1.0 INTEGRATION INTO AN EXISTING ROOF & WIND LOAD CAPABILITIES

The architect, builder or council is to ensure the existing

or new house/structure is of suitable structural integrity

and complies with all relevant Australian Building codes

and standards.

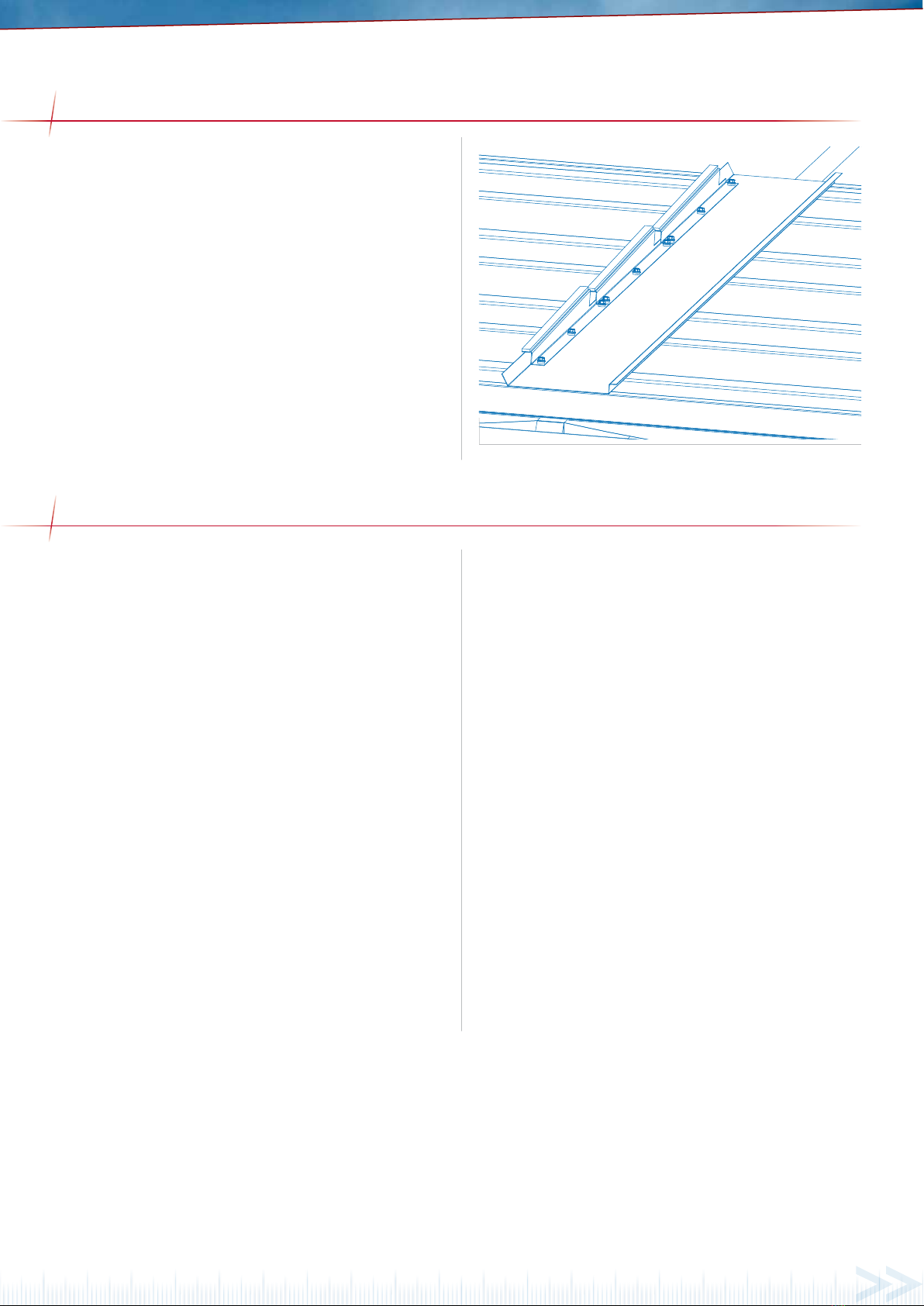

Roof structure suitability is based on the Solatop PV

panels, Panel Mount Brackets, Mounting Batten, Panel

Support Bracket and Gutter Tray’s having a combined

mass of 25kg per 1m2.

The roof rafters are to have a maximum spacing of

1200mm and to be in sound condition to withstand the

systems mass and environmental loading.

A water proofing membrane is required to be installed

between the Mounting Battens and Rafters. Sarking

membranes and sealing tapes, have to comply with local

requirements and building codes for fire resistance and

stability.

The Solatop PV panel system has been engineered for

residential applications in accordance with AS4055-2006

Wind loads for housing.

The system can withstand loads from wind class, up to

and including, N4 and a maximum wind speed of 50m/s

(permissible). Refer to your local authorities for wind

classification in the specific installation site area.

For more information regarding the suitability of the

house structure to accommodate the Solatop PV panel

system, consult a structural engineer or a building

authority.

It is the builder’s responsibility to ensure that the

existing house roof structure is capable of withstanding

additional loads imposed by the Solatop PV system.

1.1 REQUIREMENTS FOR THE SUB-ROOF AND BATTEN CONSTRUCTION

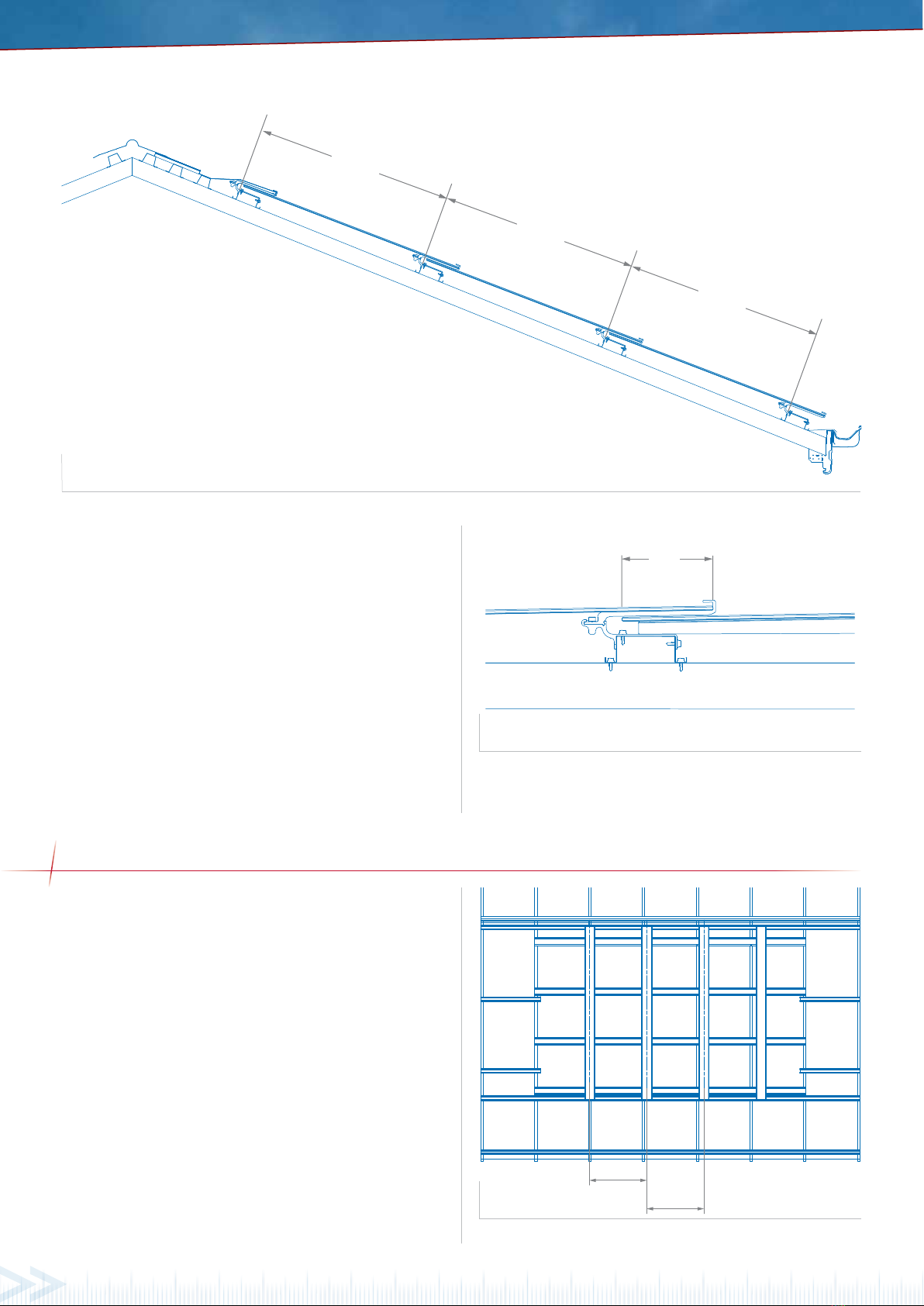

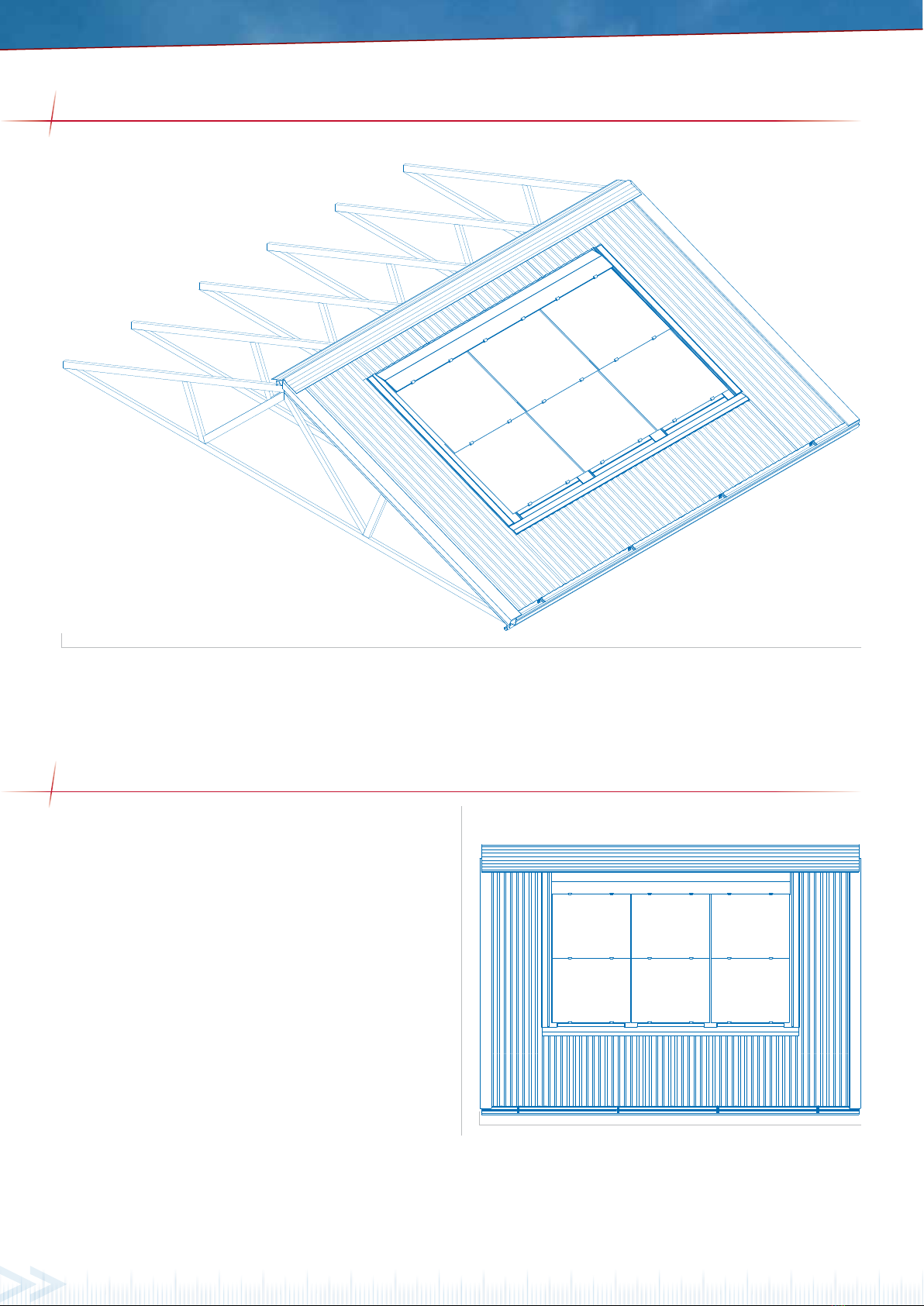

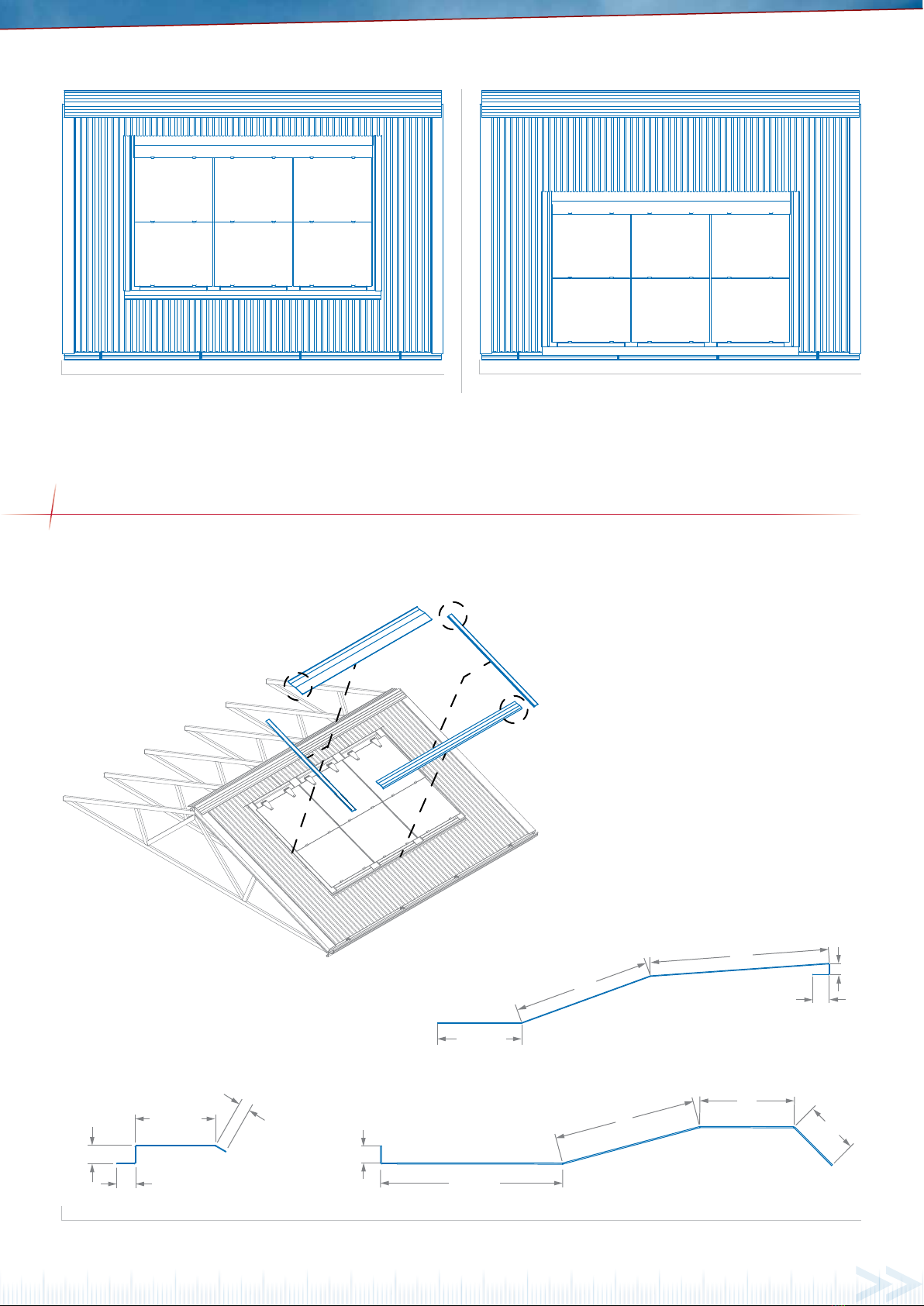

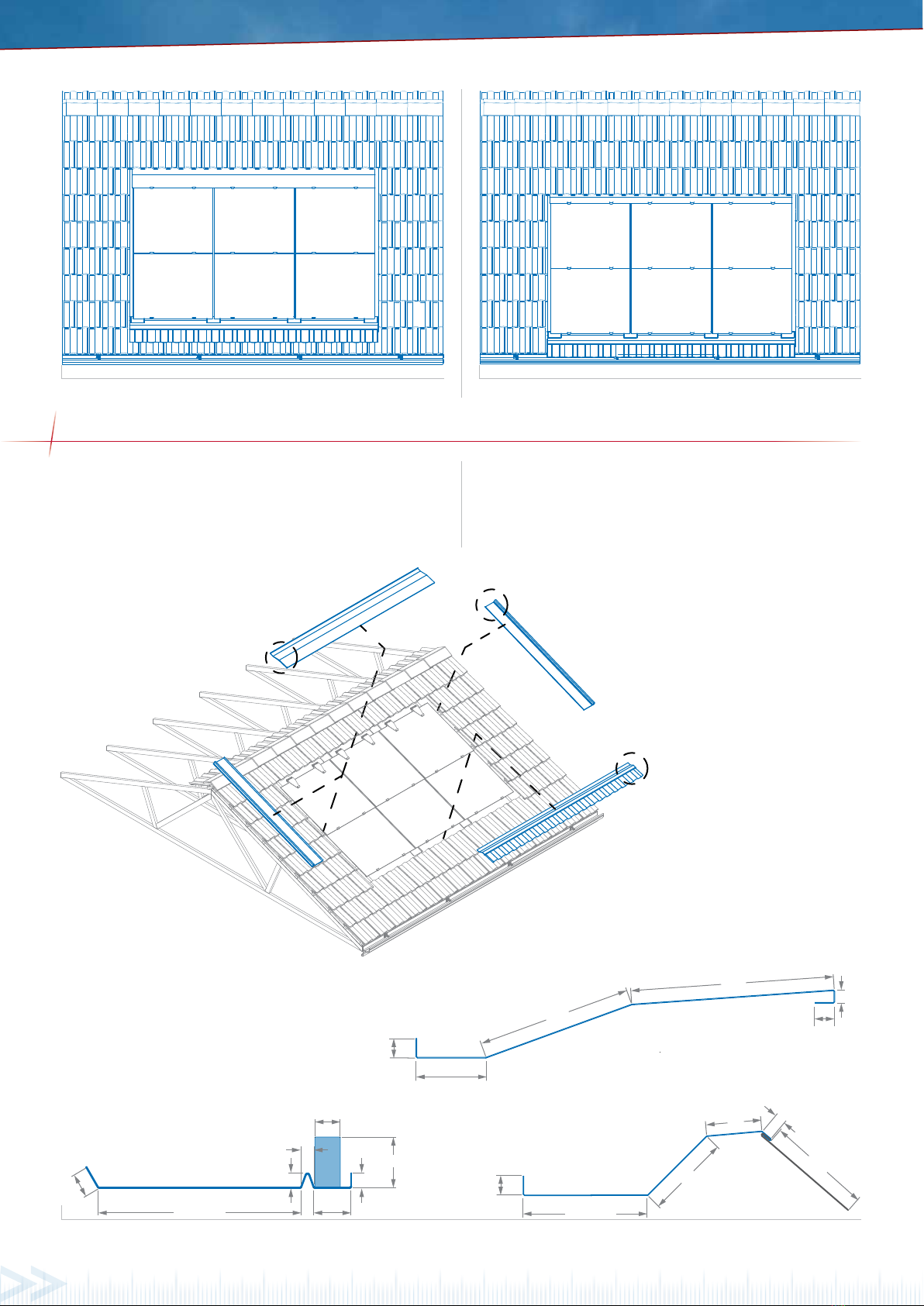

The Solatop PV panel system requires ventilation between

the overlapped panels, whilst being as water tight as

possible.

A sarking membrane is recommended to be installed on

top of the rafters, making sure the sarking membrane

is lapped from the top, downwards and sealed with the

tape at the lapping joint, to resist water penetration.

The sarking membrane is to be installed across the roof

rafters, loose enough to allow air flow underneath the

Solatop PV panels, but without the possibility of pooling

water.

The sarking membrane will need to exit and attach into

the gutter, without any pooling area’s in front of the

fascia.

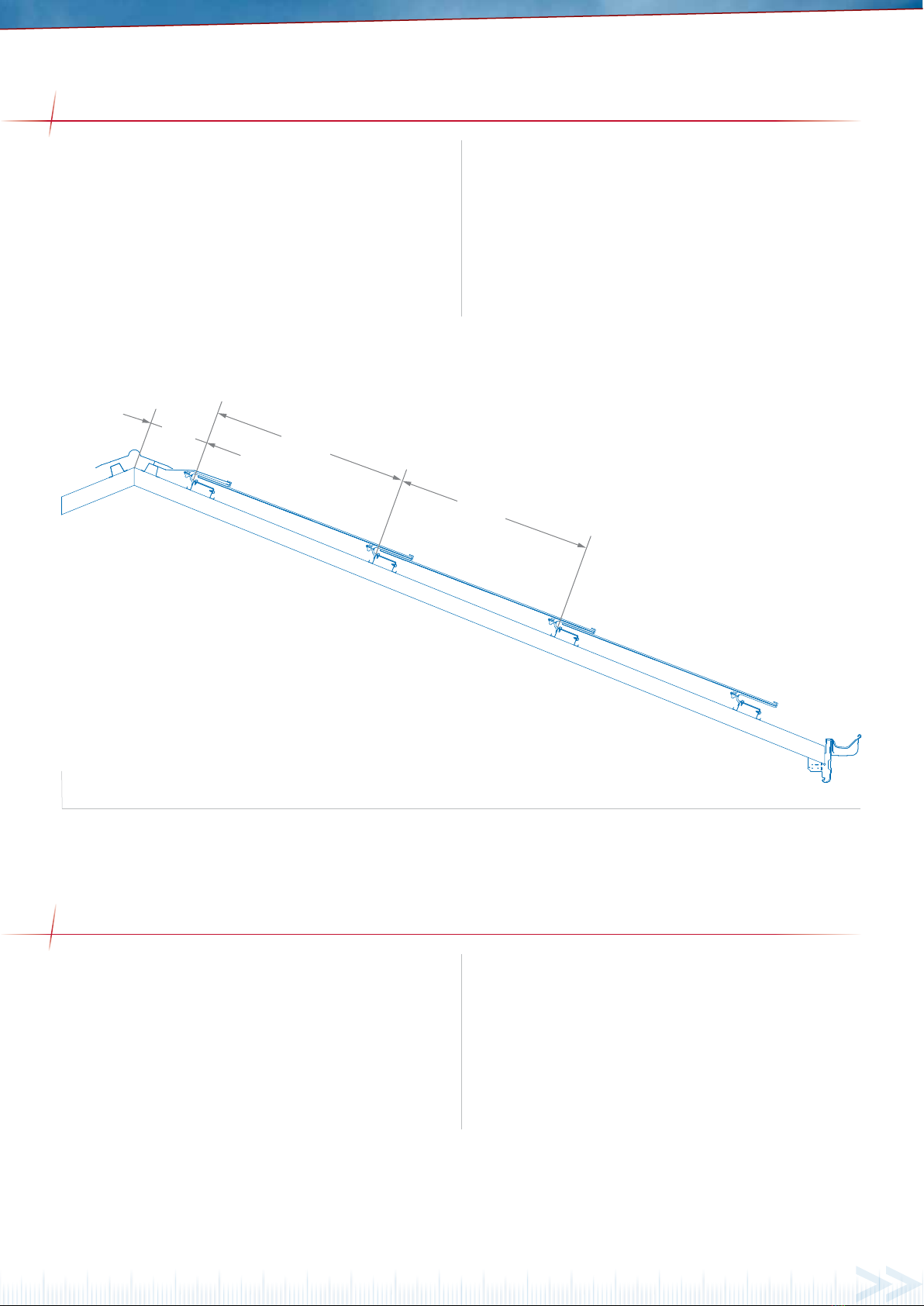

The Mounting Batten has been specifically designed

for the Solatop PV panel system. The Mounting Batten

spacing and placement is extremely important to the

finished array - battens must be planar and carefully

levelled if needed.

INTRODUCTION

This guide is intended for architects, builders and

experienced solar installers or individuals who have been

suitably trained and qualified.

Please read this layout guide thoroughly before

commencing the roof lay-out design. Double check

all dimensions, levels and locations when integrating

Solatop PV panels into the roof design.

It is recommended that the persons erecting the structure

have had some previous building experience because

some modifications to the existing house structure may

be required.

Stratco disclaims all liability for damages caused by

inadequate planning or faulty installation.