STIL CHR 150 Operating instructions

-~

ARTISAN

®

~I

TECHNOLOGY

GROUP

Your definitive source

for

quality

pre-owned

equipment.

Artisan Technology

Group

Full-service,

independent

repair

center

with

experienced

engineers

and

technicians

on staff.

We

buy

your

excess,

underutilized,

and

idle

equipment

along

with

credit

for

buybacks

and

trade-ins

.

Custom

engineering

so

your

equipment

works

exactly as

you

specify.

•

Critical

and

expedited

services

•

Leasing

/

Rentals/

Demos

• In

stock/

Ready-to-ship

•

!TAR-certified

secure

asset

solutions

Expert

team

ITrust

guarantee

I

100%

satisfaction

All

tr

ademarks,

br

a

nd

names, a

nd

br

a

nd

s a

pp

earing here

in

are

th

e property of

th

e

ir

r

es

pecti

ve

ow

ner

s.

Visit our website - Click HERE

STIL S.A.

595, rue Pierre Berthier – Domaine de Saint Hilaire – 13855 Aix-en-Provence cedex 3, France

Tel: +33 (0)4 42 39 66 51 – Fax : +33 (0)4 42 24 38 05

Email : stil.sa@wanadoo.fr – Web site : www.stilsa.com

CHR 150

Operating and maintenance manual

STIL - CHR 150 – Operating and maintenance manual Doc ref. CHR2-001-P2 Re :D

Page 2 of 49

CONTENTS

1

PRESENTATION OF THE RANGE OF CHR SENSORS...................................................................... 4

2

PRESENTATION OF THE CHR 150......................................................................................................... 4

2.1

C

ONTROLLER

........................................................................................................................................... 4

2.2

O

PTICAL PEN AND OPTICAL FIBER

............................................................................................................. 5

3

SAFETY......................................................................................................................................................... 6

3.1

T

HERMAL

H

AZARDS

................................................................................................................................ 6

3.2

E

LECTRICAL

H

AZARDS

............................................................................................................................. 6

3.3

O

PTICAL

H

AZARDS

................................................................................................................................... 6

3.4

G

ENERAL

R

ECOMMENDATIONS

................................................................................................................ 6

3.5

C

OMPLIANCE TO THE

EC

REGULATION

89/336/EEC

« E

LECTROMAGNETIC

C

OMPATIBILITY

»................... 6

4

INSTALLATION AND SWITCHING ON................................................................................................. 7

5

COMMUNICATING WITH THE CHR 150.............................................................................................. 8

6

GETTING STARTED (TUTORIAL 1)....................................................................................................... 9

6.1

U

SING THE CONTROL PANEL

..................................................................................................................... 9

6.2

S

ELECTING THE OPTICAL PEN

................................................................................................................. 12

6.3

CONFIGURING OF THE SENSOR IN

« D

ISTANCE

»

MEASURING MODE

........................................................ 12

6.4

R

ECORDING THE DARK SIGNAL

............................................................................................................... 12

6.5

P

OSITIONING THE SAMPLE WITHIN THE MEASUREMENT RANGE OF THE OPTICAL PEN

.............................. 13

6.6

U

NDERSTANDING THE MEANING OF THE INTENSITY MEASUREMENT

....................................................... 14

6.7

A

DJUSTING THE SAMPLING RATE

............................................................................................................ 14

7

GOING FURTHER (TUTORIAL 2)......................................................................................................... 15

7.1

M

EASURING MODES

............................................................................................................................... 15

7.2

C

ONFIGURING THE SENSOR IN

“T

HICKNESS

”

MEASURING MODE

............................................................. 16

7.3

C

ONFIGURING THE SENSOR IN

« I

NTERFEROMETRIC

»

MEASURING MODE

............................................... 17

7.4

C

ONFIGURING THE SENSOR IN

« M

IN

/

MAX

»

MEASURING MODE

............................................................. 18

7.5

C

OMMUNICATING WITH THE

CHR

150

VIA THE

RS232

LINK

................................................................. 20

7.6

U

SING THE

“T

RIGGER

”

MODE

................................................................................................................. 21

8

MAIN FUNCTIONS OF THE CHR 150 .................................................................................................. 22

8.1

O

PTICAL PEN SELECTION

........................................................................................................................ 22

8.2

A

CQUIRING THE

D

ARK SIGNAL

............................................................................................................... 22

8.3

S

AMPLING RATE SELECTION

................................................................................................................... 23

8.4

M

EASURING MODE SELECTION

............................................................................................................... 25

8.5

S

ET

/

REQUEST THE SAMPLE REFRACTIVE INDEX

...................................................................................... 25

8.6

A

NALOG OUTPUTS CONFIGURATION

....................................................................................................... 25

8.7

A

VERAGING

........................................................................................................................................... 26

8.8

S

YNCHRONISATION SIGNALS

.................................................................................................................. 27

8.9

R

EQUEST

/S

AVE THE CURRENT CONFIGURATION

..................................................................................... 28

8.10

R

EAD THE VERSION OF THE ON

-

BOARD SOFTWARE

................................................................................. 29

8.11

L

OCK OR UNLOCK ACCESS TO KEYPAD

................................................................................................... 30

8.12

R

ESTORE THE DEFAULT SETTINGS

.......................................................................................................... 30

9

CONTROL AND ACQUISITION OF THE DATA VIA THE SERIAL LINK..................................... 31

9.1

C

ONFIGURATION OF THE

COM

PORT OF THE HOST COMPUTER

............................................................... 31

9.2

S

ELECTION OF THE

CHR

BAUD RATE

...................................................................................................... 31

9.3

C

OMMAND SYNTAX

................................................................................................................................ 31

9.4

S

ELECTION OF THE DATA TO BE TRANSMITTED

....................................................................................... 32

9.5

D

ATA TRANSMISSION FORMATS

.............................................................................................................. 33

STIL - CHR 150 – Operating and maintenance manual Doc ref. CHR2-001-P2 Re :D

Page 3 of 49

9.6

L

IMITATION OF THE AMOUNT OF DATA TRANSMISSIBLE SIMULTANEOUSLY

............................................ 35

9.7

D

ECODING OF THE DATA

........................................................................................................................ 36

10

ADVANCED FUNCTIONS.................................................................................................................... 37

10.1

D

ETECTION

T

HRESHOLD

........................................................................................................................ 37

10.2

« D

OUBLE FREQUENCY

»

MODE

............................................................................................................. 37

10.3

F

UNCTIONS RELATED WITH THE

« I

NTERFEROMETRIC

»

MEASURING MODE

............................................ 39

10.4

F

UNCTIONS ASSOCIATED WITH

« M

IN

/

MAX

»

MODE

............................................................................... 40

10.5

A

DJUSTMENT OF THE

LCD

DISPLAY CONTRAST

..................................................................................... 41

10.6

A

CQUISITION OF THE WHITE REFERENCE SIGNAL

.................................................................................... 41

11

COMMANDS SUMMARY.................................................................................................................... 42

12

MAINTENANCE.................................................................................................................................... 44

12.1

H

ANDLING THE OPTICAL FIBER

............................................................................................................... 44

12.2

C

LEANING

.............................................................................................................................................. 44

12.3

R

EPLACEMENT OF THE HALOGEN LAMP

.................................................................................................. 45

13

TROUBLESHOOTING.......................................................................................................................... 47

TROUBLE SHOOTING (CONT). .................................................................................................................... 48

STIL - CHR 150 – Operating and maintenance manual Doc ref. CHR2-001-P2 Re :D

Page 4 of 49

1Presentation of the range of CHR sensors

Based on the innovative optical principle of chromatic confocal imagery (STIL patent), the range of

CHR sensors constitutes a new generation of high-resolution, non-contact dimensional sensors for

microtopography, shape and texture analysis, roughness measurement, reverse engineering and many

other metrological applications.

These modular, compact and sturdy sensors are capable of operating both in industrial environments

for in-line inspection during production process, and in laboratory environments as high precision

instruments.

The CHR sensors can be used to measure any type of object (transparent or opaque, polished or

rough) and any material (metal, glass, ceramic, plastic, semiconductor, fabric, paper, leather…), and

do not require any preparation of the sample.

They provide simultaneously:

the distance of the measured sample point

the intensity of the retro-diffused light beam,

the thickness of a transparent sample.

For further information on the optical measurement principle which forms the basis of the STIL

technology, and for an overview of available products, visit the STIL company web site at the following

address: www.stilsa.com

2Presentation of the CHR 150

The CHR 150 consists of an opto-electronic unit (“controller”) and one or more interchangeable

chromatic objectives (“optical pens”), each of them equipped with an optical fiber cable.

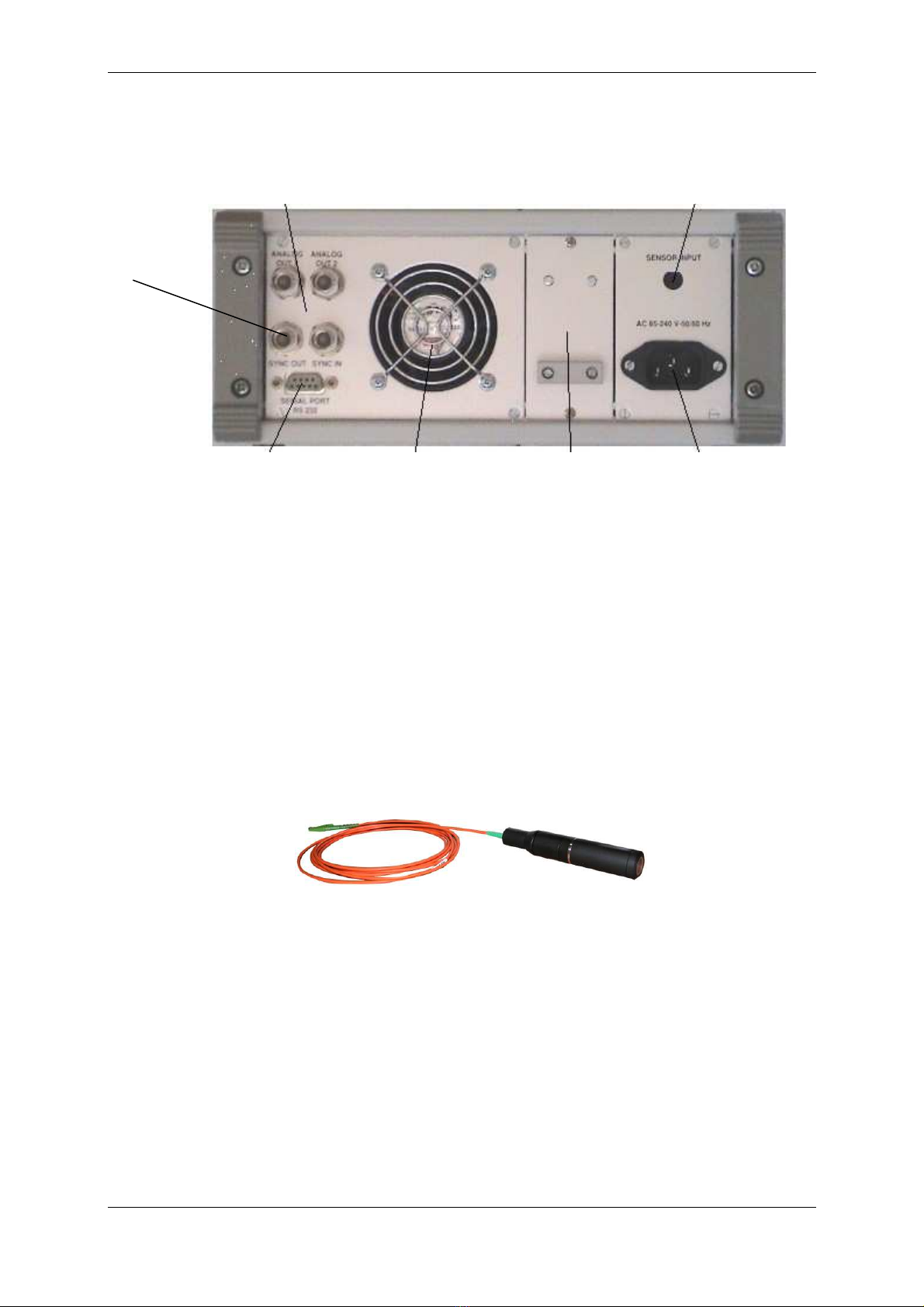

2.1 Controller

The controller comprises a light source (Tungsten-Halogen lamp), a spectrometer and a DSP-based

processing board. This board controls data acquisition, performs the computation, and provides

display and data transmission functions via the RS232 port or via the 0 – 10 V analog outputs.

The front panel of the controller features:

Control panel

On-Off switch Optical fiber lead

socket

(“Sensor Input”)

4-keys keypad

LCD display

STIL - CHR 150 – Operating and maintenance manual Doc ref. CHR2-001-P2 Re :D

Page 5 of 49

The rear panel of the controller features:

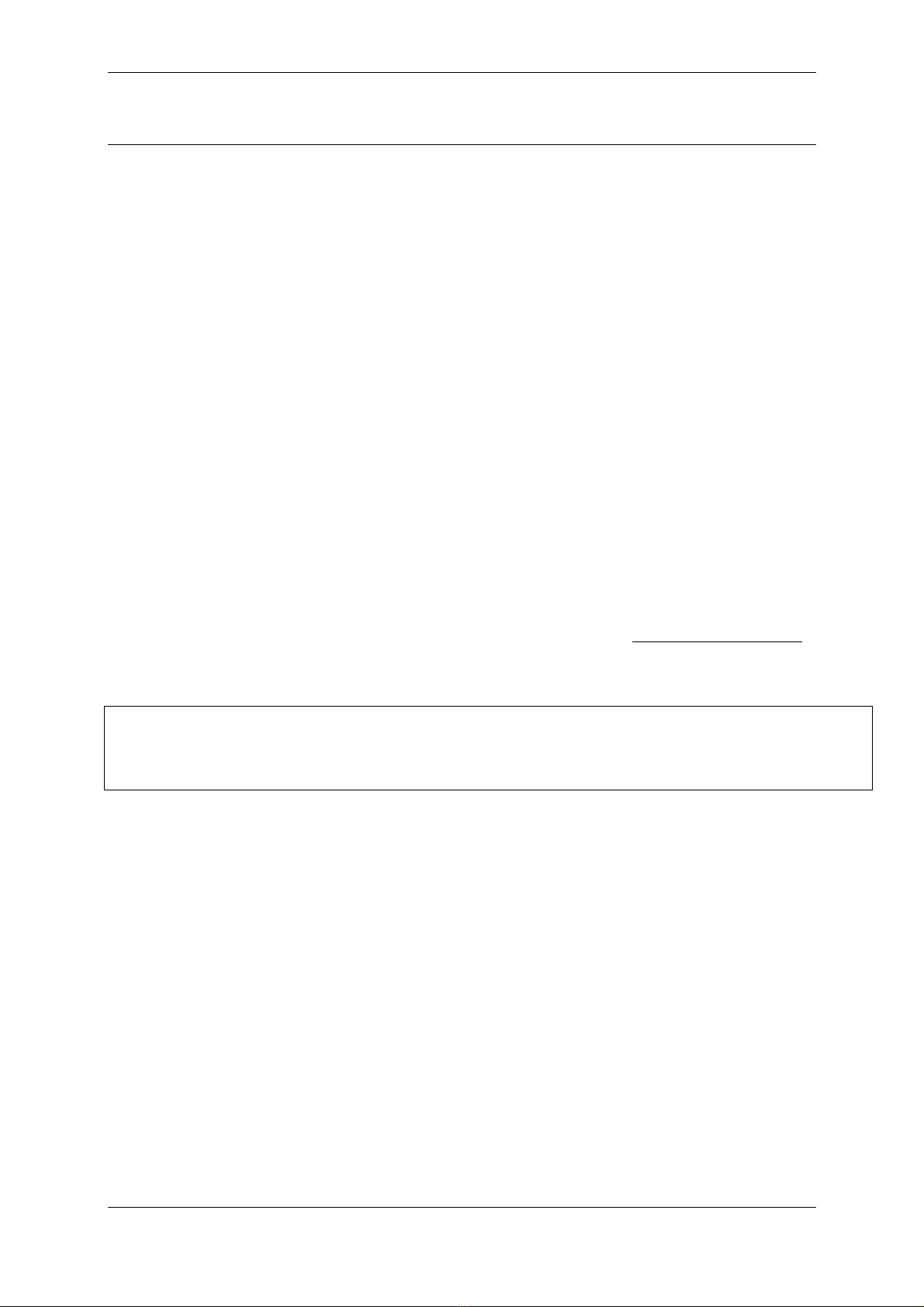

2.2 Optical pen and optical fiber

The optical pen is totally passive, since it incorporates no heat sources or moving parts, thus

avoiding any thermal expansion which could affect the accuracy of the sensor.

When handling the optical fiber lead which links the optical pen to the controller take care to avoid

bending the fiber to a radius of curvature of less than 20 mm. When no optical fiber is connected,

the socket must at all times be fitted with its protection cap to avoid contamination of the fiber tip,

which could result in malfunctioning of the sensor.

84 - 264 V / 50 - 60 Hz mains

input socket

Optional optical fiber Socket

for connecting optical pen

Extractable drawer

providing access to

the halogen lamp

Cooling fan

2 Analog output coaxial

sockets

RS232 SUB-D

9-pin socket

Sync in &

Sync out

Coaxial

sockets

STIL - CHR 150 – Operating and maintenance manual Doc ref. CHR2-001-P2 Re :D

Page 6 of 49

3Safety

The CHR 150 is an opto-electronic instrument. It is safe in normal operating conditions:

3.1 Ther al Hazards

The temperature of the Halogen lamp and its support is very high.

3.2 Electrical Hazards

The CHR 150 controller box should be opened by qualified technicians only.

Electrical hazards might exist, especially during an inappropriate intervention on the instrument.

Unplug the instrument from the power outlet before changing accessories, maintenance, cleaning, or

changing the halogen lamp.

3.3 Optical Hazards

The optical pen emits a beam of visible light with wavelengths ranging from 450 to 900 nm.

The flux contained in this beam is smaller than or equal to 30µW, a value largely under the MPE

(Maximum Permissible Exposure). Thus, independently of the light path inside the room and its

possible reflections, this light beam cannot induce any burn to the skin nor to the eyes.

3.4 General Reco endations

Do not use the instrument if it has been dropped and shows signs of damage or functions improperly.

In this case do not open the instrument and contact our help line: after-sale@stilsa.com

Repairs should only be carried by qualified technicians using original replacement parts.

In case of inappropriate use or failure to comply with the instructions, the manufacturer disclaims all

liability and the guarantee will not apply.

3.5 Co pliance to the EC regulation 89/336/EEC « Electromagnetic Compatibility »

The CHR –150 sensor complies to the generic or specific requirements of the following harmonized

standards

•EN 50 081-1 Spurious emission

•EN 61000-6-2 Resistance to disturbance

Be very careful when changing the halogen lamp in order to avoid the risk of a severe burn.

Switch the power off and let the instrument cool down for about 20 minutes before

attempting to open the lamp drawer.

STIL - CHR 150 – Operating and maintenance manual Doc ref. CHR2-001-P2 Re :D

Page 7 of 49

4Installation and switching on

Connect the controller to a mains socket with an earth connection, then connect the optical fiber lead

from the optical pen to the controller, taking care to comply with the correct orientation of the

connector.

Connection and disconnection of the optical fiber lead

To connect the optical fiber lead, simply insert the plug into the socket as shown in figure 1 until a

« click » is heard as it locks into position.

To remove the optical fiber from its socket, first press on the locking lever, then pull the connector

out of the socket.

Warning : When no optical fiber is connected, the socket must at all times be fitted with its

protection cap to avoid contamination of the fiber tip, which could result in malfunctioning of the

sensor.

Switch on the unit by operating the On/Off switch.

When the unit is switched on and after a brief initialisation sequence, the sensor displays the

following screen :

The intensity and distance values are both

displayed as "zero" so long as no object is

present in the measuring field of the sensor.

Int : 0 Dist (um) : 0.00

STIL - CHR 150 – Operating and maintenance manual Doc ref. CHR2-001-P2 Re :D

Page 8 of 49

5Co unicating with the CHR 150

There exist 5 alternative methods for communicating with the CHR 150 sensor:

a) The CHR front panel displays real time measurements and the 4-keys keypad allows a direct

and easy access to sensor configuration.

b) The RS232 serial link enables sensor configuration using a specific control language as well

as acquisition of the measured data . For example, the Windows « Hyper Terminal » utility or

any other utility intended for controlling a serial link can be used to send the commands and

receive the measurements back from the sensor.

c) The « CHR Monitor » optional software is intended for configuring the sensor and launching

measurements in three operating modes (continuous visualisation, « point by

point” measurement, acquisition of a temporal profile). It can also be used to display, save and

print-out the measurements.

d) The optional « CHR DLL » optional software is used to interface the sensor with a general

purpose user program in C++ language or similar. The operating manual of the DLL includes a

large number of code samples.

e) Finally, the « CHR Setup » optional software can be used for viewing the signal from the on-

board spectrometer and for downloading new firmware versions and new calibration tables.

These advanced features may be useful for some specific applications.

For further details regarding available software, please visit our web site

http://www.stilsa.com/

.

Recommendation : All the software applications use the same COM port to communicate with the CHR

150. Remember to always free the port by quitting one application before attempting to connect it to

another application.

STIL - CHR 150 – Operating and maintenance manual Doc ref. CHR2-001-P2 Re :D

Page 9 of 49

6Getting started (Tutorial 1)

This chapter is a tutorial intended for new users who wish to familiarise themselves with the main

characteristics of the CHR 150 sensor. For simplification purposes, this tutorial only introduces one

measuring mode (« Distance » mode) and one communication method (the control panel). We

recommend that new users follow this tutorial even if they wish subsequently to use another measuring

mode or a different method for communicating with the sensor.

6.1 Using the control panel

Press any key to access the control panel main menu:

As symbolised on the keypad, each key has its own main function:

F1 = Escape

F2 = Increase displayed value or move the cursor to the left

F3 = Decrease displayed value or move the cursor to the right

F4 = Enter.

Besides, each function displayed on the LCD display can be launched by the keys just bellow it. As an

example in the main menu shown above:

F1 may be used to clear the menu,

F2 to launch acquisition of the ” Dark” signal,

F3 to set sampling rate

F4 to enter the configuration menu, which allows setting all sensor parameters.

When configuration of the sensor is complete, the sensor prompts the operator to save the

modifications made by displaying the following message "Save settings in EEPROM ?". If the "Yes" key

is pressed, the modifications are saved permanently, otherwise the modifications are lost as soon as

the CHR 150 is switched off.

The entire menu-trees are presented next pages.

Clear Dark S.Rate Config.

F1 F2 F3 F4

LCD display

4-key

Keypad

E

sc

STIL - CHR 150 – Operating and maintenance manual Doc ref. CHR2-001-P2 Re :D

Page 10 of 49

S.R

ATE

1000H

Z

300H

Z

100H

Z

30H

Z

Free/Double

Exposure

CCD Scan Rate

Cycle

Frequency

Set E.Time

Ratio

Set Rate Menu

C

ONFIG

C

LEAR

S.R

ATE

D

ARK

MAIN

Main menu

F1

F3

F2

F4

•To access the Main menu of the Control panel, press any key.

•The S.Rate and the configuration menus are both described below.

F2 F3

STIL - CHR 150 – Operating and maintenance manual Doc ref. CHR2-001-P2 Re :D

Page 11 of 49

C

ONFIG

.

Data

averaging Take white

reference

Set default

parameters

LCD

Contrast

Config.

Analog

out1

Serial port

Baud Rate

Set

detect.

threshold

Serial data

ASCII/BIN

Set serial

output

data

Select

measuring

mode

Select

confocal

sensor

Spectral

averaging

Config.

Analog

out2

Configuration Menu

F2 F3

STIL - CHR 150 – Operating and maintenance manual Doc ref. CHR2-001-P2 Re :D

Page 12 of 49

6.2 Selecting the optical pen

The CHR-150 controller may hold up to 6 calibration tables corresponding to 6 different optical pens.

Available optical pens and their characteristics may be consulted in STIL website : www.wtilsa.com.

Optical pens are passive devices and the controller can not identify the optical pen which is physically

connected to it, so the operator has to select the calibration table corresponding to the optical pen that

is physically connected.

To configure the controller to right optical pen using the control panel:

Press any key to access the Main menu,

Press F4 to enter the Configuration menu,

Press F2 until you reach the ‘select confocal sensor’ window (if you reach the last menu option,

change the sense and press F3 until you reach this window).

Press F4 to enter the ‘‘select confocal sensor’

Use F2 or F3 to select the desired optical pen.

Validate with F4 or F1

6.3 configuring of the sensor in « Distance » easuring ode

The next step is to configure the sensor to the desired measuring mode. For distance measurement

select the “Distance” mode (‘confocal, 1 surface’).

In the configuration menu, press F2 (or F3) until you reach the ‘select measuring mode’

window

Check that ‘confocal, 1 surface’ is displayed then validate with F1 or F4. Otherwise press F2

or F3 until you see ‘confocal, 1 surface’ displayed.

Next, check that the averaging factor is set to 1 (no averaging in the ‘data averaging’ window).

The last step in sensor configuration is setting sampling rate.

To select the ‘S.Rate’ menu, exit the configuration menu using the F1 key. In the Main menu

select ’S. Rate’ (F3). The currently selected rate is displayed: ‘CCD-SCAN rate : XXXX Hz’.

Use F2 and F3 to view the available rates, and note the existence of the ‘free/double

frequency’ option. For the moment, we wish to select the lowest rate (30Hz).

Use F2 several time to select this rate, and validate with F1 or F4.

Sensor configuration is done. When quitting, save the current configuration to the EEPROM.

6.4 Recording the dark signal

The dark signal of the sensor represents an intrinsic offset level generated by parasitic light in the

sensor, which must be taken into account for the sensor to be able to operate correctly. The level of

the Dark signal depends on the sampling rate. The dark signal should be recorded at all measuring

rates, in order to be able to subtract it while the sensor is measuring.

A dark signal acquisition is performed during adjustment by the manufacturer, but must be repeated at

regular intervals in order to compensate for the halogen lamp ageing phenomenon.

In order to perform a dark signal acquisition, it is essential for there to be nothing within the

measurement field or even better, to blank off the light beam by applying a piece of paper over the tip

of the optical pen.

Press any key to access the main menu, followed by F2 to enter the ‘Dark’ menu.

Blank off the light with a piece of paper, then press F4 to start dark acquisition. The sensor then

records the dark signal over a few seconds. A message is displayed to indicate the end of this

operation. The piece of paper can now be removed and the sensor can be used in the normal way.

Warning : If on completion of the dark recording sequence, a warning message appears indicating that

there is too much light for a given sampling rate, this means that the dark signal is too high for working

at lower rates. This is generally caused by the presence of dust or impurities at the ends of the optical

fiber generating stray light reflections which interfere with correct operation of the sensor.

STIL - CHR 150 – Operating and maintenance manual Doc ref. CHR2-001-P2 Re :D

Page 13 of 49

Int. : 38

Dist. (um) :

135.00

Clean the ends of the optical fiber as described in the maintenance section of this manual, then repeat

the dark signal acquisition and check that the warning message does not reappear.

A different cause for such a warning may be that the optical pen lens was not entirely blanked off.

Recommendation : The dark signal acquisition procedure should preferably be performed at least

a quarter of an hour after switching on the sensor, in order to ensure that the temperature and the

optical characteristics of the halogen lamp have stabilised.

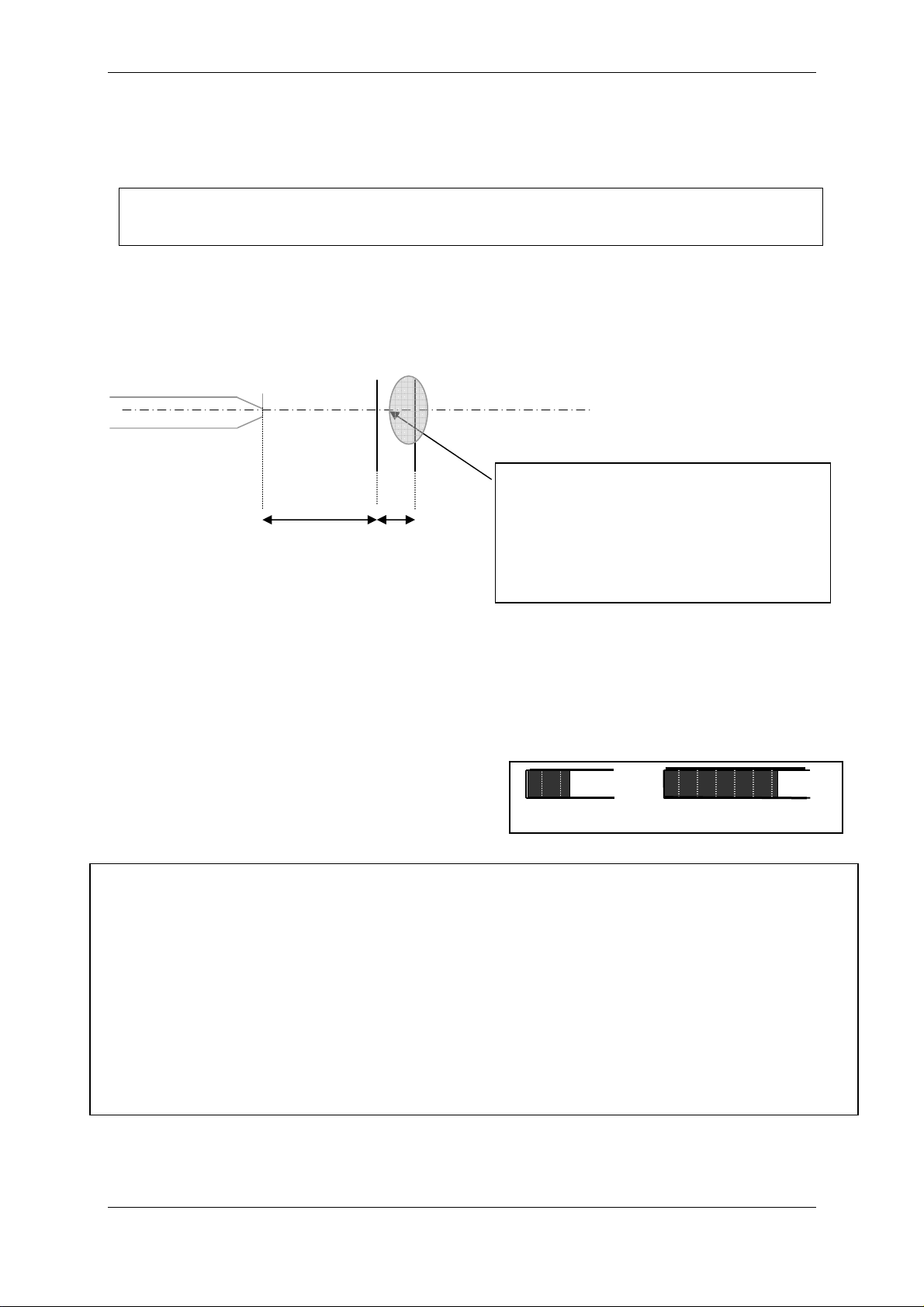

6.5 Positioning the sa ple within the easure ent range of the optical pen

Mount the optical pen on a suitable support (for example, a « V » block). Position the sample to be

measured in front of the pen, and move it forward or backward until the working distance is reached.

For pens with a millimetric measurement range, the positioning of the object within the measurement

range of the optical pen is easy to achieve, simply observe the luminous spot focused on the object by

the optical pen: as the measuring range is approached, the spot becomes smaller and smaller and its

intensity increases.

For optical pens with a micrometric measurement range, the operation is more difficult : position the

sample on a stable support on a small manually translating bed, with a suitable pitch lead screw.

As soon as the sample enters the optical pen's

measurement field, the Distance and intensity

measured are displayed on bar-graphs and digital

indicators on the LCD display.

The zone of the sample to be measured

must be located in front of the optical

pen, within the measurement range of the

pen. Its distance from the optical pen

should be approximately equal to the

working distance of the pen.

Optical axis

Optical pen

Working

distance

Measurement

range

Recommendation : If no measurement is displayed when the object is within the measuring field of the

sensor, check the following points :

•The optical fiber cable connector is fully plugged into the socket on the front panel.

•A light beam is emitted from the tip of the optical pen and the spot is focussed on the sample.

•The distance between the tip of the optical pen and the surface of the sample is equal to the

working distance specified in the table above.

•The optical axis is normal to the surface of the sample. The local slope must be less than the

“max slope” indicated in the table.

•The sampling rate selected is the lowest shown in the list (30 Hz), the measuring mode selected is

‘Confocal, 1 surface’ mode.

•The displacement pitch of the translation bed carrying the sample is suitable for the measurement

(for example, for pen model OP 020, the pitch must be ≤5 µm)

•

The Dark signal has been correctly acquired.

STIL - CHR 150 – Operating and maintenance manual Doc ref. CHR2-001-P2 Re :D

Page 14 of 49

6.6 Understanding the eaning of the intensity easure ent

The « Intensity » parameter measured by the sensor is an indication of the brightness of the signal

reflected back off the sample, as a percentage of the dynamic response of the sensor. Its value is

dependent on several parameters:

•The sampling rate of the sensor

•The local slope on the sample (angle between the optical axis and the normal to the

surface at the point of impact)

•The reflectivity of the sample at the detection wavelength λ

o

•The brightness of the halogen lamp at wavelength λ

o

•The response of the spectrometer at wavelength λ

o

The detection wavelength λo varies within the measurement range. Thus it is not surprising that the

intensity measured at a given point on the sample varies when the latter is moved within the

measurement range of the optical pen.

For each point in the measurement range, the value of the intensity varies between 0% and a

maximum value I

sat

. Beyond that, the sensor is saturated. The state of saturation is indicated by an

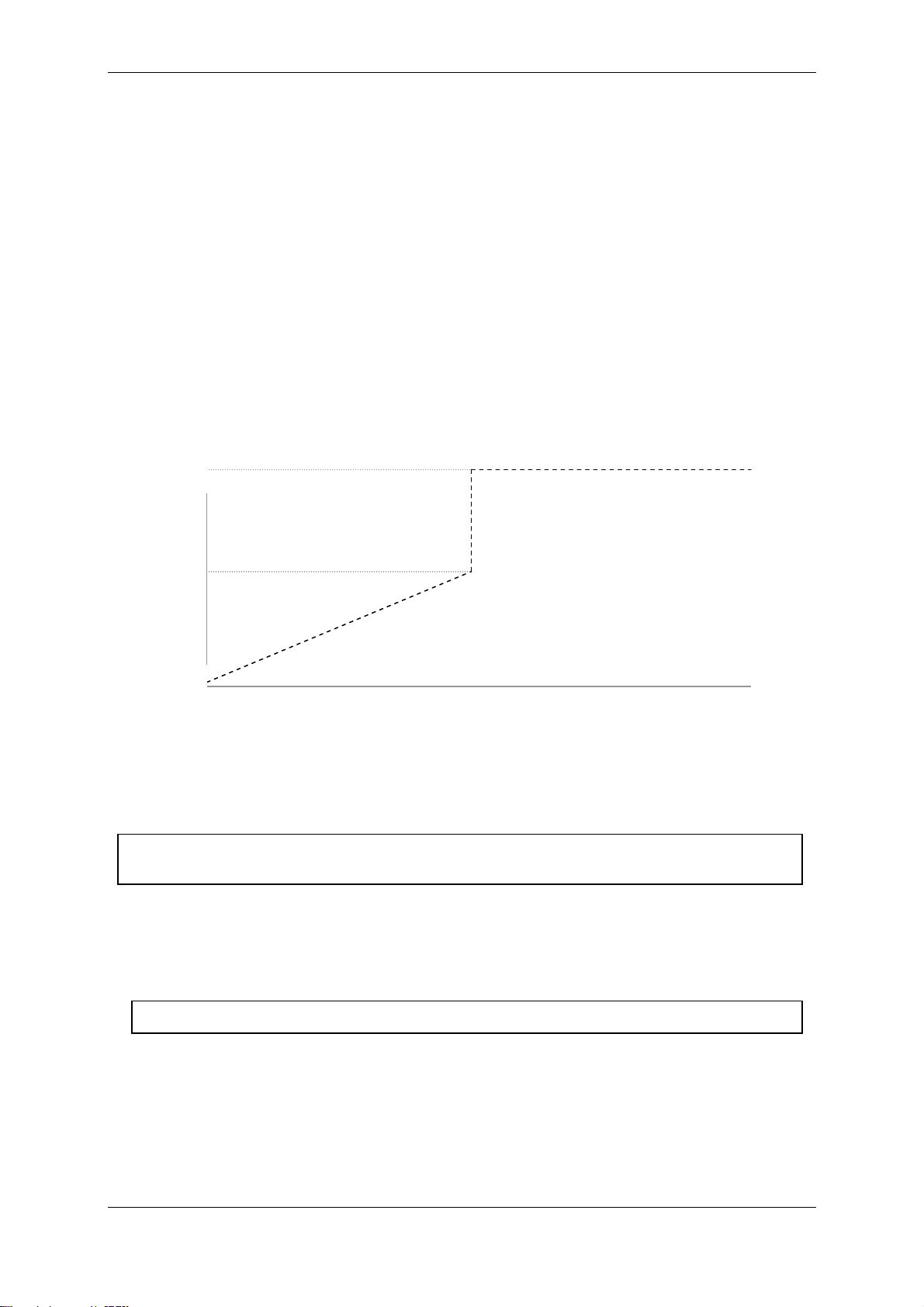

intensity value of 100% as shown in the graph below :

The value of I

sat

is dependent on the detection wavelength λo, and may vary slowly within the

measurement range of the sensor.

Example : If the intensity measured oscillates between 100% to 60%, this means that I

sat

= 60% and

that the sensor is on its saturation limit : in such case, select a higher rate.

6.7 Adjusting the sa pling rate

When the sample is within the measurement range of the optical pen, adjust the sampling rate :

Modify the sampling rate selected in the ‘CCD SCAN Rate’ window of the control panel, and observe

the value of the intensity displayed.

The first tutorial is over. In this tutorial you have learned how to:

Use the control panel to configure the sensor,

Select the rate and the optical pen,

Record the ‘Dark’ signal

Position the sample with the measuring range of the optical pen

Use the ‘Intensity’ data to adjust the measuring range.

0% Reflectivity of the sample

100%

100%

I

sat

Intensity measured by the CHR 150

0%

Recommendation : The intensity is a good indicator of the measurement quality : It should

be as high as possible, without, however reaching saturation level.

Recommendation : Always select the lowest rate for which the signal does not saturate.

STIL - CHR 150 – Operating and maintenance manual Doc ref. CHR2-001-P2 Re :D

Page 15 of 49

7Going further (Tutorial 2)

This chapter is a tutorial intended for users having acquired some initial experience with the CHR 150

sensor in the “Distance” measuring mode. This tutorial covers the following topics :

•“Thickness” ( “Confocal, 2 surfaces” ) measuring mode

•“Interferometric” and “Min/max” optional measuring modes.

•Communication with the sensor via the RS232 serial link using the Windows « Hyper

Terminal » utility.

•Synchronisation signals (« Trigger » ).

7.1 Measuring odes

The main measuring mode for the CHR 150 sensor is “Distance” mode . The sensor is calibrated and

tested by the manufacturer in this measuring mode, and a certificate of the test results is supplied with

each optical pen.

In order to measure the thickness of flat transparent or semi-transparent samples, the CHR provides

two additional measuring modes « Thickness », available as standard, and « Interferometric » mode,

available as an option. In both these modes the refractive index of the sample must be known.

The last measuring mode, « Min/max mode », dedicated to on-line measurement of the thickness of

transparent objects, is also available as an option. This mode enables the measurement of the

minimum and maximum thickness measured within a time window determined by the operator, and

comparison of these values with the thresholds established by the operator.

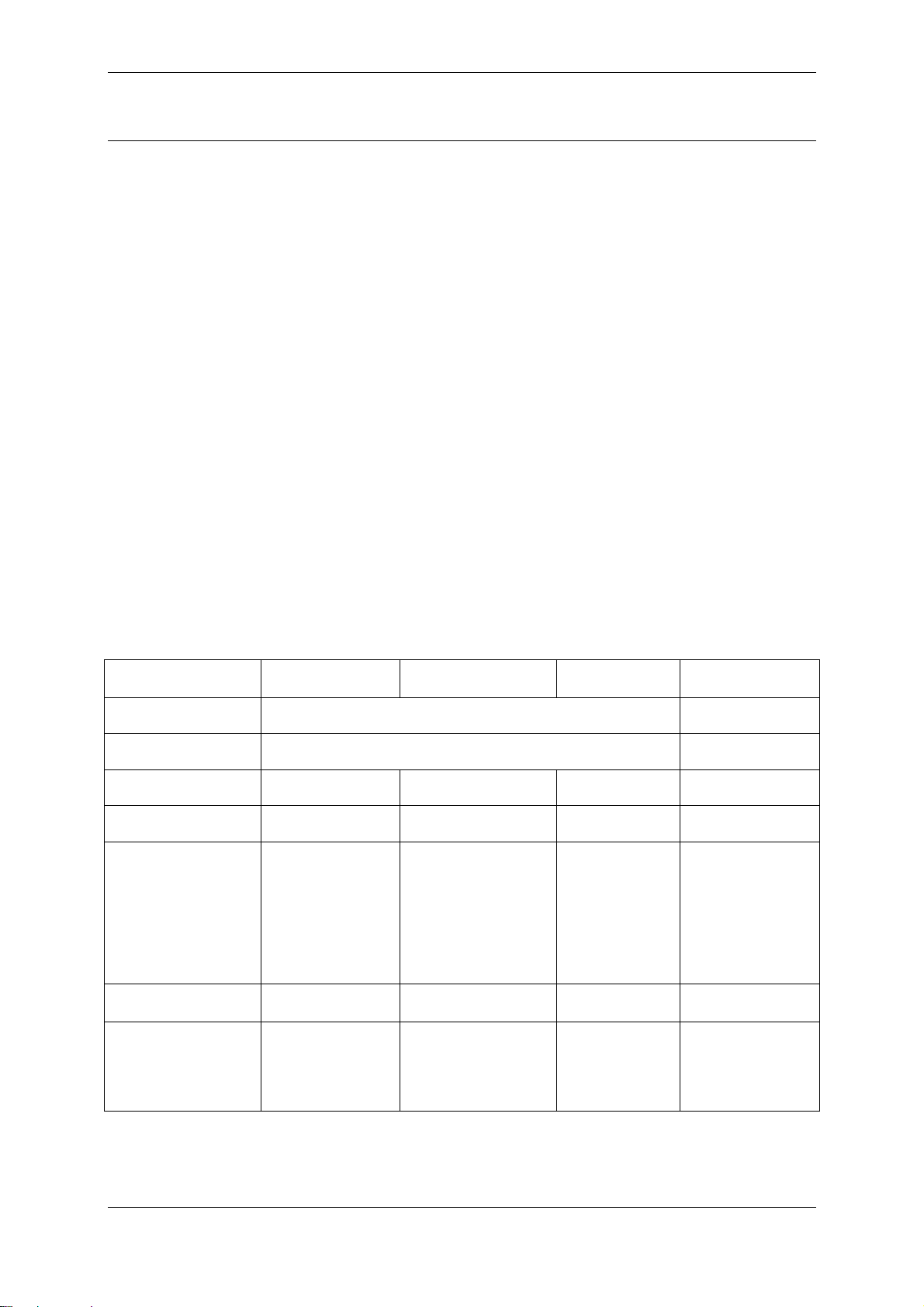

CHR sensor measuring modes

Measuring mode Distance Thickness Min/max Interferometric

Optical principle Confocal microscopy with chromatic encoding White light

interferometry

Pen models All confocal mode pens Interferometric

pen

CHR models All All

CHR 150,

CHR 150 -PC

CHR 150,

CHR 150 -PC

Availability Standard Standard Optional Optional

Simultaneously

measured

data items

Distance,

Intensity,

Barycenter (*)

Thickness,

Distance face 1,

Distance face2,

Intensity face 1,

Intensity face 2,

Barycenter face 1 (*)

Barycenter face2 (*)

Min. thickness

Max. thickness

Thickness,

Intensity

Quality indicator

Metrological test

with certificate

Yes

No

No

No

Application Distance

measurement

(surface

roughness,

microtopography)

Thickness

measurement from

~25 µm

On-line

thickness

measurement

Thickness

measurement

from ~2 µm

(*) Data items used by the manufacturer for calibration of the sensor.

STIL - CHR 150 – Operating and maintenance manual Doc ref. CHR2-001-P2 Re :D

Page 16 of 49

7.2 Configuring the sensor in “Thickness” easuring ode

In this measuring mode the sensor searches for 2 signals, reflected from the 2 faces of the sample. If

they are found, it calculates the intensity and Distance of face 1 (front face, i.e. the nearest face), the

Distance and intensity of face 2 (rear face), and the thickness. All these data are available

simultaneously.

If the sensor can only detect one signal, all the data are reset on zero. This can occur if one or other

face of the sample is located outside the measurement range.

The thickness of the sample must be compatible with the thickness measurement range of the optical

pen used:

As a general rule, the maximum thickness which can be measured is proportional to the refractive

index of the material. Thus, for an OP1000 optical pen, whose measurement range in air is 1 mm, one

can measure the thickness of a sheet of glass up to ~1.5 mm.

If the thickness of the sample is less than the « Minimum thickness » limit specified the sensor is

unable to resolve the two signals reflected from the two faces of the sample and considers them as a

single signal. Output will be set on zero.

Experimentation:

•To select the “Thickness” measuring mode, press any key, then F4. Next, use F2 and F3 to

display ‘Select measuring mode’, enter with F4 and select the “Thickness” mode (‘Confocal 2

surfaces’) using F2 or F3 then validate with F1 or F4. The LCD Screen displays ‘refractive

Index’, enter the value of the refractive index of the sample, then click on « OK » to close the

configuration window.

•Position a thickness sample in the measurement range of the optical pen, such as a glass

slide, a piece of cellophane, a transparent plastic film or any other flat transparent sample. If it

is a sheet or film, ensure it is pulled tight. Also check that the axis of the optical pen is normal

to the surface of the sample. The sample thickness should be in the range specified in the

table above.

•Slowly move the object to position both faces within the measurement range, and to obtain two

signals of comparable intensity. If the signal saturates, adjust the sampling rate.

Warning : To obtain a valid measurement in « Thickness » mode, the refractive index of the

sample must be accurately known.

Recommendation : If you manage to obtain a measurement in “Distance” mode (‘Confocal,

1surface’) but in “Thickness” mode (Confocal, 2surfaces) the thickness is zero, check the

following points :

•The thickness of the sample must be compatible with the measurement range limits

(see the table).

•The sample must be sufficiently transparent.

•The sample must be pulled tight.

•The optical axis must be normal to the surface of the sample.

•The sampling rate selected in the « Sensors » window must be the lowest in the list

(30 Hz).

Recommendation : In « Thickness » mode, center the sample within the measurement range

of the pen, avoid having either one of the faces close to the limits of the range.

STIL - CHR 150 – Operating and maintenance manual Doc ref. CHR2-001-P2 Re :D

Page 17 of 49

7.3 Configuring the sensor in « Interfero etric » easuring ode

The “Interferometric” measuring mode is optional. If your sensor is not equipped with this

option, skip to the next section (§7.4).

To select the Interferometric measuring mode, press any key, then F4. Next, use F2 and F3 to display

‘Select measuring mode’, enter with F4 and select the Interferometric mode using F2 or F3 then

validate with F1 or F4. At that step, enter the refractive index and press F1.

This measuring mode is dedicated to thickness measurement of transparent coatings or transparent

films, whose thickness is within the range 2 to 100 µm approximately, for a refractive index of 1.5 (3 to

150 µm in air). It requires the use of a specific achromatic optical pen, and a signal processing

algorithm specific to this mode.

In this measuring mode the sensor calculates an intensity value, a quality indicator and a thickness,

(actually it calculates 3 quality indicators for 3 theoretical possible thicknesses. The second and third

thicknesses are significant for multi-layer samples only).

The « Interferometric » optical pen is equipped with a removable tip which enables it to work in contact

with the object. Its working distance is about 42 mm.

Tip Adjustment Procedure:

In order to ensure good quality measurements, it is essential to comply with the following adjustment

procedure :

•Connect up the « Interferometric » optical pen to the sensor.

•Select the “interferometric” measuring mode ( ‘Interfer. thickness ‘).

•Acquire the « Dark » signal.

•Approach the optical pen to the sample in order to obtain a non zero "Intensity" signal.

•Adjust the distance by screwing the tip in or out in order to maximise the intensity

measurement.

•According to the reflectivity of the object being measured, adjust the sampling rate in order to

obtain maximum intensity without saturation.

Warning : If the sensor saturates (Intensity = 100%), measurement becomes impossible.

•Finally adjust the distance by screwing the tip in or out in order to maximise the measurement

quality parameter. The optimum distance obtained by maximising the « Quality» parameter

may be slightly different from that corresponding to maximum intensity. When the adjustment

is optimum, tighten the locknut in order to lock the tip in that position.

The equipment is now ready to perform thickness measurement.

Measurement

Take the sample to be measured and position the « Interferometric » optical pen equipped with its tip

in contact with the point to be measured. The optical pen must be positioned strictly perpendicular to

the surface of the object. In order to find the correct position, slowly pivot the optical pen around the

point looking for the maximum intensity value. As soon as an available measurement is detected, the

Quality indicator and the Thickness value are displayed.

Bracketed mode

In order to stabilise the measurements when the quality factor is low, it is possible to "bracket" the

thickness measuring range using the keypad:

Key F4 is pressed to switch successively between bracketed mode (with black bases representing the

excluded values) and non-bracketed mode.

It is also used for adjusting alternately the right hand or left hand limit of the window.

Keys F2 and F3 are then used for displacing the edges of the valid thickness window respectively to

the left or to the right.

STIL - CHR 150 – Operating and maintenance manual Doc ref. CHR2-001-P2 Re :D

Page 18 of 49

Example : starting from non-bracketed mode

F4 bracketed mode, LH edge selected

F2 displacement of the LH edge to the left

F3 displacement of the LH edge to the right

F4 non-bracketed mode

F4 bracketed mode, RH edge selected

F2 displacement of the RH edge to the left

F3 displacement of the RH edge to the right

7.4 Configuring the sensor in « Min/ ax » easuring ode

The “Min/max” measuring mode is optional. If your sensor is not equipped with this option,

skip to the next section (§7.5)

This mode is dedicated to on-line measurement of the thickness of transparent objects.

To select the Min/Max mode, press any key, then F4. Next, use F2 and F3 to display ‘Select measuring

mode’, enter with F4 and select the Min/Max mode using F2 or F3 then validate with F1 or F4.

« Min/max » measuring mode is used to determine the minimum thickness and maximum thickness

measured. In this mode the sensor permanently measures the objects passing beneath the optical

pen, but only records the extreme values observed. These values are compared with two thresholds

(maximum thickness and minimum thickness) preset by the operator, in order to identify the objects

exceeding these limits.

The « Activate inspection » input determines the time interval for thickness measurement. In the

« Closed » state, the sensor saves the minimum and maximum thickness values measured, and

compares them in real time with the two thresholds defined by the operator. If a thickness

measurement exceeds these limits, the « Defect » output signal is activated, triggering for example

ejection of the object off the production line.

At the end of the measurement (i.e. when the « Activate inspection » input returns the « open » state)

the min. and max. thicknesses are transmitted via the serial link as data 7 and 8 (see. « Select output

data »).

7.4.1 Signal specifications

•The « Activate inspection » input and « Defect » output replace, respectively, the « Sync in »

input and « Sync out » outputs.

•« Closed » state of the « Activate inspection » input : the 2 pins for this signal are short-

circuited or connected together by an impedance of less than 100 ohms. The sensor delivers a

voltage of 5V into an impedance of 1 kOhm, thus limiting the current to 1 mA.

•« Defect » output : This output is connected to both pins of an insulated static relay. It switches

to the « Closed » state as soon as a defect (exceeded threshold) is detected. The maximum

external load for this output is 40V DC and 0.5 Amp.

STIL - CHR 150 – Operating and maintenance manual Doc ref. CHR2-001-P2 Re :D

Page 19 of 49

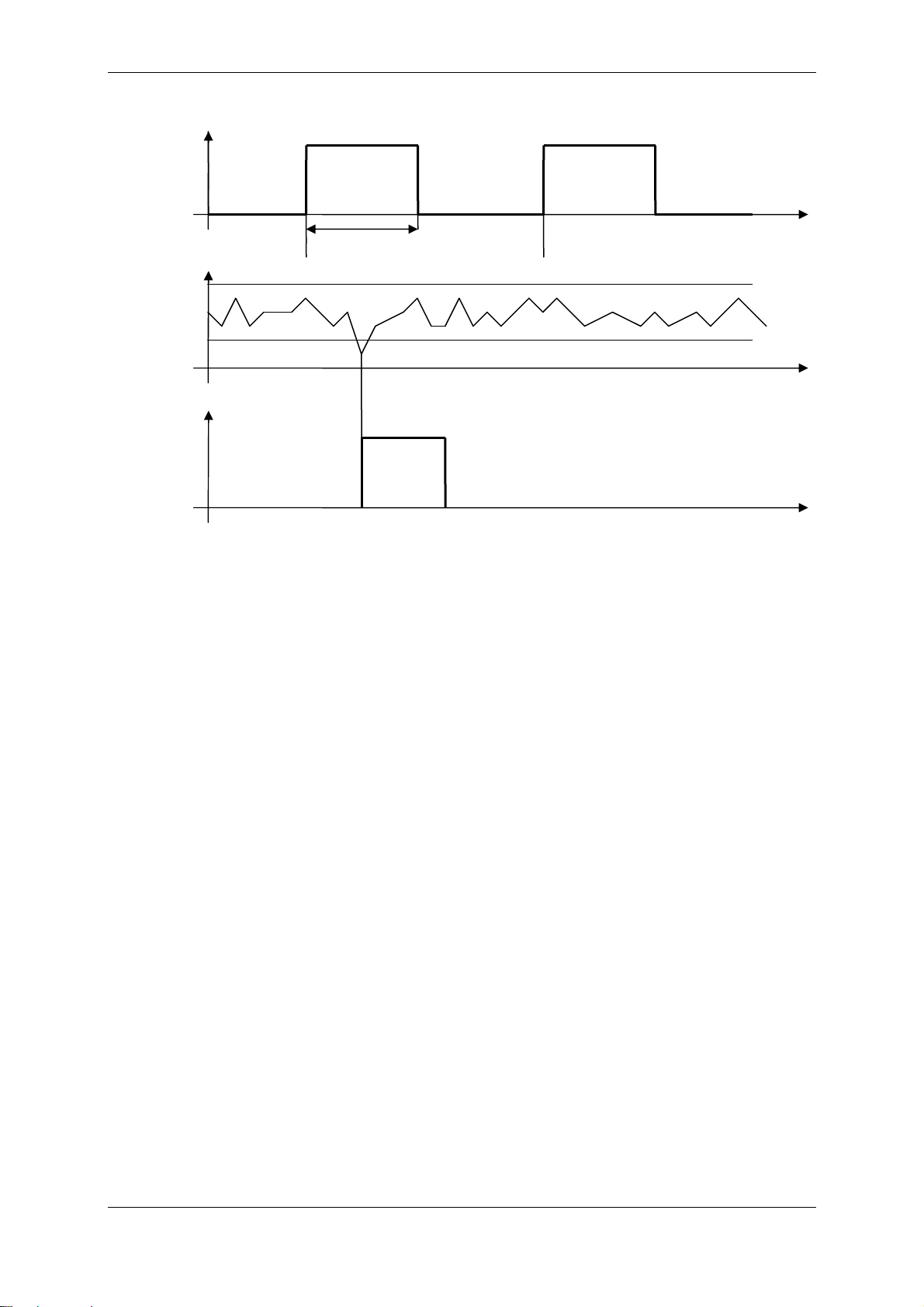

The diagram below shows an example of the operating sequence :

7.4.2 Experi enting with « Min/ ax » easuring ode

A) Prepare a thickness sample and determine the min. and max. thicknesses

•Connect an optical pen to the sensor, select the optical pen in the ‘Select confocal sensor’

window of the control panel configuration menu

•Configure the sensor in “Thickness” measuring mode (‘confocal, 2 surfaces’).

•Execute a « Dark » signal measurement.

•Place a variable thickness transparent sample within the measurement range of the optical

pen (for example, an ophthalmic contact lens, a bottle or a glass). The thickness must be

compatible with the thickness measurement range of the optical pen (see ‘Configuring the

sensor in “Thickness” measuring mode’).Configure the sensor for the refractive index of the

sample.

•Centre the sample within the measurement range and adjust the sampling rate.

•Move the sample horizontally in order to measure the thickness variation from one point to the

next on the sample. Record the min. value (E0) and max. value (E1) of the thickness.

B) Configure the sensor in « Min/max » mode

•Connect the coaxial “Sync in” plug (« Activate inspection» input) to a switch in order to be able

to switch from the « Closed » state to the « Open » state (cf. « Signal specifications »).

Ensure that the input is Open.

•Configure the sensor for « Min/max » measuring mode

•Adjust the thickness thresholds to E0*0.5 and E1*1.5, respectively.

•Select the « Min. thickness » and « Max. thickness » data for the bargraphs of the « Sensors »

window.

C) Use the « Defect » output

•Stop the measurement

•Connect the “Sync out” plug (« Defect » output signal) to an ohmmeter (cf. « Signal

specifications »)

•Start the measurement.

•Move the sample horizontally and observe the ohmmeter : the resistance measured should be

infinite.

•Stop the measurement

T1

Max threshold

« Defect »

signal

« Activate

inspection »

signal

Min threshold

Thickness

Defect

detected

Inspection

activated No

inspection Inspection

activated

No

inspection No

inspection

No defect

Table of contents

Popular Accessories manuals by other brands

PCB Piezotronics

PCB Piezotronics HT356A26 Installation and operating manual

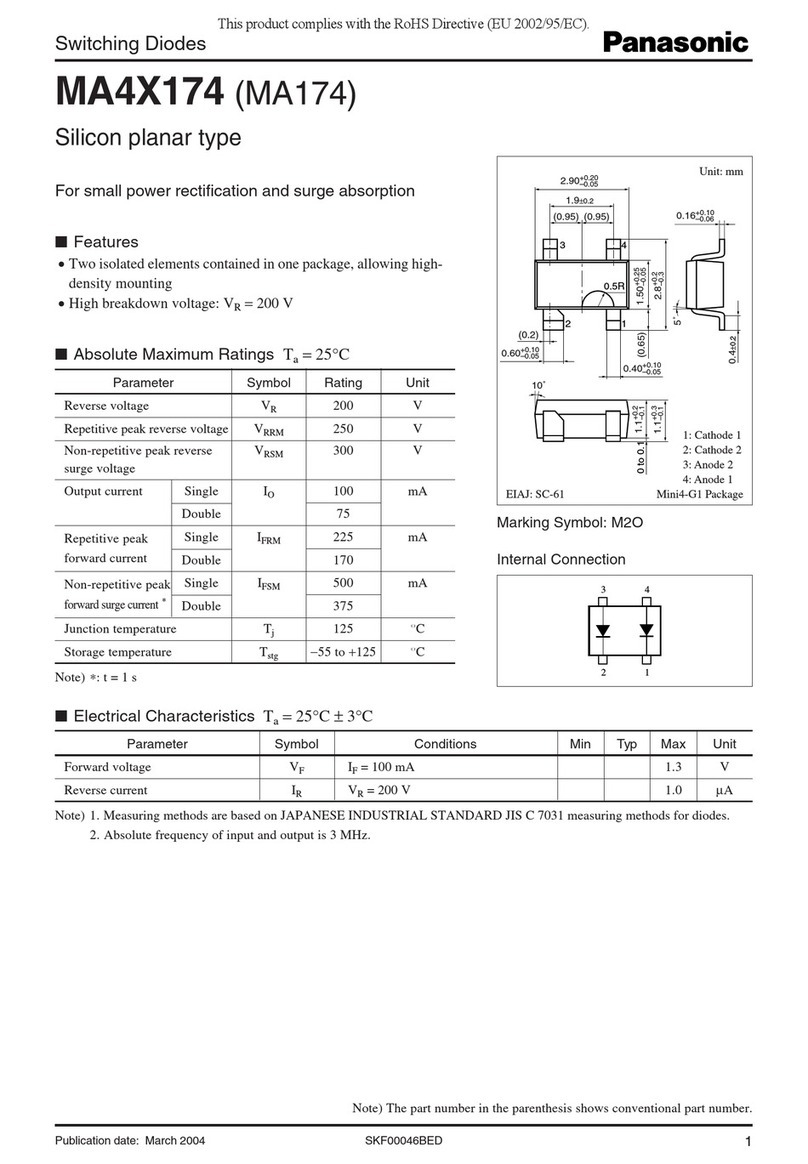

Panasonic

Panasonic Switching Diodes MA4X174 (MA174) specification

Philips

Philips DLA91000H Specifications

RIB

RIB ACG2275 quick start guide

Garmin

Garmin GRF 10 installation instructions

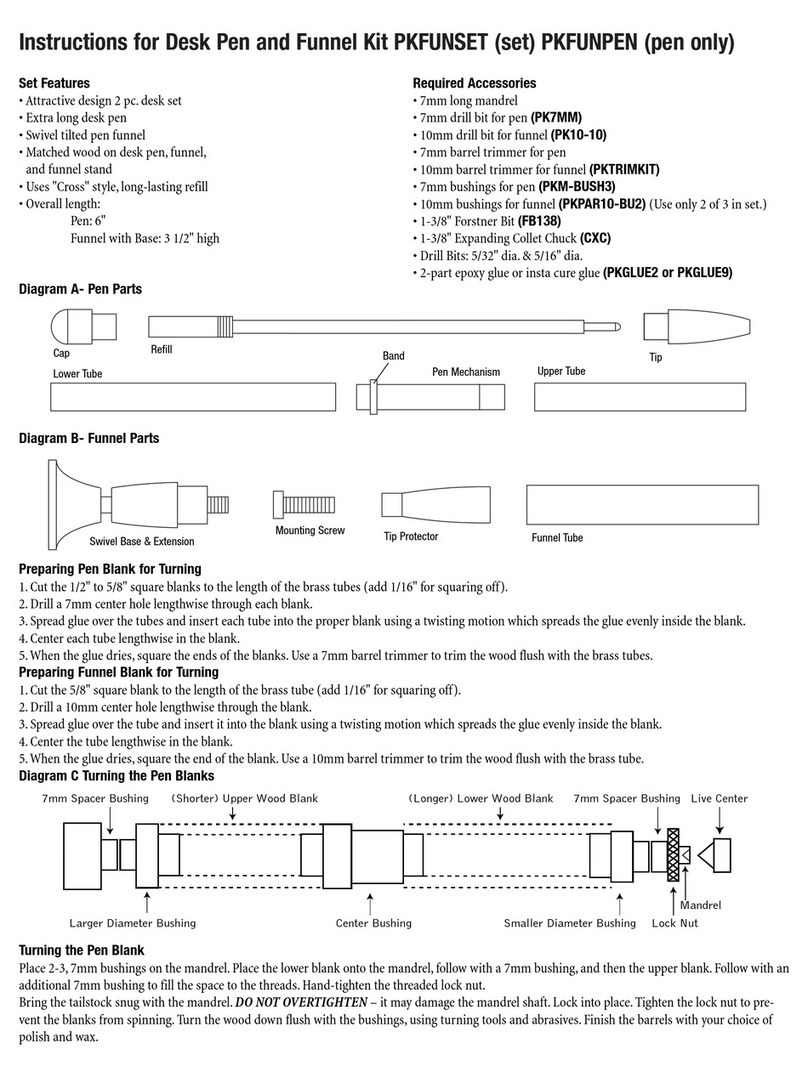

PSI Woodworking Products

PSI Woodworking Products PKFUNSET instructions

Master Grade

Master Grade Pro user manual

Promate

Promate Provolta-21 user guide

Airmar

Airmar WeatherStation 110WXS Owner's guide and installation manual

Royal Catering

Royal Catering RCCC-160ST user manual

NTI

NTI SPLITMUX-DVI-4RT Installation and operation manual

Liberty Safe

Liberty Safe Safe Power Outlet Kit Installation and operation manual