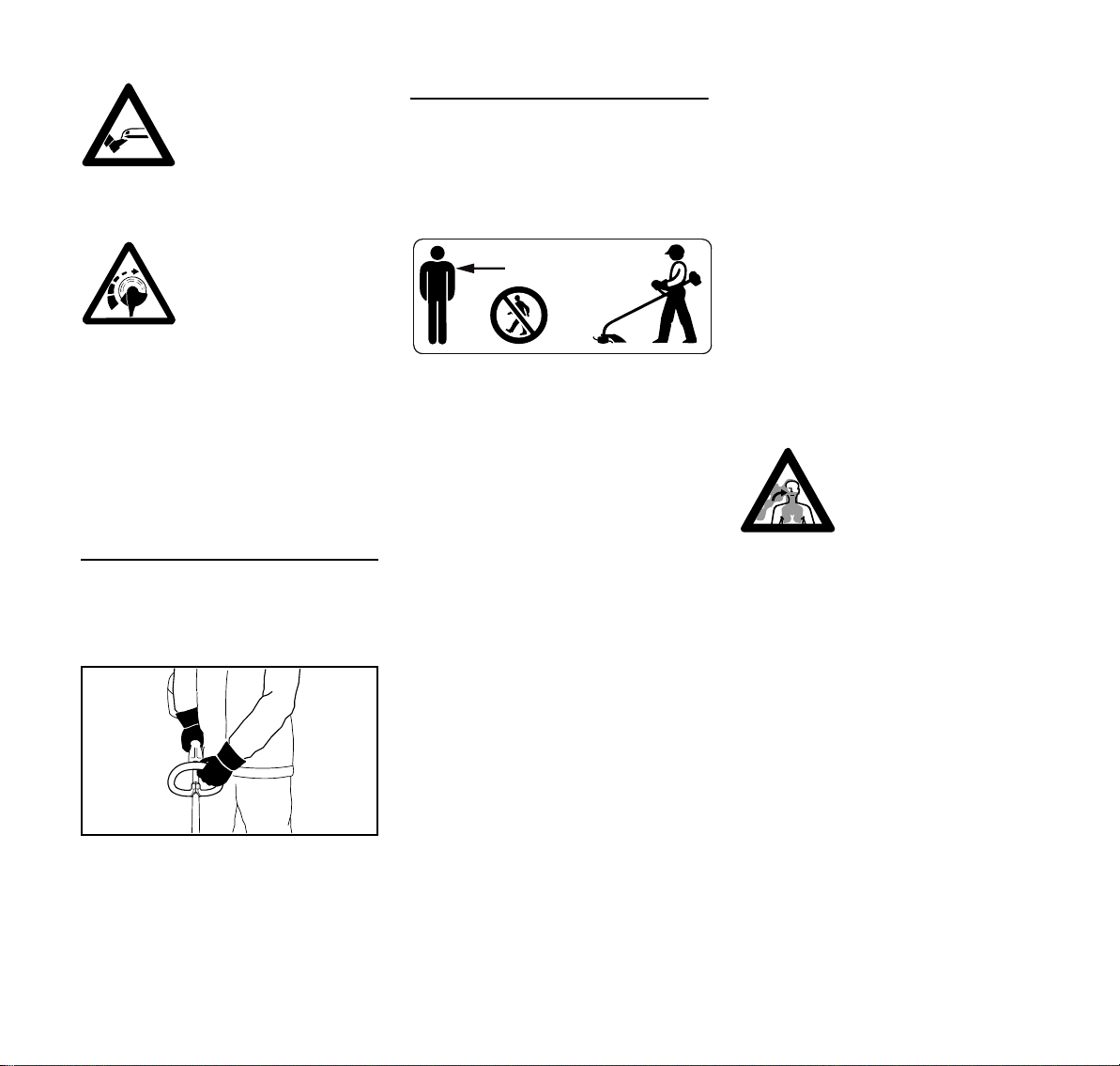

Never work with-

out protection

suitable for the

respective

machine and cut-

ting tool – risk of

injury from ejected

objects!

Check the work site –

rocks, metal objects etc.

could get caught up and

ejected – potentially

beyond a distance of

15 m – risk of injury! Such

objects can also damage

the cutting attachment

and other property (e.g.

parked vehicles,

windows).