Responsibilities

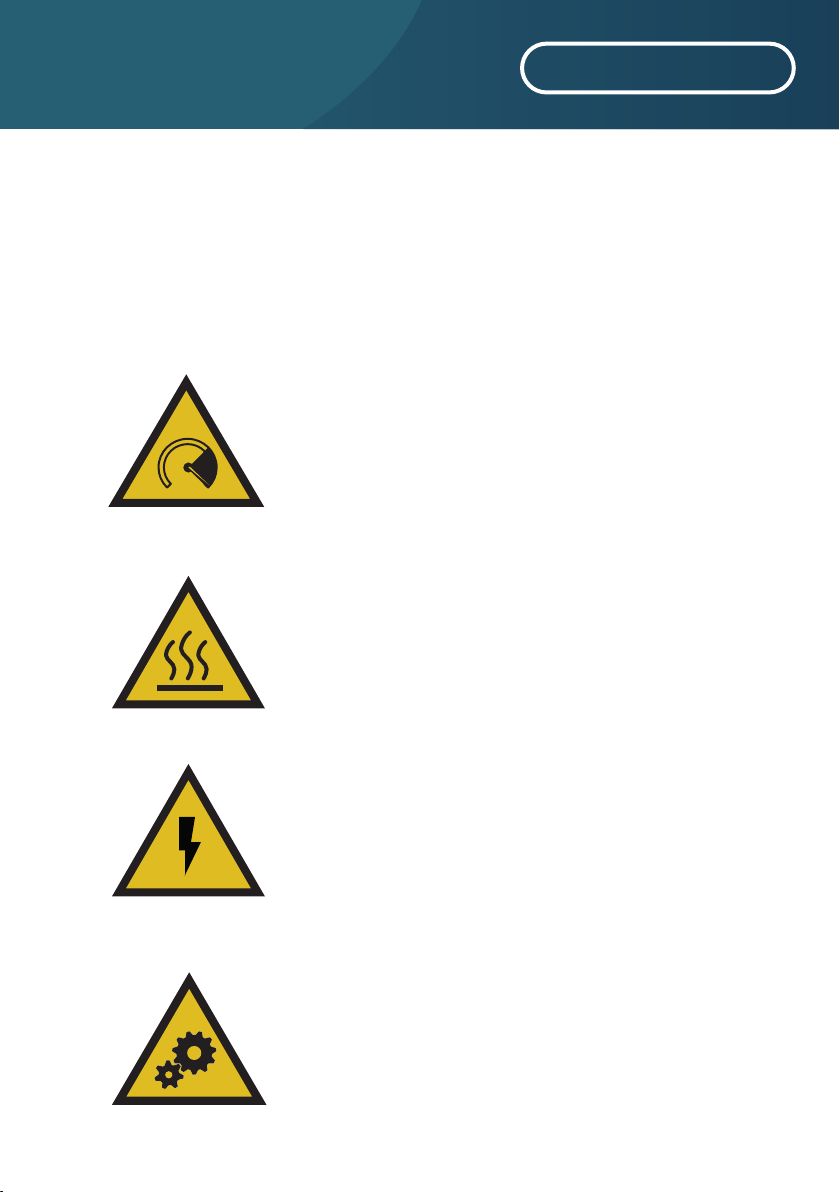

Electrical Specifications & Safety

This applies to all Combi™system configurations

Electrical connections must be carried out in respect of

current legislation (in compliance with the provisions of the IEC

60364-1 standard) and in accordance with the manufacturer’s

instructions. Please check that the installation and sockets are

adequate for the maximum power of the appliance indicated on

the rating plate. If in doubt, consult a qualified electrician. The

correct plug should be fitted by a qualified electrician.

VARITECH SYSTEMS Ltd, the manufacturer of STREAMLINE® declines all liability for

damage to persons, animals or things caused by faulty or incorrect connection.

- Before connecting the equipment, check that the specification given on the rating

plate corresponds to that of the mains electrical supply.

- If the equipment is connected via an extension, use cables with an adequate cross

section, never less than 1,5 mmq. The plug and socket must be watertight.

- The electrical safety of the equipment is guaranteed only when correctly and

eciently earthed as specified in current electrical safety legislation (in

compliance with the provisions of the IEC 60364-1 standard). This fundamental safety

requisite should be verified. If in doubt, ask a professionally qualified electriciant

check the system thoroughly. It is recommended that the electric supply to this

machine should include a residual current device that will interrupt the supply if the

leakage current to earth exceeds 30 mA for 30ms or a device that will prove the

earth circuit.

- The equipment can be disconnected from the mains only by unplugging the plug

from the mains socket.

- When using any electrical appliance, certain fundamental rules should be respected:

• Do not touch the appliance with wet hands or feet;

• Do not touch the appliance with bare feet or unsuitable clothing;

• Do not pull the power cable or appliance itself to unplug the plug from

the mains. he supply if the leakage current to earth exceeds 30 mA for

30ms or a device that will prove the earth circuit.

VARITECH SYSTEMS Ltd, the manufacturer of Streamline® declines all liability for

damage to persons, animals or things caused by faulty or incorrect connection.