Contents

1 Guide to Using this Manual.........................2

2 Safety Precautions and Working Techni‐

ques............................................................ 2

3 Using the Unit............................................. 7

4 Approved Combinations of Cutting Attach‐

ment, Deflector, Handle and Harness.........8

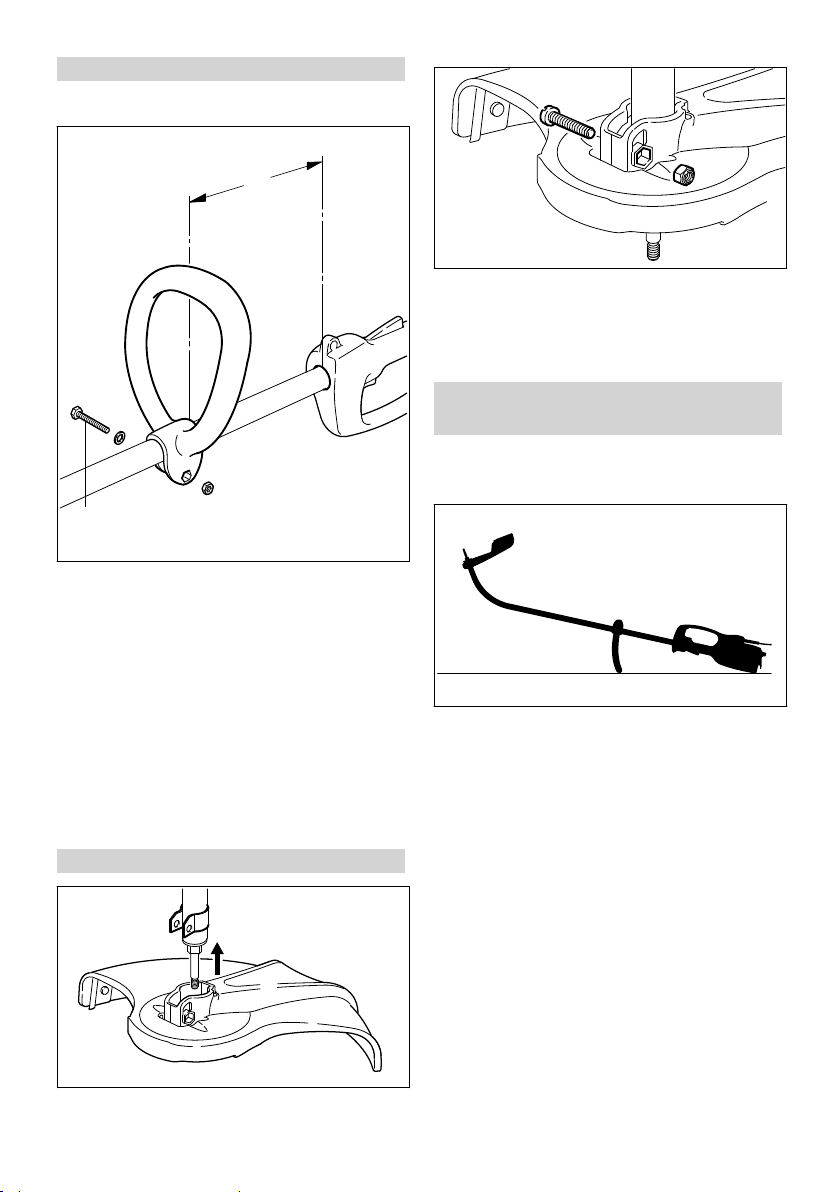

5 Mounting the Drive Tube.............................8

6 Mounting the Loop Handle..........................9

7 Mounting the Deflector................................9

8 Mounting the Cutting Attachment................9

9 Mounting Depth Wheel............................. 10

10 Converting Unit to Power Edger............... 11

11 Connecting to Power Supply.....................11

12 Fitting the Harness....................................12

13 Switching On.............................................12

14 Switching Off.............................................12

15 Overload Cutout........................................12

16 Storing the Machine.................................. 13

17 Maintaining the Mowing Head...................13

18 Maintenance and Care..............................14

19 Minimize Wear and Avoid Damage...........14

20 Main Parts.................................................15

21 Specifications............................................15

22 Maintenance and Repairs......................... 16

23 Disposal.................................................... 16

24 EC Declaration of Conformity................... 16

25 General Power Tool Safety Warnings.......17

1 Guide to Using this Manual

1.1 Pictograms

All the pictograms attached to the machine are

shown and explained in this manual.

1.2 Symbols in text

WARNING

Warning where there is a risk of an accident or

personal injury or serious damage to property.

NOTICE

Caution where there is a risk of damaging the

machine or its individual components.

1.3 Engineering improvements

STIHL's philosophy is to continually improve all

of its products. For this reason we may modify

the design, engineering and appearance of our

products periodically.

Therefore, some changes, modifications and

improvements may not be covered in this man‐

ual.

2 Safety Precautions and

Working Techniques

Special safety precautions must be

observed when working with this

machine because of the very high

speed of its cutting attachment and

the fact that it is powered by electric‐

ity.

Before commissioning, it is important

to read and understand the User

Manual and to keep it in a safe place

for future reference. Failure to

observe the User Manual may lead to

serious or even fatal injury.

Observe the national safety regulations issued,

e.g. by the employers' liability insurance associa‐

tion, social security institutions, occupational

safety and health authorities and other organiza‐

tions.

If you have not used this machine before: Have

your dealer or other experienced user show you

how to handle your machine safely or attend a

specialist course.

Minors should never be allowed to use the

machine – except for young trainees over the

age of 16 when working under supervision.

Children, animals and onlookers must not be

allowed near the machine.

When the machine is not in use, shut it off so

that it does not endanger others. Secure it

against unauthorized use and disconnect the

mains plug.

The user is responsible for accidents or risks

involving third parties or their property.

Do not pass on or lend the machine to persons

who are not familiar with this model and its han‐

dling – always include the User Manual.

Persons who are not able to operate the power

tool safely due to limited physical, sensory or

mental ability may work with it only under super‐

vision or after being instructed appropriately by a

responsible person.

The use of noise-emitting power tools may be

restricted to certain times by national or local

regulations.

Before each use, check that the unit is in proper

condition. Pay special attention to the connecting

cable, mains plug and safety devices.

English

2 0458-282-0121-C

© ANDREAS STIHL AG & Co. KG 2023

0458-282-0121-C. VA1.C23.

Printed on chlorine-free paper

Paper is recyclable.

Original Instruction Manual

0000000880_023_GB