Strack Z6 User manual

Z6 PUSH LOCKS

OPERATING INSTRUCTION

Entformungselemente -- indirekt IDemoulding elements -- indirect

Eléments de démoulage -- indirects

6

1 STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

D 3002A 07.2018

Operating instruction english -- Push locks Z6

A component having the following features:

1. Safe function

The Z6 push lock is an addition to the Z4 latch locks.

It is used to ensure that the mould tool’s main parting plane is opened first. Only after opening the main parting plane, for example using a Z4 latch lock (with delay), can

the second parting plane be opened.

2. Simple mounting

Easy mounting and adjusting. No milling work required on injection mould

3. Wide range of applications

With the Z6 push lock, the already wide range of applications offered by the combination of different latch lock variants of the Z4 design has been extended yet again.

Entformungselemente -- indirekt IDemoulding elements -- indirect

Eléments de démoulage -- indirects

6

2

STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

D 3002A 07.2018

Operating instruction english -- Push locks Z6

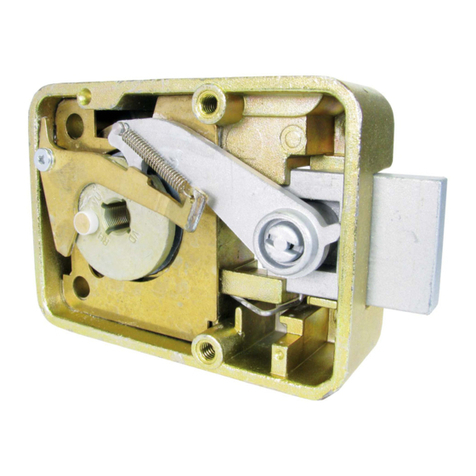

Principle of Operation:

Figure 1

The control bar (31 ) is bolted to the mould plate (H2). The latch housing (11) is

bolted to mould plate (H1V) plate and control plate (21) is bolted to the clamp plate

(H5). The control plate (21) is positively locked to the latch housing (11) by the

catches (6).

S3

S2

325

350

375

3-L1

H1V

2

1

6

(Z4)

S1

S2

H6 H3

H4

H2

H1V

H1 H5

6

21

H7

H8

31 11

S

11

1

6

(Z4)

21

6

(Z6)

325

350

375

3-L1 S1

1

2

3

4

Figure 2

When the main parting plane of the injection mould is opened, the closure or ejector

side initially moves back in the direction of the arrow by the specified opening travel

(S1). Until this opening movement (S1) has ended, the mould cannot open in the se-

cond parting plane, since it is locked by the positive connection between control plate

(21), latch housing (11) and catches (6). As soon as the opening movement (S1)

has been covered, the latches (6) of the push lock (Z6) are released and thus the

locking of the second mould parting plane is eliminated. The catches (6) are guided

out of the cutouts in the control plate (21) as soon as the limit stops of the latch bar

(325, 350, 375 or 3-L1) bear against the catches (6) of the actual lock (Z4).

Figure 3

Now the latch (Z4) draws the mould plate (H1V) forward by the opening stroke (S2)

in the direction of the arrow „S2“. When this opening movement has been completed

the actuated mould plate (H1V) is locked.

Figure 4

The main parting plane (S3) can now be fully opened.

The closing process is effected in reverse order.

NOTE:

In combination with the Z4 latch locks, the locking travel distance „S“ (see fig. 1),

which must be completed before the second parting plane is opened, is shorter by

half the width of the latches (6) than the delay travel of the latch bar (325, 350,

375 or 3-L1).

Entformungselemente -- indirekt IDemoulding elements -- indirect

Eléments de démoulage -- indirects

6

3STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

D 3002A 07.2018

Operating instruction english -- Push locks Z6

1

2

3

4

1. Selection

Push Locks are used to prevent a second parting plane (S2) opening (T2)

prematurely, e.g. in the case of 3-plate moulds in conjunction with slides

and /or core pullers.

When combined with the Z4 range of latch locks they can:

a) Open the mould

The main parting plane is to be opened first, the stripper plate having to

remain in the starting position (e.g. when using slides and/or core pullers)

until the main parting plane has opened completely through the distance „S1“

(cf. figure 1).

b) Close the mould

The closure sequence takes place as for the stripper movement in reverse

order, i.e. the stripper plate (H1V) is moved backwards by the pulled stroke

before the main parting plane is closed.

Fitting and mounting instructions

1. General

All push locks must be mounted square, parallel and symmetrical to the

mould guide. Secure all screws with spring washers or STRACK NORM

adhesive Z9092 (fig. 2).

All areas of the control plate and control bar that are exposed to wear are

case hardened to 58 HRC. The surface hardness is about 33 HRC on the bol-

ting surfaces of the Z6 latch lock, so that the mounting holes can be drilled.

2. Preparatory work

Match the length of the control plate (21), control bar (31) and spacer (102) in

accordance with the mould design and shorten if necessary. If the abovementioned

components are to be shortened, the hardened layer on the side faces must first be

ground down (see figure 3).

Drill mounting holes in control plate (21), steady (4), control bar (31) and spacer

(102).

Drill mounting holes for control plate (21), steady (4), control bar (31) and spacer

(102) in the mould plate. The parallel dowel holes for the latch housing (11) must

be made in the mould plate at the same time (see figures 4 and 5).

S1

S2

A

II

A

31

21

102

4

11

621

33

102

Entformungselemente -- indirekt IDemoulding elements -- indirect

Eléments de démoulage -- indirects

6

4

STRACK NORMA GmbH & Co. KG · Königsberger Str. 11 · D-58511 Lüdenscheid · Tel +49 2351 8701-0 · www.strack.de

D 3002A 07.2018

Operating instruction english -- Push locks Z6

5

6

7

8

Notes on mounting and assembly (continued)

3. Mounting and adjustment work with mould assembled

Proceed as follows:

Dowel and screw down latch housing (11). Check the position of the catches (6).

Insert the edges, which are chucked at the sides, downwards into the latch housing

(see figs. 4 and 5).

Insert the control bar (31) and screw on loosely. Adjust blocking travel (S) taking

into account the specified dimension (S1), where S = S1 minus half catch width.

Tighten control bar (31) so that it is fixed parallel to the mould guide and secure

with pins (cf. figures 6 and 1).

Attach control plate (21) together with steady (4) and screw on loosely. Set the

control plate to „no play“ by placing against the catches (6). Tighten the screws to

be fixed in place and secure with pins (see figure 7).

Check correct functioning manually.

4. Mould safety device

The catches (6) of the push lock (Z6) and of the latch lock (Z4), when

closing the injection mould, must be protected against unacceptably high

locking forces in the strokes (S1 and S2) by the mould safety device of the

injection moulding machine (see Figure 8A).

If there are mould slides with angle pins within the stroke range (S2), the

mould safety device must respond even before the angle pins enter the

mould slides.

If the two mould halves are to be mounted separately, it is important to

ensure that the drawn mould plate (H1V) is in the limit position of the fully

drawn stroke (S1) and that the lock is active before the injection mould

closes.

A = Right; B = Wrong

5. Maintenance

All the functional components of the push lock must be lubricated regularly

(e.g. STRACK NORM Z9080).

The fastening screws should be checked and tightened regularly.

S2

H1V

H1V

A

B

S1

11

6

661

61

Auf die Einbaulage

achten!

Please observe the

mounting position!

Tenir en compte de

la position de montage!

31

S1

S1

S

6

S1S2

4

21

11

6

661

61

Auf die Einbaulage

achten!

Please observe the

mounting position!

Tenir en compte de

la position de montage!

Table of contents